Jim,

I had a similar "chatter" character in what became my "go to" chassis design three years ago. I cut a vertical slot for some .025" wire to mount flush (or slightly below) into the face of the motor bracket such that the wire, after being soldered in, gets sandwiched between the motor mounting face and the bracket (trapped so it can't go anywhere or even flex to weaken or fail the solder joint).

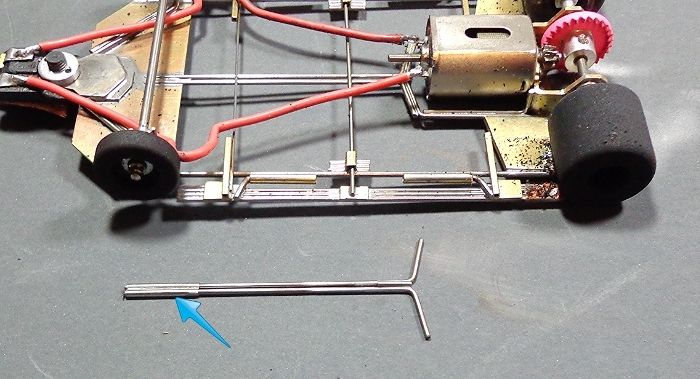

This wire went "up" and then had a 120 degree bend that took it to the mainrail, another 30 degree bend so that I had a land about 1/2 inch long to solder it to the mainrail ahead of the but along side the motor. This was quite a bit lighter than the .055" wire "L" you show but seems absolutely stiff in gusseting up that cantilever zone from the motor bracket to the mainrail.

Like yours, the chatter went away but, much more importantly, the chassis ALL really hook up off the corners allowing me to just glide the car into the corner and punch it out very early. Extremely forgiving and very fast for every lap because it is not driven as a straight, then a turn, then a straight - it just strings the whole lap together as a smooth "rhythm" kind of driving. Just as important, when pushed, it will allow you to step up your laps to chase someone down!

Also interesting is that it did not seem to change the twist stiffness from front axle to rear axle at all - just stiffens up the longitudinal flex where it needs it. Actually, I think it changes the "resonant" frequency of the rear axle torque "wrap up", kind of like traction bars on a leaf spring 1:1 car. If the stiffness of this area matches the torque/bite, it seems to get on a "resonance", the source of the chatter.

I really like your outside the box thinking and watch your threads with great interest. Not enough people experimenting out there with new things that are completely within the spirit and letter that the rules allow, in my opinion. Glad to see you are and that you choose to take time to share with well thought out and written articles with nice, clear pictures.

Keep it in the slot,

AJ

Sorry about the nerf. "Sorry? Sorry? There's no apologizing in slot car racing!"

Besides, where would I even begin? I should probably start with my wife ...

"I don't often get very many "fast laps" but I very often get many laps quickly." ™

The only thing I know about slot cars is if I had a good time when I leave the building! I can count the times I didn't on one two three hands!

Former Home Track - Slot Car Speedway and Hobbies, Longmont, CO (now at Duffy's Raceway), Noteworthy for the 155' Hillclimb track featuring the THUNDER-DONUT - "Two men enter; one man leaves!"