I had a chance to run some laps with this car Saturday night. I ran the car just as built on both the king and

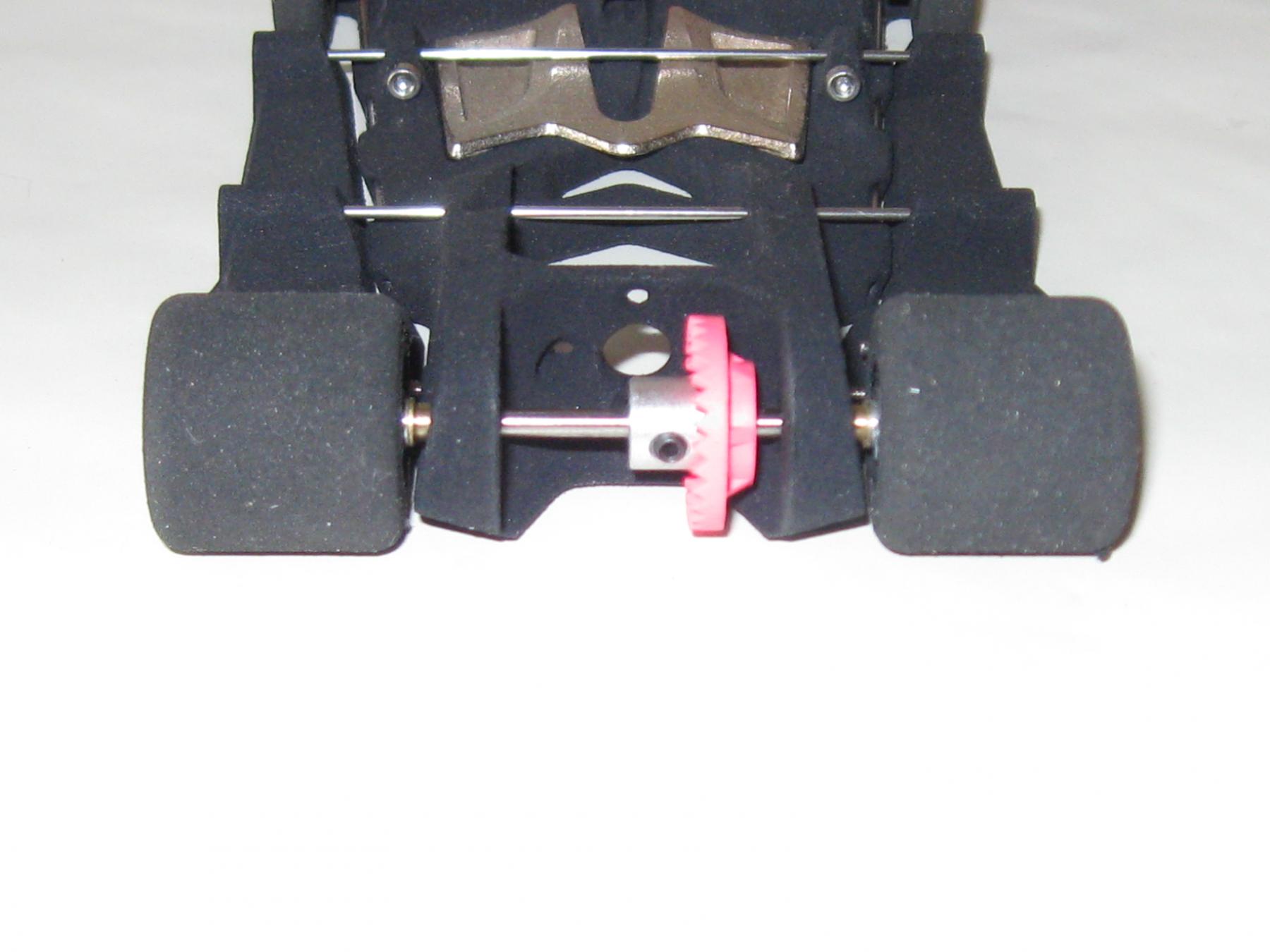

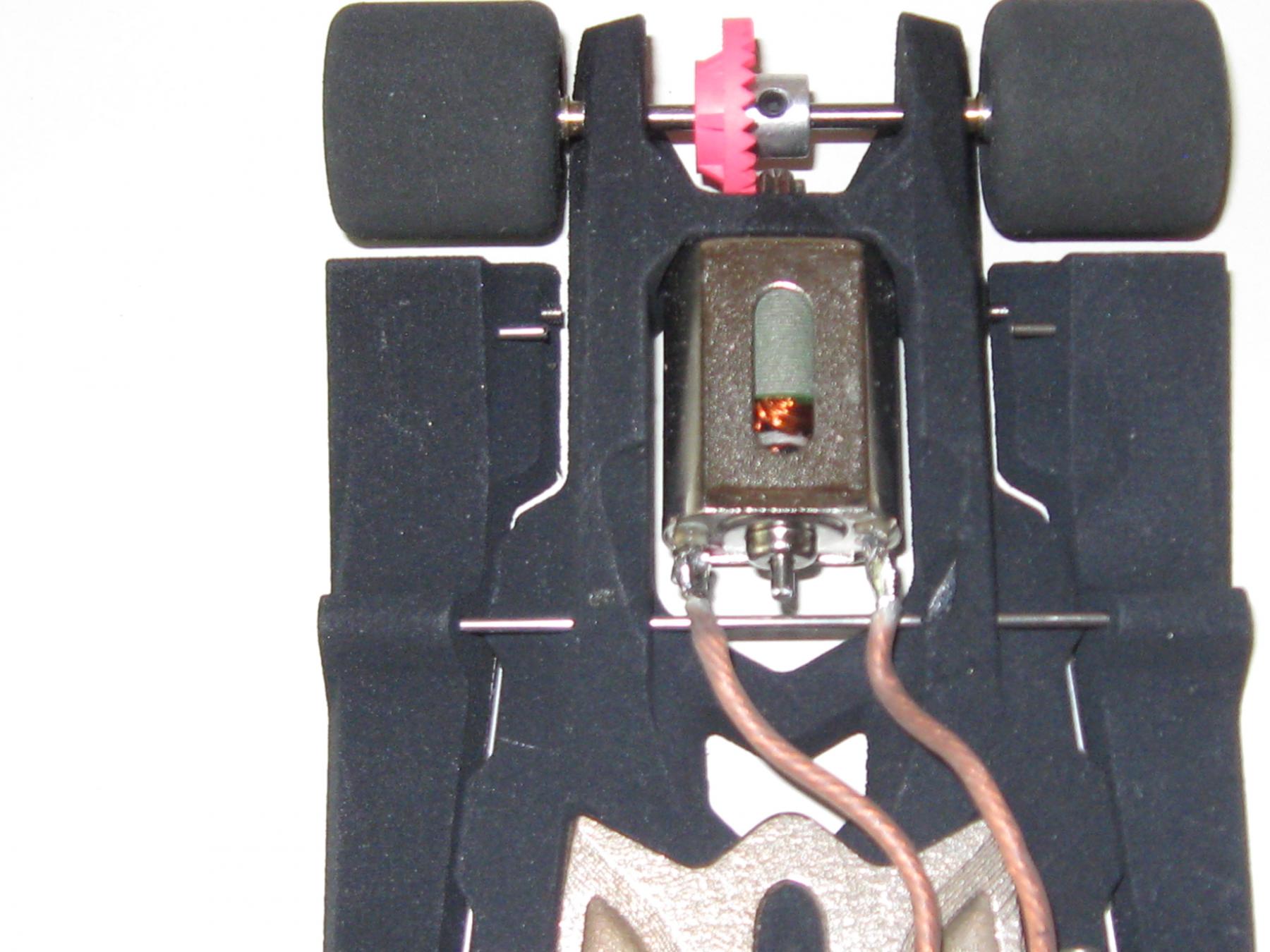

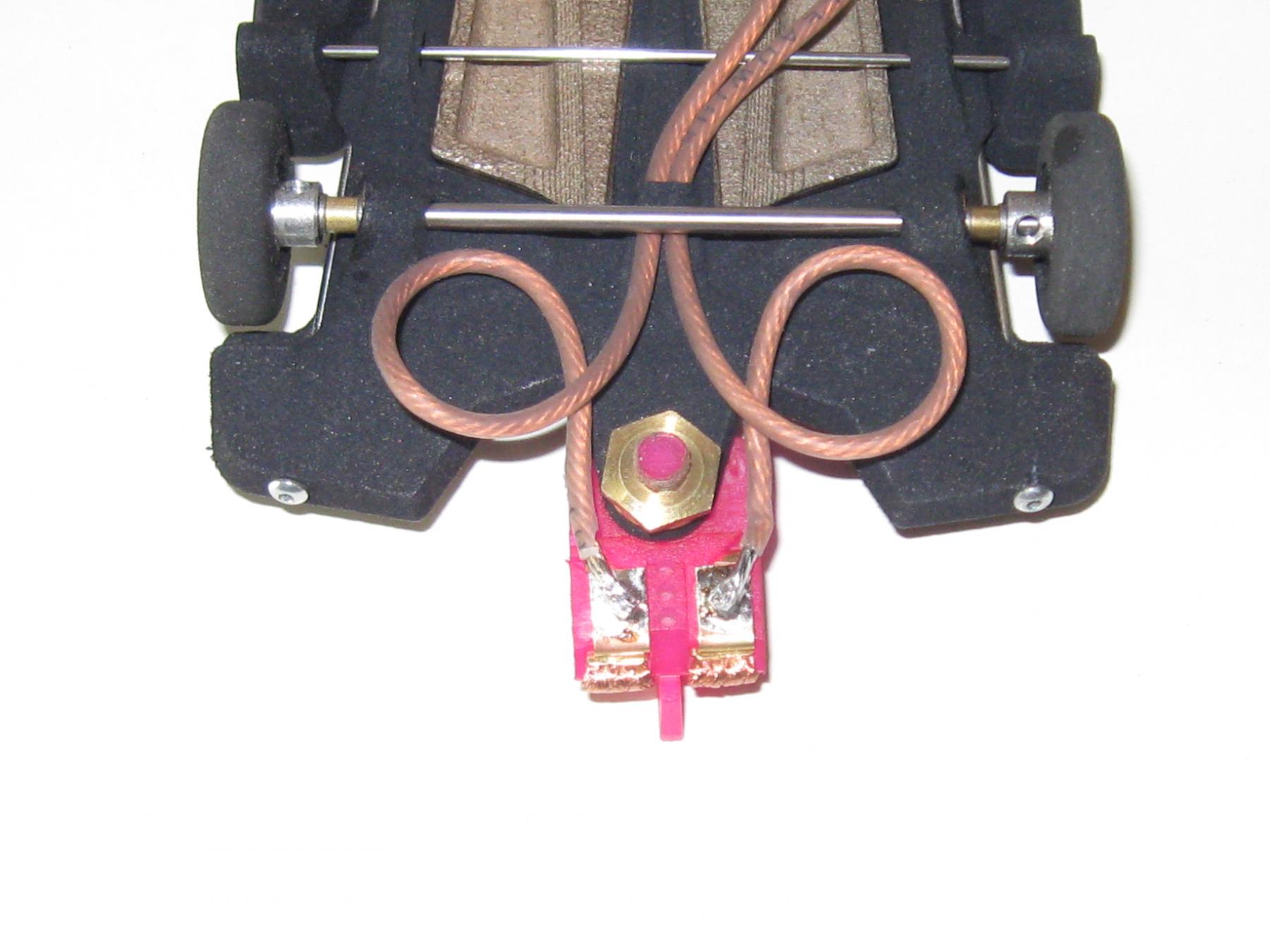

flat tracks. The car set-up is

Weight; 120 grams total

50 grams on the guide flag

70 grams on the rear tires.

Motor; JK Retro Hawk

Gearing; 8 / 28

Rear tires; JK 8713PP

I ran a few laps, and decided the car needed to have some break in laps put on it since everything was new, and the

car seemed a little tight. So I ran 100 laps at a not too aggressive speed to get some time on the motor and gears.

It seemed like it had improved considerably, so I started checking times as I began to push the car harder. At first

I was getting lap times in the 5.4 range, pretty slow for retro times. Eventually I had worked it down to a 5.100 even,

still pretty slow. But the car was topped out by the middle of the front straight, so I knew it had to be geared too short.

Mike Swiss tried the car and ran 4.916. The good thing was the car felt very consistent to me.

So I moved to the flat track, and with some laps managed 5.405. Mike was able to get a 5.196.

At this point, I changed the crown gear to a 26 tooth. The car definately had more straight and bank speed. But what

caught me out was how much less brakes I had. I knew it might be a little less, but I now had trouble getting through

the dead man. In fact, I stuffed it pretty seriously, bending the nose of the body to the point where it would not stay

off the track surface, even with it trimmed back. This compromised any further testing. The best time I could get was

5.120. Mike tried the car again and was only able to match his previous time. I did not run any more laps on the flat

track, I need to replace the body for that.

The car seems a little loose in the rear with the smaller crown giving more straight speed. Mike also thought a 9 tooth

pinion is needed, but I need to get the rear planted better before that. The next time i might play with weight, and

different rear tires. A compairative time for a good retro car is 4.7 to 4.8 on the king. I don't expect to get it down to

that point, but I may get close..

![]()

![]()