Larry I have used the Lenk brand soldering irons for over 20 years. I thought that they had stopped making them. I believe Mike Swiss had used these for a while also.

Soldering iron selection

#26

Posted 28 December 2017 - 10:59 PM

#27

Posted 28 December 2017 - 11:12 PM

Not that I remember.

I used Ungar/Weller's, until they got real bad for awhile.

I then went with the Hakko 936 with the larger element.

I loved it.

It was super-light and just hot enough to, to put together, and take motors out of, a Koford aluminum chassis.

At the 2003 Nat's, I started building my Pro G27 chassis, after tech opened,( and was not the last one to tech).

When we started doing Retro in 2007, it just wasn't hot enough, to do the type of chassis, we were building in the beginning.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#28

Posted 29 December 2017 - 11:23 PM

I just got in the 601.I sell and have a 50 watt Weller (Ungar) at my work station.

It just seems a bit lethargic so I just ordered a Hakko 601.

I'm hoping it's better, but regardless, having 2 irons plugged in, at once, makes motor removal on something like a Cheetah 7, with the motor soldered on top, much easier.

I really got spoiled by the 100 watt Inland, when they were available.

Despite being a bit clunky, you just couldn't argue with the heat.

IMO, it was either 1200 degrees, or at the very least, easily had the most superior recovery rate of any iron I ever used.

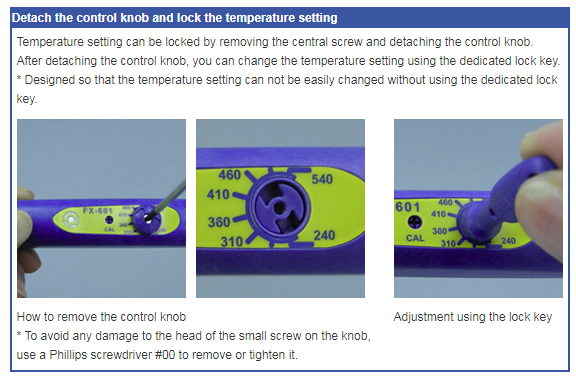

Does anyone know what that little blue, forked thing, zip tied to the power cord, does?

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#29

Posted 30 December 2017 - 12:32 AM

I just got in the 601.

Does anyone know what that little blue, forked thing, zip tied to the power cord, does?

I believe it is for setting and securing the temperature control to a fixed temperature for a production environment.

There is a mention of it in the material on the package or a slip of paper inside.

#31

Posted 30 December 2017 - 06:49 AM

There's a company called American Beauty Tools that make a line of soldering irons, some are very high power units. I don't have any experience with them.

Here's a link . . . . . . https://americanbeautytools.com/

#32

Posted 30 December 2017 - 09:25 AM

Lifelong half-assed slot racer

#33

Posted 30 December 2017 - 09:30 AM

.No info what so ever in the packaging.I believe it is for setting and securing the temperature control to a fixed temperature for a production environment.

There is a mention of it in the material on the package or a slip of paper inside.

Thanks for the info.

Also big thanks to Ron Bryce for getting me the info, via Greg Wells.

I look forward to using the iron.

The tip size and and shape looks pretty ideal.

The cord does seem a bit on the stiff side.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#34

Posted 30 December 2017 - 09:38 AM

Yes.I was going to ask what that little gizmo is that came with my 601! I havent been able to find a use for it. Do you have to remove the adjustment knob to utilize it Bob Schlain?

From Ron Bryce;

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#35

Posted 30 December 2017 - 09:39 AM

Lifelong half-assed slot racer

#36

Posted 30 December 2017 - 09:41 AM

Lifelong half-assed slot racer

#37

Posted 09 January 2018 - 06:25 PM

We used to use 60/40 tin lead,but I'm afraid for whatever brain cells I have left and not wanting to promote use of brain damaging lead fumes.

#38

Posted 09 January 2018 - 10:50 PM

Bruce:

You can't go wrong with the Hakko FX-601, probably the best all around iron out there right now. As for solder 60/40 rosin core is still the most used solder and will work for virtually all your slot car soldering needs. As for flux, use a rosin core solder and RMA (Rosin Mildly Activated) flux for electrical connections. Use an acid flux containing zinc chloride and hydrochloric acid for chassis work, You don't have to clean the electrical joints with RMA flux but it's a good idea. However you must clean any chassis work with baking soda and water (or at least motor spray) to remove/neutralize the acid or your chassis will corrode. Do NOT use any of the no-lead low temperature solders for slot car applications. Brain Damage, well we're all slot car racers so that's really not an issue! ![]()

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#39

Posted 18 January 2018 - 09:07 PM

I noticed that.

Maybe I'll try one on the future.

I just spent $70 on the Hakko 601, plus another $50 or $60 on 4 or 5 cheap, but decent irons, to sell to new racers.

I just got a chance to try my Hakko 601 to do a track related repair that requires a lot of heat.

Awesome heat, but that cord is really something.

I don't recall dealing with something that stiff since about 1988. LOL

- Half Fast likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#40

Posted 18 January 2018 - 09:12 PM

The cord seemed very stiff when I first started using it but i guess I got used to it. I still think about cutting the outer cover off it.

It is a great iron.

- Half Fast likes this

#41

Posted 18 January 2018 - 09:27 PM

I still think about cutting the outer cover off it.

Good idea.

I may play it on the safe side, and take mine to a Rabbi.

- Eddie Fleming likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#42

Posted 18 January 2018 - 09:37 PM

I never thought about cutting off the outer cord insulation, that would sure make it more user friendly. I don't know any Rabbi's. My lack of knowing the right way to do something has never stopped me before.

Matt Bishop

#43

Posted 19 January 2018 - 06:59 AM

Sent from my iPhone using Tapatalk

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#44

Posted 19 January 2018 - 09:25 AM

Now best solder and fluxes.

We used to use 60/40 tin lead,but I'm afraid for whatever brain cells I have left and not wanting to promote use of brain damaging lead fumes.

If you don't want to use a lead based solder, then you won't need a soldering iron, because you won't be soldering.

Cheers

- tonyp likes this

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

#45

Posted 19 January 2018 - 10:22 AM

Lead "fumes" at soldering temperatures are non-existent. The only likely source of lead poisoning is via the inhalation of solder dust while power sanding or grinding to clean up joints - easy enough to avoid with a simple mask.

EM

- slotcarone, Half Fast and Eddie Fleming like this

#46

Posted 19 January 2018 - 10:56 AM

Flux fumes are a different matter.

#48

Posted 19 January 2018 - 04:00 PM

Show off. ![]()

South Carolina, USA

"Assuming either the Left Wing or the Right Wing gained control of the country, it would probably fly around in circles."

- Pat Paulsen, 1968

"I drive way too fast to worry about cholesterol."

- Steven Wright ca. 1983

#49

Posted 19 January 2018 - 04:47 PM

I liked the Hakko 936 so much I bought another one before they changed. Best iron I've ever used. Mr. Swiss you are a funny man.

#50

Posted 19 January 2018 - 05:34 PM

I sell and have a 50 watt Weller (Ungar) at my work station.

It just seems a bit lethargic so I just ordered a Hakko 601.

I'm hoping it's better, but regardless, having 2 irons plugged in, at once, makes motor removal on something like a Cheetah 7, with the motor soldered on top, much easier.

I really got spoiled by the 100 watt Inland, when they were available.

Despite being a bit clunky, you just couldn't argue with the heat.

IMO, it was either 1200 degrees, or at the very least, easily had the most superior recovery rate of any iron I ever used.

Im with Mike. I like lots of heat that makes the solder flow like water.

I use 2 heaters when im building one is a 100w 1000+ degree unit for stained glass. You almost need a asbestos glove after it heats up.

and for only. 19.99 https://www.theavenu...-soldering-iron

F

F

For electrical soldering and at the track i bought 2 of these. still going strong after 8 months. adjustable w/ ceramic heaters for fast work. 11 bucks.

https://www.ebay.com...tQAAOSwGllaXuhD

John Chas Molnar

"Certified Newark Wise Guy since 1984" (retired)

"Certified Tony P Chassis God 2007.2023

Retro Chassis Designer-Builder