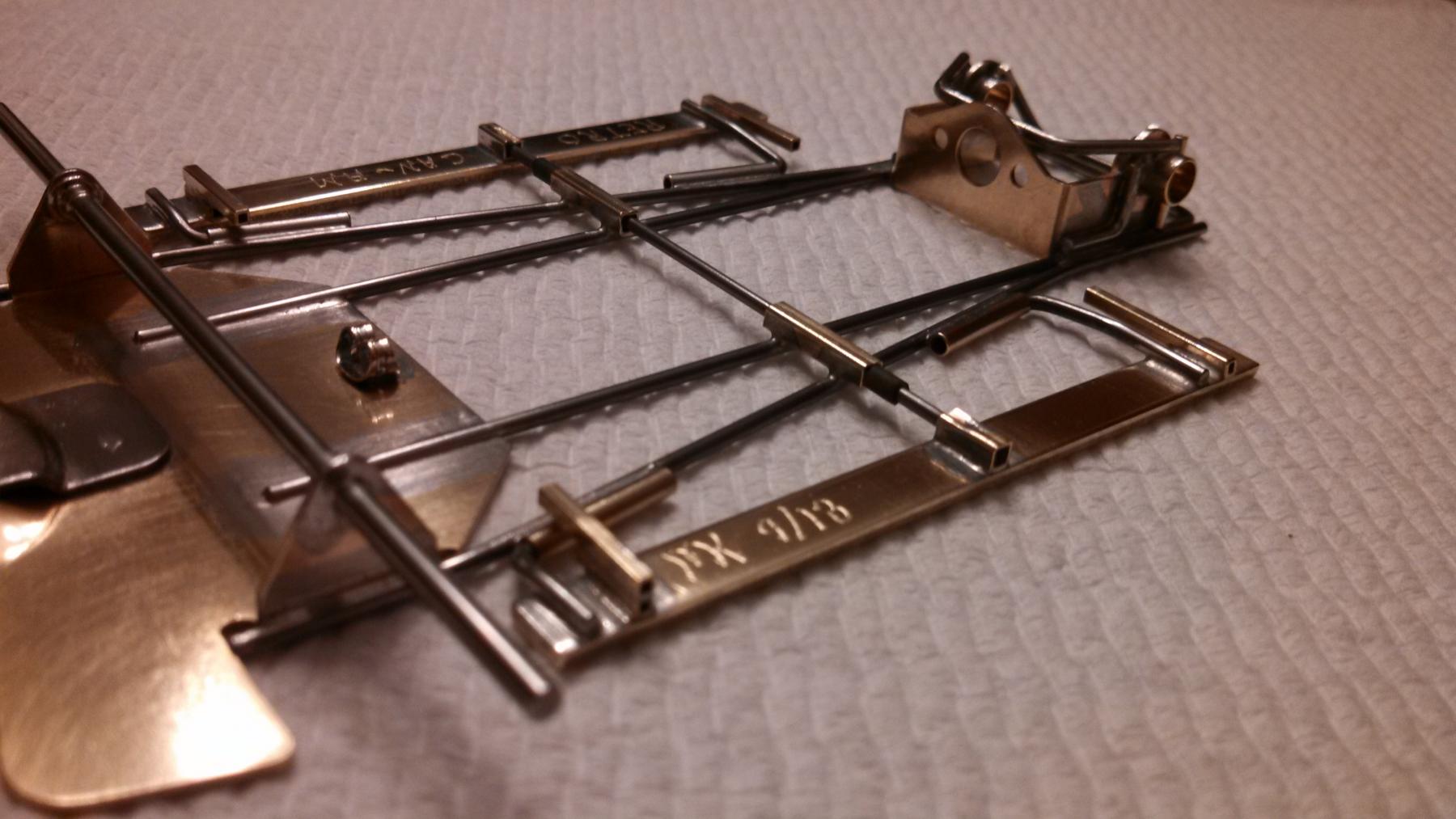

First off I don't have a problem getting good strong joints.But I've always wondered how guys control the excess solder?I always seem to get a small bit that flows out and can never get it to look like the pro's stuff.I've tried painting flux just on the surfaces where I want it but it is always the same.Even if i tin just the 2 surfaces first and then add a TINY bit it still seems to flow out.

Now I'm not talking globs of excess here.I'm talking about that little bit that you can barely feel that tends to color the brass or steel.Or does everyone sand off the excess? Or is there a way or trick to keeping it only where you want it?

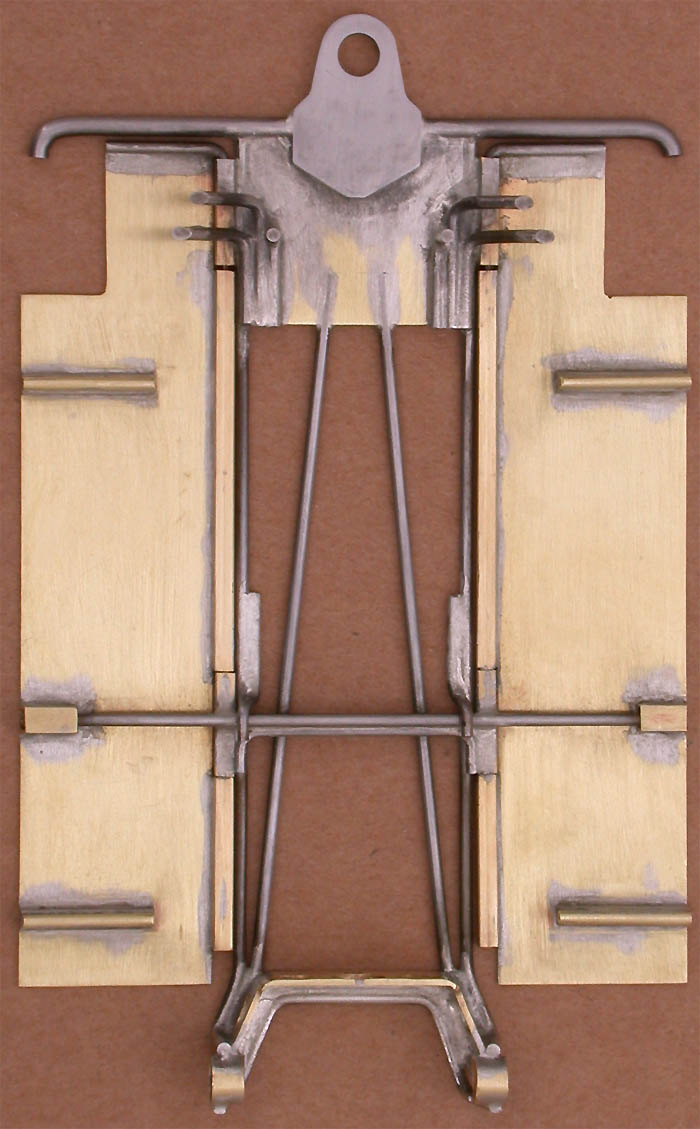

For example when i install pillow blocks I always get some on the rails.Whereas the pros have just enough in the joint and no more.Are they sanding the little excess off too?and I'm just driving myself crazy?Or do they really get just enough in the joint?

Thanks