Thingie Tyro

Page 2

On to the side pans. First, we make up the parts:

And then install them:

The square hinge tubes are very slightly oversize, and allow the sidepan arms to move around a bit, keeping them floating loose and free. Other builders have done something similar, using .055" piano wire in .063" ID round hinge tubes. It provided a lot more "klunk", maybe too much, and so it wasn't (as far as I know) widely used.

Don't forget to include the slight bend in the arms:

You may have noticed there are no side pan up stops. I noticed that too. What to do? How about extending the front axle braces to serve as up stops? All it requires is cutting out the ones I had already made and installed, and fabricating new ones to suit (easy, huh?):

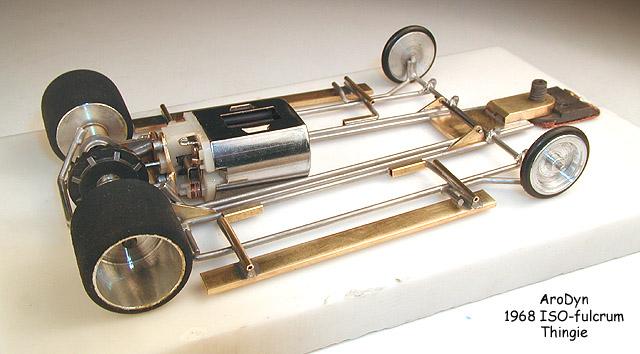

Except for some fancy front wheels, I think we're done.

But wait! There's more.

I've recently completed one of these chassis with some variations from the original. First, I used .078" (1.98 mm) piano wire, instead of 1/16" (1.59 mm), for the upper motor bracket brace, and installed two wire wrappings on each side of the Iso hinge:

Aside from being much stronger, I think it looks better, too.

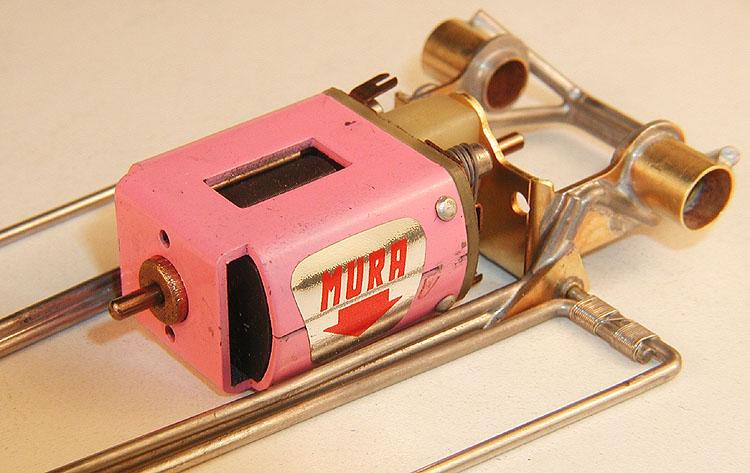

Next, I built the center section with the upper main rails bowed outwards slightly to fit a Mura B Production motor:

Up at the front end, I used modern ProTrack pinhole front wheels, which have much wider hubs than the vintage disk type pinhole fronts I had been building with. This forced some changes to the geometry, and the appearance, of front end of the chassis.

First, this chassis was originally designed to have the axle drops outside the body, so that at the point where the front axle passes through he body, it would be "down", and only minimal cutting would be required to clear the front axle. The wider hubs meant that the bends that formed the "drop" in the drop front axle would have to be closer together, but not so close as to interfere with the body! There was going to be very little space left between the body and the front axle drops!

Next, since the front axle braces attach to the front axle at the drops, the angle which they depart from the outer rails of the Iso section would be considerably smaller. I have to admit I used this as a convenient excuse to abandon the "integrated" side pan up stop I'd been using for a completely different style of up stop.

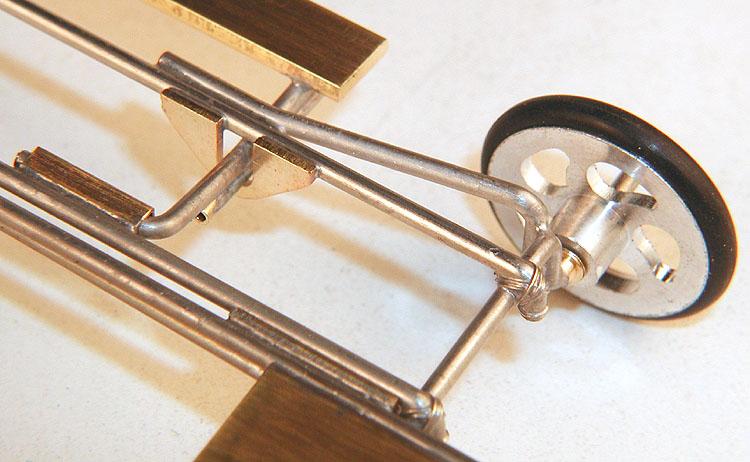

So, first I shortened the side pans 1/8" (3.18 mm) to avoid the issue of having the side pans push the body outwards against the front axle drops. Then, I installed "horseshoe" shaped up stops made from .032" (.79 mm) thick brass strip:

I think it worked out just fine!