Good question, John, I'll try and remember to explain that when I solder them.

What good is a jig motor if it isn't exactly the same as the real motor? Not much.

Trimming the tube and setting the motor angle to fit the jig motor, then realizing the real motor won't fit, sucks.

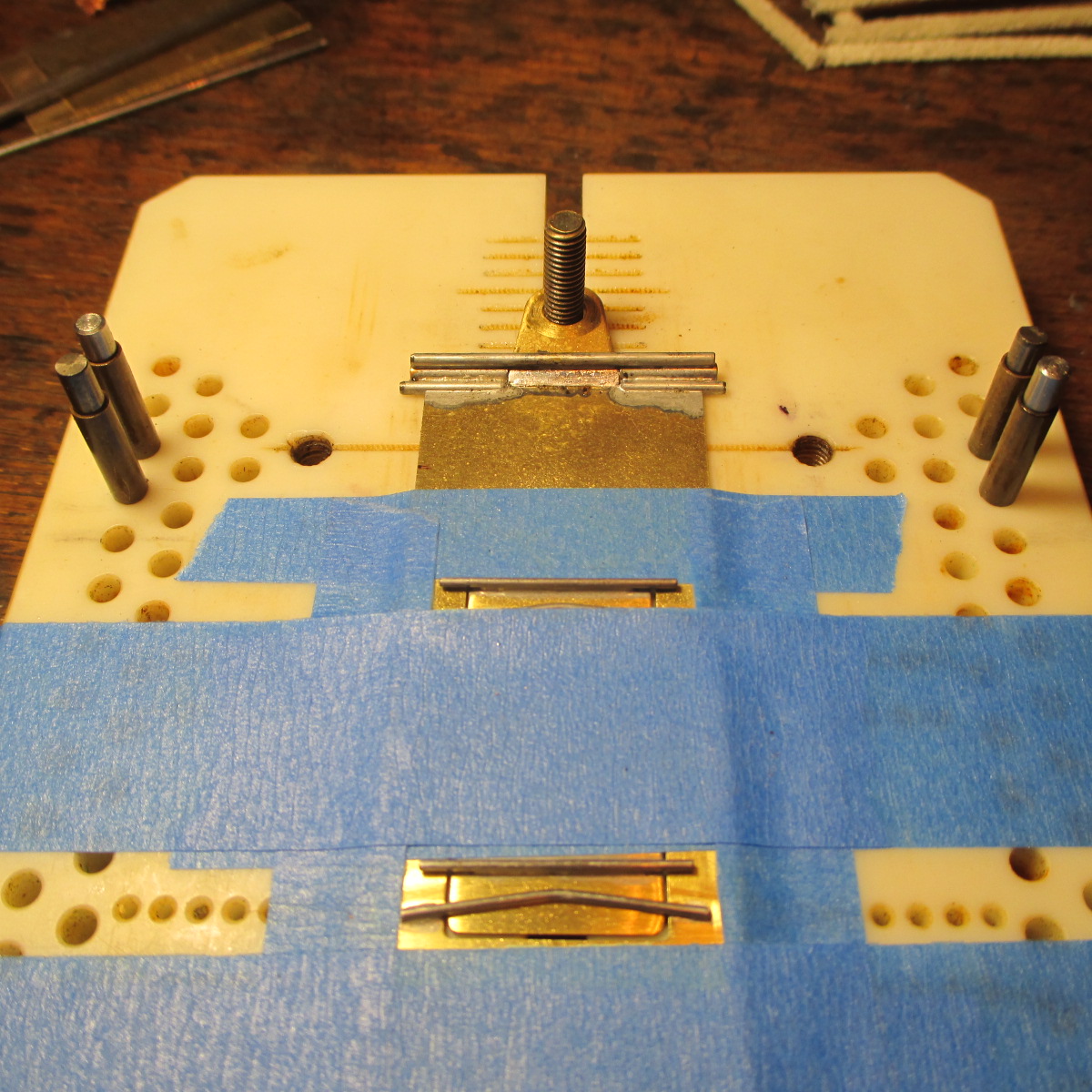

To preclude that from happening, I did the best I could by:

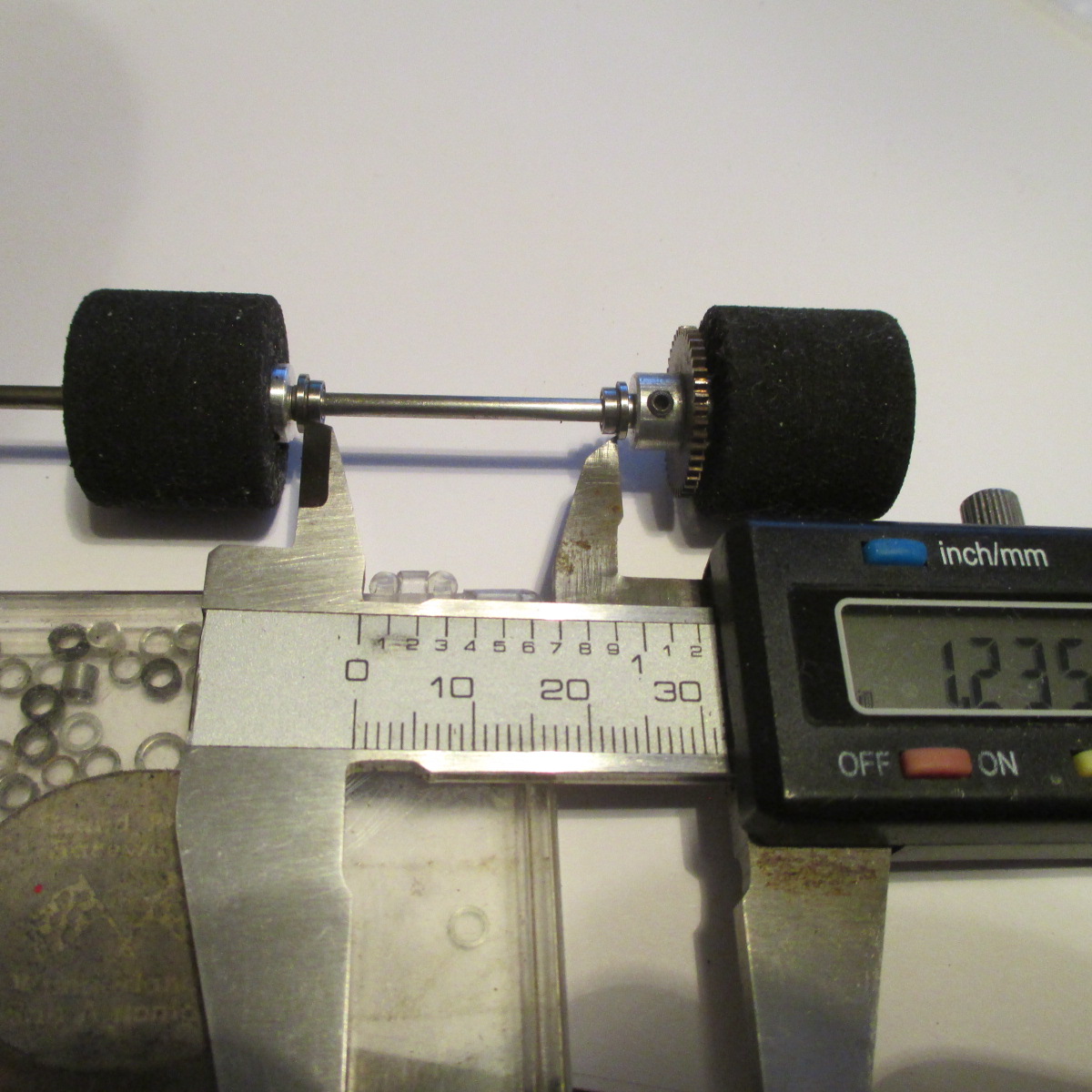

-using exactly the same brand and size pinion on both

-ensuring the length from can end to pinion is exactly the same (Krazy Glued both pinions in place temporarily)

-Krazy Gluing a junk magnet in the jig can to emulate the real motor's magnet setup

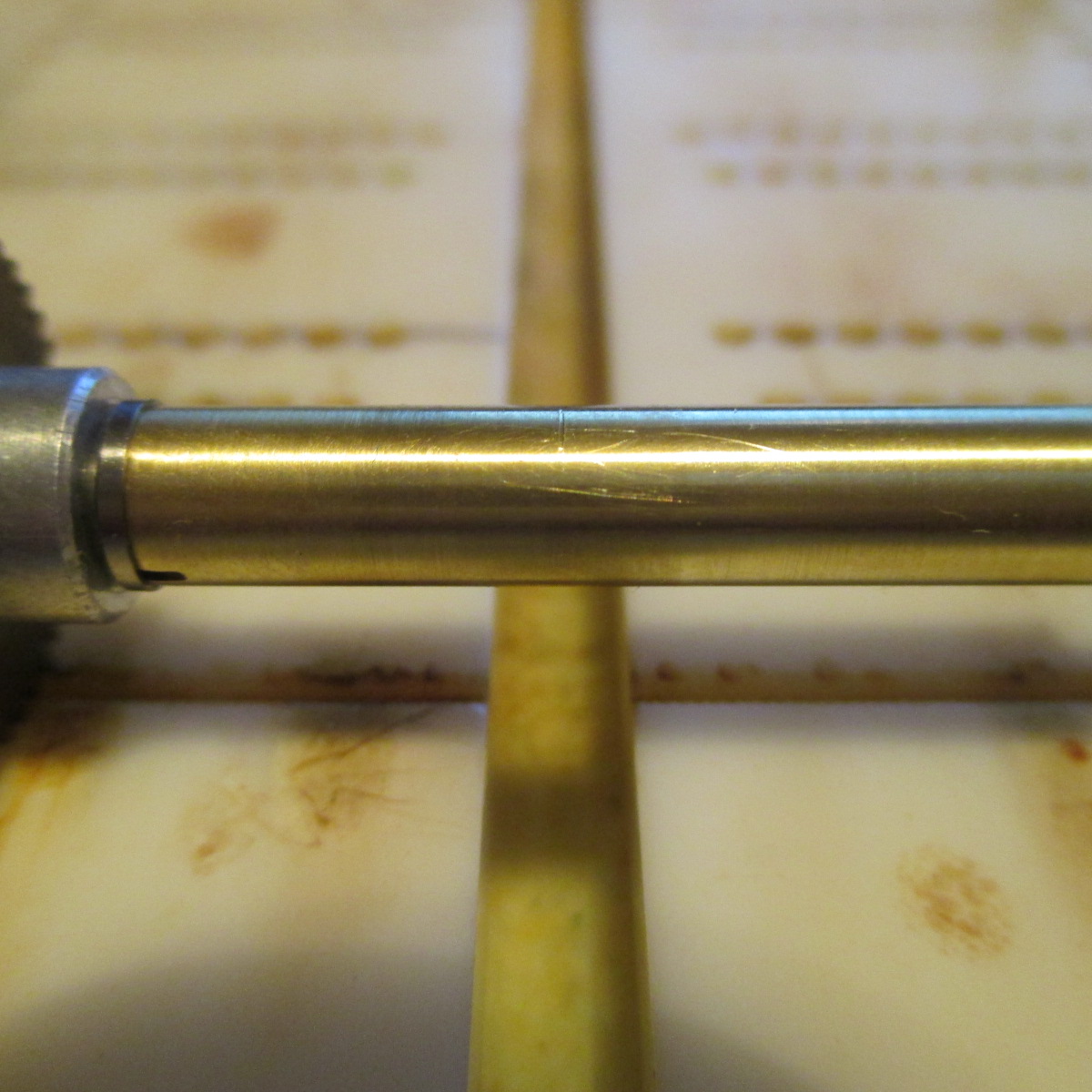

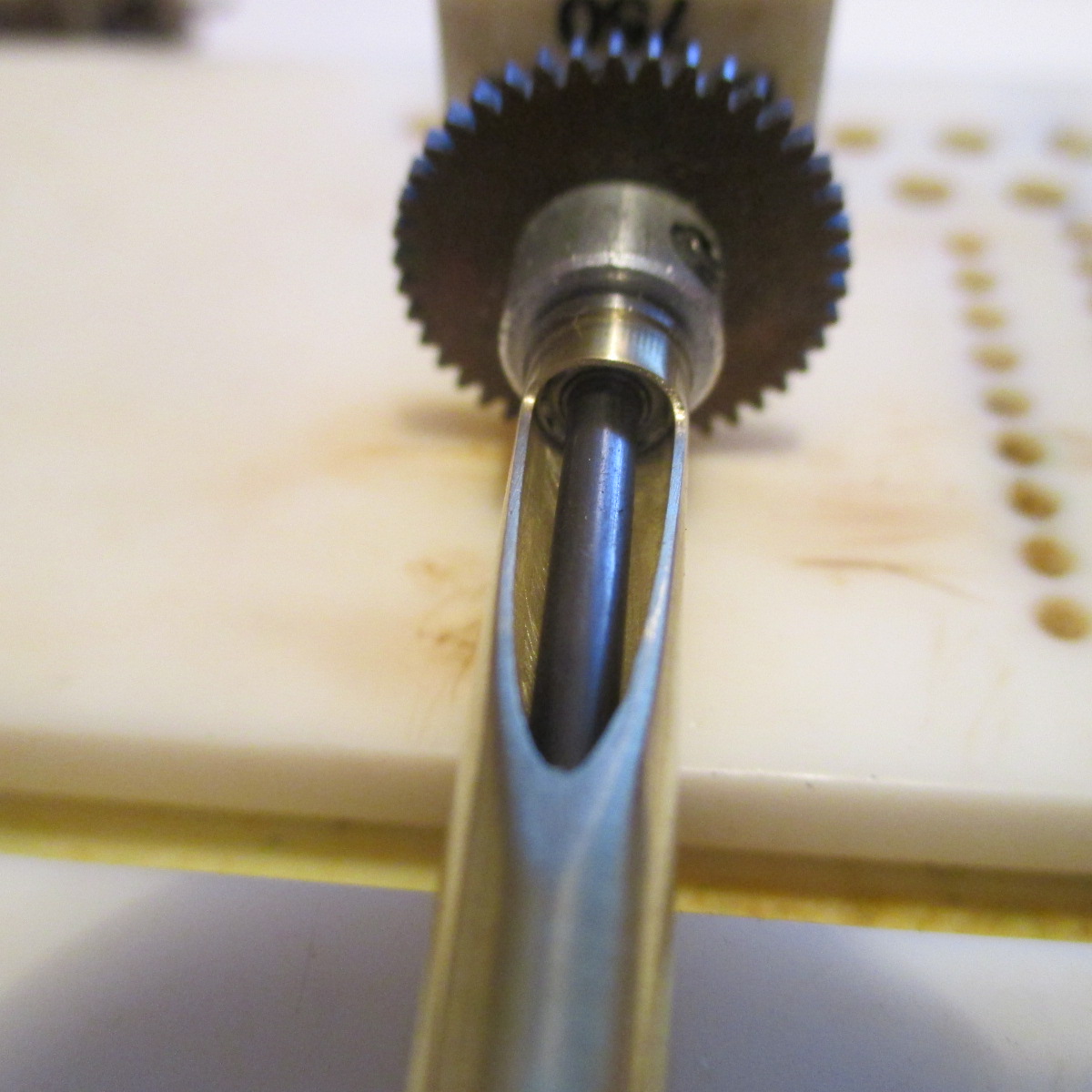

Here's another thing that sucks - making a perfect axle tube, planning the notch, cutting it and realizing it's not perfect.

This time I made a rough aluminum tube, put some old BB's in it, and jigged it up as a test mule for the notching.

If I screw one up I'll just toss it until I succeed, then make an identical cut to the good one

![]()

![]()