I have some bits and pieces and a nice R-Geo kit to use in building a tuning fork chassis. Problem is.........I don't really know what it does. After looking at the various pictures and reading postings regarding the tuning fork......I still don't know enough. I had a general idea of what the concept does of course but just not enough to go on for a serious build attempt. Sooooo..........I took some bits and built one figuring to just slap it on the track and see. I didn't take a lot of time or effort for a super sano build and I didn't use up any of my favorite components, because I think I'll be hacking and slashing on this thing.

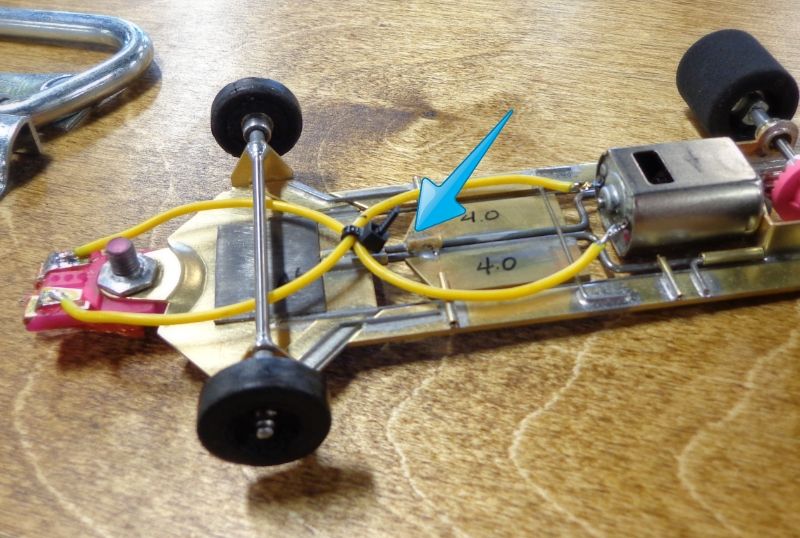

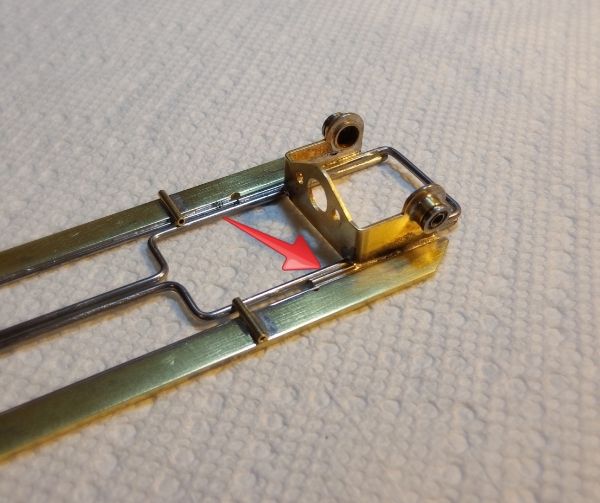

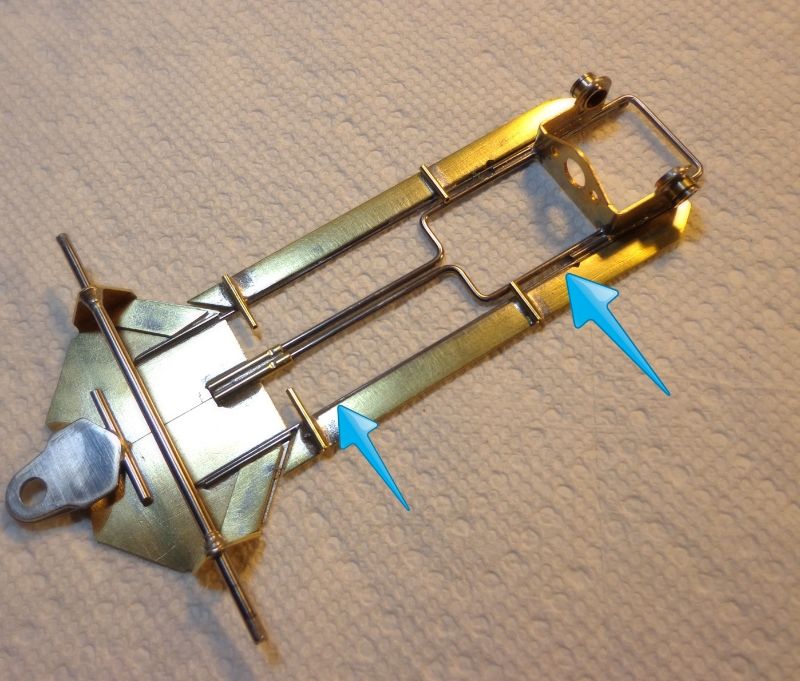

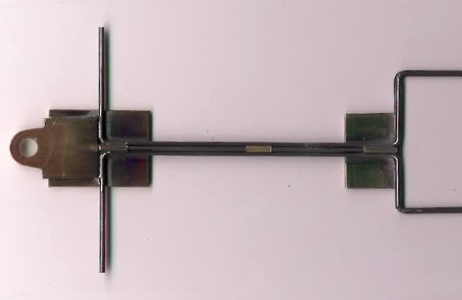

This frame was built up with a pair of forks in .062 supplied by 'R-Geo' Rick. The rest is an old JK nosepiece, JK bracket and 1/4" X .062 pans.

Some details:

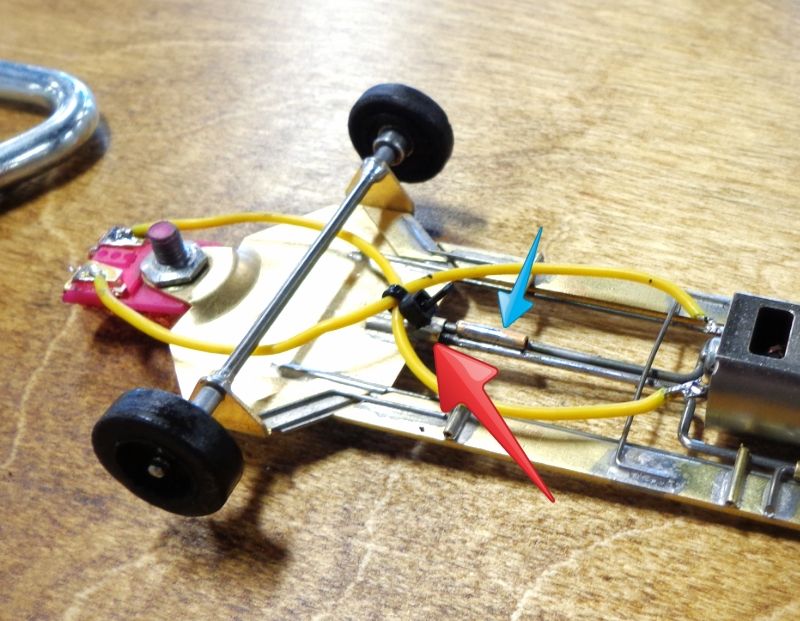

- Forks twist freely in the 3/32 tubing bits. Thus, nothing is holding the front and back halves together.

- To tie the ends together without changing the character of the fork concept, I added secondary rails of .039 wire.

- Pans are hung on a bit of .032 wire and form a fixed plumber arrangement.

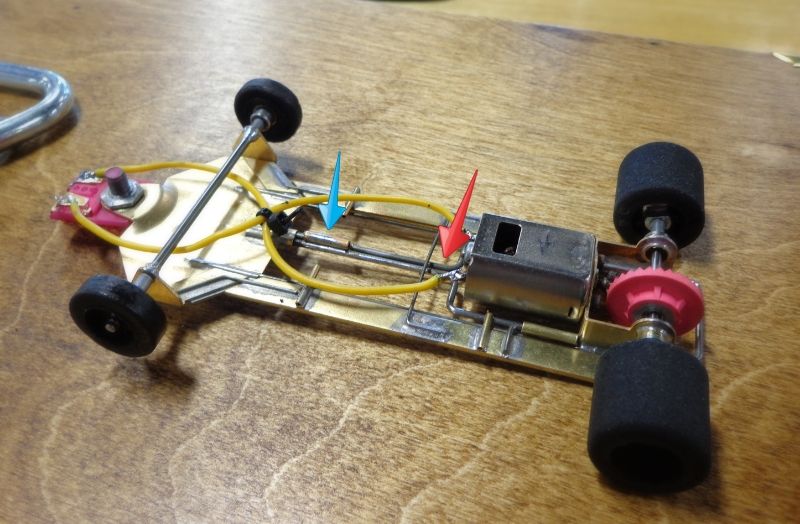

- At the mid-rear, there is a bit of 3/32 soldered only to the fork rail. A bit of .047 goes into this to form an up/down stop.

- The longitudinal flex is more or less as one would expect but the torsion is ridiculously soft.

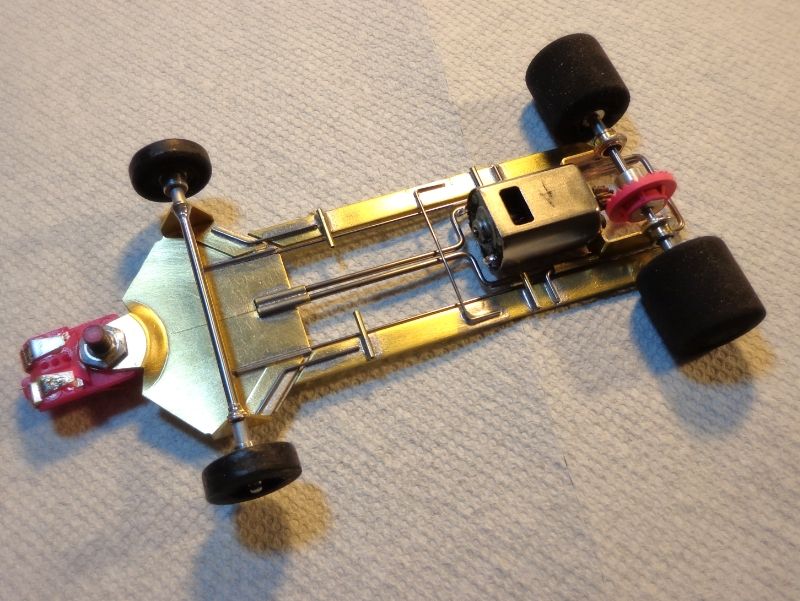

- This car is stoopid-light @ 84 gr as shown.

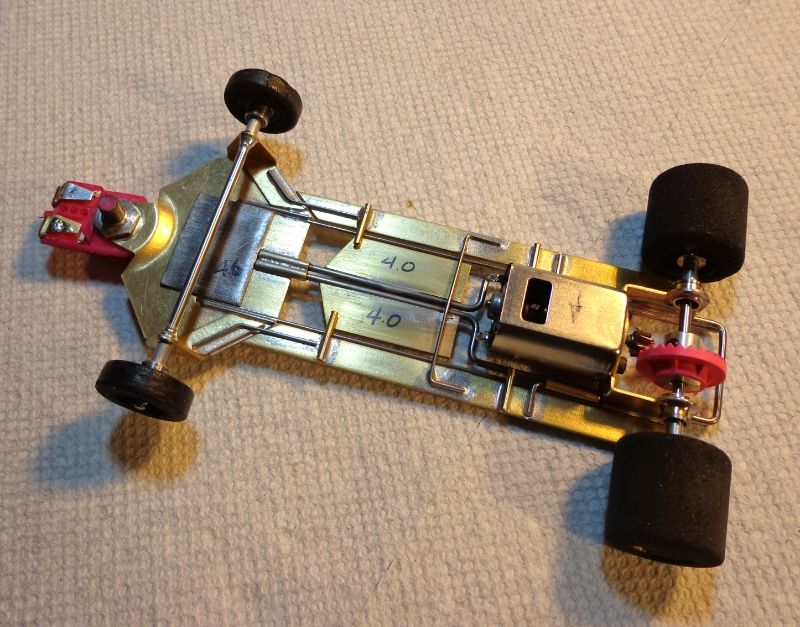

Here is how the car will get tested today with weight added as shown to hit 96 gr. Still really light for me.

Development thoughts:

- Actually, my first thought is that this car won't work at all......but a lot of good builders are using the concept so.......????

- Brass weights are soldered to the center forks. No effort was made to create any 'suspension' system for the weights.

- The extreme torsional flex may make the car really tippy and 'bitey'

- The torsion can be stiffened by soldering the forks into the tubes or tying the fork to outer rails in various locations.

- The outer rails could also be made of larger gauge wire (like .055)

- I'll be testing today @ Fast Track Hobbies and this is always a mixed bag due to highly variable conditions.