Well, in the meantime, you'll have to settle for these . . . a small family portrait of the sidewinder integral axle motors that gave birth to the XL500. But first, my first NOS vintage car, built about 10 years ago, when I never thought I'd find an XL500 in my lifetime . . . This started out as a simple Kemtron frame with the pivoting front axle, but I braced it more and more as it was raced!

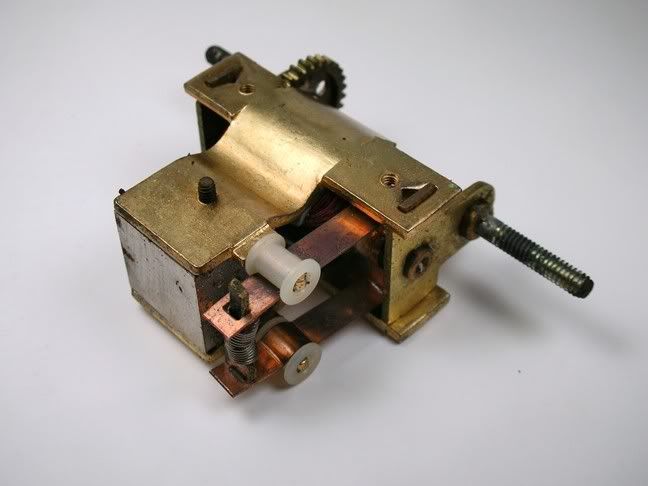

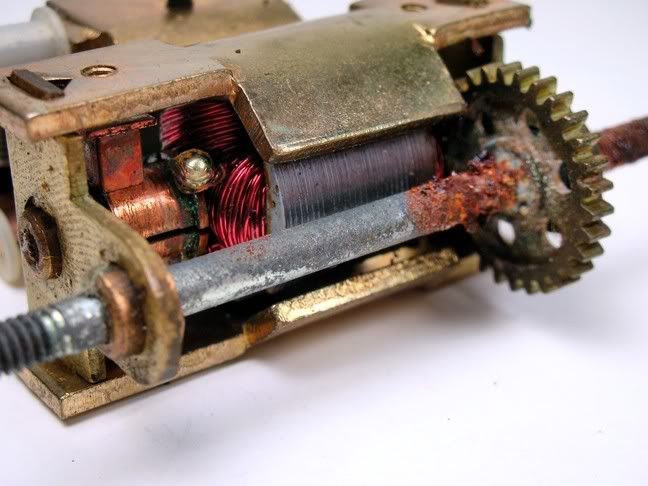

Now, come back with me to the origins of this whole line, the venerable Pittman DC703, where you can see the choo-choo origins. Plastic gear and a shaft about 6" long, labeled as a belt-drive conversion motor.

Next, the DC704A, one of the first purpose-built slot car motors, along with the DC196 (and still about 6 years after Scalextric and VIP, in 1963 I believe). The hop-up hint here was of course to take the motor apart and turn the endplates around so the weight was more towards the center of the chassis! Pittman did this on the DC705, but I don't seem to have one of those babies - incroyable!

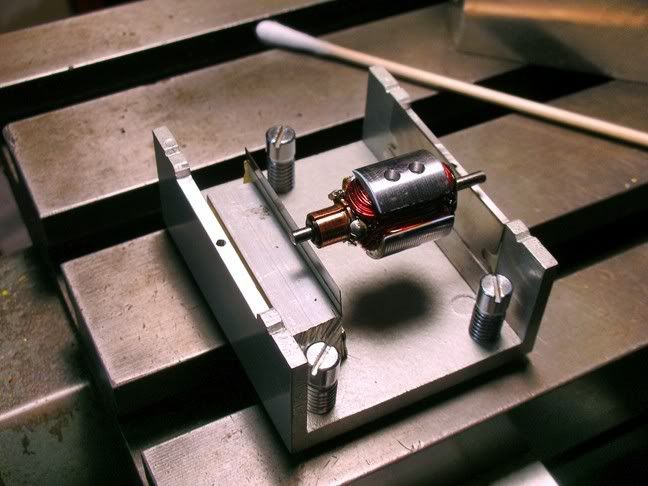

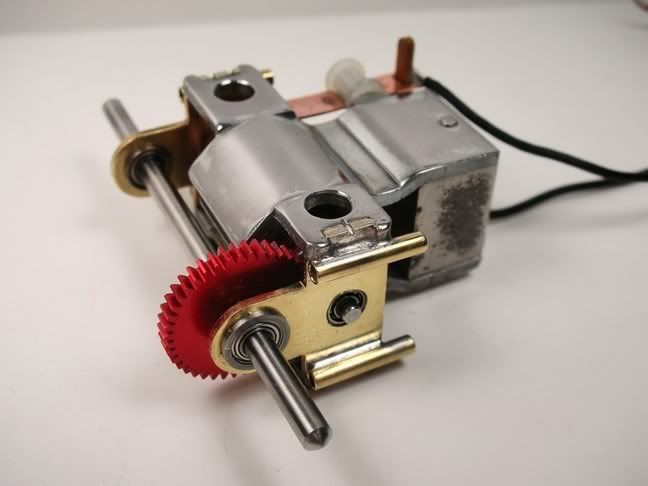

Now, the workhorse of the line, which came out in about 1965, just in time to be obsolete! These are very nicely built, with screwed-on endplates so you can decide yourself where you want the axle (the compact version is very good for cars like the Morgan or Allard, allowing you to keep more or less a full cockpit).

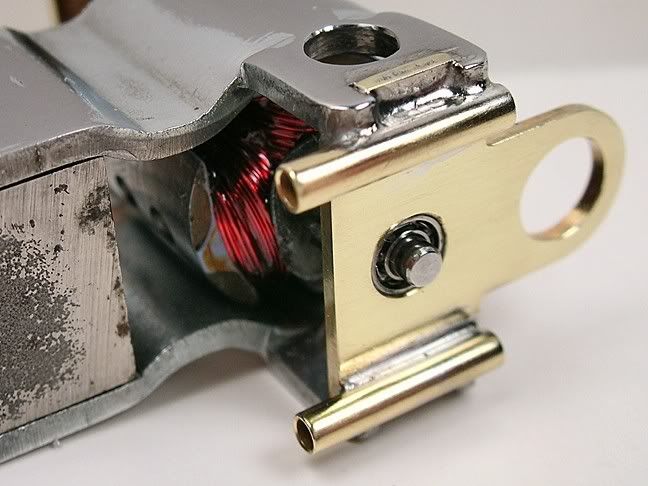

Here's the Ram DC222 that Rick mentioned earlier - yep, Ram copied everything, even the designation! - but their motors may have been a bit faster than the Pittmans. This one came with brass axle brackets to screw on to the motor. And a 7-pole armature, the only one on this type of motor.

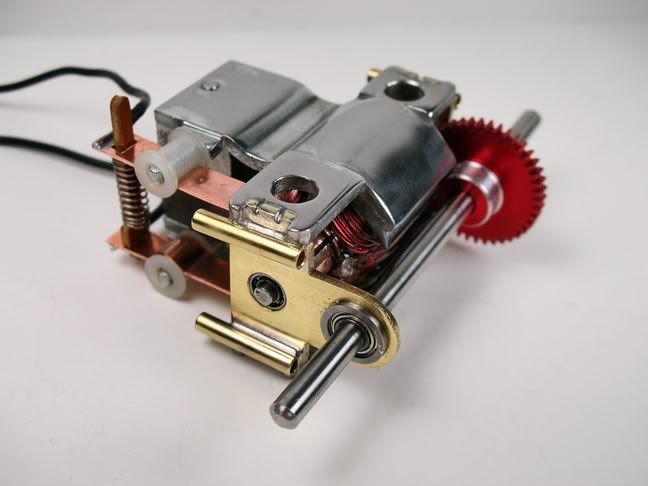

Another Ram, the 426A. The 426 has the axle through the middle but I don't seem to have one of those either - a scandal!

Ram also did just about the only 1/32 sidewinder motor of the type, the cute little DC283, again with the screw on brass axle brackets.

And now the Strombecker Devastator, a copy made in Japan, like most of their stuff.

And one more, another favorite of Rick's I believe, since it was the basis for another 65X conversion that enjoyed a brief vogue in So-Cal pro racing, the Tyco 951 - that's the 6 volt version, the 952 was the 12 volt version - also known as the Mila Miglia Capalupo sidewinder motor!

All for now, still working on my lighting, but have I got motors for you!

Don

.

.