So, I'm jumping into the deep end here. I've got a selectionn of dead armatures (from that pile of old Ebay motors in another thread) and I'm going to rewind a couple of them, and see what happens. My goals are simple - a running motor - or two - that will push a slot car down the track.

It also seems that I'm collecting 36D parts, and so I figured I'd start on one of those.

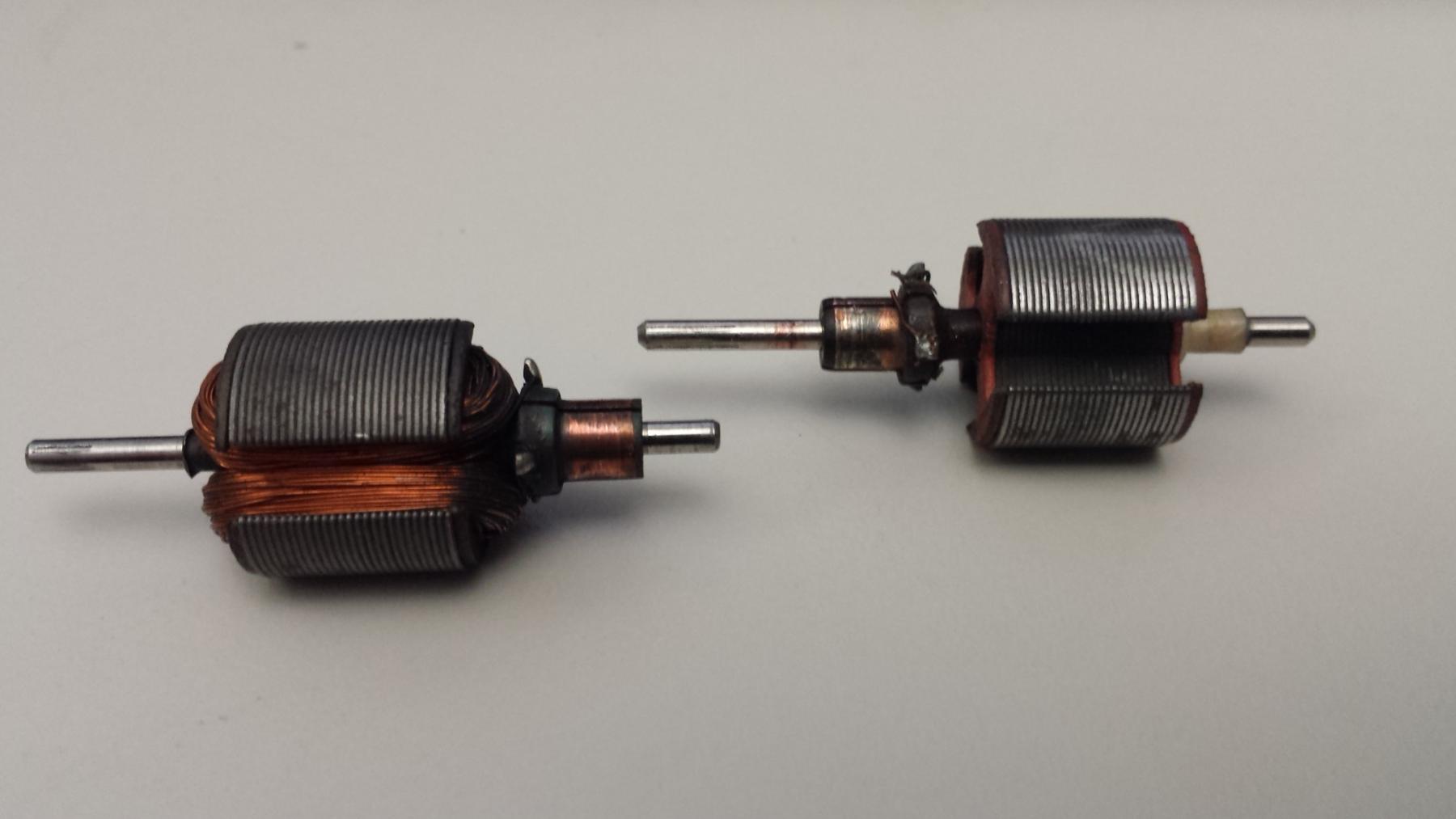

here are my two current candidates, one endbell driver, and one can driver.

the stripped endbell armature had 47 turns on each pole with 27AWG (.014 thick) wire, and subsequent dis-assembly of the can driver gave 111 turns of 30 AWG (.010 thick) wire. I noticed that the wire was wound counter-clockwise around each pole. the 30 gage windings definitely had some sort if light varnish on them. the 27AWG, not so much, that I could tell.

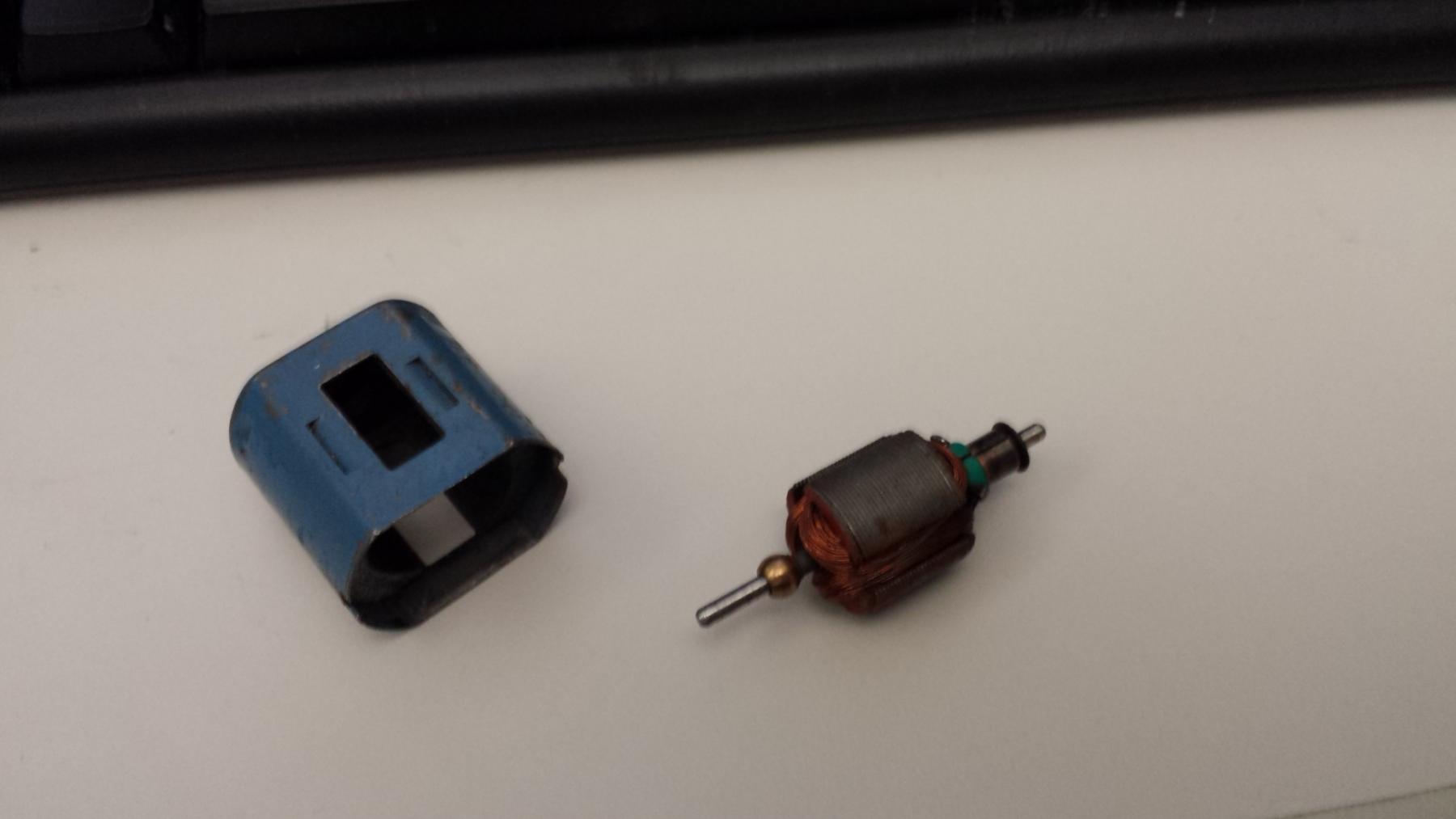

I was surprised to find that the commutators are not adhered to the armature shafts - just a slip fit, though a little snug - but are positioned (as john H had revealed in the "Clean Parts" thread) with a tiny tab fitting into a hole on the stack end insulator.

both all apart, endbell drive left, can driver right...

the locating tab on the endbell drive armature's commutator ( the black one) does not fit tightly into its corresponding slot, and allows some movement which my calibrated eye tells me is something like +15/-10 degrees, where as the can drive (green) commutator fits tightly into its slot and doesn't really move at all.

the endbell drive stack measures at .500 where as the can drive stack measures .513.

So...I bought two spools of wire, both 30 and 28 AWG, and at some point over the next couple weeks, I'm going to try winding one of these things up. I'm going to polish and re-use the commutators. somewhere in there I'll also be re-bushing one of my several 36D cans, and then, we'll see what happens.

so, some questions...

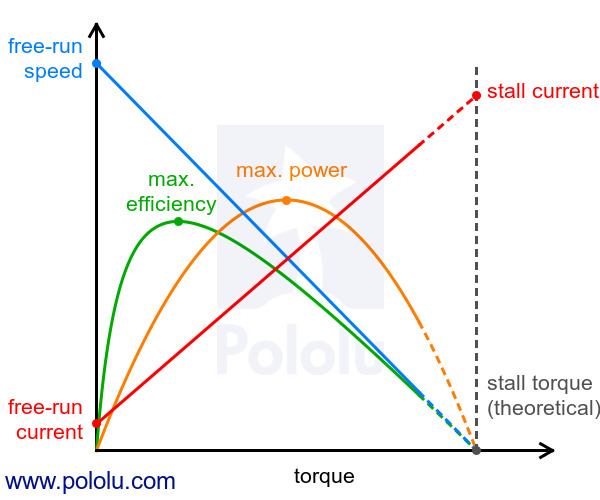

1. in general, all else being equal, is fewer turns of thicker wire a hotter wind than more turns of thinner wire? that seems to be what I've gotten from reading John H's various build threads.

2. does advancing the commutator make the motor spin faster?

3. does it matter which direction the poles are wound (clockwise versus anti-clockwise) ?