This build is going to be one of my favorite kinds, a “What If” build! What would an R&C GP car built with a period “Midwest” influence run like?

In Car Model, February 1966, pg. 24, Mike Morrissey wrote about his travels as Captain of Team Russkit, specifically to The Groove, in Royal Oak, Michigan:

"To begin with, everywhere we went, we were surprised at how fast cars are going. From Las Vegas to Long Island, we found cars almost as fast as ours, and in Detroit... well, I'll come to that later."

Detroit was the home of The Groove Raceway and there things did not go exactly as planned according to Morrissey:

"We didn't have much trouble going as fast as anyone else except in one place, The Groove, in Royal Oak, Michigan. It was here that we got clobbered, whipped, and obliterated. I mean, they could have saved themselves some time by simply beating us with hammers and throwing us outa the joint!"

"You see, it was at The Groove that we learned all about 'super-traction' tracks... the hard way. We had heard about these Midwest track surfaces, but we'd never realized just how sticky they were. They use a high-gloss paint that is nearly shiny. Then after the track is broken in and builds up a little tire goop on the paint surface, it becomes so sticky that you can't believe it!"

"Anyway, our cars are built for normal surfaces and are, as I said, very light. They wouldn't slide or drift at all, but instead would just do snap rolls. The locals' cars weigh 5 to 6 ounces or more. They use flat brass plate about 1/8" thick for frames, those 'Silastic' tires, and a variety of motors. The flat plates give a very low center of gravity, which kills the flipping tendency, and the weight stabilizes them. To get all that mass down the straights, they use hairy motors like Dyno-Chargers, Rams, and wildly rewound Pittmans and Mabuchi’s. To stop they use up to 6 volts of power brakes. We'll be back that way, though, and next time we'll be properly armed!”

The “super-traction” track Mike describes reminds me a bit of a modern high-gloss track surface that has been cleaned and freshly glued. On that kind of surface, with modern black tires, my R&C cars would snap roll into the wall instead of doing a nice controlled drift at the limit. I could add lead to the drop arm and it just increased the cornering speed before the snap roll.

Switching tires to a harder, lower traction tire like vintage VC or Tiny’s greys really helped with the problem. Alpha colored SBR rubber also helped. But back to my “Midwest” theme……..how about something like this:

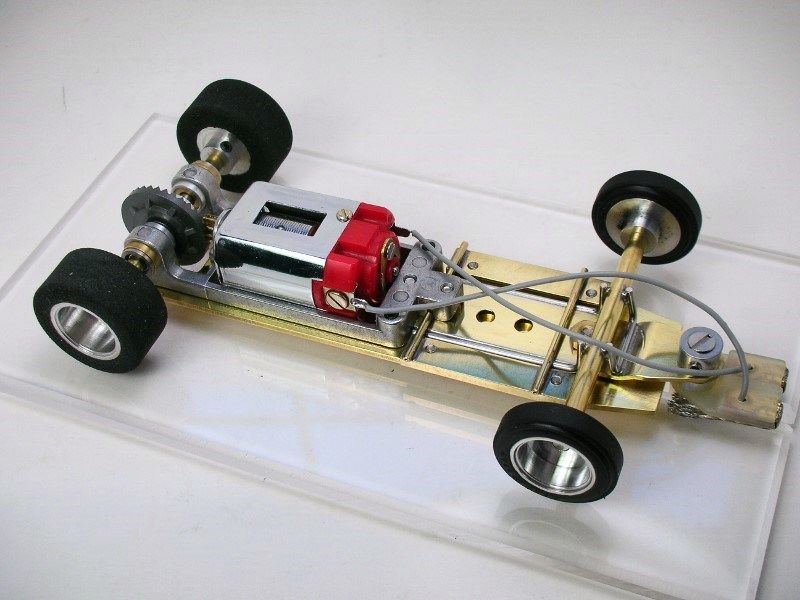

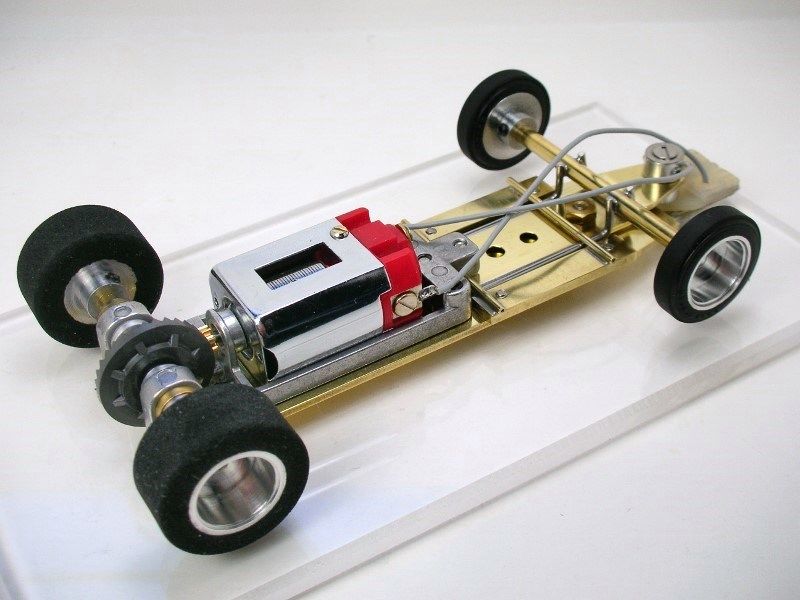

A big hunk-O-brass pan………….I mean PLATE. In deference to the great Midwest builder Pete Hagenbuch I’m calling this a plate chassis. In his June 1964 Car Model Magazine article, “ A Second Look At Slotcar Handling” he defined a pan chassis as, “…a chassis hogged out of a solid hunk of brass or aluminum and closely surrounds the motor.” This build is going to have a PLATE chassis.

So, what to hang this honk’n plate under? Rodney’s latest GP entry gave me an idea:

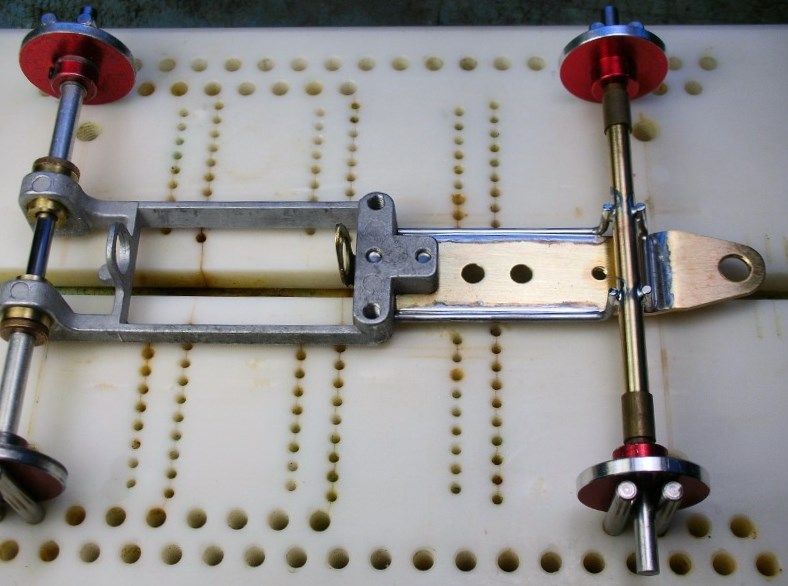

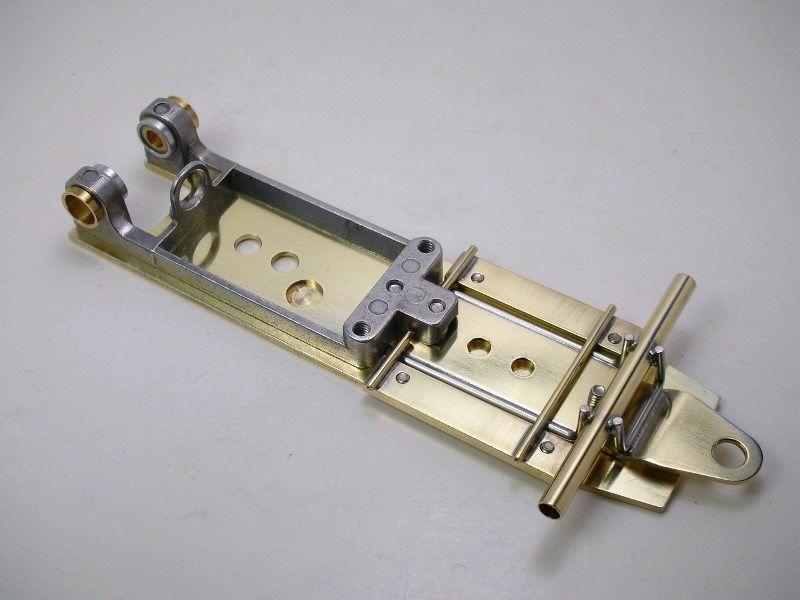

Okie Dokie, a Dynamic chassis but we need more “Midwest”. How about this:

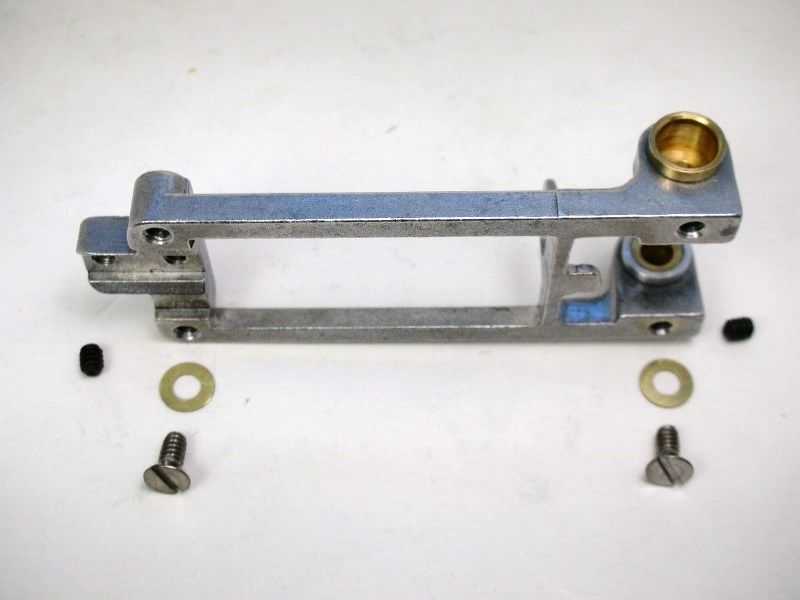

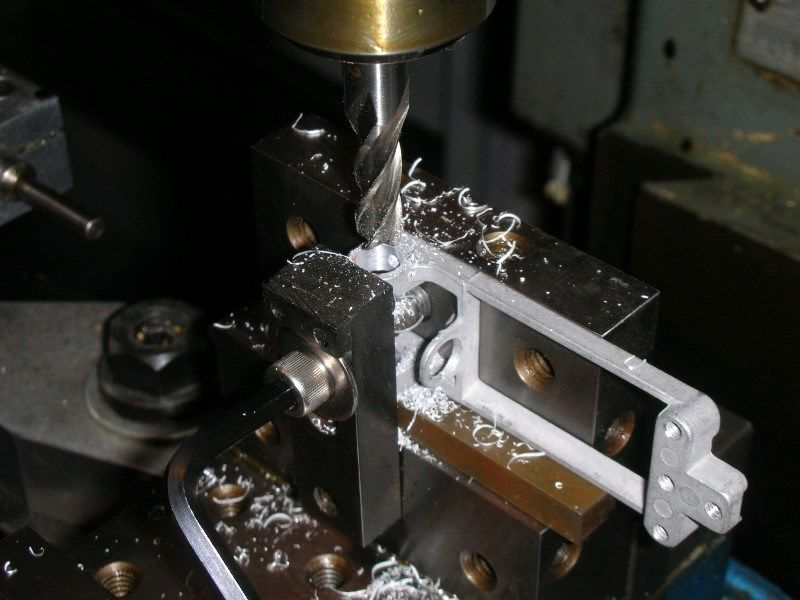

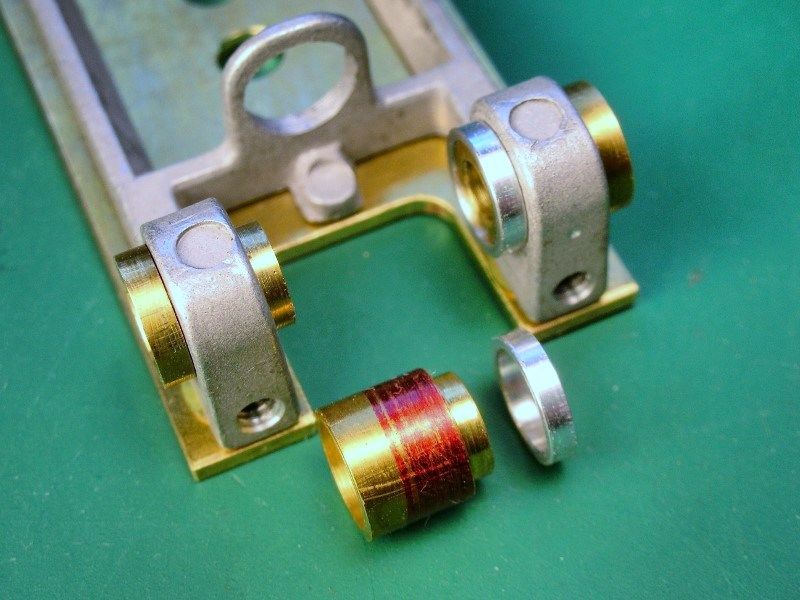

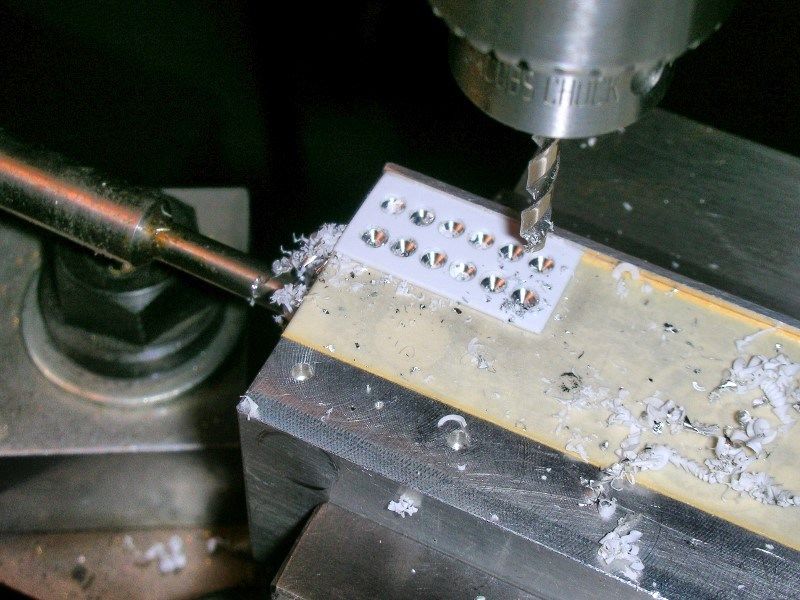

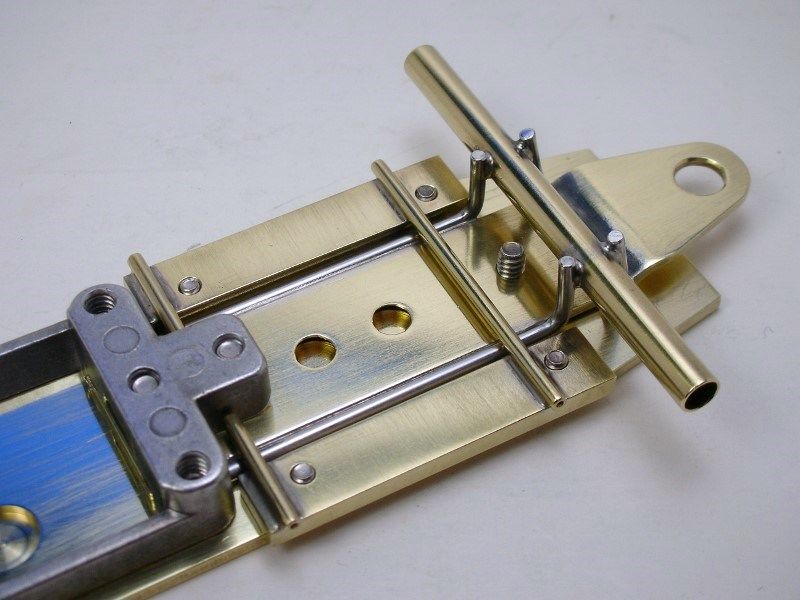

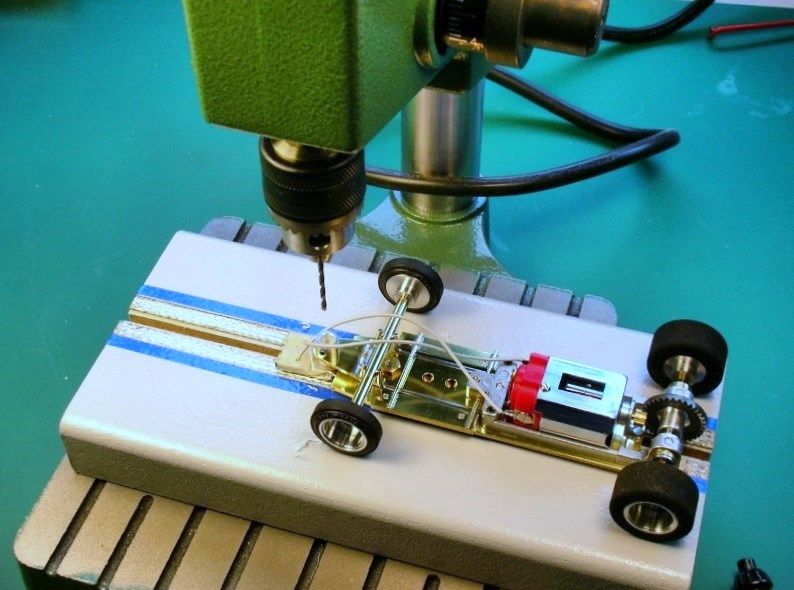

Master fabricator R-Geo Rick sent me a sample of his prototype repo and that’s what I decided to use instead of the fragile Dynamic piece. But first I needed to get the Dynamic motor mount drilled and tapped for pan.......I mean PLATE mounting.

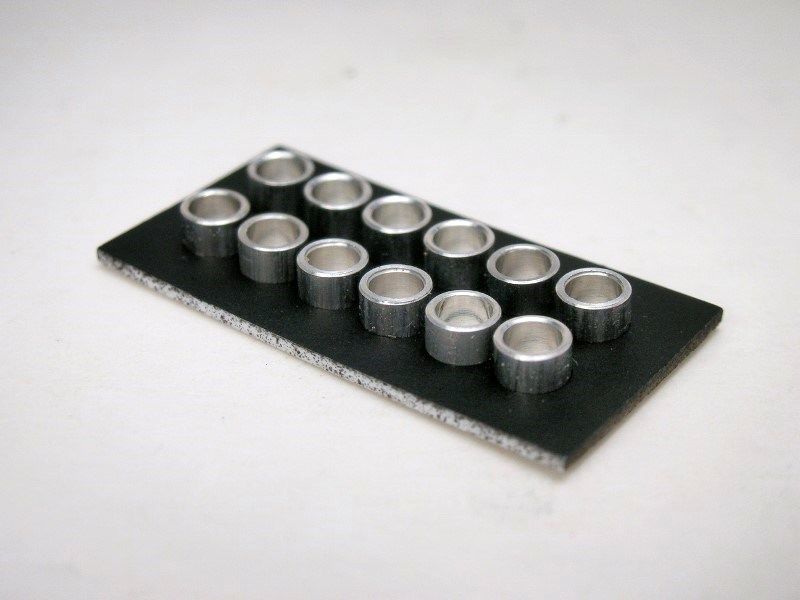

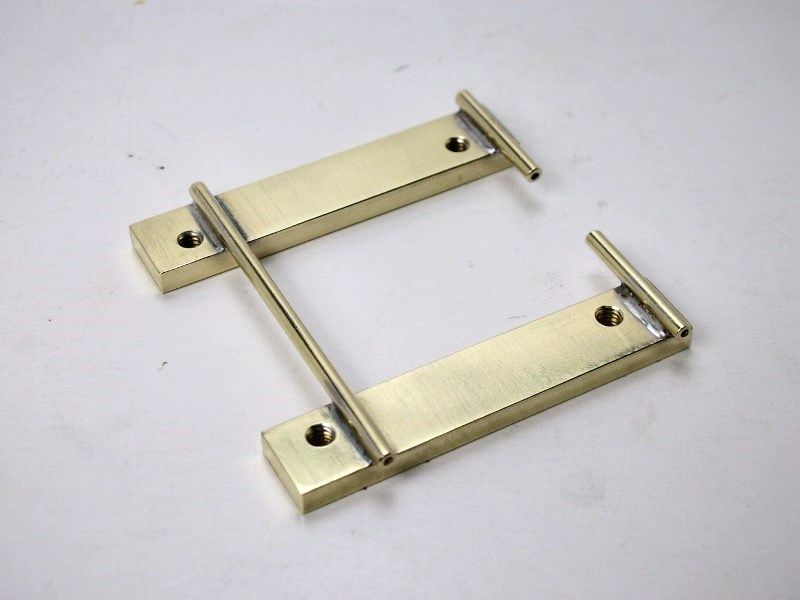

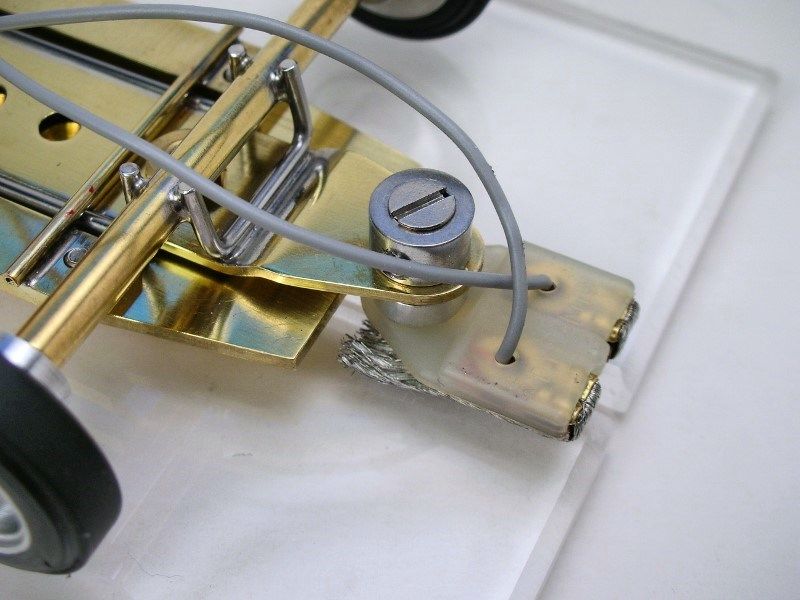

Here the holes for set screws that will lock the plate mounting screws in place so the plate can be a nice, loose "rattle fit":

The loose body mounting was also discussed by Pete Hagenbuch in the same June 1964 article:

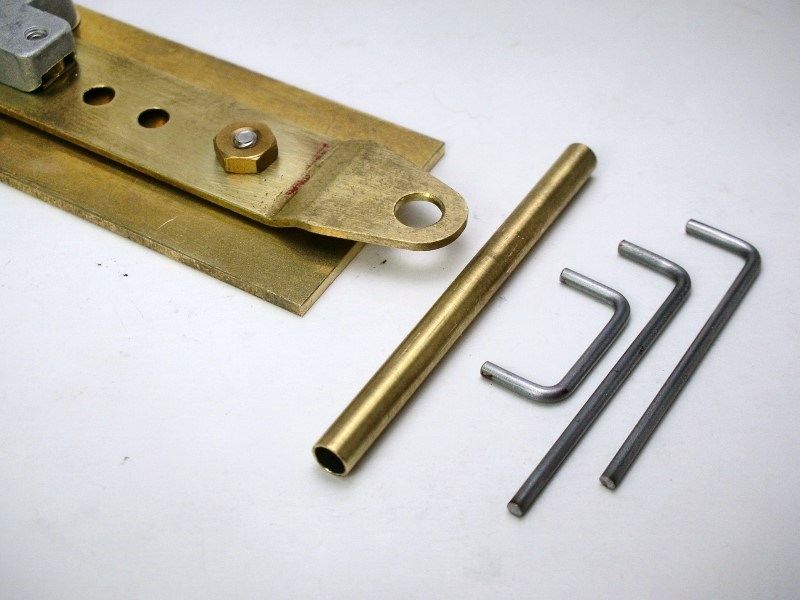

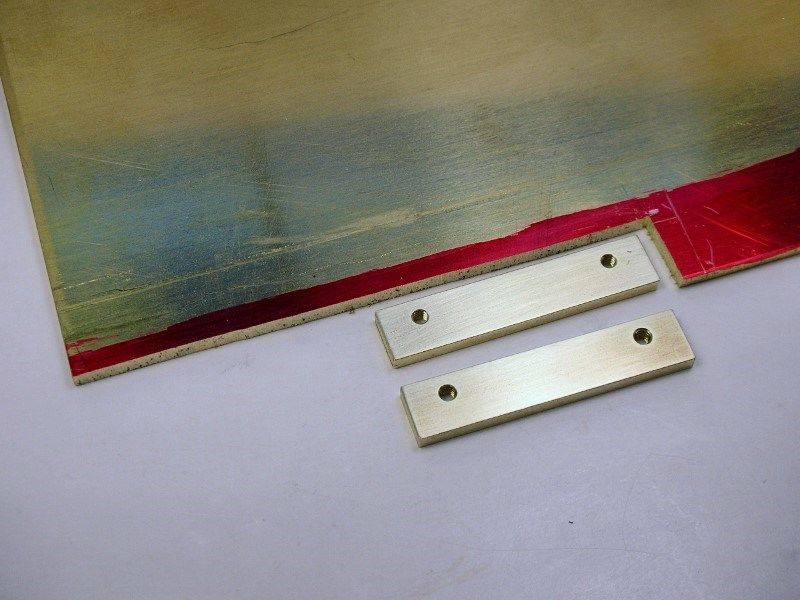

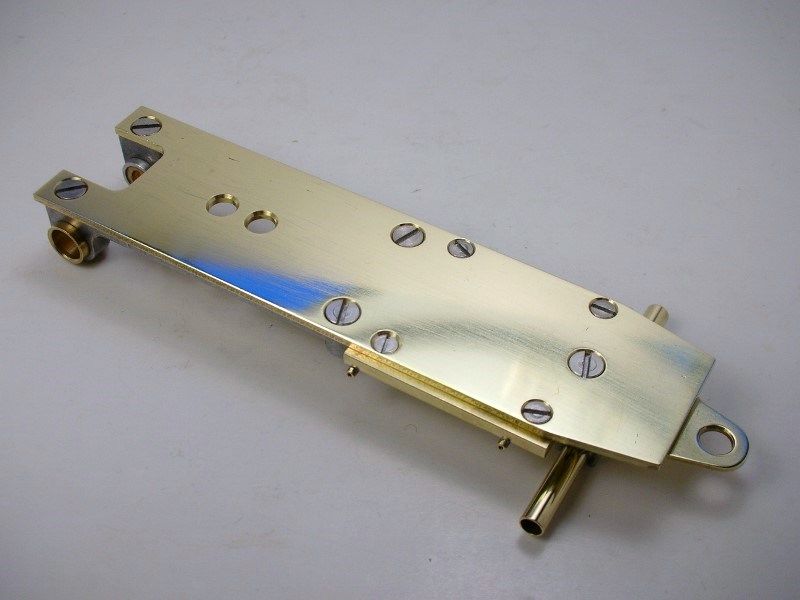

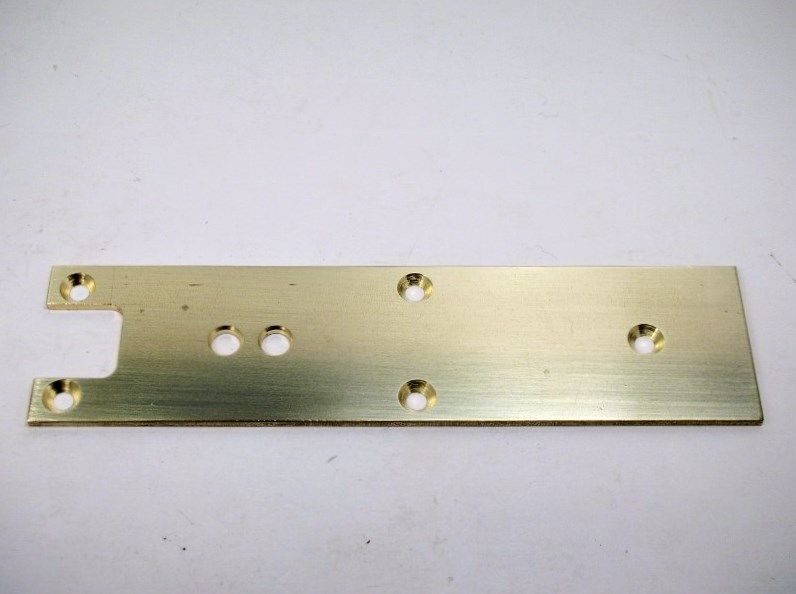

It's brass plate hogging time. This plate is 1/16" thick and 1.150" wide:

It's got a notch for gear clearance and 2 motor cooling holes. It may get the outside profiled a bit depending on my body choice:

Onward ![]()