* * *

With the permission of the author, George Shannon, I'm going to post this motor-building article from the second issue of the now-defunct "Slot Car Enthusiast" magazine. And since I have the original photos in my files, the pictures will be in color, as opposed to the B&W of the original printed article.

While this article is almost ten years old, it still has a lot of good info, even for racers building motors other than C-cans. Because this is a long article, it will be split up among several posts. George did want me to tell you that he no longer recommends the Slick 7 can bushings and now uses JB Weld for securing magnets.

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

Building Race-Winning C-Cans

by George Shannon

In slot car racing, as in full-size racing, horsepower is the name of the game. In classes that don't use spec or sealed motors, careful assembly, which is usually termed blueprinting, is what makes horsepower and wins races. Blueprinting basically means to assemble a motor with the highest possible level of precision, with bearings coaxial, magnets parallel and exactly 180-degrees apart, and clearances at specific figures, all pointing toward the goal of maximum performance.

This article spotlights the C-can slot car motor, which has been commercially available in the slot car market for many years and which is used by both 1/32 and 1/24 scale racers around the world. What follows certainly is not the only way to assemble a C-can motor, as each racer has his own bag of tricks, but the techniques described are one racer's way of achieving the kind of precision that usually produces fast and durable slot car motors. Note that many of these techniques are equally applicable to D-cans as well as to other size motors. And be warned that some of the procedures described may not be legal in every racing series, so read the rulebook or check with the tech director before proceeding.

__________

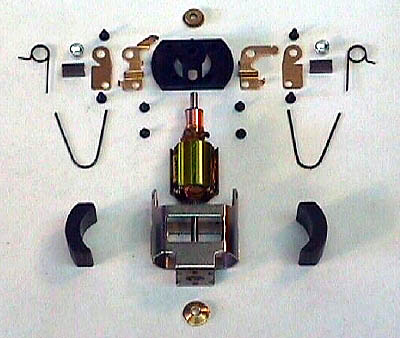

Parts List

Pro Slot thin motor can

Pro Slot endbell & hardware

Mura C-can magnets

Pro Slot S16C armature

Pro Slot Golddust brushes

Champion Light springs

Slick 7 can bushing

FastOnes motor screws

__________

First we must gather the parts and tools required to build a race-winning C-can. The parts list on this page shows the components we will use in the construction of this motor. One may start with a complete motor or one may pick and chose from different manufacturer's parts, as we have done. We will assume that we have obtained matched (equal strength) magnets and a balanced and tagged armature appropriate to the class being raced. We must also assemble a few specialized tools to help us achieve the level of precision we are seeking. Some of these, such as the armature slugs, dial calipers, and brush hood alignment tool, are necessities. Others, such as the endbell alignment jig, the spring tension tool, and the diamond brush radius hone, are optional or can be substituted for.

__________

Tools List

Camen .530 & .525-inch armature slugs

DRS C-can alignment mandrel

Slick 7 brush hood alignment bars

Magnehone brush hood tool

Magnehone brush radius tool

Magnehone armature tool

PureFast endbell alignment jig

Sonic Fiddlestick spring tension tool

Dial calipers

3M Double-Stick cellophane tape

Super glue

Lighter fluid

400-grit Wet-or-Dry sandpaper

__________

The order in which we approach the blueprinting process is important. The following steps must be done in the order indicated to achieve the proper results. Additionally, it is very important to check and recheck all measurements as we proceed. Make certain that everything is accurate before gluing or soldering. Always remember the old adage about measuring twice and cutting once. It is much easier to do it right the first time than to fix it later.

The first order of business, after removing the can bushing if one is installed, is to grind away the spot welds on the inside of the curved surfaces of the can. In many cases, these welds form small bumps which will prevent the magnets from making full contact with the can. A Dremel MotoTool or similar small grinder with the appropriate stone makes short work of this.

Next, we will true the motor can, as this mass-produced item is often out of square or bent. The easiest way to straighten and true the can is to use the appropriate C-can mandrel. If the can won't slide easily onto the mandrel, push it on and then tap softly with a brass hammer on the curved surfaces and at the edges, where the curved surfaces meet the flat sides, until the can will slide easily on and off the mandrel. Be certain that the can fits onto the mandrel in both of the two possible orientations before considering this step complete.

After truing the can, solder the can seams on both curved surfaces for greater strength and stability. To achieve better solder bonds, sand the plating away on either side of the seams and scrape a hobby knife backwards down the seams before soldering. File any excess solder present after soldering, and then recheck that the can slides easily on and off the can mandrel.

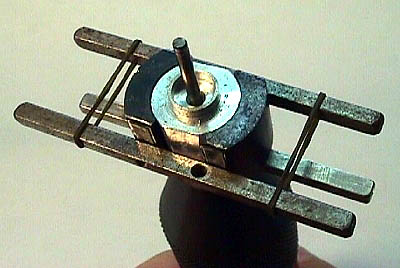

Now we want to establish the bushing axis. Slide the magnets into the can and install the spring clips that retain them. Take an armature slug of a diameter that will fit tightly between the magnets (for our motor, this is a .530-inch slug) and install a can bushing on the short end of the slug's shaft before inserting it into the hole formed by the magnets. If the bushing will not seat into the hole in the end of the can, it will be necessary to ream this to a larger diameter. The can bushing should fit loosely in the hole before soldering. Test fit the endbell to be sure that its bushing is not off-center and that the endbell will fit properly into the end of the can. What we are doing here is using the magnets to locate the armature axis and as we proceed, all other installations will pilot off of this axis.

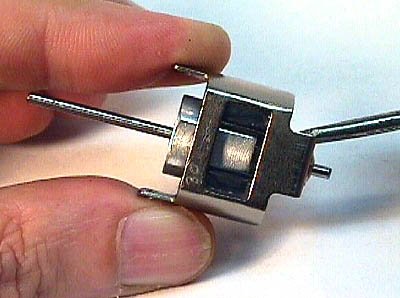

Next we must install the endbell onto the can and drill the holes for the screws, if they are not already present. (It is a good idea to mark the endbell and can so that the endbell will always be installed in the same orientation; an engraver works well for this.) We want the endbell to fit fully and squarely into the can when the screws are installed. One way to accomplish this is to position the endbell properly and then to lightly glue it in place using cyanoacrylate (super glue) while drilling the holes for the four endbell screws (and always use four endbell screws). The Pro Slot can we are using is a bit different from some of the other C-cans on the market in that the can does not restrain the endbell's rotation. Temporarily install the brush hoods and the brush hood tool onto the endbell and then place the assembly into the endbell alignment jig to square everything up before gluing the endbell in place. Carefully drill the first hole, making certain that the drill is aligned 90-degrees to the can in all four directions. A cordless Dremel MotoTool on slow speed works well for this task. Install a screw in each hole before drilling the next one. Drilling the endbell holes is a critical step as we only have one chance to get it right. If the holes aren't right, i.e. if the endbell doesn't fit flush and square, we will have to buy another endbell and try again. After the four screw holes have been drilled, and before the super glue has a chance to fully harden, break the endbell loose from the can and clean off the small bits of glue with a hobby knife. Reinstall the endbell onto the can with the four screws to be certain that we have achieved the square and snug fit we are striving for.

Now solder the can bushing in place after sanding off the plating around the hole. Be certain that the bushing is fully seated and that there is solder completely around the circumference of the bushing. Do this with the endbell, slug, and magnets in place with all four screws inserted. Stand the motor can in a block of wood which has a hole for the slug's shaft. Rotate the motor under the soldering iron to achieve the 360-degree solder fillet desired, using only enough solder to get a good bond. If the endbell bushing is not secured in the endbell, now is the time to remove the endbell and to carefully glue the bushing in place using a small drop or two of super glue. Use an old armature to seat it in the endbell's bushing recess. Again, this should be done with the endbell on and all four screws installed in the can.

When everything is cool, remove the endbell and the slug, install the armature, and reinstall the endbell to check the bearing alignment. The arm should spin very freely in its bushings. If it doesn't, correct the problem now before proceeding to the next step, resoldering or regluing as necessary to achieve a free-spinning armature.

Next, we must determine the magnet position which will locate the armature in the can such that the brushes properly contact the commutator and such that the armature floats between the bushings. We don't want either end of the arm to contact the bushings yet the commutator must be positioned to allow full brush contact. Accomplish this by using dial calipers to push the magnets toward the endbell end until the armature floats in the magnetic field in the correct position. Once this magnet position is achieved, write down the distance between the end of the can and the end of the magnets as shown on the dial calipers. This measurement will be needed when gluing the magnets.

(con't in next post)