Building a dyno question

#26

Posted 07 August 2017 - 07:45 AM

Brian Ambrose

#27

Posted 07 August 2017 - 08:01 AM

Dale, have you had a great reading on a motor and it be a turd on the track?

#28

Posted 07 August 2017 - 11:13 AM

Dale, have you had a great reading on a motor and it be a turd on the track?

Happens to me all the time, and I've also had what I thought were duds turn out to be rockets. IMO dyno and RPM readings are useless, all you doing is determining what motors run best on your power supply at low votlage. If we raced power supplies it might be worth all the effort lol. You just have to try every motor on every track. Actual track power is way different then a power supply or "dyno" at 5 or 6 volts.

- JerseyJohn, Bud Greene, Samiam and 2 others like this

Ralph Thorne

ralph@ralphthorneracing.com

RTR Facebook page

#29

Posted 08 August 2017 - 07:41 AM

Happens to me all the time, and I've also had what I thought were duds turn out to be rockets. IMO dyno and RPM readings are useless, all you doing is determining what motors run best on your power supply at low votlage. If we raced power supplies it might be worth all the effort lol. You just have to try every motor on every track. Actual track power is way different then a power supply or "dyno" at 5 or 6 volts.

I've seen similar comments in the past in other threads regarding dynos, so I knew in advance that my device would likely have limited usefulness.

#30

Posted 08 August 2017 - 07:43 AM

Sent from my iPhone using Tapatalk

- Phil Hackett and boxerdog like this

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#31

Posted 08 August 2017 - 08:06 AM

I think the dyno could work fine. the key and weak point is the data acquisition.

How quick will the motor accelerate a load?

What is the top end under load?

how quick will it decelerate a load under breaking?

- Rob Voska likes this

#32

Posted 08 August 2017 - 09:35 AM

I think the dyno could work fine. the key and weak point is the data acquisition.

How quick will the motor accelerate a load?

What is the top end under load?

how quick will it decelerate a load under breaking?

Here are some more:

How hot will it get get under load?

How long will it need to run under load for a stable "run"?

How many amps will it pull through the range of load?

At what point will the harmonics of the balance affect the amp draw/rpms?

How close is the load you're providing to the real application of pushing a slot car around a track?

Data is the key and you should have a system of recording it and analysing it....

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

#33

Posted 08 August 2017 - 11:44 AM

If simply putting a motor "under a load" on the power supply or dyno was the answer, explain the following that happened to me a few weeks ago...

Good dyno motor motor reads 33,200 rpms at 6 volts. It runs a 3.65 geared 13/35 and a 4.24 geared 10/35 with 13.5 volts track power.

Bad dyno motor reads 27,800 rpm at 6 volts. It runs 3.85 geared 13/35 and a 4.01 geared 10/35 with 13.5 volts track power.

Now if I was going by dyno readings I should have left the second motor at home. Glad I didn't because it was my best motor with a 10/35 gear on it. Just putting a load on a motor doesnt factor in the important things such as, weight of the car, track power, gear ratio, final drive ratio or the correct power band the motor will be in once you selected your pinion and spur gear. Some motors also run good with 1 car on the track and slow down with 8 cars and vice versa, again no way to replicate that IMO. Anyone with brand new "bad dyno motors" send me a PM and I'll take them off your hands!

Ralph Thorne

ralph@ralphthorneracing.com

RTR Facebook page

#34

Posted 08 August 2017 - 12:51 PM

sounds as if one needs a dynamic acceleration load across Voltage. that would be a Lot of data!

but I'd love to be able to do it.

speedy

Steve Lang

#35

Posted 08 August 2017 - 01:06 PM

- Danny Zona likes this

Cry like a baby, drive like a girl, walk like a man.

Give me enough rope and I'll build a fast car... or hang myself?

#36

Posted 08 August 2017 - 02:47 PM

Running a motor on 6V on a dyno is kind of like running a fuel engine at half throttle and expecting full usable readings from the dyno.

If you can't run it at full voltage it is not under enough load. or the wrong kind of load.

sampling and plotting enough data points is still the key to useful results.

Much easier to put it in the car and see how it runs.

IMHO

#37

Posted 08 August 2017 - 02:48 PM

Ralph is about a half a tenth slower when the girlfriend is present.

😂😅😂😅

- Bud Greene and Tampabay racer like this

You're never fast enough!!! 💯

Preparation leads to separation.

Success is never owned but rented, and the rent is due every day.

KELLY RACING 😎

#38

Posted 08 August 2017 - 03:22 PM

- Danny Zona likes this

Brian Ambrose

#39

Posted 23 February 2020 - 12:14 PM

If using a prop it seems humidity (weight of the air being moved) would need to be monitored. If it is back to back testing not much of an issue. If it is week to week testing it all needs to be factored in.

- Matt Sheldon likes this

#40

Posted 23 February 2020 - 12:58 PM

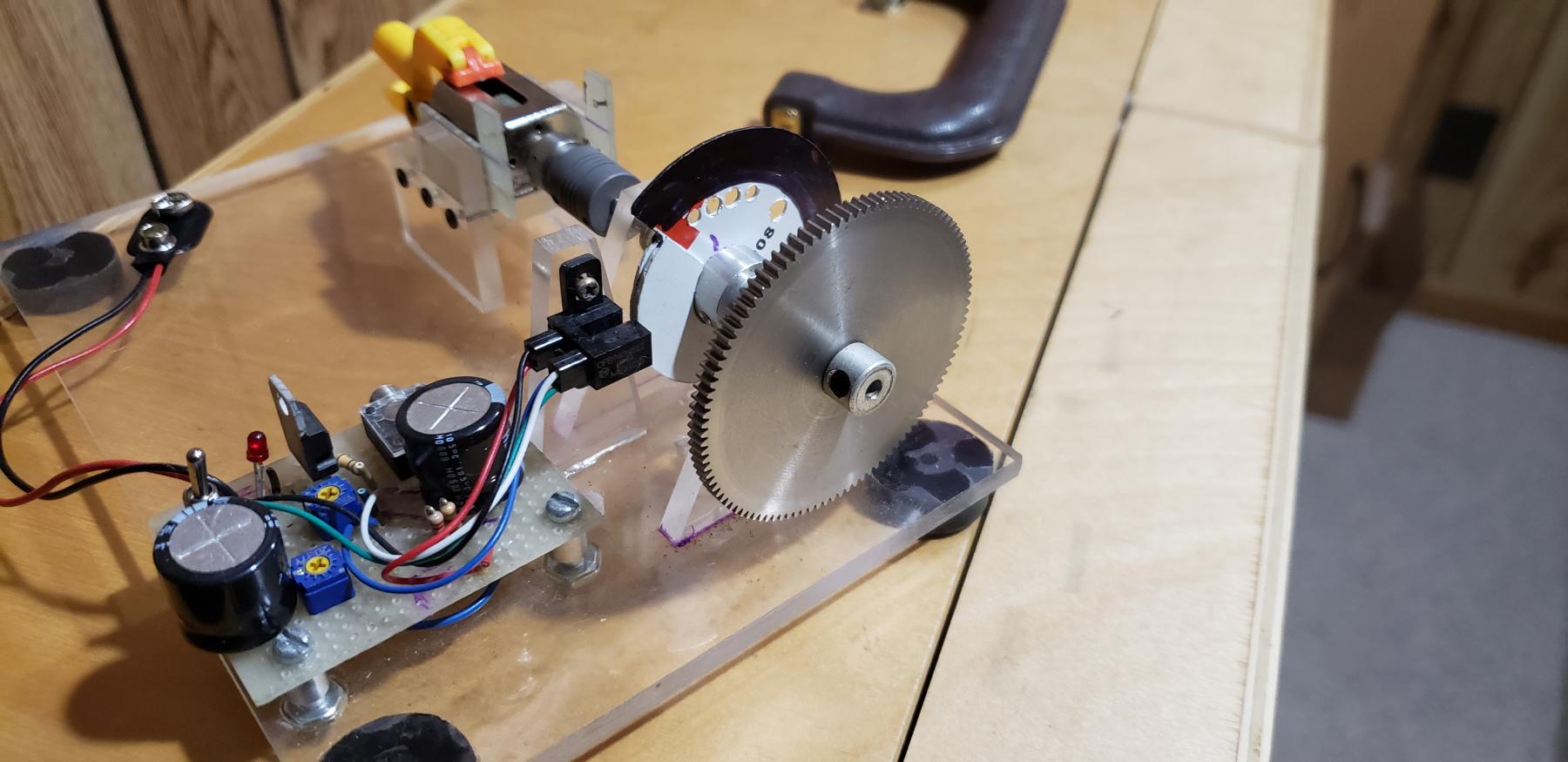

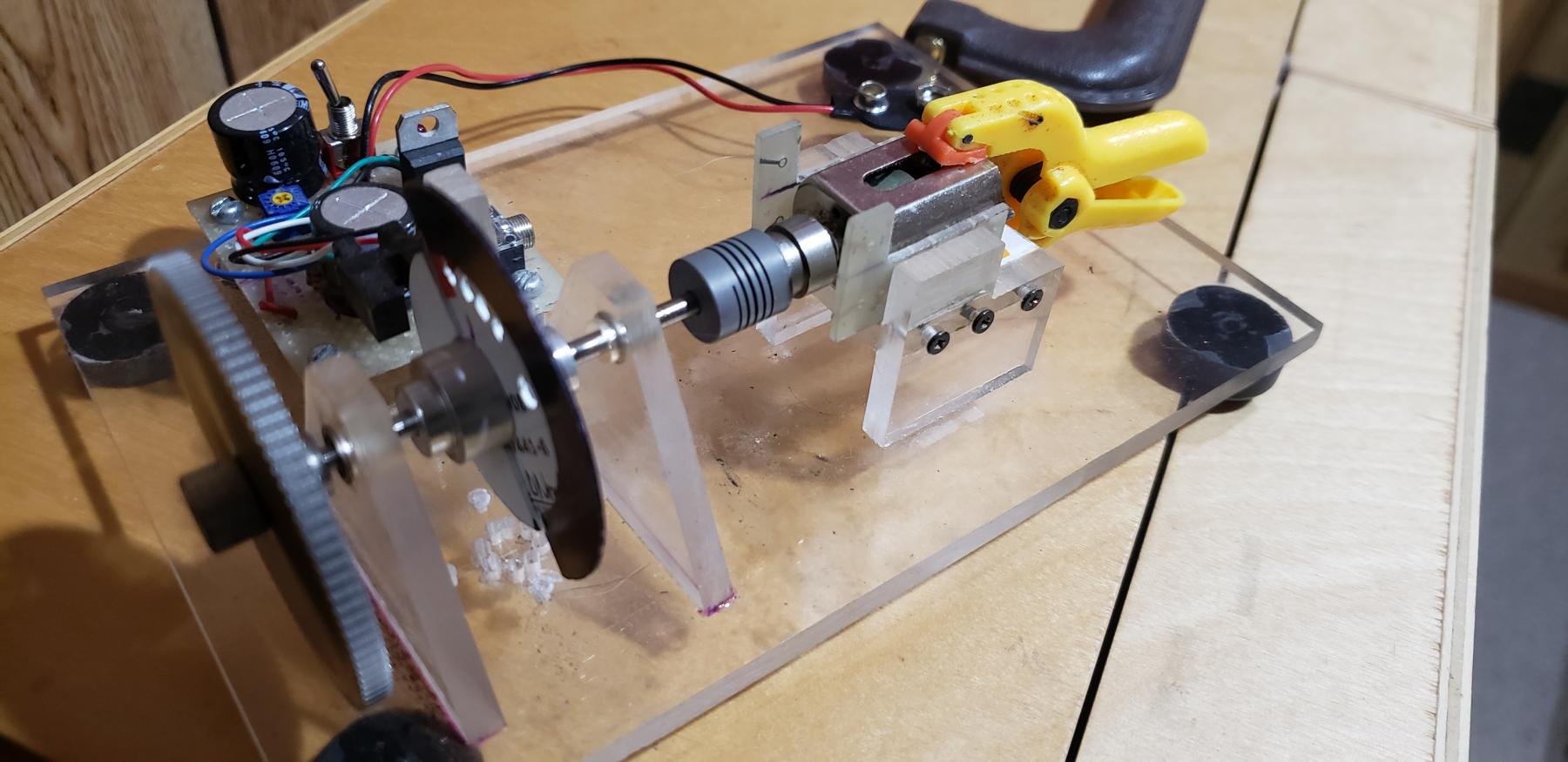

This was my approach to an inertial dyno some years ago. It generates a wave signal you can plug into a computer audio input.

I got some nice plots using a freeware software I downloaded ( i believe it was the Symple Dyno) but my racing program wasn't worth the effort so I sopped the development.

- Rob Voska, boxerdog and Jaeger Team like this

Because light travels faster than sound, some people appear to be bright until we hear them speaking.

#41

Posted 23 February 2020 - 05:29 PM