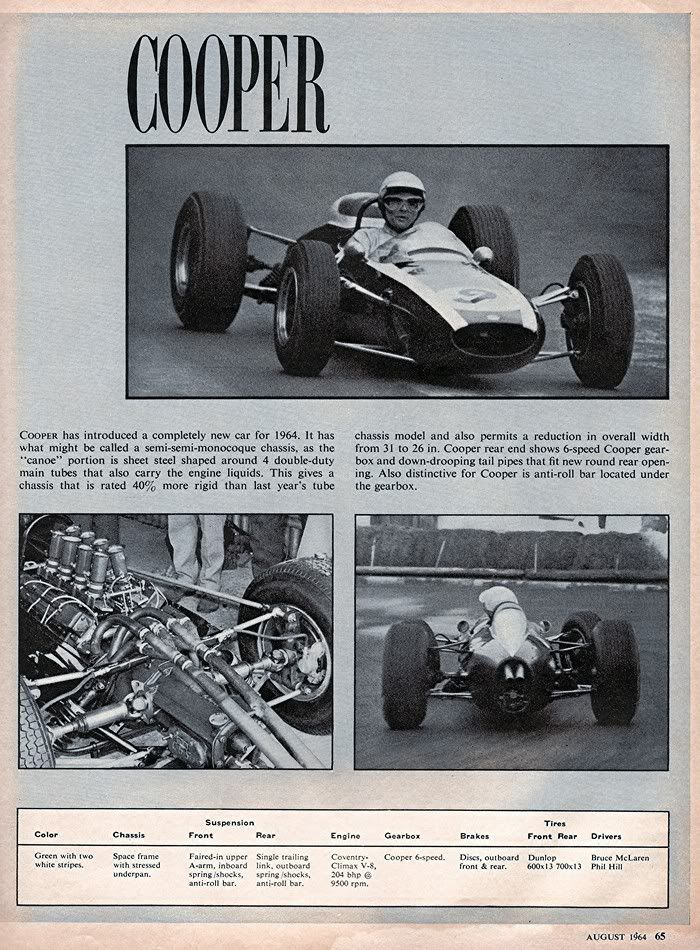

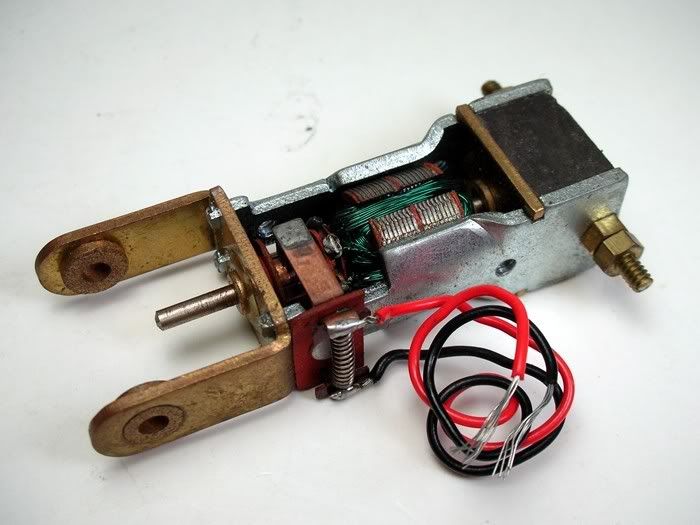

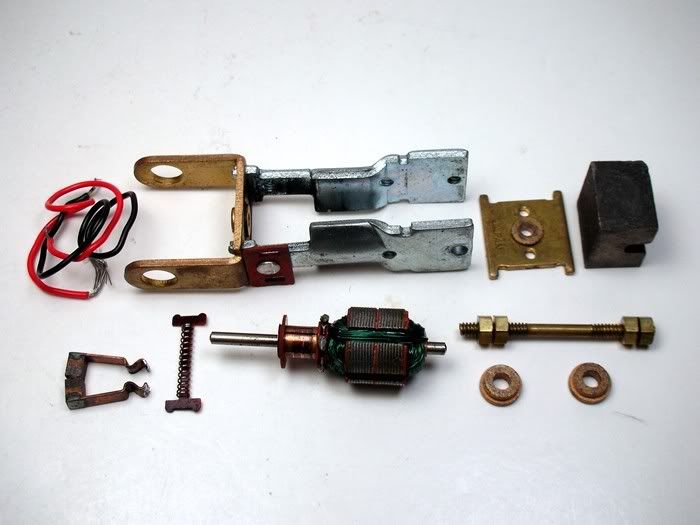

These motors were on eBay as a Buy It Now for $5 for weeks. The lady that was selling them had a ton of them and they sold very slowly. All I remember about this motor from back in the day (around 1964-5) is that they were FAST and blew up often.

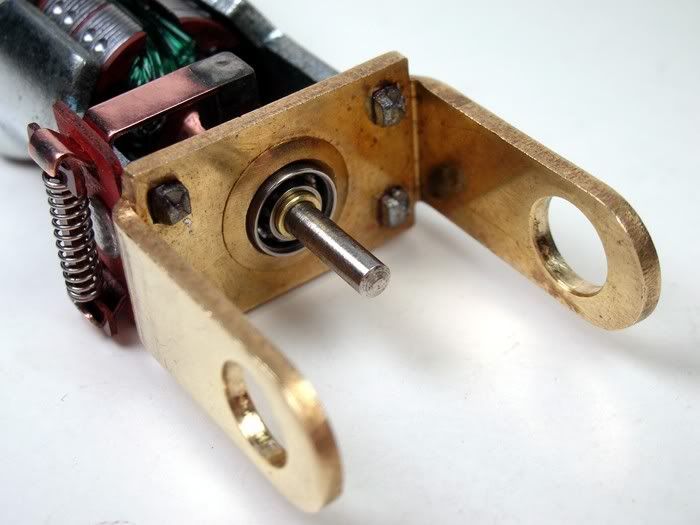

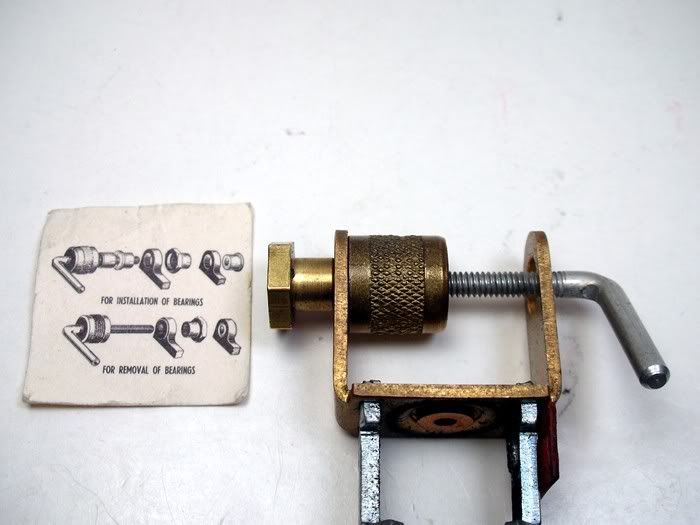

To remove the axle bearings I used this handy dandy vintage Dynamic bearing tool. It works great to remove or install press fit bearings. If you see one eBay you might want to give it a try:

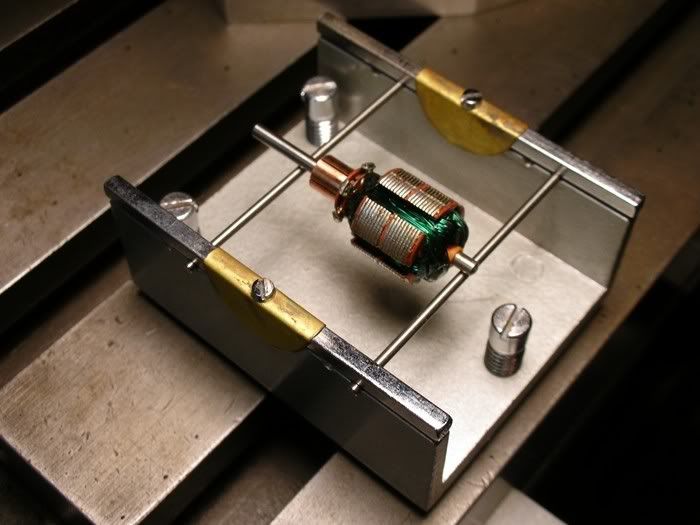

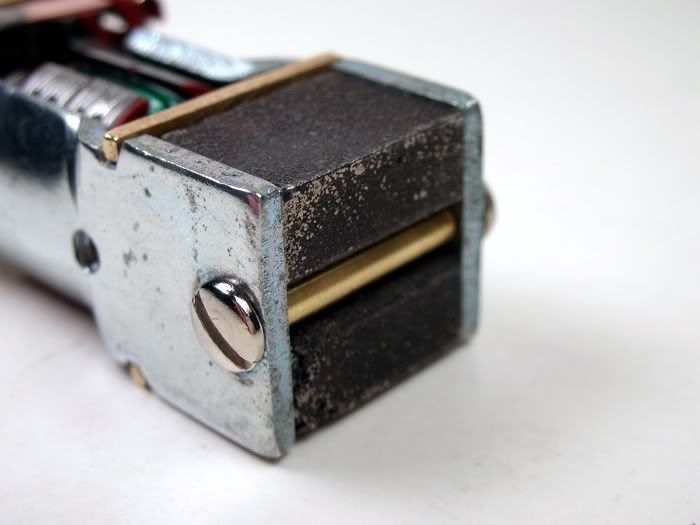

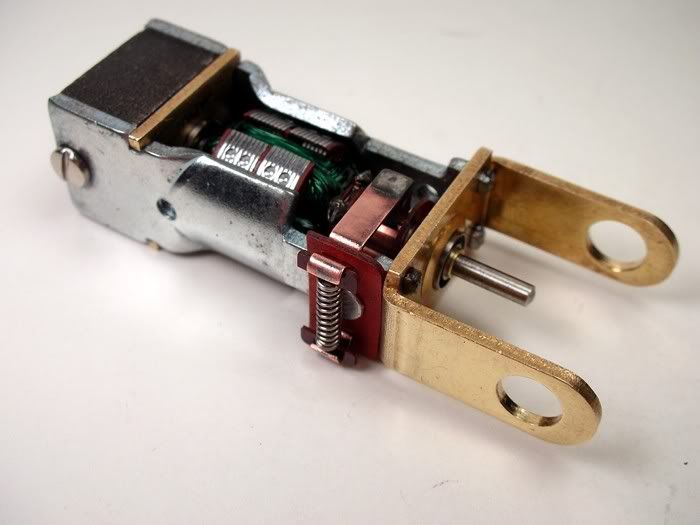

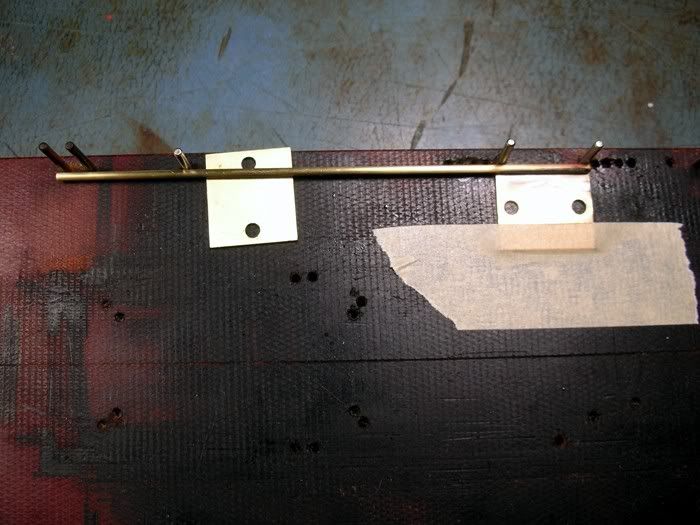

Now that it was apart I need to do an early '60s "hop-up", which usually consisted of ball bearings and a stretched brush spring. The ball bearings proved to be a problem because the armature shaft is a metric size of 2.3mm or .0905". 3/32" bearings were way too sloppy and try as I might I couldn't find any 2.3mm bearings... 2mm, 2.5mm, and 3mm yes, but no 2.3mm. Maybe they are out there but I couldn't find them so I did what Bob Braverman did in one of his old R&C hop-up articles. I decided to use 1/8" bearings and make an adaptor to mate the armature to the larger bearings. I found some thick-wall brass tubing at McMaster-Carr with a 1/8" OD and a .085" ID. They also had a reamer in .0905":

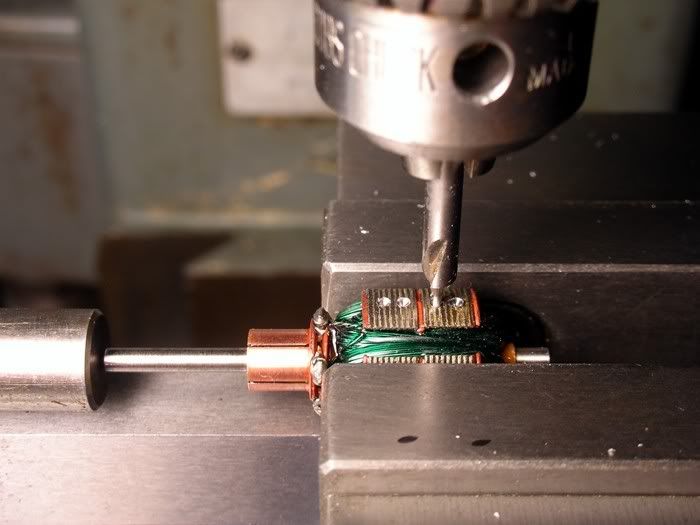

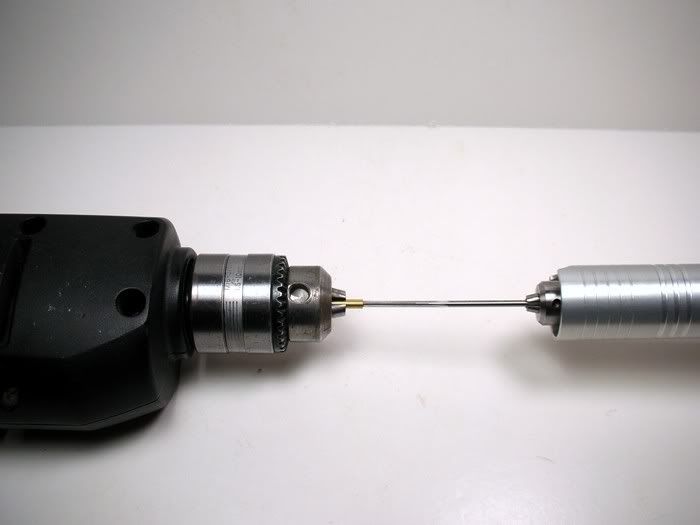

The tube fit the 1/8" ball bearings perfectly but I had to ream out the tube's ID to fit the armature shaft. Somewhere in an old slot car magazine they talked about reaming a concentric hole without a lathe. They spun the work piece backwards in a drill motor and then used a reamer in another drill to enlarge the hole. Here's what I did with a drill and my Foredom grinder:

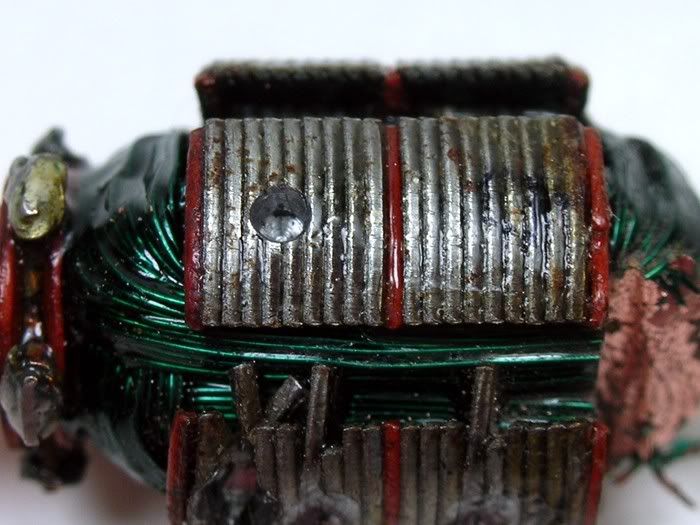

It worked like a charm and I had a couple of bushing adaptors that were a slip-fit to the armature and bearings. Next I used a taper reamer to open up the holes in the motor for the larger bearings. I finished with a 1/4" reamer:

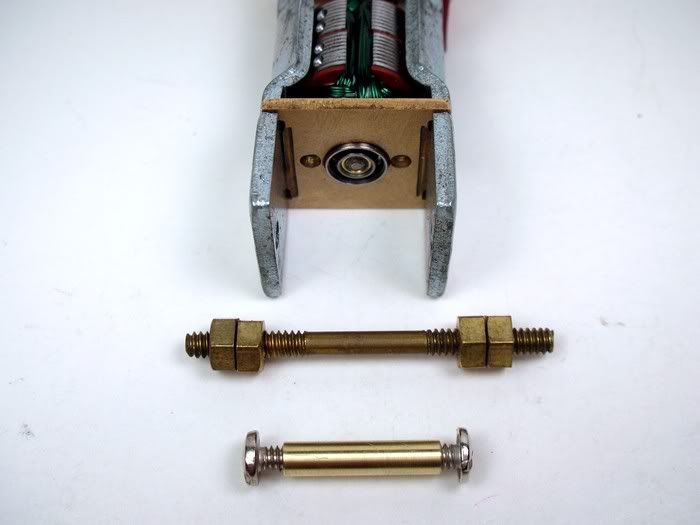

Here is the ball bearing installed the axle bracket. The enlarged rear bearing support plate, adaptor bushing, ball bearing, and stock bushing are shown for comparison:

Time for dinner