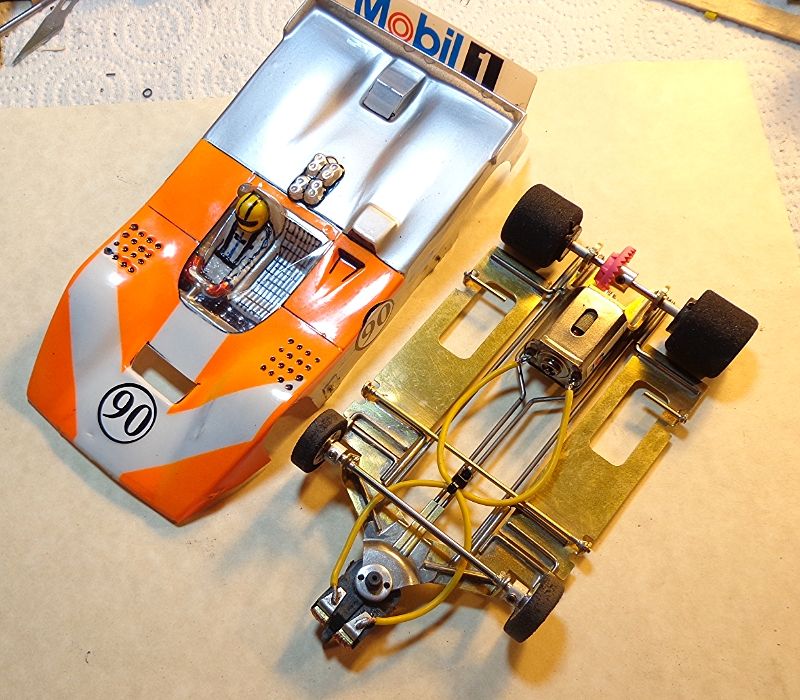

I just received this from Rick at R-Geo to build the justly famous "GVP" chassis. In a case like this, with a proven winning design, I'm not going to reinvent the wheel (or the chassis). This won't be an exact copy; it will be an attempt to remain faithful to the race winning design of the original. Any deviations will be in the interest of strengthening.

Because of my work schedule, I couldn't finish this tonight. I'm going to break this into two segments for the complete job. I promise that I won't drag this out over the next few weeks showing one solder joint a day or somesuch. Off we go...

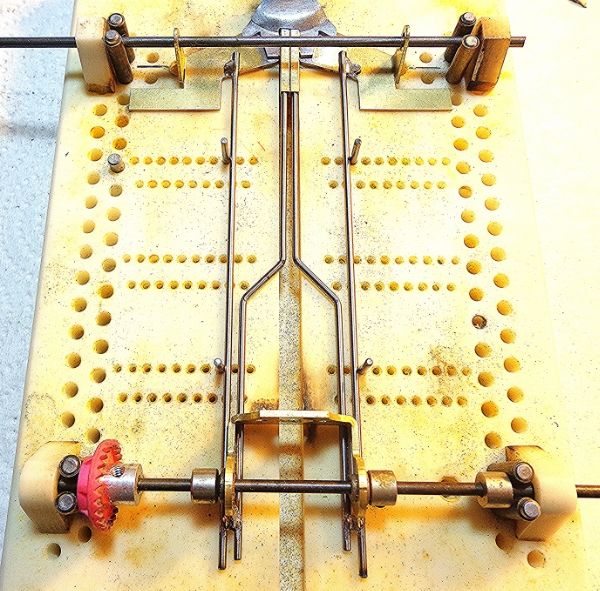

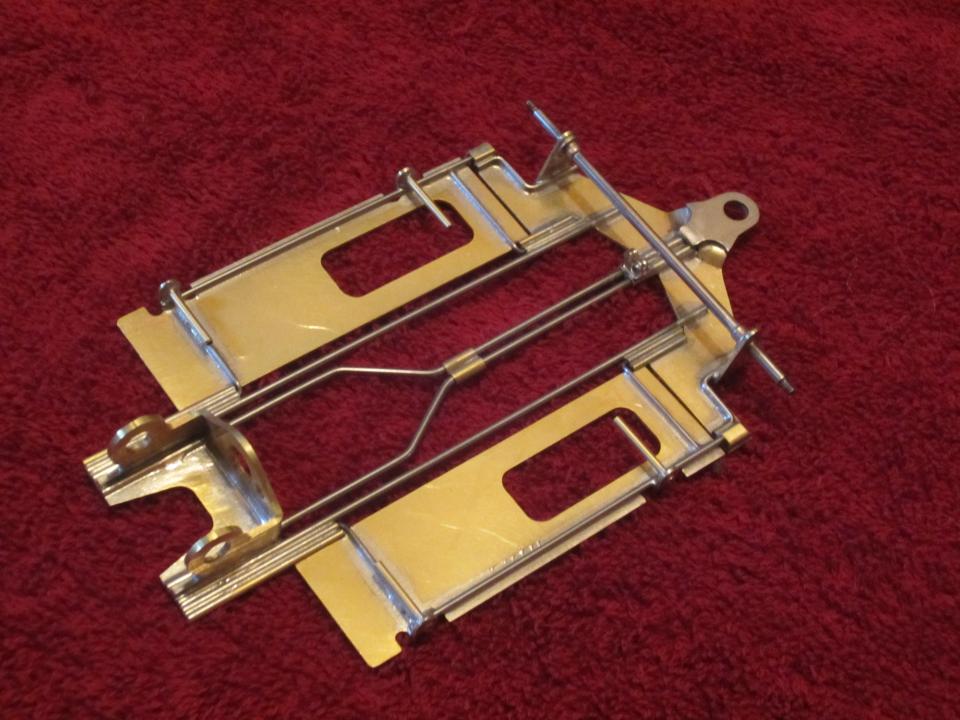

Here's what you get to start with. All brass is .032", bracket is .050". This is a nice builder's kit as opposed to some of the "Lego" kits out there.

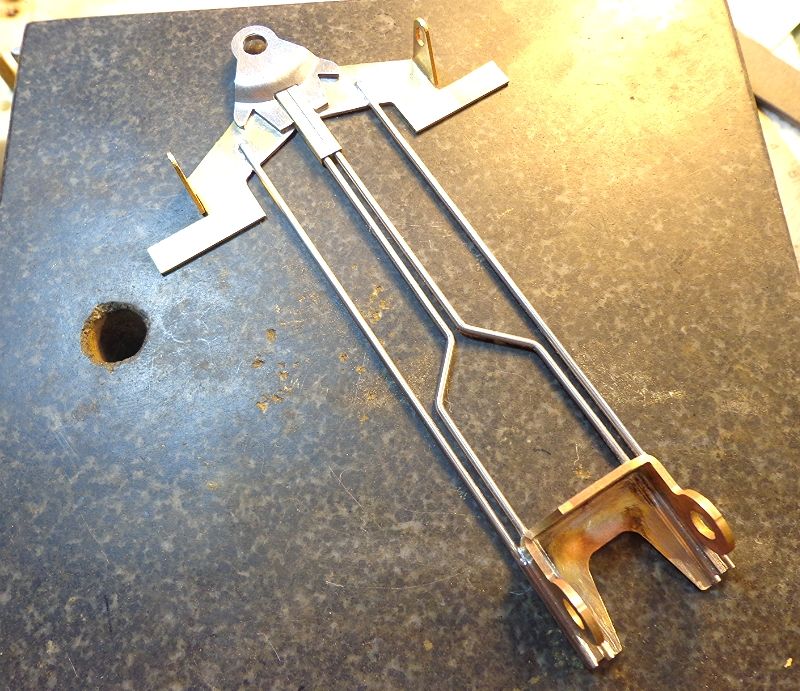

First step is to square and prep the bracket. This is basic stuff. The bracket face is filed until flat then the legs are bent square to the bracket face. The bracket is cut out slightly to accommodate the tuning fork rails which will run along the inside of the bracket. To the side are two bits of 3/32" square tubing about 3/4" long. These are soldered together and then dressed flush and square. These will be the fork hinge tubes.

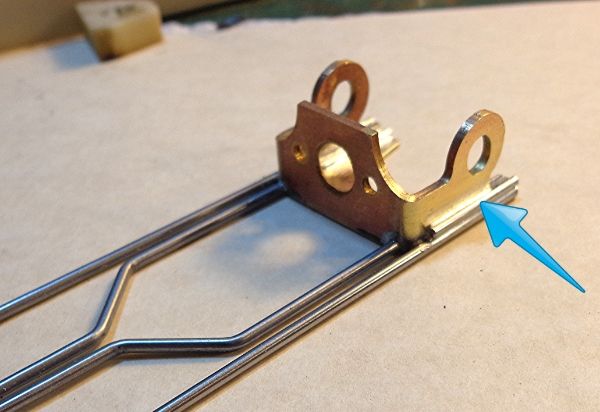

Here is the nosepiece with the hinge tubes. Lines on the ears of the nosepiece show they need to be sanded square or at 90* to the chassis centerline.

Nosepiece squared up and the guide tongue reinforcer is notched to clear the hinge tubes.

Here's the nosepiece with all parts tacked in place but not yet fully soldered.

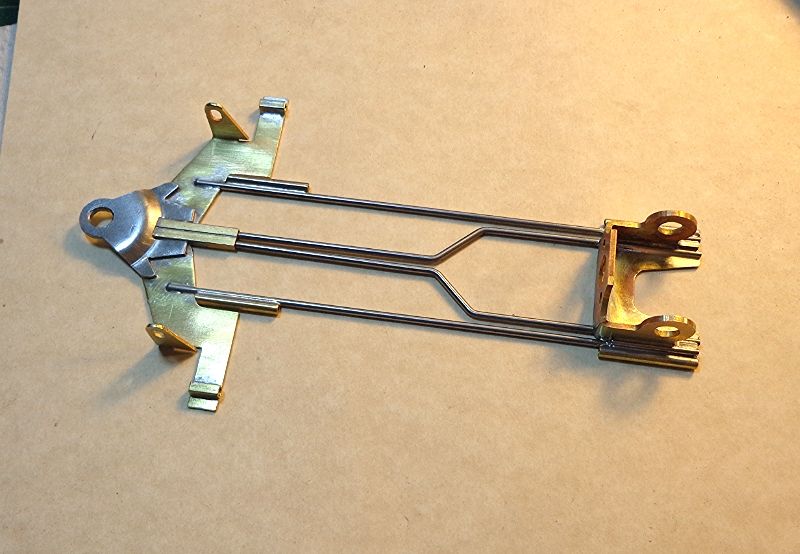

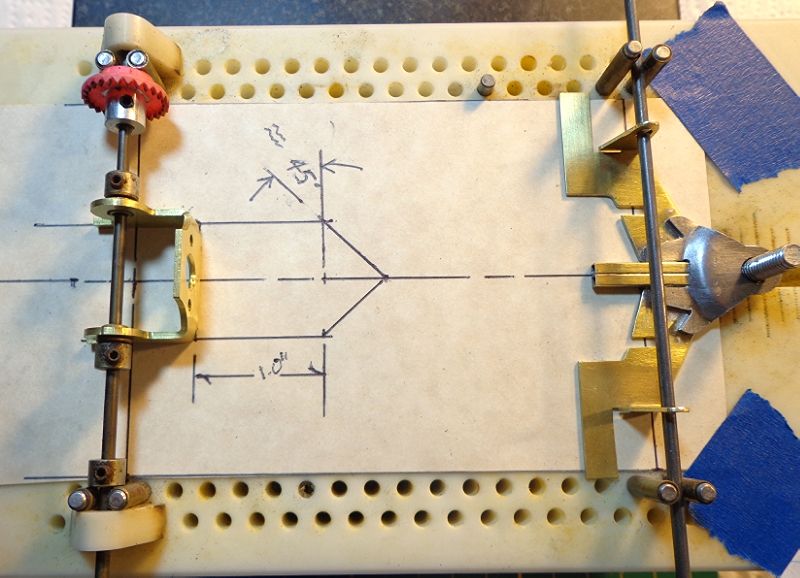

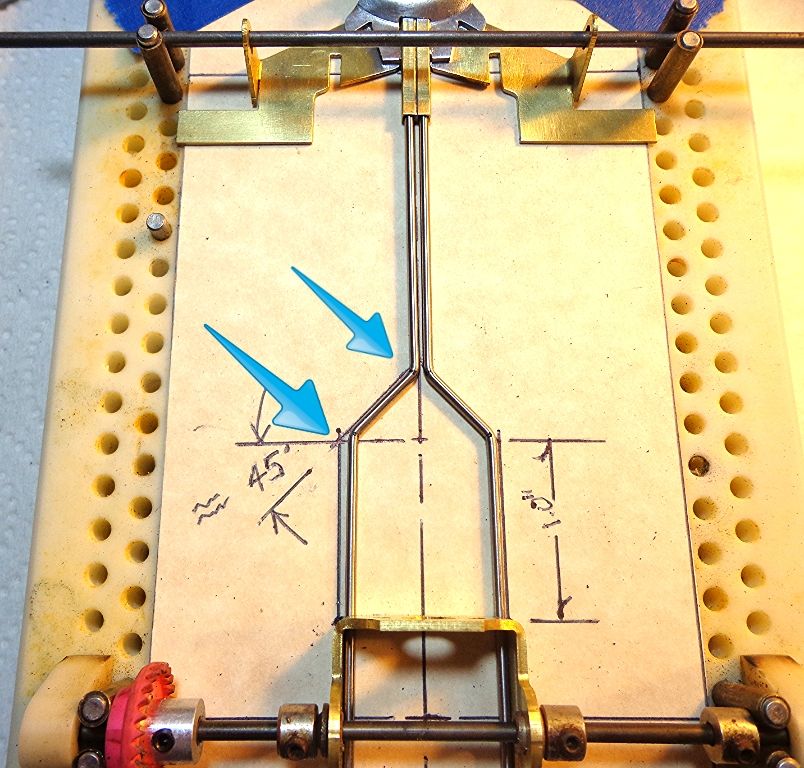

The nosepiece is dropped into your jig along with the motor bracket. The paper template underneath will be your guide for bending, placing, and adjusting the forks. The first bend in the fork will be 1" forward of the bracket face. Both bends in the forks will be 45*. Neither the distance forward from the bracket nor the angles are critical.

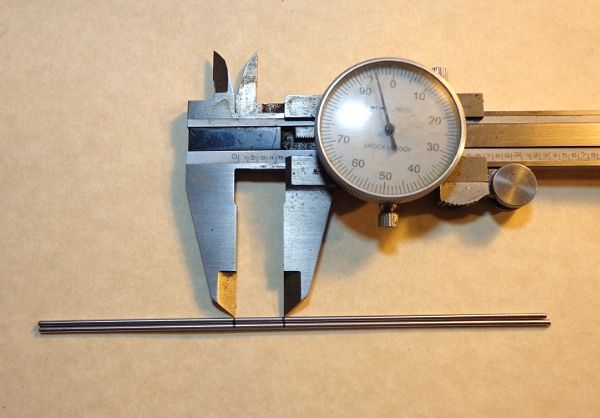

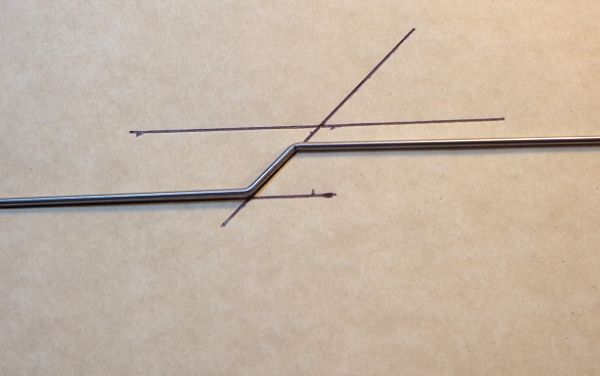

Take two pieces of .062 piano wire about 5" long, and place a sharp mark at about the 2.100" point. Then measure .495" forward of the first mark and make a second. These will be your two bend points.

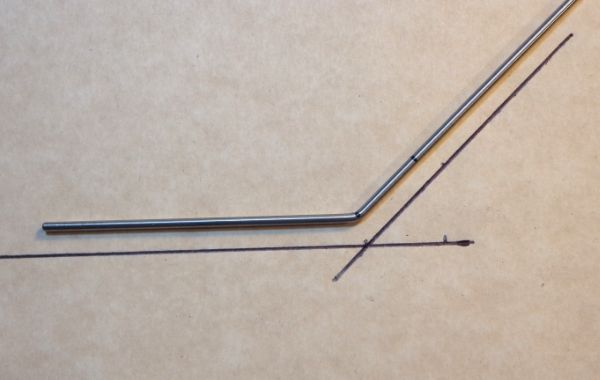

Make your first 45* bend. A little hand drawn template is handy here to check your angle.

Make your second 45* at the forward mark you made on the wire. Again, the template comes in handy to check that the fore and aft legs are as close as possible to parallel. You'll be surprised how accurately you can judge this by eye. After your bends are complete, your angles matched as close as possible, and the legs are parallel, slap this piece on a block and bend the legs until the piece lays flat. Then go back to the template and check the angles and the parallel again Repeat this process for the second fork rail.

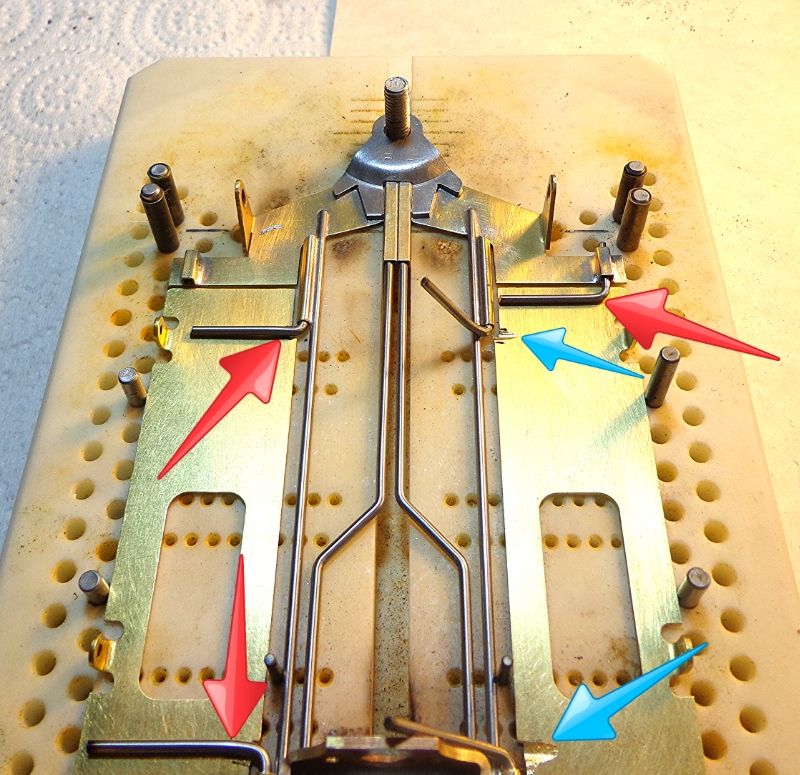

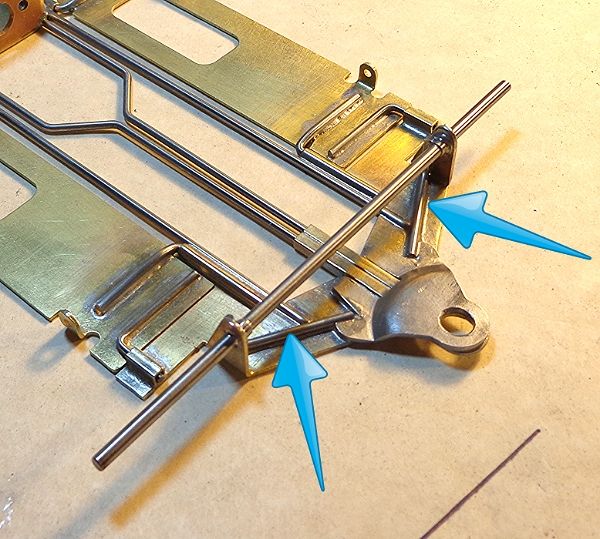

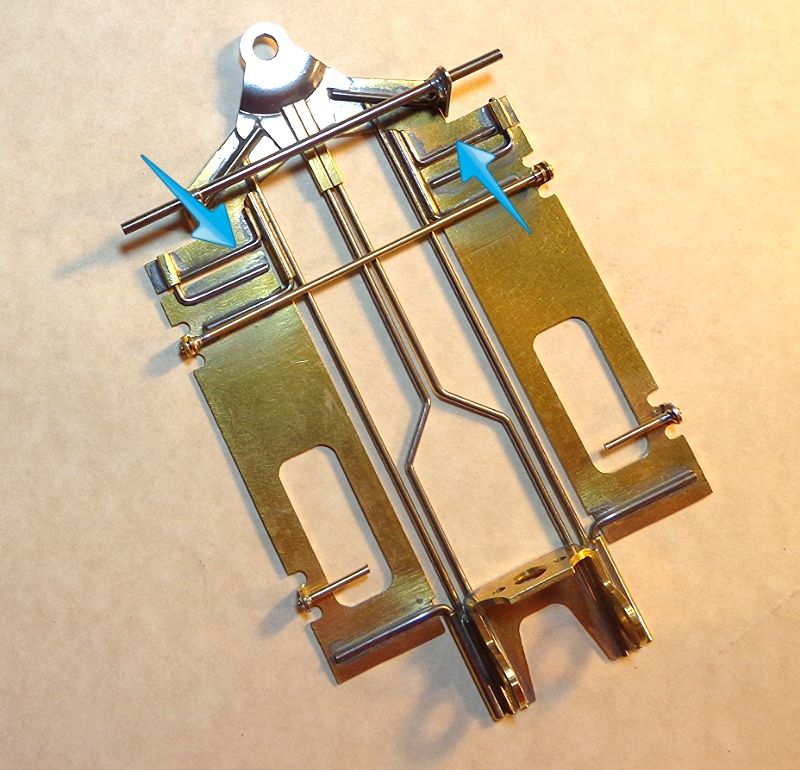

When both fork rails are bent, tweaked, flattened, and aligned, slip the forward ends into the hinge tubes and the aft legs inside the bracket legs and see how you did. The template paper will show you how well you hit the angles necessary and how well matched they are.

In this case, my right rail was almost perfect, but my left was off a little at the two points indicated.

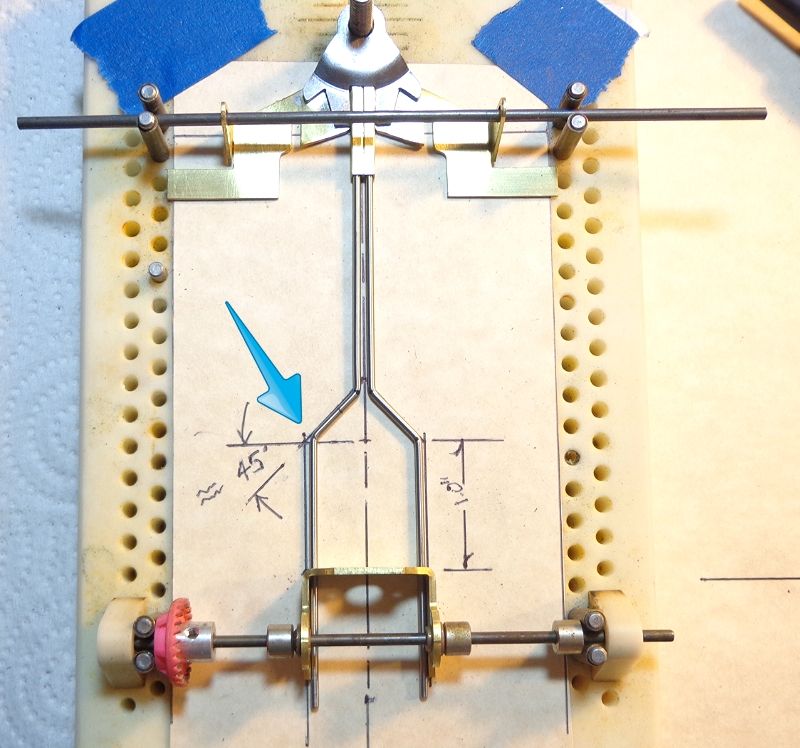

A little corrective bending got the left rail a lot closer as seen here. At this point, I could have just kept on bending and tweaking that rail but I decided to just bend another. The next one was spot on so I called it good and moved on.

That's the end of the first segment. Next up are the main frame rails, pans, some reinforcement, and finishing up.