OK... first race in flat track form.

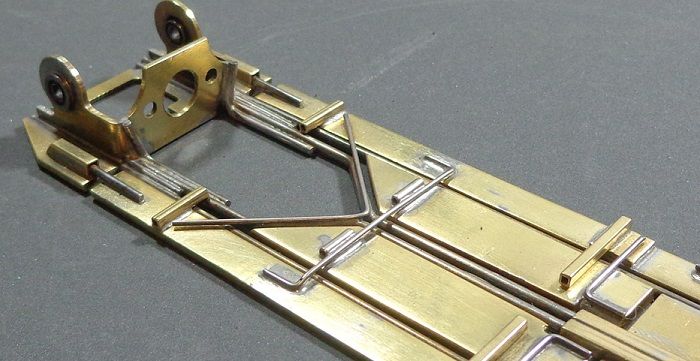

I was down south at Buena Park for last weekend's flat track race on their MTT road course. I had all my various F1 chassis with me. I ran everything over several lanes and the Toronto as shown above was on average the best. I didn't do much to the set-up shown above except to add about 3 grams more nose weight, fiddle with gearing, and run through the litany of tires that I had with me. The car felt fast and easy to drive although my frame of reference for BPR is over two years old (and) the track was prepped a little weird, although I didn't know that at the time. I was practicing on Friday evening before Saturday's race and thought I had things wired so I moved out to the red lane with all my cars for some practice on this very slow lane.

- Within about 30-40 laps, the Toronto started to do oddball things. It seemed loose and tippy at the same time and chattery in some turns.

- At this point, I made a mistake and started chasing the problems.

- I added weights, I took off weights, I changed tires, I added tape to the pans.

- Eventually, I added some "L" braces to the bracket, and added a flex limiter to the fork rails.

- Finally, I soldered the floating rod that supported the rear of the center weights solid into the square tubes that it was floating in.

- All these things improved the problems a little but the car still felt rough and weird.

- Then... I switched back to a middle lane and everything was fine (even better than before).

- It turns out that the red lane had been very poorly prepped and the glue was very spotty.

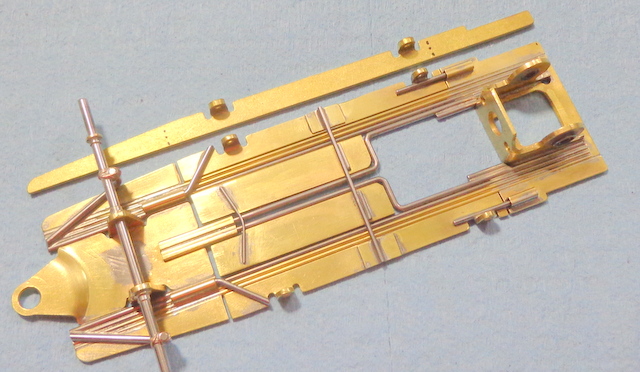

Race day came on Saturday and naturally, I started on the red lane. I wasn't sure if the car was totally bad or what so I choked the car and took it very easy early on. After about two-three heats, I decided that I had something good and started pushing a bit. At the the halfway point, I was down four laps to the lead group and in fifth or sixth place. In the second half, I pushed my pace and started to come back. It is very hard to make up ground in this crowd because, they basically don't come off. I made up two laps on the eventual winner and four-five laps on everyone else and finished in second. This car was really very good and could possibly have finished better than it did (If... I had done a better job in the first three heats). This pic below shows how I have finalized the stuff that I cobbled up at the track.

- "L" braces at the rear bracket face.

- Moved the spreader bar further back and soldered the rear of the center weights to the spreader bar, thus tying the weights to the pans.

- Removed the floating rod and tubes that had supported the weights and allowed them to float independently from the pans.

- Removed the flex limiter that I had soldered in between the forward arms of the forks.

- Moving forward, I think I'll leave the bracket braces in place. I could convert this to a speedway version in 30 seconds by just unsoldering the center weights from the spreader bar and dropping them out.