Resistor question

#1

Posted 24 January 2014 - 08:55 AM

#2

Posted 24 January 2014 - 09:35 AM

- 1A Racing likes this

Scott Salzberg

PCH Parts Express

#3

Posted 24 January 2014 - 10:06 AM

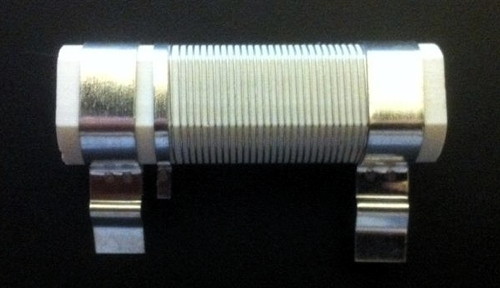

Early controllers used much higher ohm resistors than came later to accommodate "hotter" motors; resistances of 25-40 ohms were the norm. These resistors used fine wire windings and no coating. The flat side where the controller wiper traveled was not sanded to flatten and smooth it.

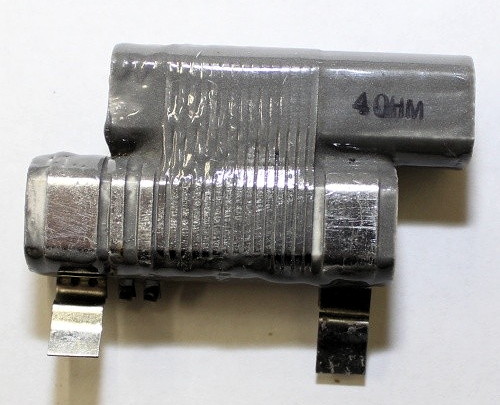

As motors became faster and "hotter", the ohm ratings of controller resistors dropped substantially and the resistors, having to dissipate more heat, started having problems with the windings coming loose. So a coating was applied to help keep the resistor windings in place under the thermal cycling they endured. This was a chalky, ceramic-like coating that had no gloss at all. And about this time, due to the larger wire winding on the resistor, it became common to sand the wiper travel area flat to make the controller operate more smoothly.

As controller ohmage continued to drop, down to 2, 1-1/2, 1, and the round wire winding became flat wire, stronger epoxy-based coatings came into use and these coatings did have a glossy finish, thus the "wet-wound" term. The flat wire basically required the wiper travel area to be sanded, to remove the sharp edges.

All of these changes in the commercially-available resistors were patterned after what the faster guys were doing on their own to modify their controllers. I can recall smearing epoxy on uncoated resistors and sanding the wiper travel area flat for my own use before the coated Parma pieces came to market.

- triggerman, Gator Bob and 1A Racing like this

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#4

Posted 24 January 2014 - 10:21 AM

11/6/54-2/13/18

Requiescat in Pace

#5

Posted 24 January 2014 - 11:14 AM

This ceramic-like coating will crack and flake off over time, even if the resistor has not been used. I've had a couple new resistors become bare just sitting in a parts box. I'd recommend epoxying over this coating or spending the extra money to buy a "wet-wound" resistor.

- 1A Racing likes this

I intend to live forever! So far, so good.

#6

Posted 24 January 2014 - 12:06 PM

The resistors are not wound wet but they are submerged, baked, and then 'planed' where the wiper button makes contact.

The 'pink' ones fail due to the inferior porous coating material that allows moisture to permeate the coating and the thermal expansion compounds the problem by lifting and 'cracking' the binder coating.

I disagree with Scott as these get 'less smooth' over time as the wind is lifted by the corrosion on the back side of the 'wire'.

- 1A Racing likes this

Bob Israelite

#7

Posted 27 January 2014 - 09:01 AM

#8

Posted 27 January 2014 - 10:39 AM

The 'pink' ones fail due to the inferior porous coating material that allows moisture to permeate the coating and the thermal expansion compounds the problem by lifting and 'cracking' the binder coating.

Parma once sold bottles of the ceramic-like coating material so you could repair a resistor that had flaked off or become cracked. I forget what color it was but I don't think it was pink, maybe red-orange or yellow. Some people used to try that coating to repair Ungar ceramic elements.

I intend to live forever! So far, so good.

#9

Posted 27 January 2014 - 12:17 PM