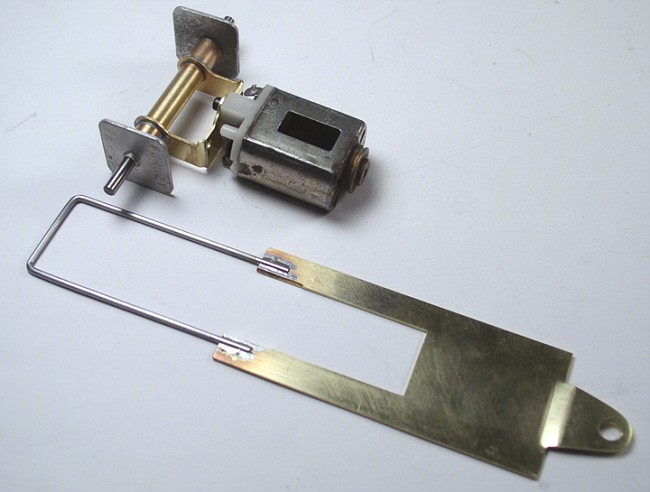

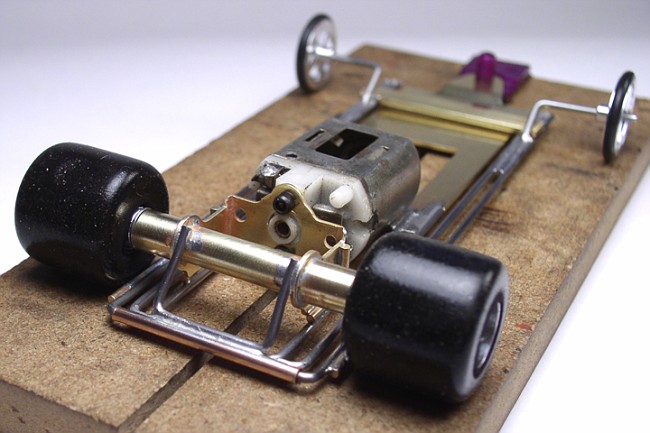

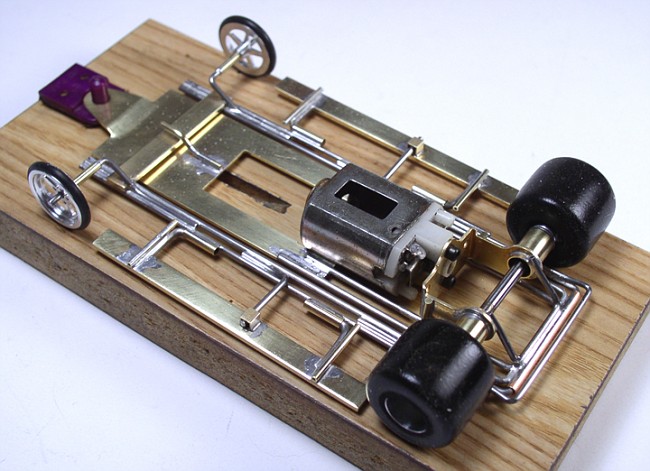

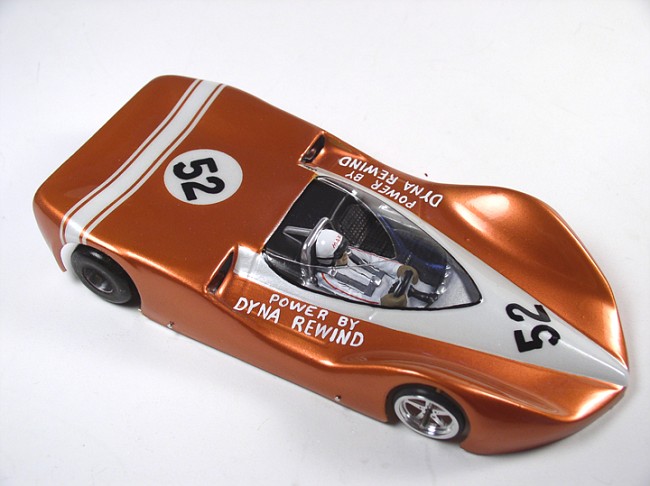

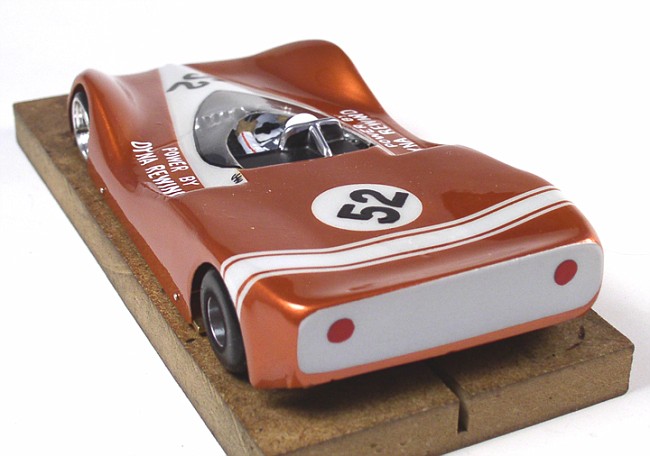

This Thingy body looks so much like a Can-Am car that I decided to build a chassis that was worthy of its sleek lines. One27Ray is the maker of this Vacuum formed piece, which I assume is a back pour of something available in 1968. The molding is very nice and has very few flaws in the surface. It should paint up very nicely! The 1.25” drop arm is .040 brass and the motor bracket Russkit.

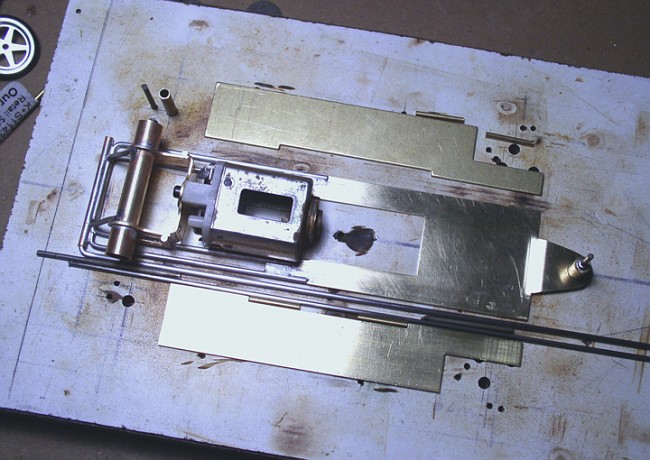

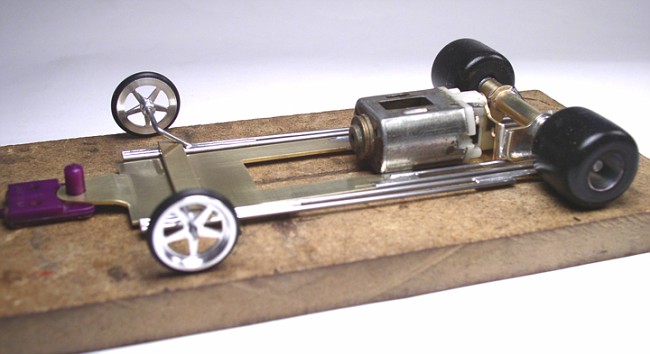

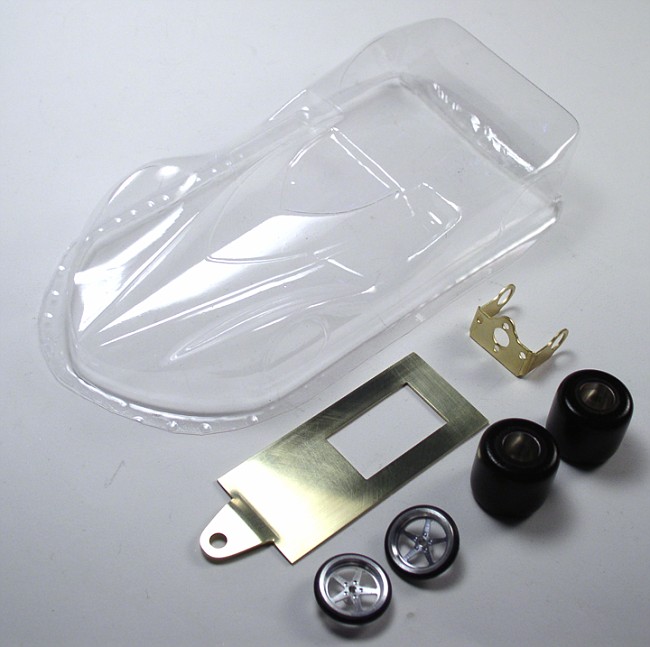

The first step before building any chassis, besides a general idea of its construction, is the length of the wheelbase, chassis width and tire size. Tire size is most important because you want the lowest possible center of gravity while still allowing legal track clearance. A quick measure of the body determines that this is going to be a 4” chassis. Width is 3.125” and rear wheel diameter is 7/8”. Now we can get started!

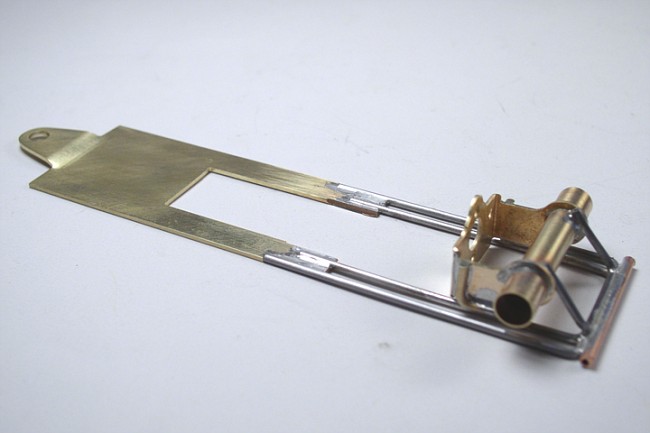

The next step is to assemble the rear axle, wheels and bearings in order to determine the correct width of the rear axle assembly. We want to place the bearings as close to the wheels as we can and still allow spacing for axle washers.

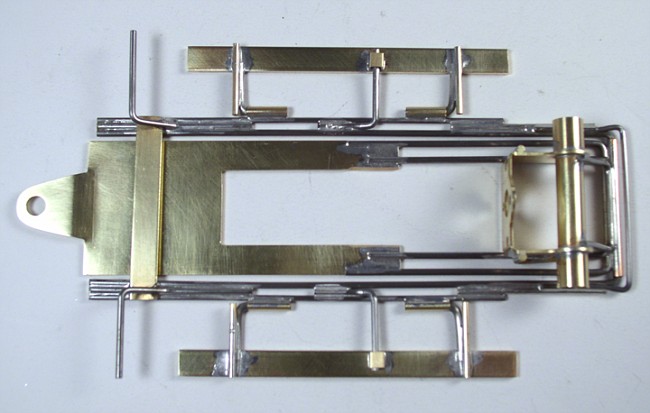

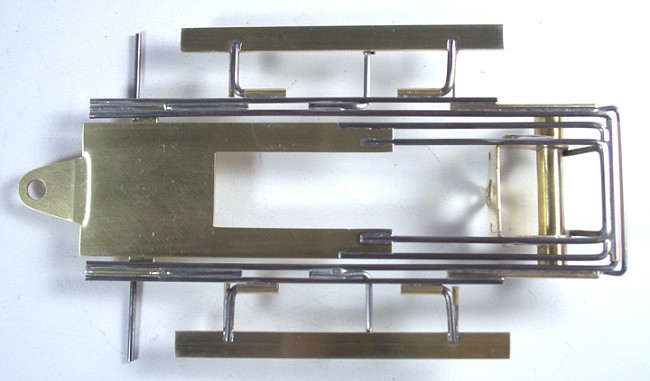

The rear axle assembly is soldered up using two diameters of tubing with the centerpiece left across during construction for strength. That will be cut away later…. The motor you see is just a shell that I use for assembly while in the jig.

Next: Center section completed….