When I'm not doing builds that people have asked for, I'll look at my "stuff" and see where it takes me. Not long ago I was gifted some of those krazee-strong solid neos that had been bought for a 36D motor. The thing is, they're really too short (top to bottom) for a 36D, and would have required all kinds of heavy shimming to get them centered and to produce a usable "hole." The magnets are actually a pretty much perfect fit for a 26D though, so things started moving in that direction. ![]()

The problem is that they are really too long (front to back) for the 26D can... soooo, they had to be cut. That is one heckuva messy, awful and probably potentially dangerous (?) job. If you've ever tried to cut the things, you know what I mean. They spark like crazy and the dust is flammable... burning up as you go. To make matters worse, the material is very tough, not at all like the bonded "poly neos," and more like cutting ceramics, sort of.

Cutting these things means going slow, stopping and letting things cool off, letting the tool do the work and holding on tight because they're slippery and will grab anything magnetic that comes with 50 yards of them. Of course, each micrograin of the dust the material produces when cutting is in effect a tiny super-duper neo magnet. Not much of it goes very far, but cleaning up the magnets after cutting is no small thing in itself.

The cut edge of the magnet will have a shiny silver appearance that looks like the nickle plating, but the plating is there to prevent corrosion because (I think) the material is very reactive and will oxidize rapidly, which would explain why it also burns the way it does. Since the magnets are quite thin, I epoxied a set of .011" shims to their backs made from Arco semi-can shims. While doing that, I also slathered-on some JB Weld to the cut ends to help protect them. All-in-all, this was a nasty job, and it only gets me started... but at least I'm started!

On this side you can see the cut edge covered with JB Weld.

With the shims on them, I get what would be a pretty much dead-bang perfect hole for the stock .590" diameter arm, but I'm going to wait until the can is done and see how these things feel with a .590" blank and with a .560" blank... because these magnets are ridiculously strong. How strong are they?... beats me, my meter won't measure them, but here's a clue. With the magnets just sitting in the can and it propped on its bearing, the can will rotate on my glass table top pointing to the nearest magnetic thing like a compass. That's strong!

The other thing about these is that the tips are headed in the wrong direction. Instead of angling towards the arm, they angle away from it, they are true arc-segments, and four of them will make a complete 360 degree circle when connected. That means more "cog." We shall see, but I'm building a motor by smell, touch, and feel here. ![]()

Sometimes the magnets determine the build

#1

Posted 25 May 2017 - 05:52 AM

- Jairus, slotbaker, C. J. Bupgoo and 3 others like this

#2

Posted 25 May 2017 - 06:23 AM

Might be a good candidate for a skewed arm??

![]()

Steve King

#3

Posted 25 May 2017 - 06:34 AM

That would be a possibility, Steve.

These magnets are difficult to make work in anything other than a hot drag motor. Guys tend to just run them with large air gaps, which kind of defeats the purpose of using them in the first place. The skewed lam arm tends to negate the cog effect (as does the very wide crown/small pole gap type lams). So, doing something that counteracts the magnets' characteristics (strength and tip design) is one way to go.

Another way to go (I think???) is to do a moderate wind (like a #28) where you can get more turns on there and go for torque (see the torque vs revs thread).

So, a skewed-lam #28 using the stock lams (because of their wide crown) might be a smart way to have at this.

- Jairus, slotbaker, boxerdog and 2 others like this

#4

Posted 25 May 2017 - 03:16 PM

John,

I want first dibs on this motor. That's if you're going to sell it. ![]()

I think I got the perfect chassis for it. My 1/ 20 scale sprint car, that's if you're going for torque more then revs. The car has 1-1/2'' dia tires x about 1'' wide .

As always keep up the great work!

Ken

#5

Posted 25 May 2017 - 05:28 PM

Hi Ken,

Sounds good. I made some more progress on the motor using the previous one as a template... more pics to follow.

#6

Posted 25 May 2017 - 05:41 PM

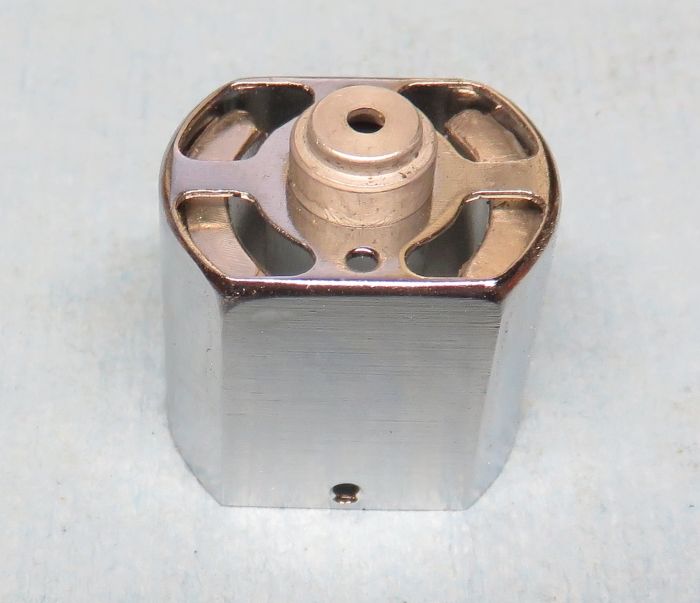

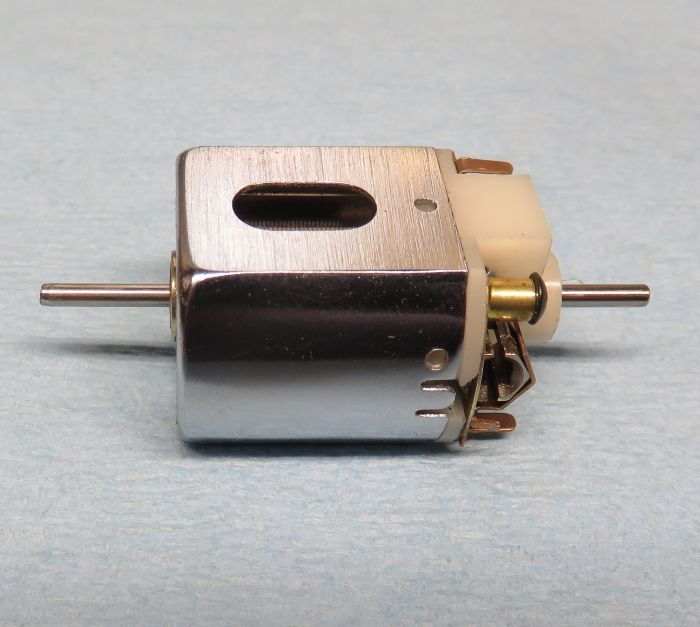

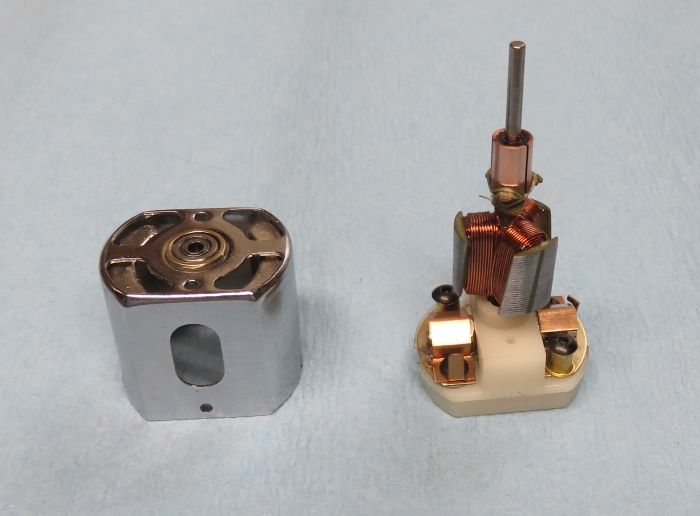

Well, using the previous 26D as a template, I did the living daylights out of this set-up. The magnets are installed with their shims, the can bearing got removed, an adapter made up, and the new bearing installed.

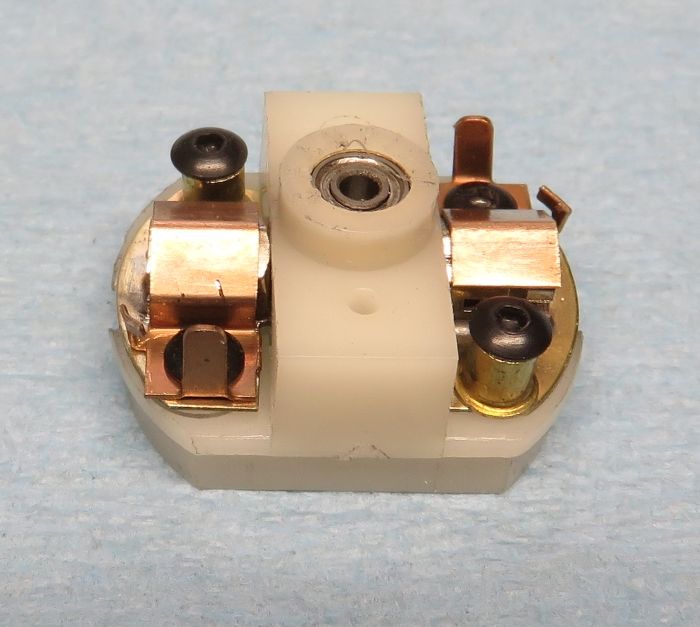

The endbell got the same type soup-to-nuts treatment as well... bulletproofing plates with the brush tubes soldered-in, an adapter, and bearing installed.

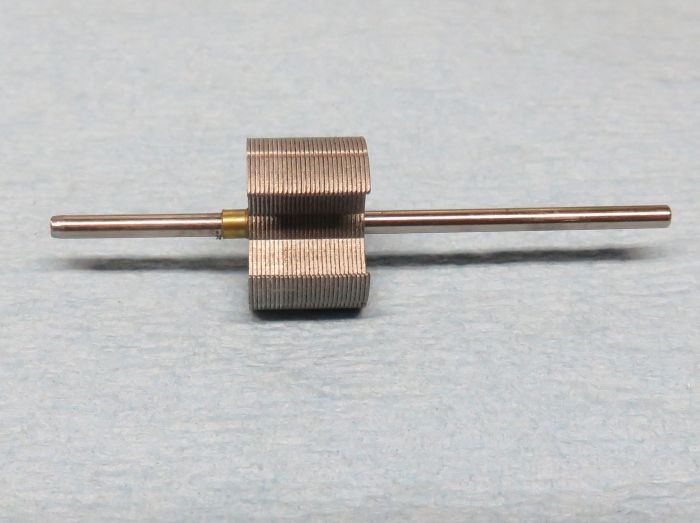

I tried both a stock 26D arm blank and then made up a .560" one. I chose the .560" one, and even that one is tough to turn by hand... did I mention that these magnets are "stoopid-strong"?

This motor will be another "dealer's choice" with the dual-shaft thing .Either endbell drive or can drive will work... but I know which way I'd go if I were building a chassis for it!

So, the arm will be either a #28 or a #29, either way will be on the high end of the scale as to number of turns, and the timing advance will be kept low.

- slotbaker, Jencar17, C. J. Bupgoo and 2 others like this

#7

Posted 26 May 2017 - 06:12 AM

I've been thinking a lot about how to go with the wind on this one. I really don't know if even a #28 will be "enough arm" for the magnets, even with low timing. Even with the large air gap, the arm is actually difficult to turn by hand in a setup with bearings on both ends.

The 26D can is also a fairly closed design by today's standards, and probably is a good design for producing a strong field... yikes!

- Geary Carrier likes this

#8

Posted 26 May 2017 - 09:27 AM

Hi John,

You probably are going for #25 or #26 which is a might fine vintage wined indeed...

You might want to hire a test pilot on this one.

Thanks,

g

- havlicek likes this

Yes, to be sure, this is it...

#9

Posted 26 May 2017 - 01:22 PM

You probably are going for #25 or #26 which is a might fine vintage wined indeed...

You might want to hire a test pilot on this one.

Well...t here's already a test pilot, but this one shouldn't have such a big wire arm.

I'm thinking more and more of skewing the lams as a way of taming some of the starting amps required to get the arm spinning. Yeah yeah... I know... winders hate winding on skewed-lam blanks, but I have a really good relationship with my winder, and he's not at all opposed to a challenge. ![]()

- Cheater, slotbaker, C. J. Bupgoo and 1 other like this

#10

Posted 27 May 2017 - 06:57 AM

So, as they say in the land of Chateu Nuef du Pape and Auguste Renoir...et voila! ![]()

Not yer 1960's 26D for sure, but it is "in the family" anyway. The arm is a 44/28 on a skewed-lam stack around the stock length (minus the fiber end insulators) and with only around 5-7 degrees advance CCW, and measuring exactly .178 ohms per pole. I'm navigating totally uncharted waters here, hoping to avoid shoals and rogue waves, so I've thrown everything I have at this thing. These magnets are (I guess?) useful for drags with really hot winds, but my thought was to see about how to put them to use in a more normal type motor. I suppose I'm going to find out!

- slotbaker, boxerdog and C. J. Bupgoo like this

#11

Posted 27 May 2017 - 08:38 AM

OK... so the suspense was killing me. Well, not really killing me, but bothering me some. ![]()

I decided to do a quickie-assembly and try this thing out before sending it off for grind/balance, only to wait and have it possibly come back not-ready-for-primetime. As is always the case with sooper-dooper strong magnets, it can be a little dicey to properly center an arm, since where exactly the arm wants to be is a little harder to figure out. This gets a little harder still with some bearings and shafts if the arm won't slide easily back and forth.

In this case, both things make centering a little more difficult, but the stronger the magnets, the more important good centering becomes. Anyway, I got it sorted pretty well, installed a set of brushes and some of my springs and went for it. The results are better than I had thought... much better actually. The motor runs fast and smooth (even without balancing and grinding) and only gets a little warm.

The motor right now draws a little less current from 7v up, around 1.4 amps, and that rises to 1.8 amps below 7v. That might seem to mean the arm is a little "behind" the magnets, or that a hotter wind is in order, or it could just mean that the motor as-is wants to run.

Either way, I ran the motor for a full 10 minutes at a little over 6v and it never got more than a little warm. I expect even these results to get better after grind/balance. As for perceived torque, there sure seems to be plenty of that on tap, since trying to pinch the shaft results in a pretty quick finger burn. ![]()

So the motor will get disassembled, the comm cleaned up/retrued, and the arm sent out!

- slotbaker, C. J. Bupgoo, grooverunner and 1 other like this

#12

Posted 27 May 2017 - 09:10 AM

Looks nice and sounds very promising.

Curiosity question about the timing... 5-7 degrees advance.

With a normal (not skewed) arm, that 5-7 degrees would be relative to the centreline of the pole, which is the same at each end of the stack.

But with the skewed arm, and the centreline of the stack being rotated at each end, where is that timing relative to?

I'm guessing that a new centreline needs to be determined, between the leading tip of the stack at one end, to the trailing tip at the other end of the stack. (Hope that makes sense!!)

![]()

- havlicek likes this

Steve King

#13

Posted 27 May 2017 - 09:30 AM

Your thoughts about how to reference comm timing on a skewed-lam stack are right there with mine, but I only guess about these things.

Having said that, I still reference the top of the stack for this and it "seems" to work. There is a slight increase in revs hooking this particular motor up to run CCW, even with only the very mild advance in that direction and the skewed-stack. With the stack "sort of" acting like a wider straight lam stack, I would expect the center of the coils to be half that much away from the center of each lam as you imagined... so I'm not sure what exactly goes on with this aspect of skewed-lam stacks.

In the past, I've always done a more typical moderate advance with them.

#14

Posted 27 May 2017 - 07:07 PM

Hmmm, could be interesting (and a lot of work) to wind two identical arms with 'zero' timing, and skew them the same amount in opposite directions, then see if they run better in opposite directions to each other in the same setup.

That might show how the skew affects the timing.

![]()

- Benno - SAC likes this

Steve King

#15

Posted 28 May 2017 - 06:30 AM

- slotbaker and olescratch like this