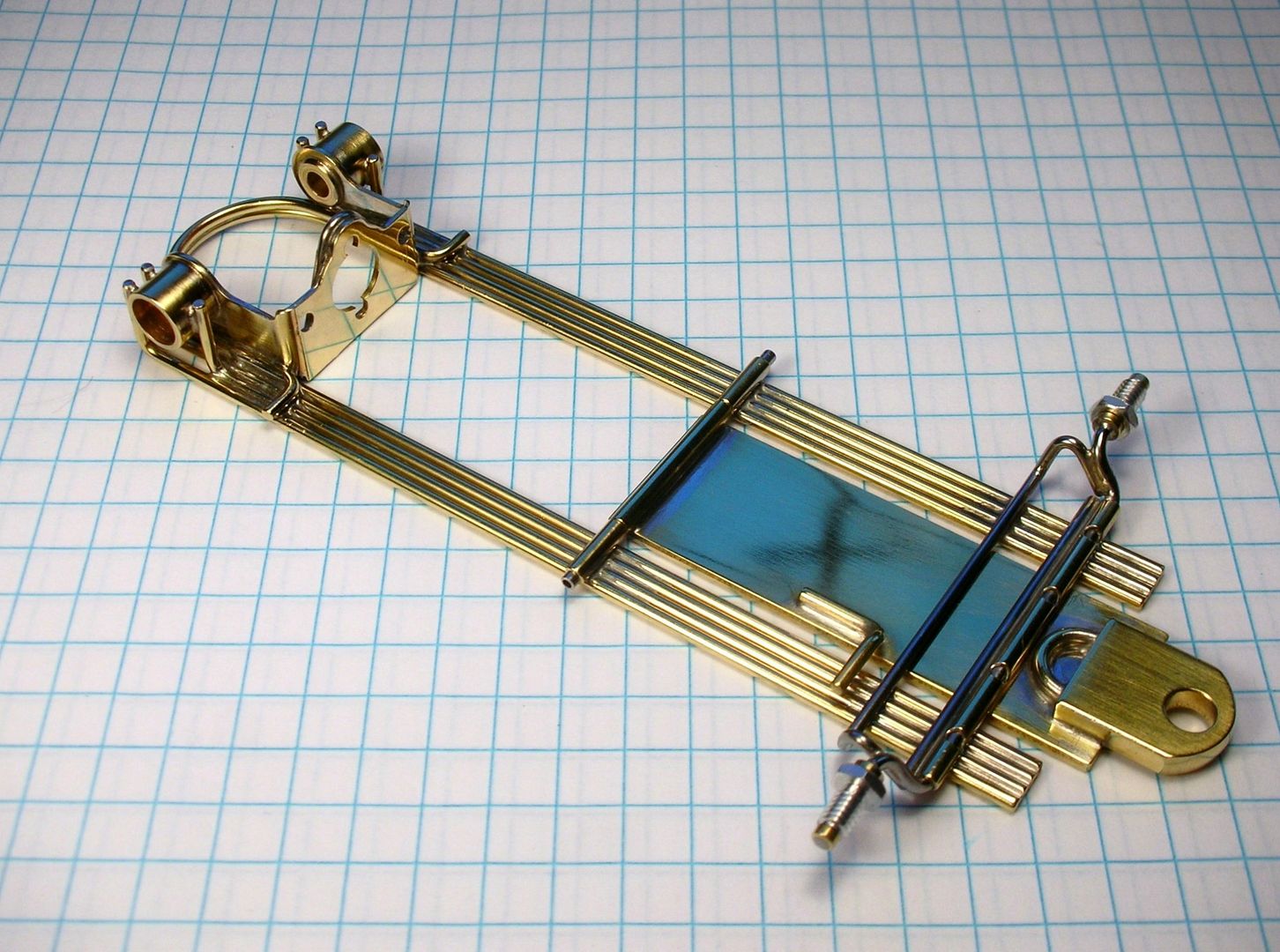

I'll play devil's advocate.

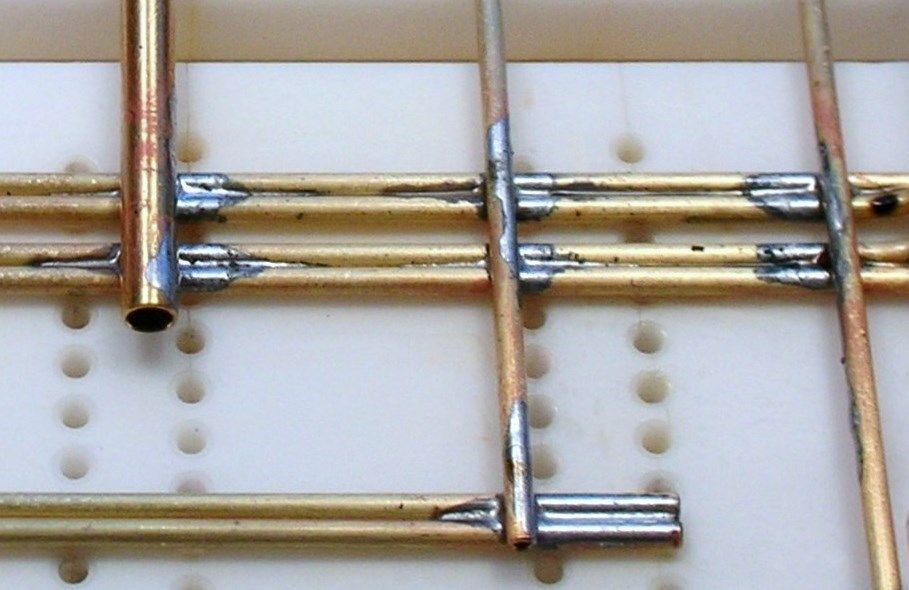

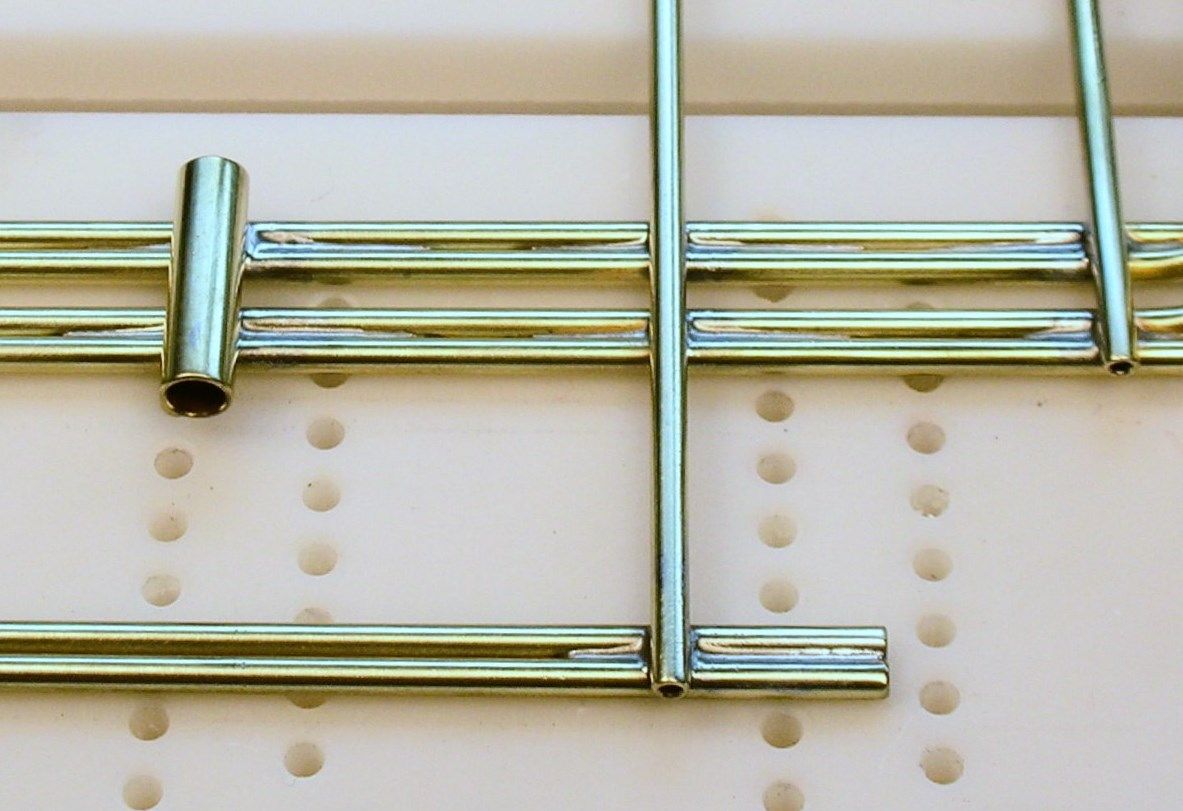

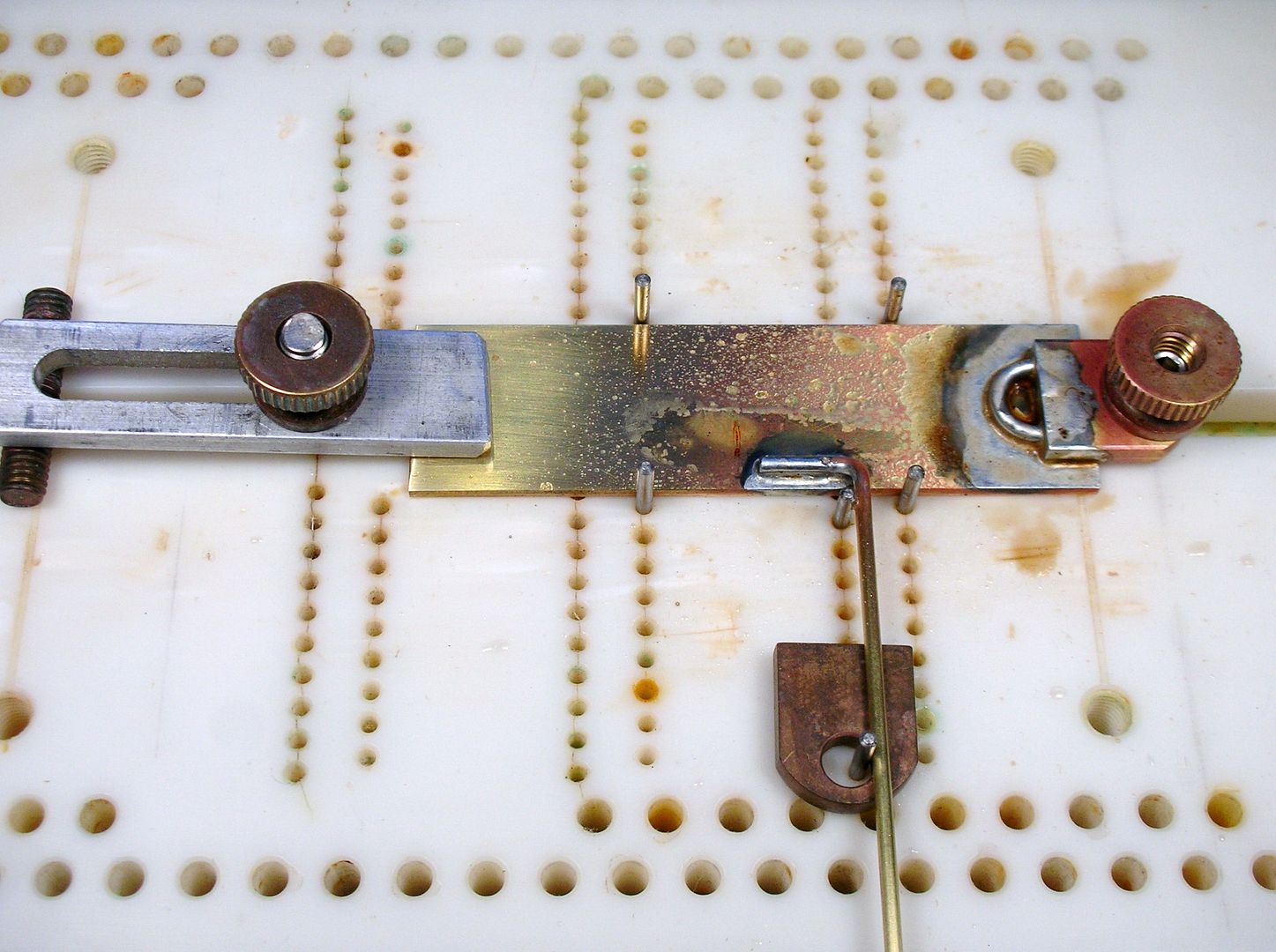

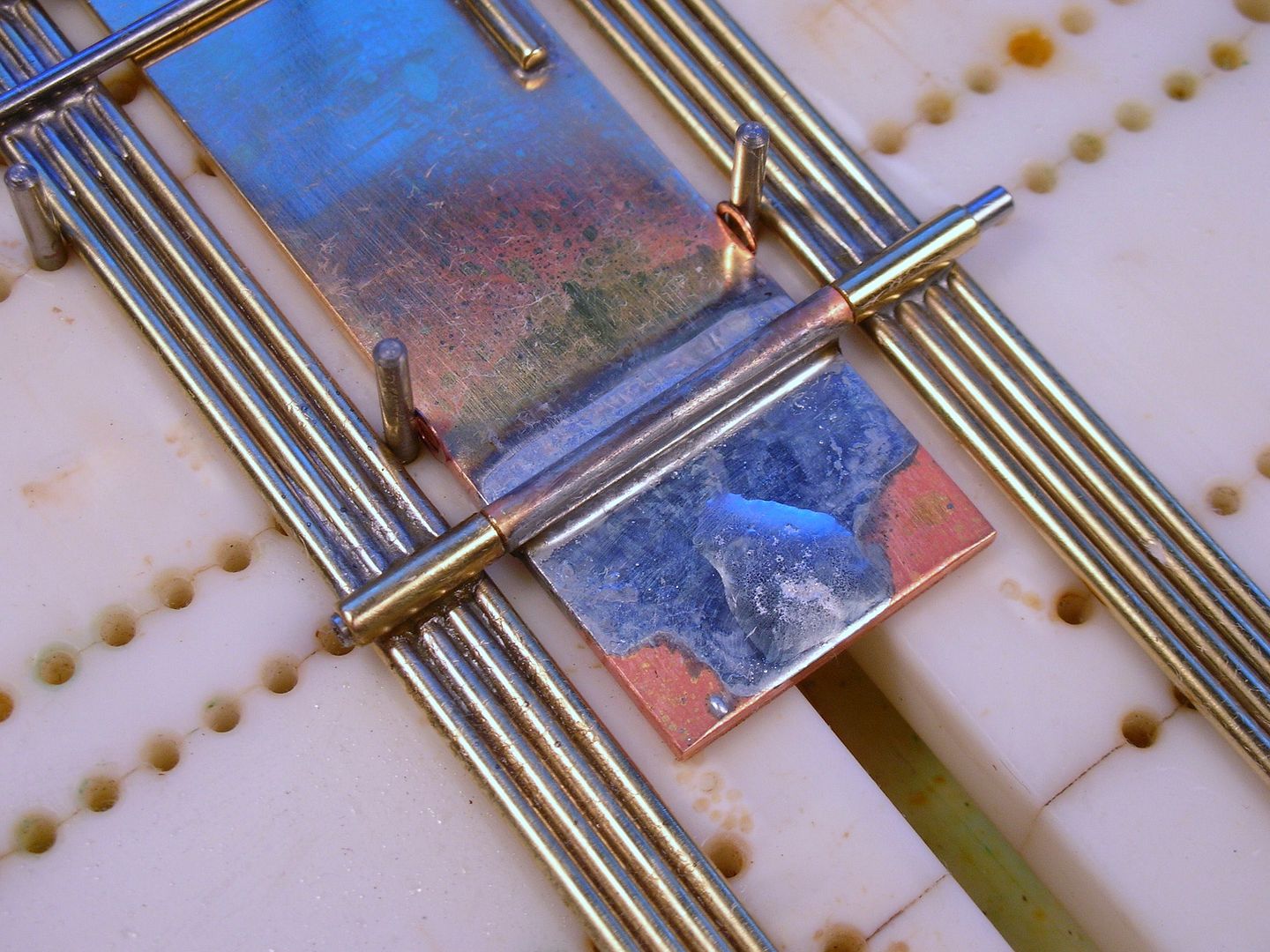

You do beautiful work, Mike, but your method, if the object is to heat the metal no more than necessary, is accomplished at an obvious penalty.

A - you sometimes have to reheat.

B - with less solder on your tip, you have less heat transfer. It's the same thing as having a slightly less hot iron, and the joint isn't "finished", quite as quickly.

Agree on both A and B Mike. I almost always reheat every joint usually adding more solder and putting acid on the underside to make sure the solder connects evenly. I find this works for me and makes for very strong joints that don't break in a crash. My method has nothing to do with not getting the parts hot though. I will even add extra solder to a chassis that I know is going to be raced by a newbie for extra strength.