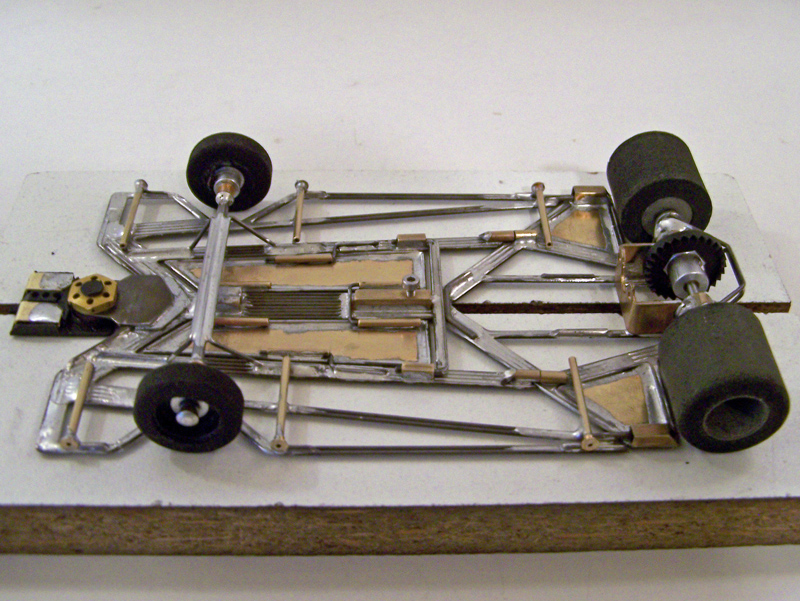

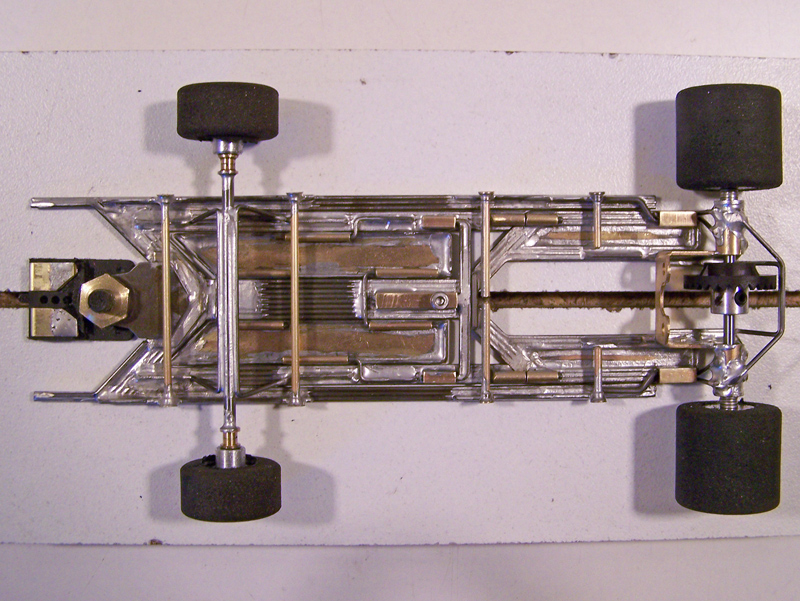

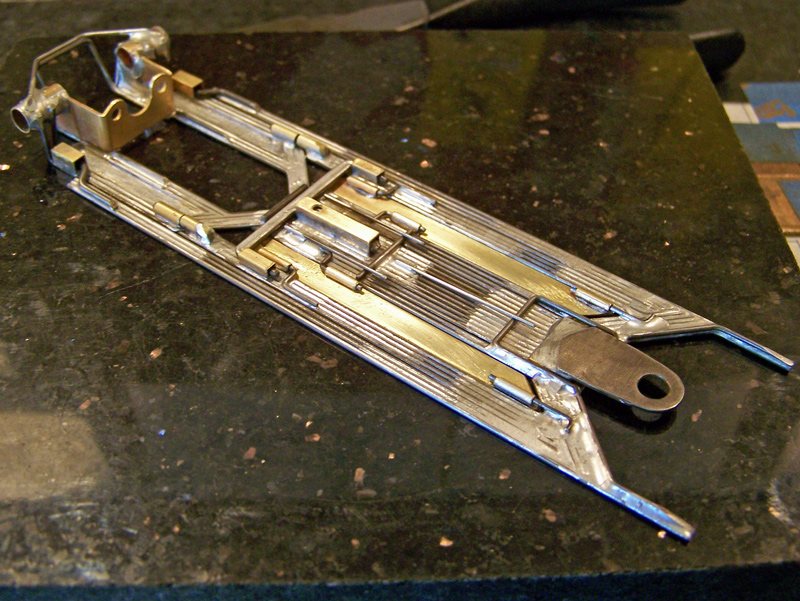

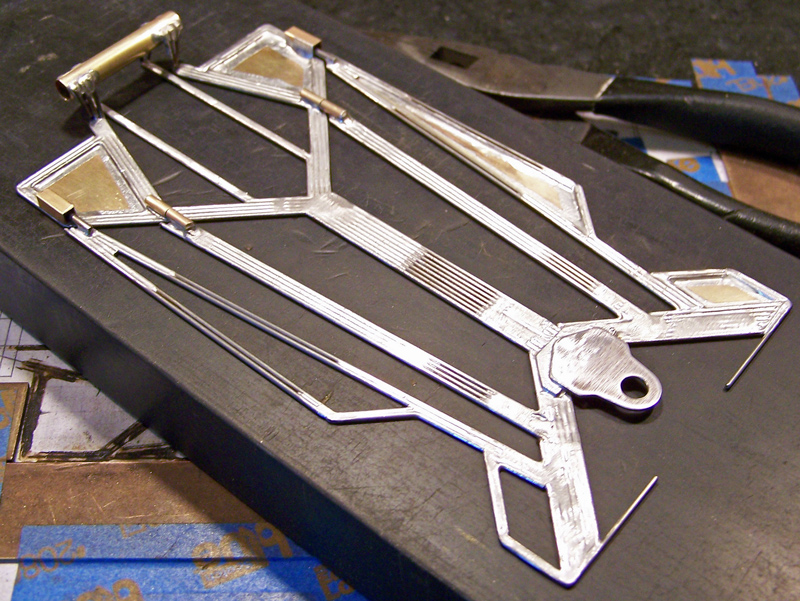

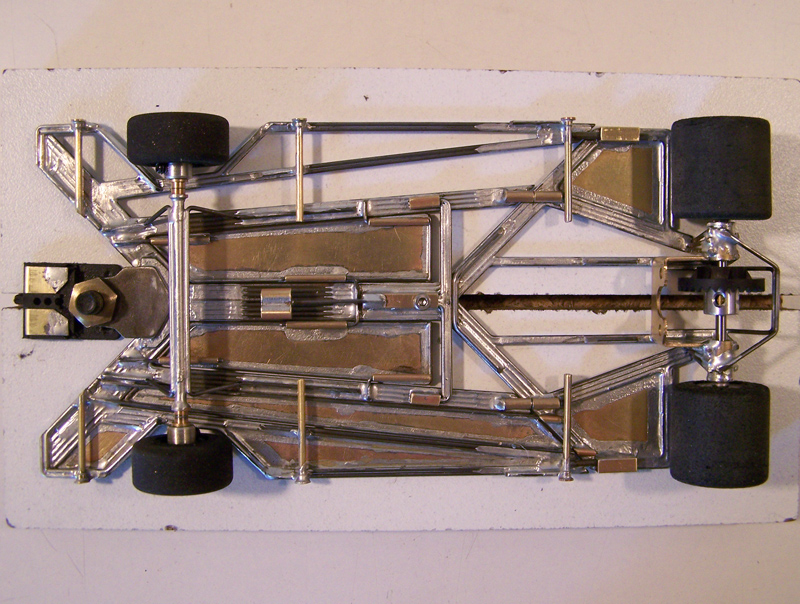

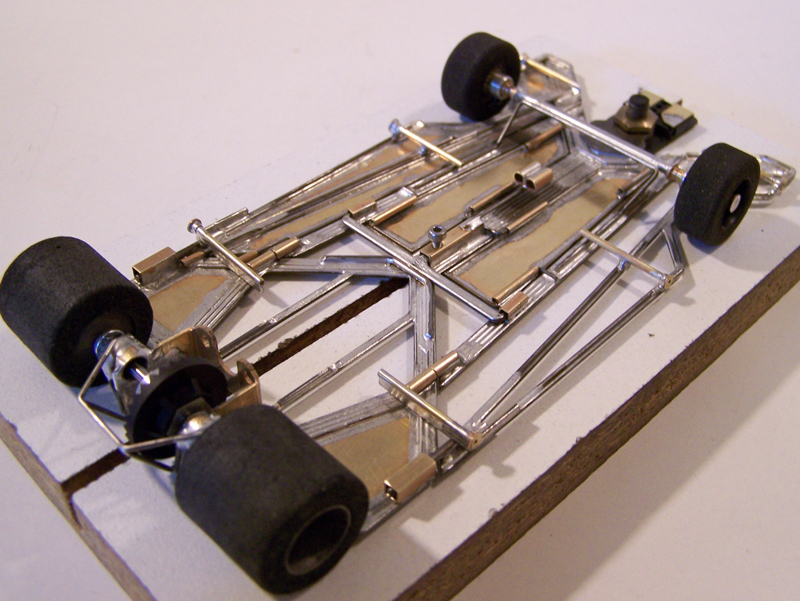

CMF3 1237-Series Design and Build Progression

I thought it might be amusing, and possibly informative (and hopefully not too annoying), to post a compilation of my last few chassis designs and builds to illustrate the progression through a series of chassis. While certainly nothing earth-shattering here, it was just a matter of the opportunity presenting itself, so I figured why not.

Background:

For the last couple of years I’ve been building chassis that were largely based on an initial design, the 1219. The 1219-based frames would morph through a lot of chassis, up to the 1233 (and even the unbuilt 1235), about which time I realized the 1219-series had pretty much run its course. After the tracks closed in west Florida, I took a break from scratchbuilding for about a year; however, early on during that respite I had doodled out a stick-figure of a chassis design with the moniker “1237”. Numerous doodles, notes, and drawings later, I not only had the 1237 design hashed out, but also its successor chassis, the 1238, the 1239 and the 1240.

So at the end of 2015 I was finally ready to start building again. Admittedly I was sorely tempted to skip some builds in this 1237-based progression, and almost did, but caution and reason finally won over, especially considering I had pretty much regretted any time I had skipped design/builds in the past, and more than once had to backtrack. I found out in those instances that when I would make more than one change to a chassis, the resulting chassis would invariably produce the same conundrum of trying to figure out which design/structural change caused what change in handling characteristic(s), and would just as invariably require the aforementioned backtracking of building the very same chassis I had skipped in the build sequence... Picture of an idiot in action.

Foreground:

So, for your perusal, and maybe even some enjoyment, I will be posting the 1237-series design/build progression in subsequent posts to this thread, for the following chassis:

1237-Cc2

1237-Cc3

1238-Cc3

1239-Cc3

1240-Cc3

I figure long before the last chassis listed here I will have bored y’all into a coma, so any additional chassis posted may warrant additional medication…

Consider yourselves warned!

Rick/CMF3