What you get with this kit is as follows...

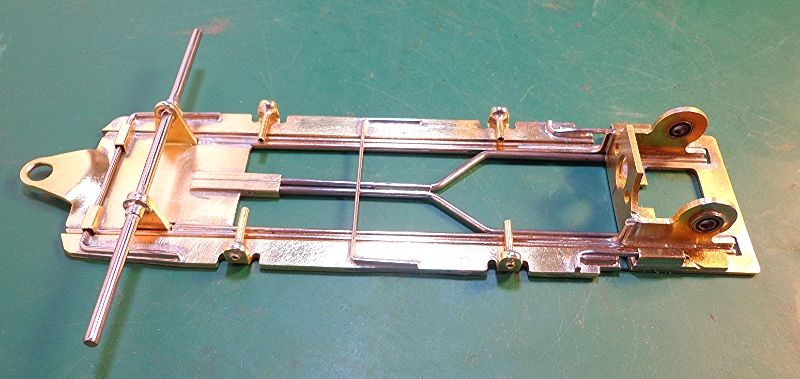

1" bracket

1" nosepiece

bracket plate

Two nicely-formed tuning fork rails (.062" wire)

Four straight bronze rails (.062")

Two nice .062" thick pans. (I'm sure you can get the lighter pans as well)

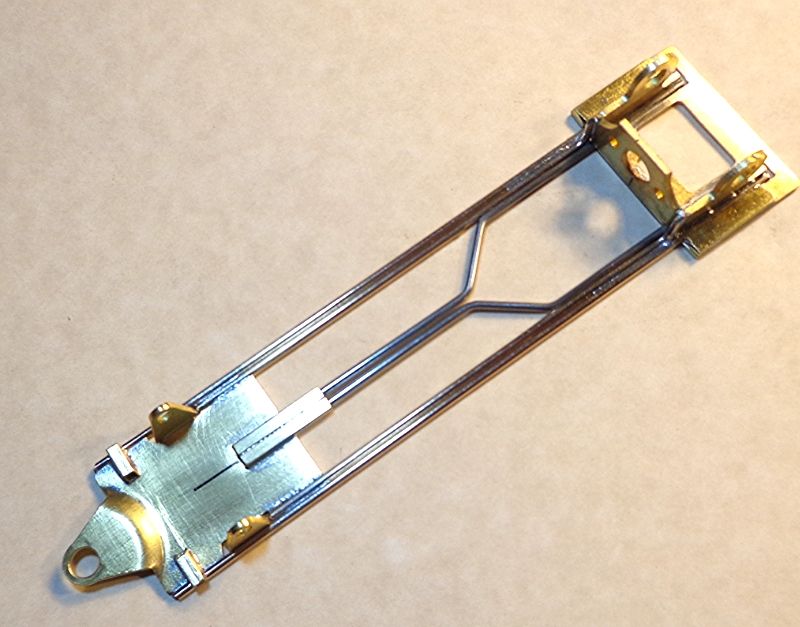

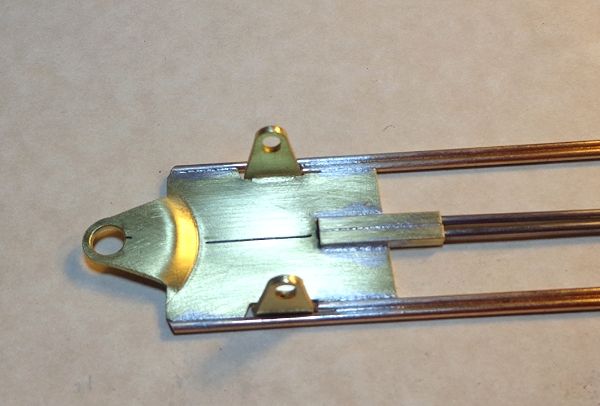

- You start from the inside out working with the wire forks running inside the bracket.

- Next, you place the inner main frame rail which butts against the face of the bracket.

- You want at least .005" clearance between the inner main rail and the tuning fork.

- You can just lay the rail in place and butt solder to the bracket face and the nosepiece.

- If so, then your inner rail will be about .010"-.015" wider than the bracket sides

- Thus... your outer main rail will have a small gap next to the bracket. No big deal, but...

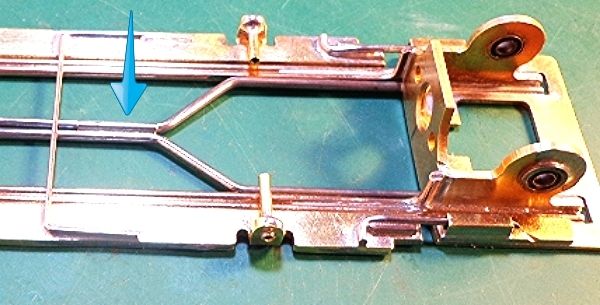

- I wanted the outer rail to go flush against the bracket and square and straight to the 1" nose plate.

- This is the inner frame rail bent to go against the bracket face.

- I filed a ~ .015" flat about 1.062" forward of the bend.

- This allows the inner main rails to nestle around the tuning fork and still be 1.00" outside width.

- Then your outer main rail will go flush to the sides of the bracket and nose plate with no gap.

- I notched the nose plate aft of the axle upright .062" on each side.

- The inner main rail is inset into the plate.

- Then, your outer rail will lay flush with the front part of the plate which is still 1" wide.

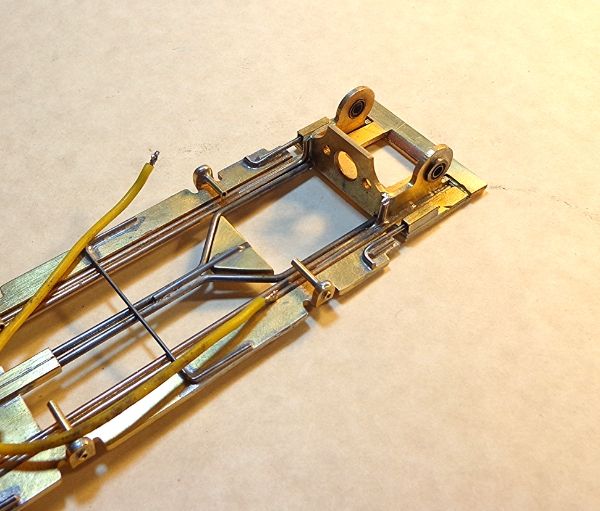

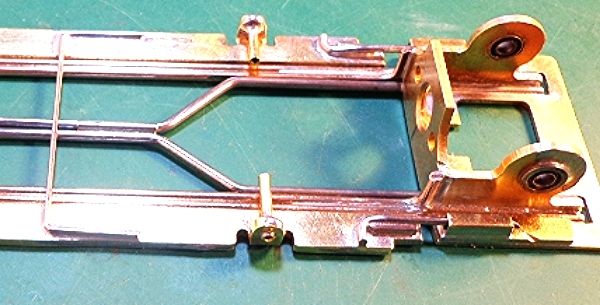

Detail of finished front end.

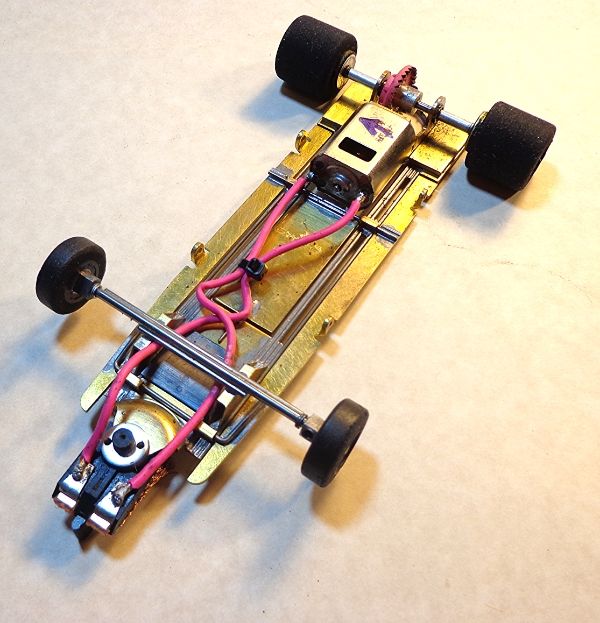

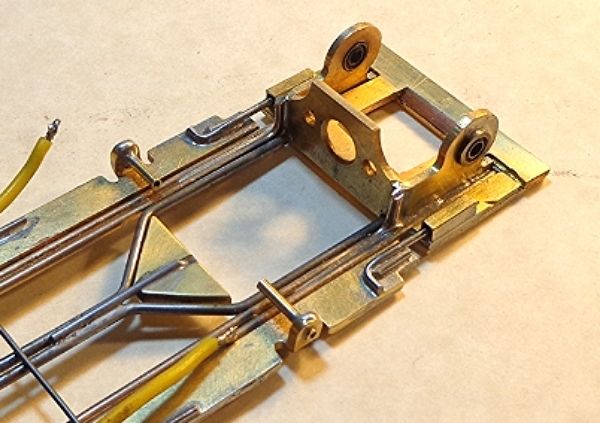

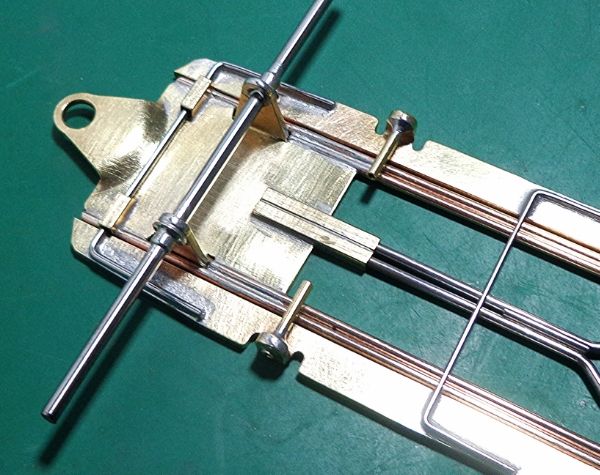

- I did these following steps before putting the axle in place so it's easier to get at the front bits.

- Square 3/32" tubes form the front pan hinge tubes.

- .047" piano wire forms your hinge rod. Bend one leg then slip through tubes and bend the other side.

- When soldering up the hinge wire, I leave about .010" between the pan and the main rail.

- Spreader wire is .032" but could be any size. Small wire allows the pans to be slightly independent.

- Small bit of .047" wire goes right at the crux of the fork rails to tie them together. (Quick and easy to remove)

- The bracket plate comes with fairly long ears going forward.

- I cut the ears off flush with the front face of the bracket and soldered the cut offs on top.

- This makes the bracket plate a little thicker than the pans which are .062.

- Square 3/32" captures the .047" wire which forms a downstop and upstop.

- Slight dogleg is bent into the .047" wire and a little scrap of wire reinforces the solder joint.

- Note that the main rails are soldered together only about 1/2" forward of the bracket.

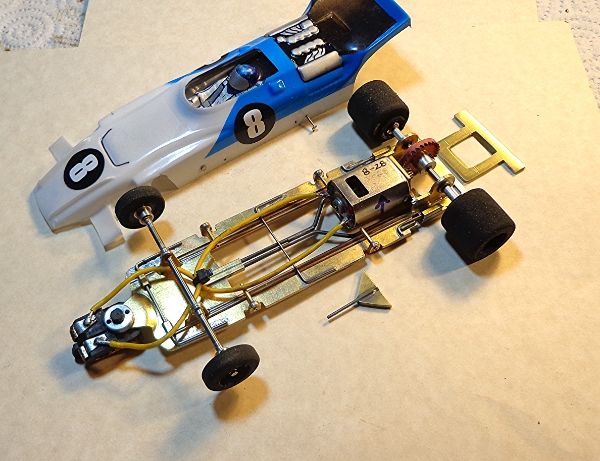

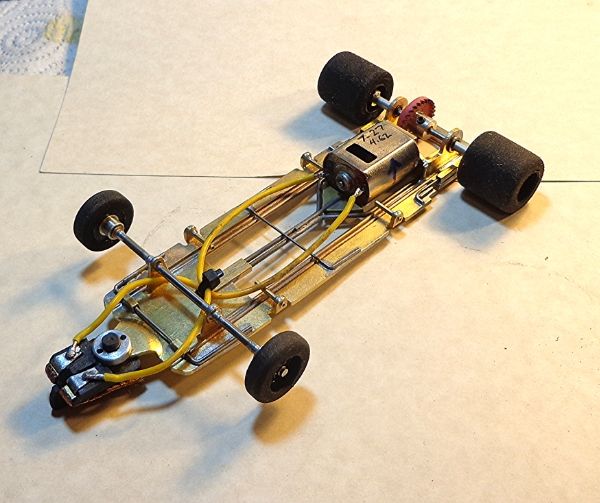

- Finished product: Bare frame as shown here is 56.5 grams. All up with body will run 98-100 grams.

- This will get tested first on the "Korkscrew" flat track at MoTown raceway in Modesto.

- This build might be a little light for that twisty 88' track or our other technical flat tracks.