Here is the first test mule for something I've been thinking about for a bit. I'm calling this experimental because I'm completely unsure as to whether there's much merit in it or not. What I mean is that if I took a current standard build (saaaay.... multi-rail .047") and varied it from 4-5-6 rails per side or changed the wheelbase or guidelead... that's no great experiment. I know that the variations will work, just a question of what track and what conditions. But with this... I just don't know.

So... what is it and why?

What...

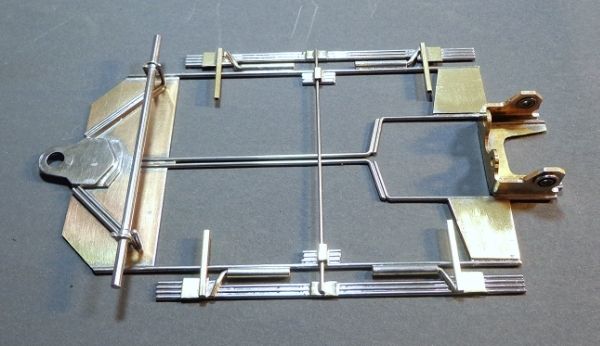

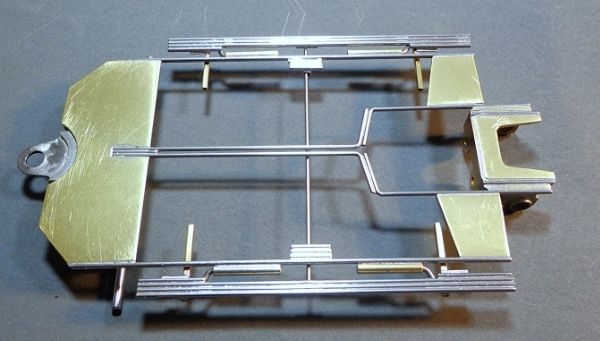

- The what is almost a full perimeter design with main rails and forks that can be changed.

- Handmade .032" nose with an R-Geo bracket and bracket brace.

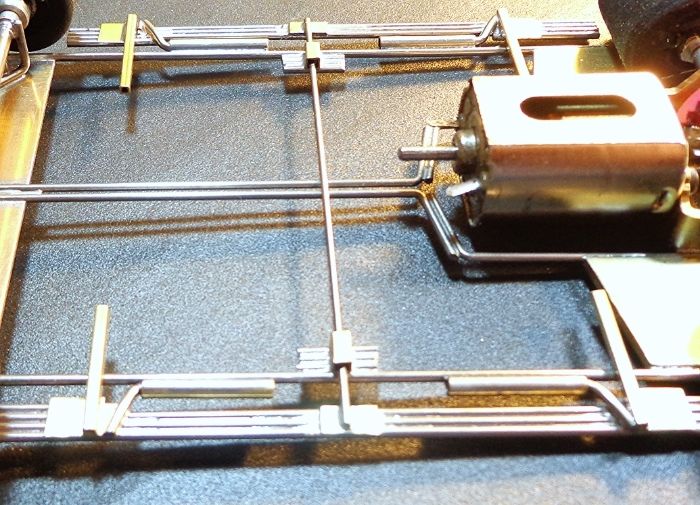

- Tuning forks are fixed in front and are .047"

- This is version 1.2 with a single frame rail of .055".

- Version 1.1 had single frame rails of .047". I just changed this today after initial testing yesterday.

- Rear brass tabs are for weight placement and to spread the frame rails.

Why...

- Inspired by Rick's "Toronto" F1, this is an experiment with a softer flexing frame.

- Weight placement... There is very little weight in the mid-section of this frame.

- Most weight is concentrated at front and rear corners (mostly rear)

Variability...

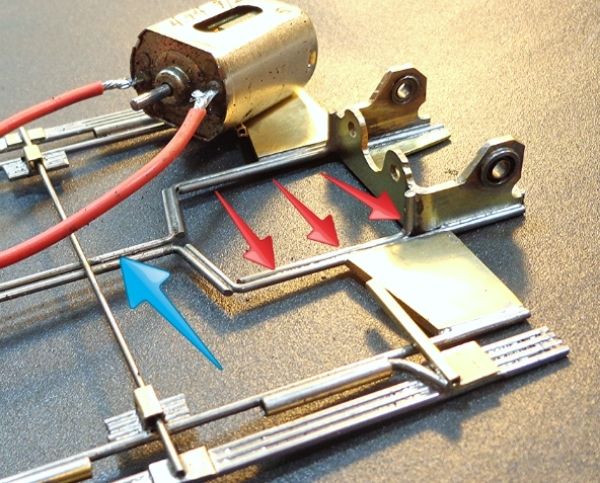

- After initial testing, I dropped out the two original (.047") main rails and replaced with .055".

- This was very easy to do and didn't disrupt anything else.

- The forward half of the forks (currently) .047" could also be easily be replaced with .055".

- I could also replace them with fork rails in tubes without disrupting the rest of the chassis.

So... I'll clean this up and then testing will continue.