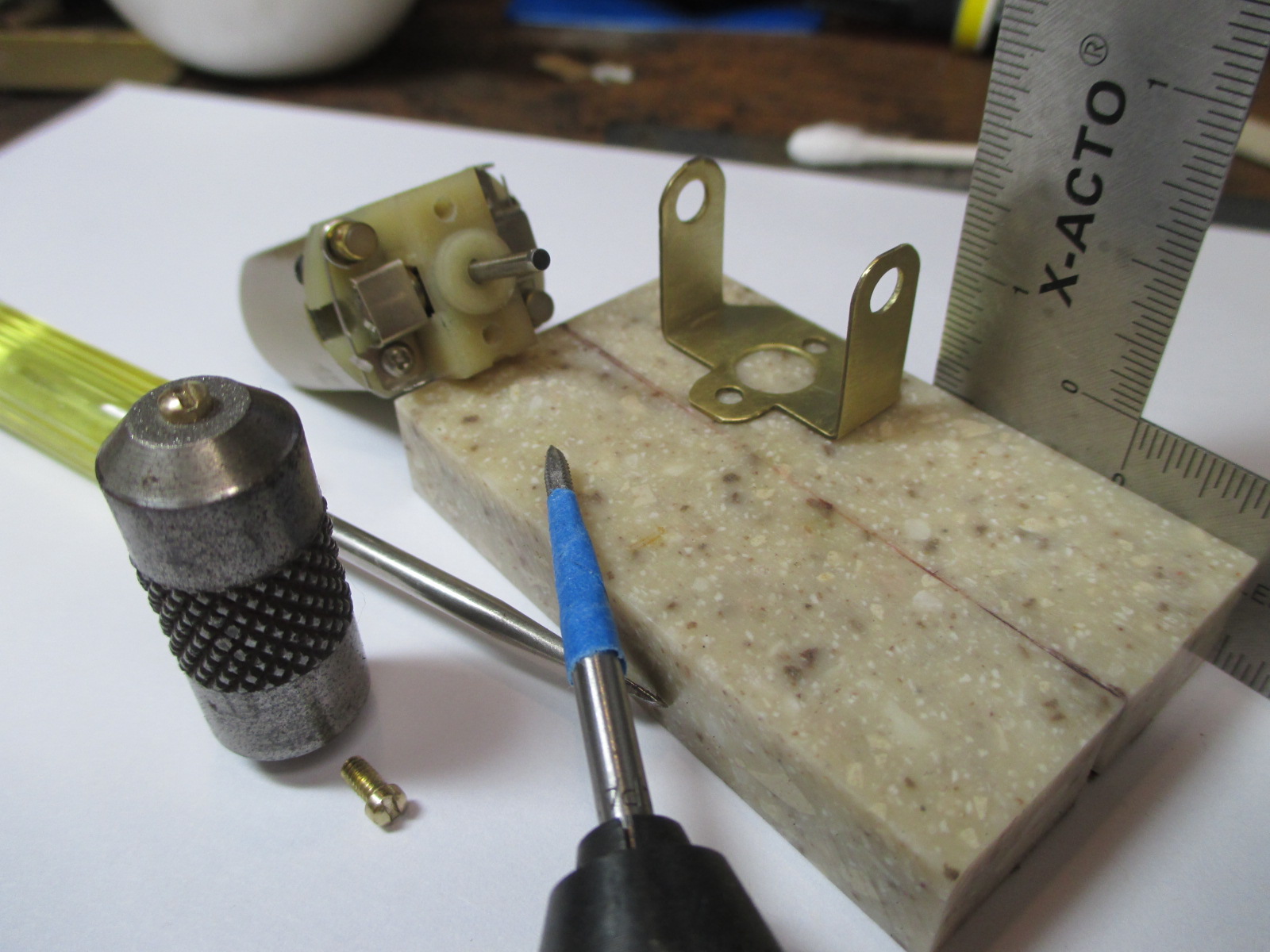

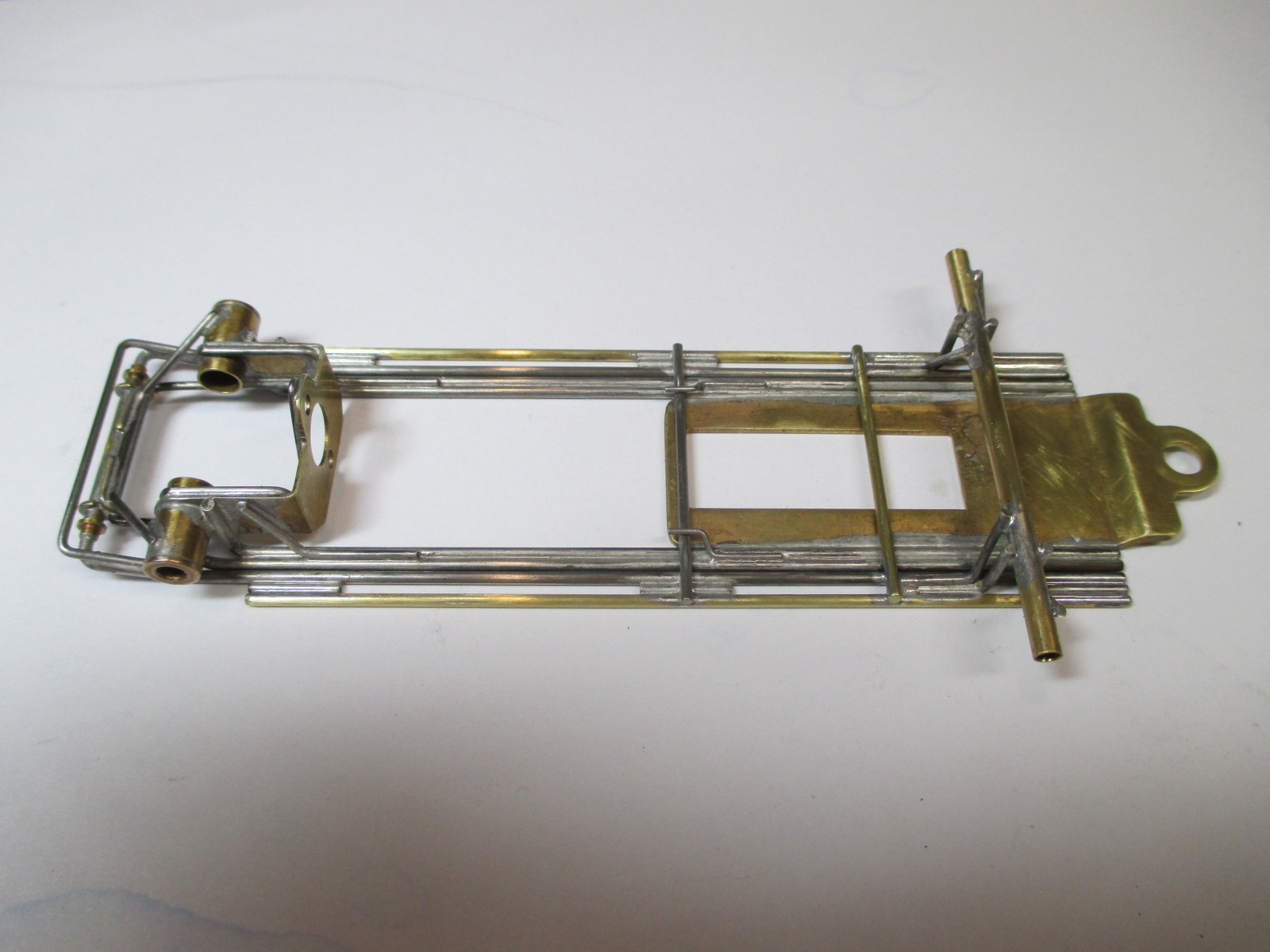

WB: 3 7/8"

GL: 1 1/16"

Width: 3.125"

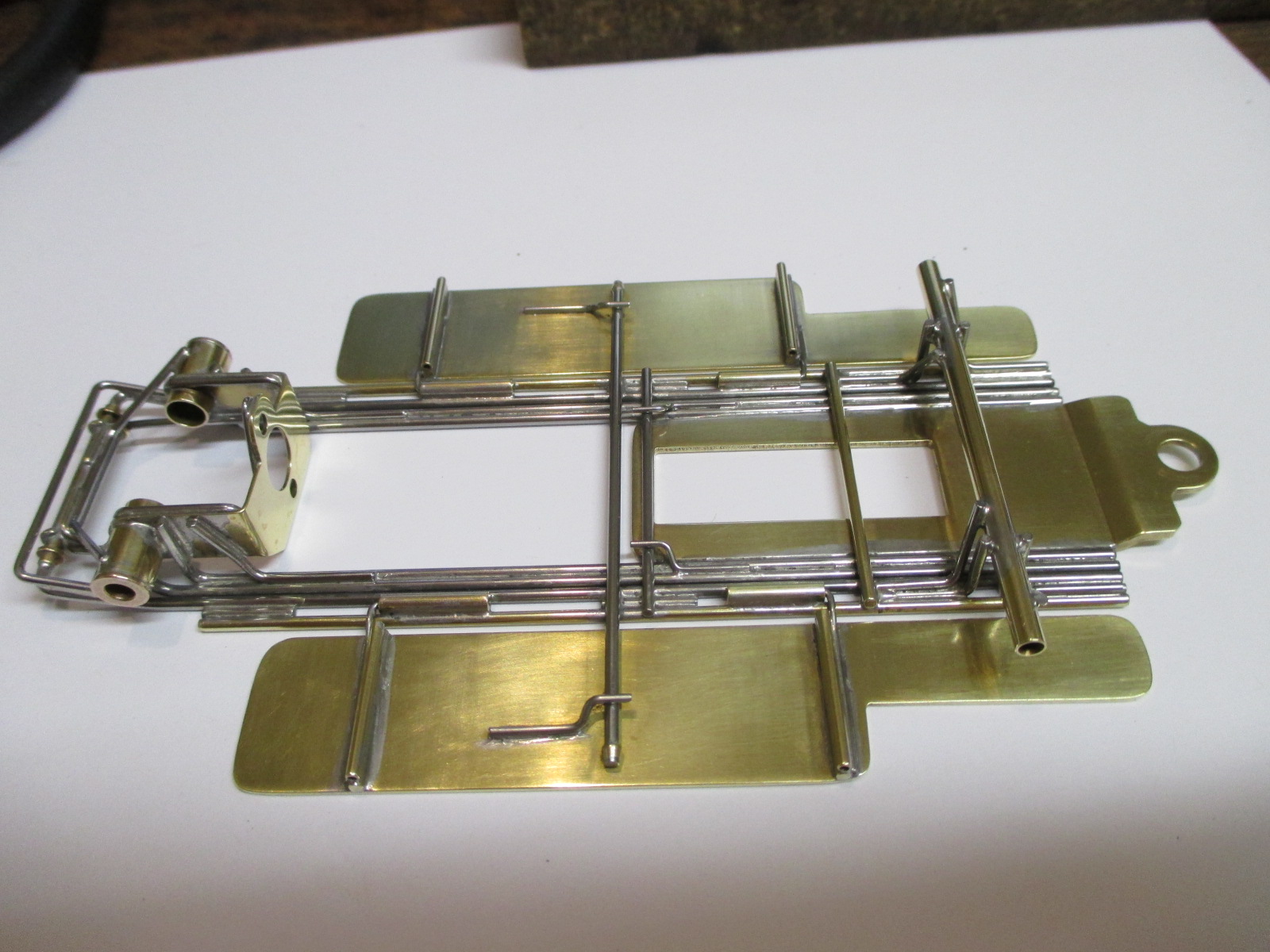

Motor: Havlicek 16D, 40T/27

Bracket: Russkit 26D

Front wheels: Vintage set screw with O-ring rubber, 13/16" OD

Rear wheels: Vintage set screw with Alpha Wonder Rubber, 13/16" OD

Clearance: front .032", rear .062"

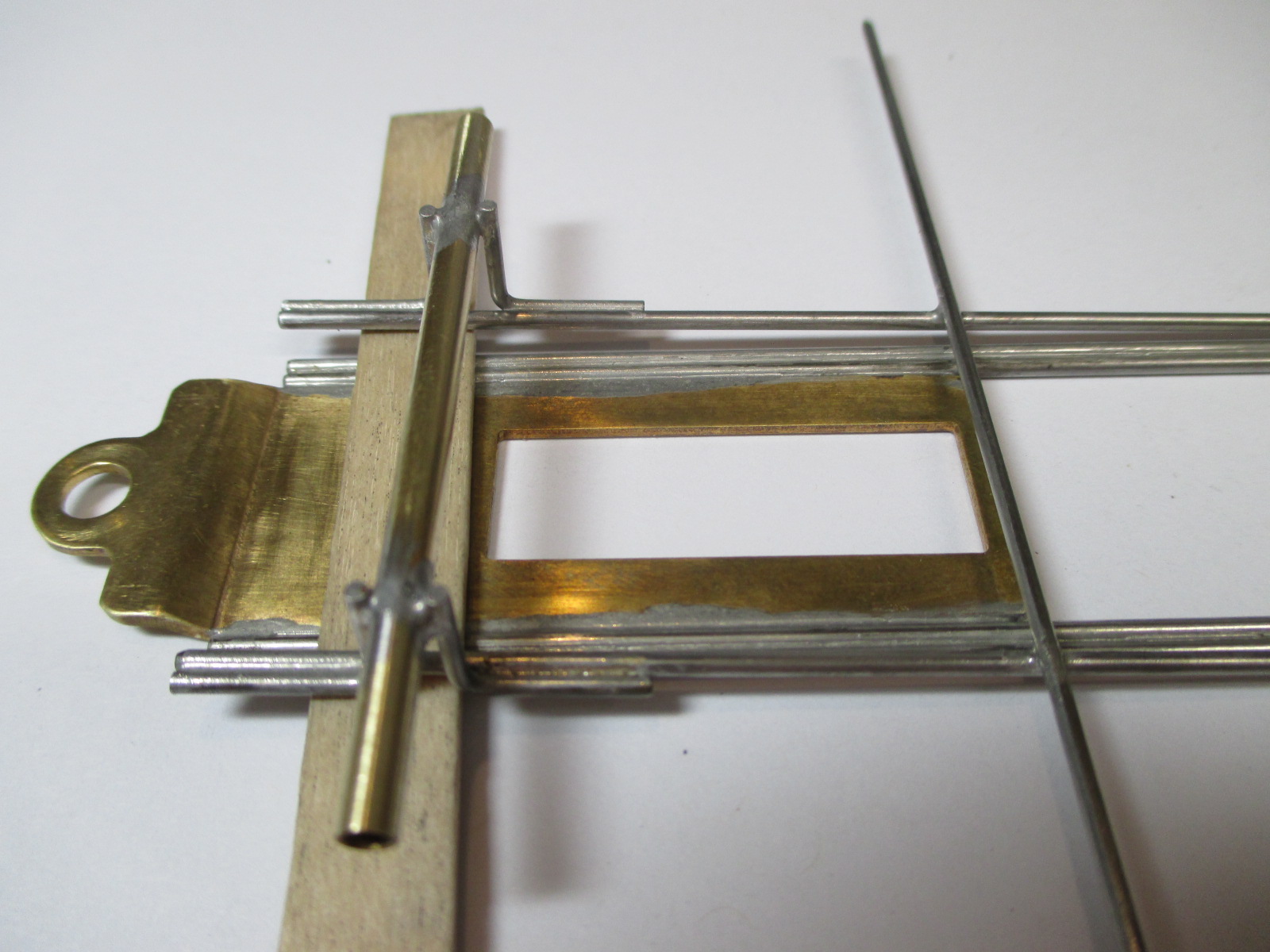

Flag: Jet Flag secured with Classic weight

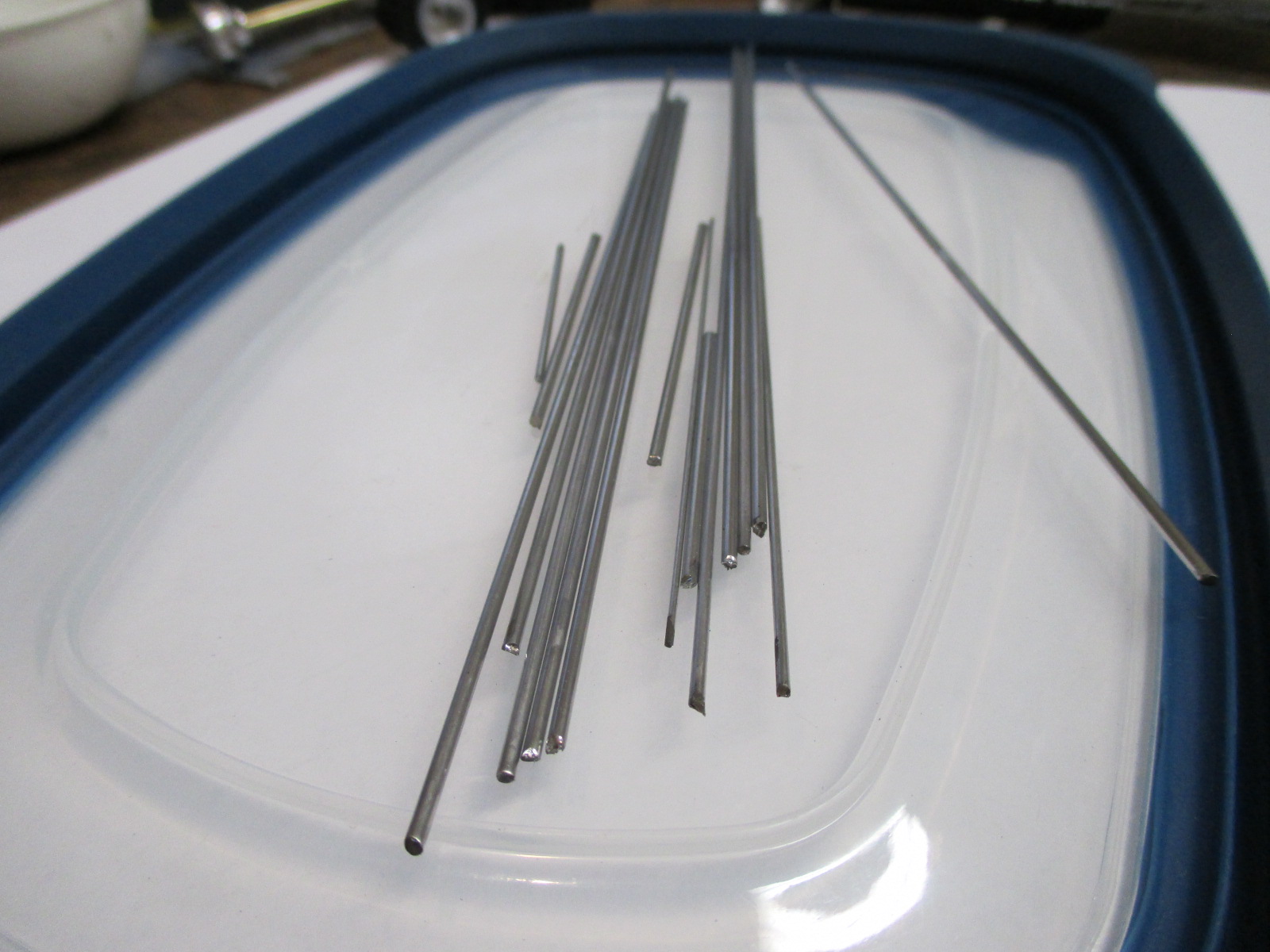

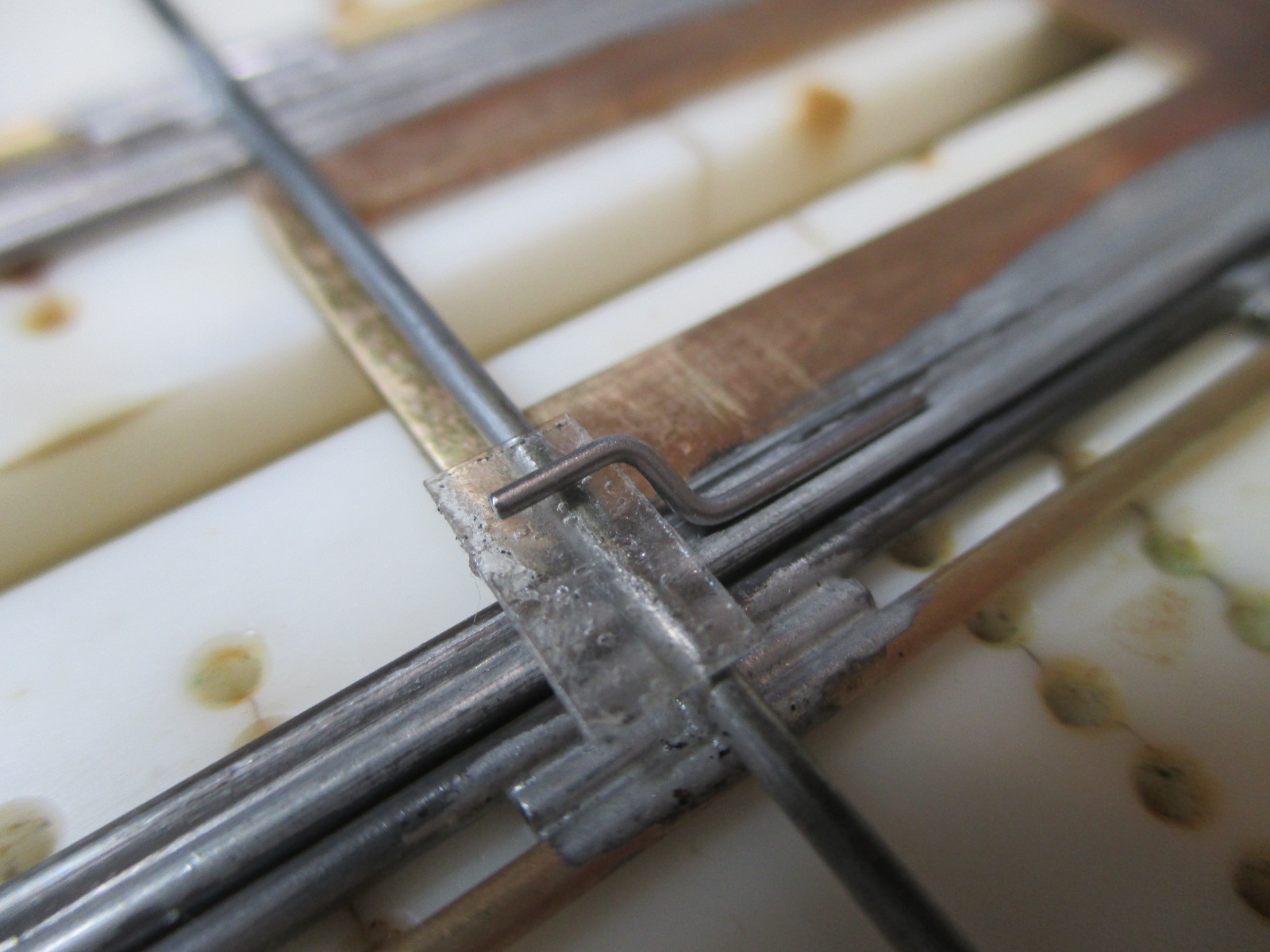

Chassis: ISO, tapered center section with .050" thick (drop arm) tongue, outer section/front axle: rails and tilting bat pans.

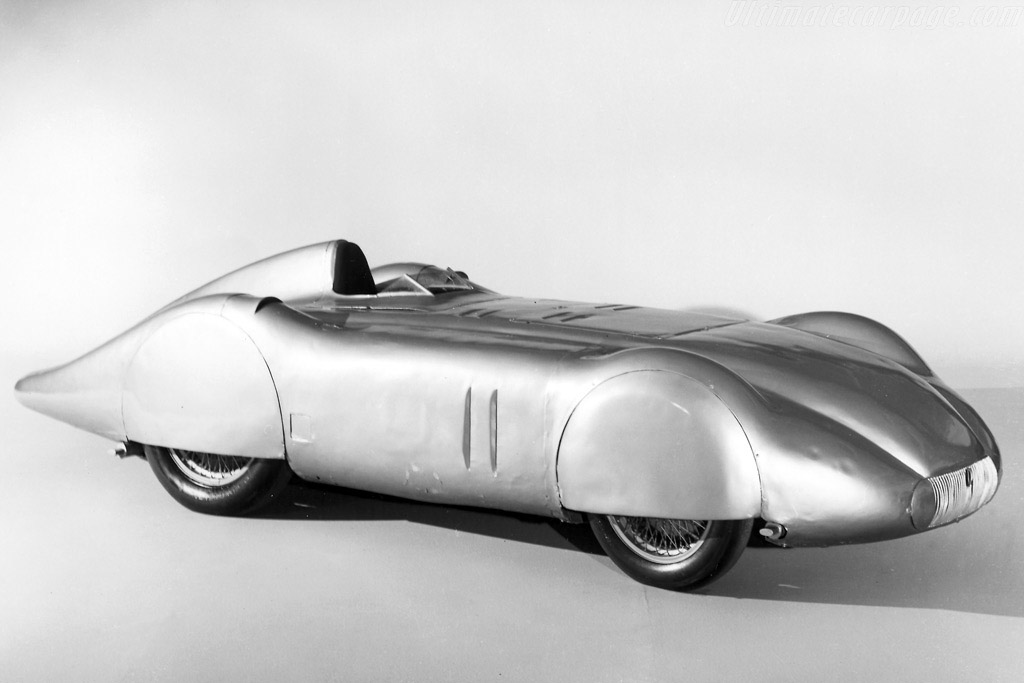

Body is an original, not a re-pop, and has a protective covering. I'm guessing it's a Betta but not sure: