Hi, hope I'm posting this in the right spot.

I'm just getting started on a project of making 3D printed replicas of a few famous vintage slot car chassis. I know how ridiculous this might sound to some people, but it is a fun project for 3D printing, and who knows what will come of this.

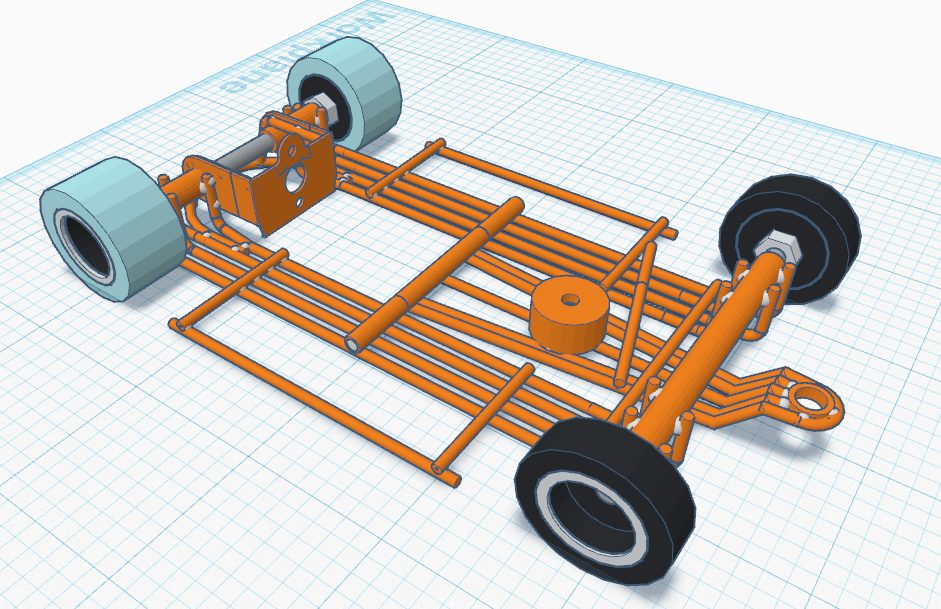

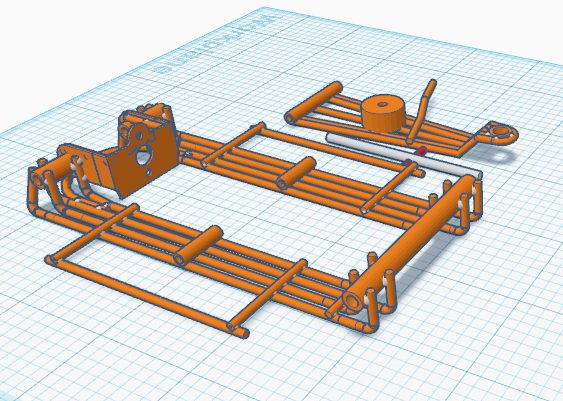

To begin, I have carefully copied a vintage Brian Warmack "jail door" chassis from the first Car Model Road Race in Feb. 1967. There is a picture of the chassis in the Car Model race report. In addition, Steve Okeefe has made a detailed drawing of the Warmack chassis at Slotblog's own The Independent Scratchbuilder, which I used as a guide.

I made two versions using the free software at TinkerCAD.

First, a static model with non-rotating wheels, axles, (and in the future, maybe a motor.)

Second, I made an almost practical version, to which you could, in theory, add wheels, axles, and a real motor, and maybe try to drive the thing.

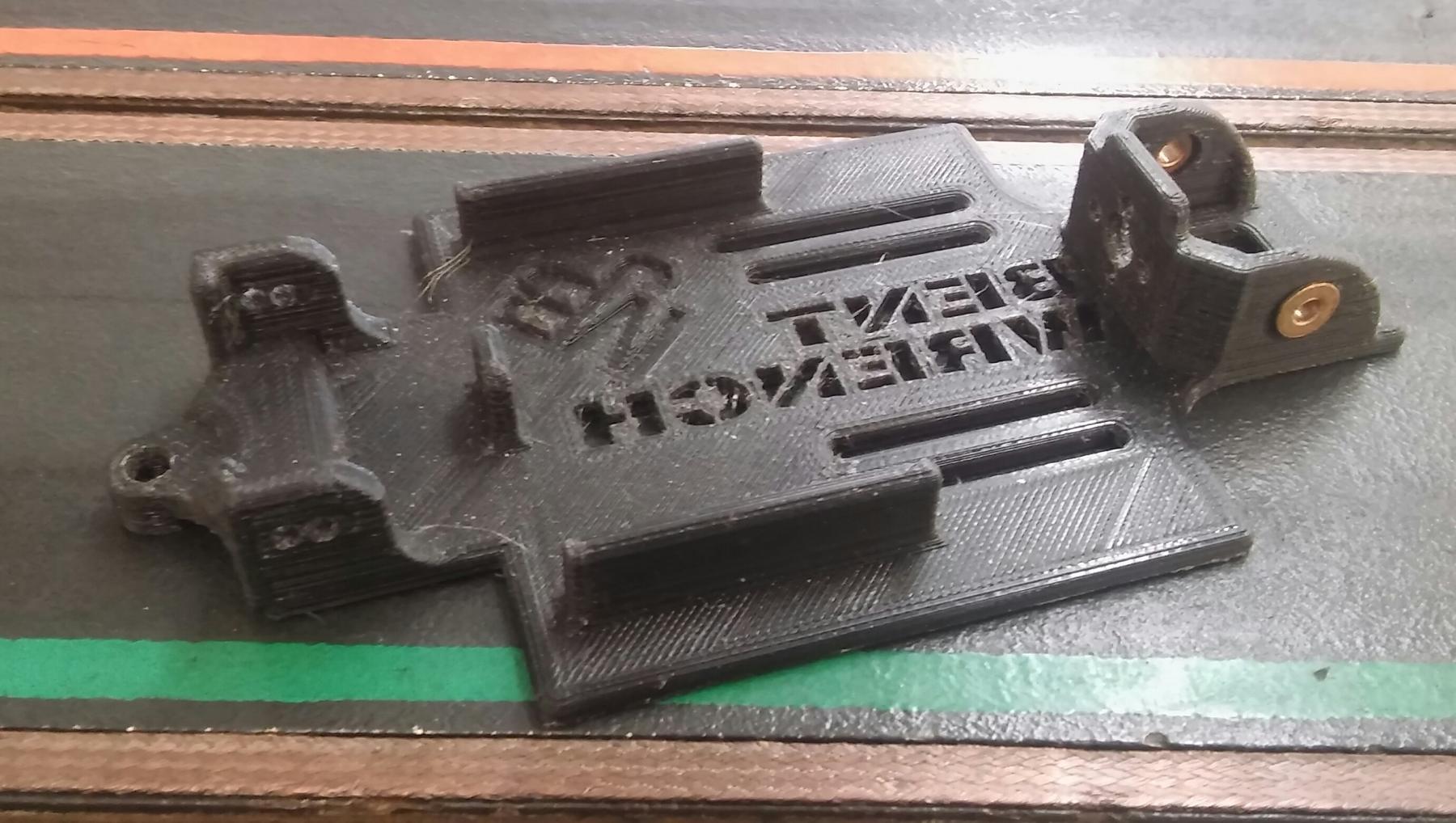

I have sent my design to Shapeways, and ordered my first sample in plastic, which should arrive in a week or so.

I hoped to be able to order a brass version, but the chassis exceeds the size limits for brass (about 3.5 x 3.5 inches is the max), and some parts like the bracket, are listed as too thin to print in brass. I could order an aluminum version for about $275. Stainless steel is almost reasonable $50 to $60, and nylon might work too, at approx. $40. The plastic version that I ordered will be about $20. (These are prices for the raw materials, and excludes any shipping, designer profit, etc. )

Already I have learned a few lessons to share, and found many questions I could use help on.

So, any comments or suggestions, so far? Thanks.