Posted 04 May 2009 - 09:44 PM

Posted 04 May 2009 - 09:47 PM

Jairus H. Watson

3/12/59-5/19/25

Requiescat in Pace

Posted 04 May 2009 - 09:50 PM

Posted 04 May 2009 - 09:57 PM

Posted 04 May 2009 - 10:12 PM

Posted 04 May 2009 - 10:18 PM

Mike Katz

Scratchbuilts forever!!

Posted 04 May 2009 - 10:25 PM

Half Breed

Half Breed

Posted 04 May 2009 - 10:33 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 04 May 2009 - 10:41 PM

Posted 05 May 2009 - 12:30 AM

Posted 05 May 2009 - 01:10 AM

Mill Conroy

AKA : TWO LAP CONROY, Anointed Trigger Monkey by Mike Swiss

Deal me life's toughest cards, without chance for hope nor fame, just let me play this one last hand, and I'll win this whole damn game.

Second Most Interesting Man in the World.

Posted 05 May 2009 - 04:55 AM

Posted 05 May 2009 - 05:24 AM

Posted 05 May 2009 - 06:48 AM

Joe "Noose" Neumeister

Sometimes known as a serial despoiler of the clear purity of virgin Lexan bodies. Lexan is my canvas!

Noose Custom Painting - Since 1967

Chairman - IRRA® Body Committee - Roving IRRA® Tech Dude - "EVIL BUCKS Painter"

"Team Evil Bucks" Racer - 2016 Caribbean Retro Overall Champion

The only thing bad about Retro is admitting that you remember doing it originally.

Posted 05 May 2009 - 11:34 AM

Posted 05 May 2009 - 11:39 AM

Posted 05 May 2009 - 11:42 AM

Posted 05 May 2009 - 11:43 AM

Posted 05 May 2009 - 11:58 AM

There is no standard, only personal choice.

Posted 05 May 2009 - 01:21 PM

Posted 05 May 2009 - 03:41 PM

Slots-4-Ever

Brian McPherson

REM Raceway

"We didn't realize we were making memories, we just knew we were having FUN!"

Posted 05 May 2009 - 05:56 PM

Posted 06 May 2009 - 01:39 PM

Posted 06 May 2009 - 07:11 PM

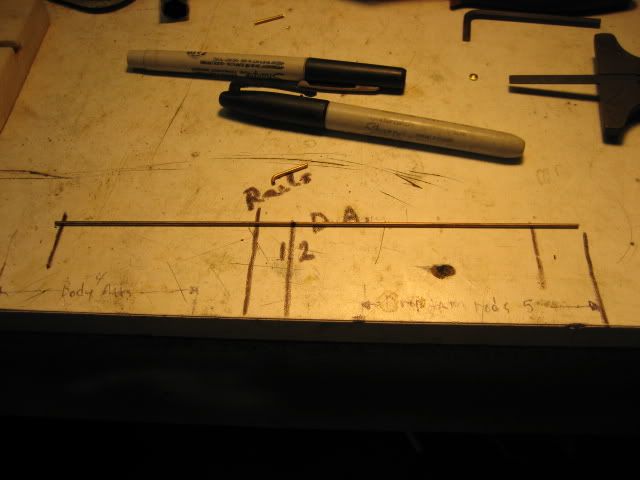

I've found that we don't all visualize in the same ways; some don't visualize at all! I can't draw a picture, f'instance, but I can build chasses in my head where the next guy might not! All different.[Mike S.] I've held back from posting specs. I think each builder needs to measure the body and choose his specs.

Posted 06 May 2009 - 09:14 PM