Band saw vs scroll saw

#1

Posted 18 June 2011 - 07:15 AM

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#2

Posted 18 June 2011 - 08:55 AM

If you are making furniture and other big stuff then the Band saw is as nice tool to have.. You and do gentle curves and re saw with the band saw. And cut most any thickness of wood. (as well as fingers)

The Scroll saw is great for fine detailed work. and making sharp cuts and turns. but you are limited to the thickness you can cut and it cuts much slower than the band saw.

I have the scroll saw as I do a lot of fine line and Intarsa art work. ( can't figure out how to post pictures ) so here are some links to some of the work I do with the scroll saw..

http://i202.photobuc...sK9/liberty.jpg

http://i202.photobuc.../lighthouse.jpg

http://i202.photobuc...ggsK9/clock.jpg

With the light house and statue of liberty all the lines you see are all separate pieces of word and it is put together like a jig saw puzzle set on a backer board.

The scroll saw is the safest saw their is.. I have taught childern (mine and others)as young as 10 to use this saw and it is impossible to cut a finger off..

The only advantage I see to a band saw is when re sawing lumber. for curve cuts on my furniture project I just use the Jig saw to make the cuts.

If you go with the scroll saw get one with as least a 21" throat

hope this helps

Chris

#3

Posted 18 June 2011 - 11:10 AM

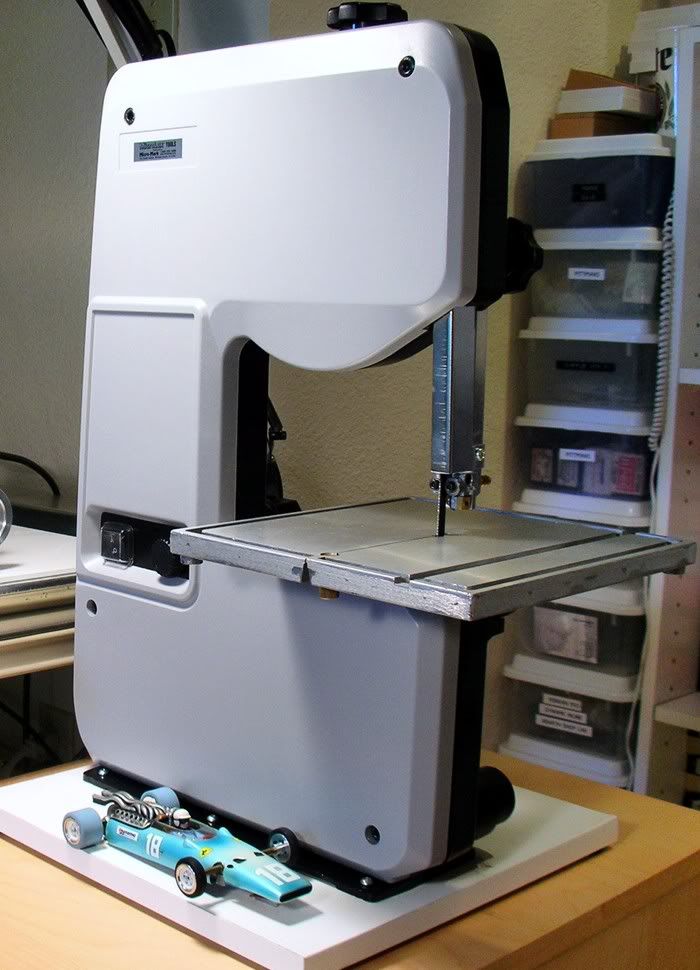

119 bucks at Home Depot. I bought one for work & it worked great. Cut through 1/32" brass with the right blade.

First Place Loser in the JK Products

International D3 Builders Competition

#4

Posted 18 June 2011 - 02:27 PM

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#5

Posted 18 June 2011 - 02:39 PM

Ernie

#6

Posted 18 June 2011 - 03:43 PM

John Albright

I have a chassis jig and I'm threatening to use it!

#7

Posted 18 June 2011 - 03:45 PM

Eric Balicki

#8

Posted 18 June 2011 - 04:02 PM

It is very small and compact. The speed is variable with the turn of a knob.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#9

Posted 18 June 2011 - 05:50 PM

The scroll saw has a blade so small, it is 'challenging' to make straight cuts.

1/24/48-2/18/16

Requiescat in Pace

#10

Posted 18 June 2011 - 06:48 PM

John Albright

I have a chassis jig and I'm threatening to use it!

#11

Posted 18 June 2011 - 07:16 PM

I've tried that, but the blade has so much flex in it, the cut is actually 'scalloped' when you look at it with a magnifier.

1/24/48-2/18/16

Requiescat in Pace

#12

Posted 19 June 2011 - 06:58 AM

Chris

#14

Posted 19 June 2011 - 08:56 AM

saw for scratchbuilding.

With the metal cutting blade,(about$12-$20) it cuts 1/16th brass

straight, with very little effort.

IIRC, the blade is 24 TPI.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#15

Posted 19 June 2011 - 09:41 AM

A couple of quick clamps and a straight edge or a piece of metal stock will fix that.

...yep, it's called a "fence".

-john

#16

Posted 19 June 2011 - 10:02 AM

BTW, I've got a nice Hitachi scroll saw with stand for sale.

I am not a doctor, but I played one as a child with the girl next door.

#17

Posted 19 June 2011 - 10:13 AM

...yep, it's called a "fence".

In any case, you never force a cut and the saw will "tell you" how fast you can feed. You'll do a sloppy job if you don't listen to it. If I had a nice shop, I'd have a band saw like Rick's and a nice scroll saw for finer/more intricate work. If budget and space were limited, I'm sure I could get by just fine with just a bandsaw and some patience and prep.

-john

John, I can not agree with you more. Always listen to your power tools. Let them do the work and dont force it.

Did I mention the bee's wax?

John Albright

I have a chassis jig and I'm threatening to use it!

#18

Posted 19 June 2011 - 10:15 AM

Now, that's really unnecessarily snotty, but just factor those things in when you consider this stuff. Sometimes we get sidetracked when we start thinking about how to make something and what we really need, and our hobby becomes making this new doohickey work rather than using the doohickey for our hobby. You choose.

Most important part of a bandsaw, after usable speed range, is the upper and lower blade guides: they need to be rigid and easily adjustable, and one would hope the guide bits are hardened--if you're investing, check them! the guide should not allow a surreptitiously-applied knife edge to dig in, otherwise it's dead-soft steel and worthless. Your guides should be dead-flat and set with zero slop on the blade, and also brought up to the blade in tension so that there's no pulling the blade out of line by the guides.

Properly-set guides will do far more for accurate cuts than a fence will, since a bad blade can be pulled off-line by the unyielding fence. A fence is good in a production run, but often more trouble to set up than just freehanding a one-off.

A metal-cutting blade even finer than 24p is a good idea (we say we require one and a half teeth in the work, minimum, but we're not gonna get that!), and don't run it fast: under 200fpm is good, especially with thin stuff.

Brass will round-off the teeth of a Bi-Metal blade in seconds, just by rubbing rather than cutting, so expect a learning curve in how to feed the stock in.

Look for waxy tool-dressing sticks, better & less messy than oil: just touch to the blade every few seconds.

Another very important thing about cutting metal: the stresses imparted by the cut will be transferred to the metal and distort it, sometimes to a disturbing extent. To see this, try cutting a quarter-inch strip if 1/16" off a plate and look at how it curves! Plan your cuts accordingly, and leave stock to clean up with file or whatever. I'm a big fan of bench filing myself, it takes up less room in my under-the-loftbed cubby than a Bridgeport mill.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#19

Posted 20 June 2011 - 12:23 AM

Looks like they might be handy for some RC airplane projects though.

Mike Boemker

#21

Posted 20 June 2011 - 11:37 AM

Phil, now tell them how much a blade costs. LMAOMuch better for all saw needs:

That is exactly the same saw used where I worked last, except ours also had a power feed. Nice Saw............

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#22

Posted 20 June 2011 - 04:46 PM

Twenny-eight bucks. What?Phil, now tell them how much a blade costs.

I don't think the DoAll Metalmaster bandsaw has changed its basic casting patterns in forty years; they just crisp 'em up now and then. A really lovely instrument.

Duf

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#23

Posted 20 June 2011 - 05:17 PM

Great machine.

Steve King

#24

Posted 20 June 2011 - 07:47 PM

Phil, now tell them how much a blade costs. LMAO

That is exactly the same saw used where I worked last, except ours also had a power feed. Nice Saw............

That's not mine. It's a picture I snagged off the net. Sonic doesn't have a band saw.... we should but there's no room. Recently there was a 60" DoAll on Ebay. A 5 foot throat!! I think it sold for under $3k.... the one in the picture is a 20".

I believe if you're gonna do it, do it! Buy the best you can afford and take care of it. It'll last a lifetime and you won't regret it in the long run. One of my Dad's lessons for me.

If you're good and know your stuff, this is a good Ebay seller. I have brought a number of things from them (they're local so I can inspect) including a CNC lathe. But, as always, read the descriptions carefully and ask questions. The CNC lathe needed some work but the price I paid was very fair. Sometimes small tools and lathes show up (like Levin or small milling machines).

http://stores.ebay.c...able-Tool-Store

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

#25

Posted 21 June 2011 - 01:48 AM

Or maybe my scroll saw technique is lacking?

John Dilworth