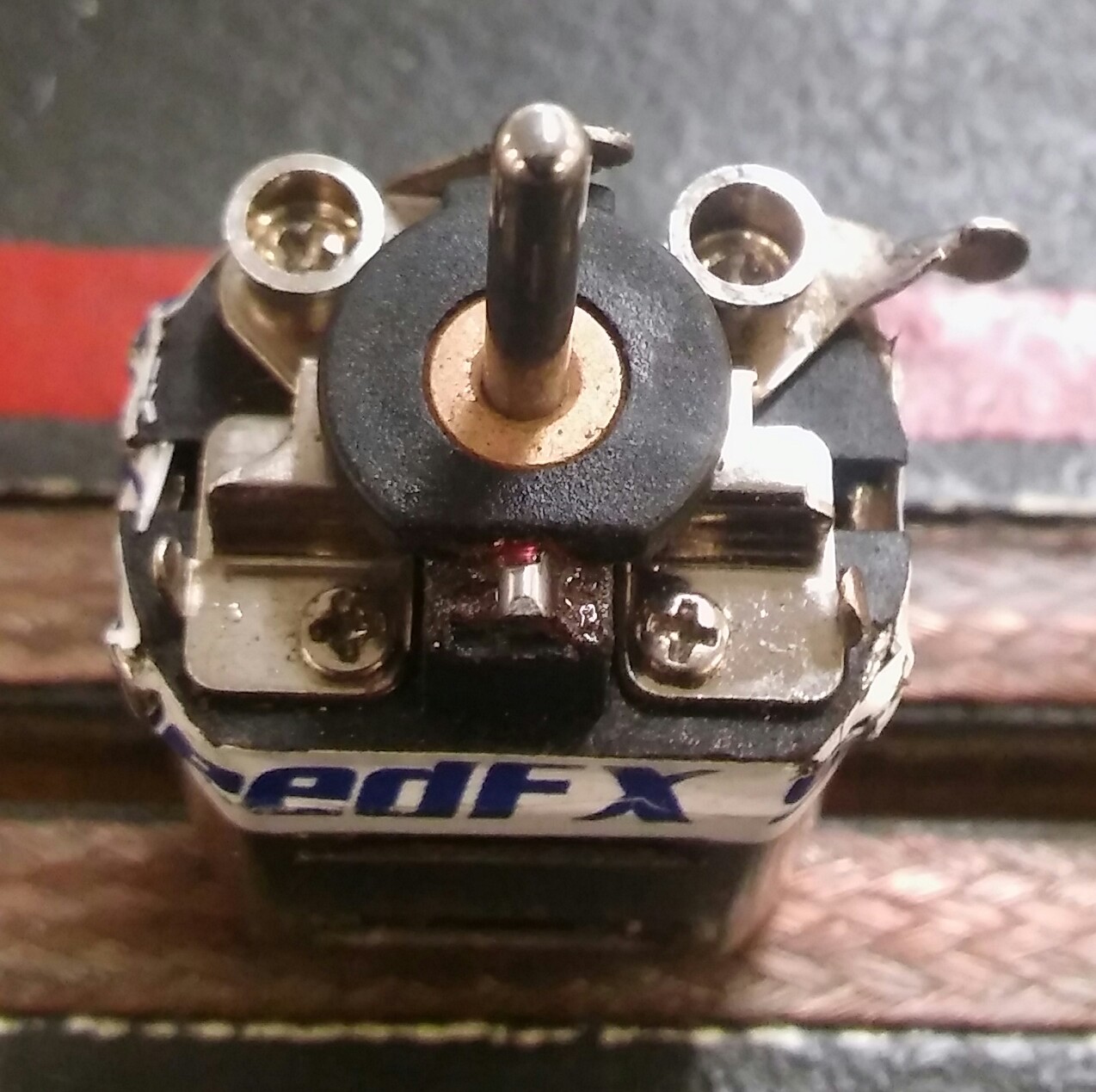

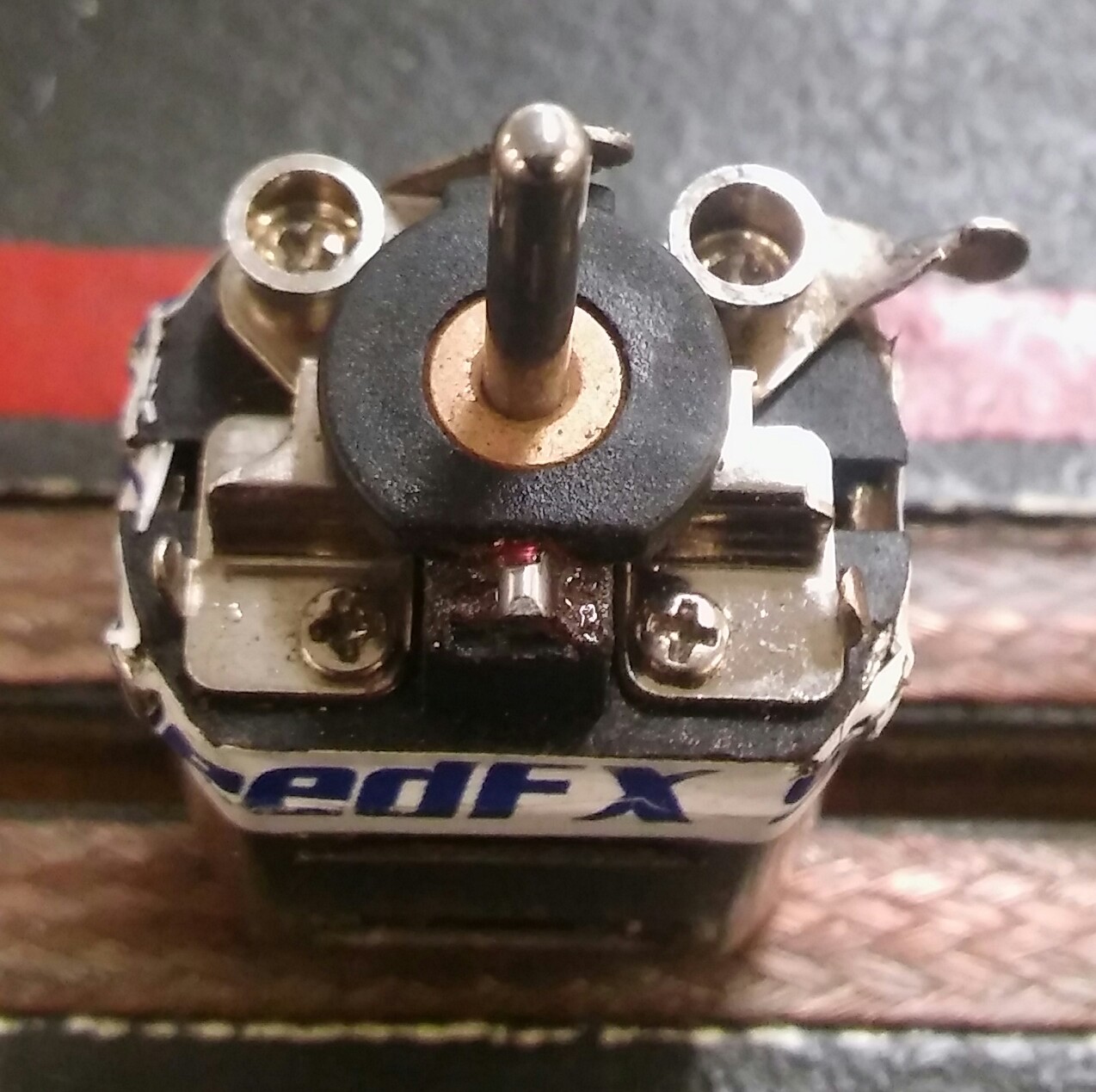

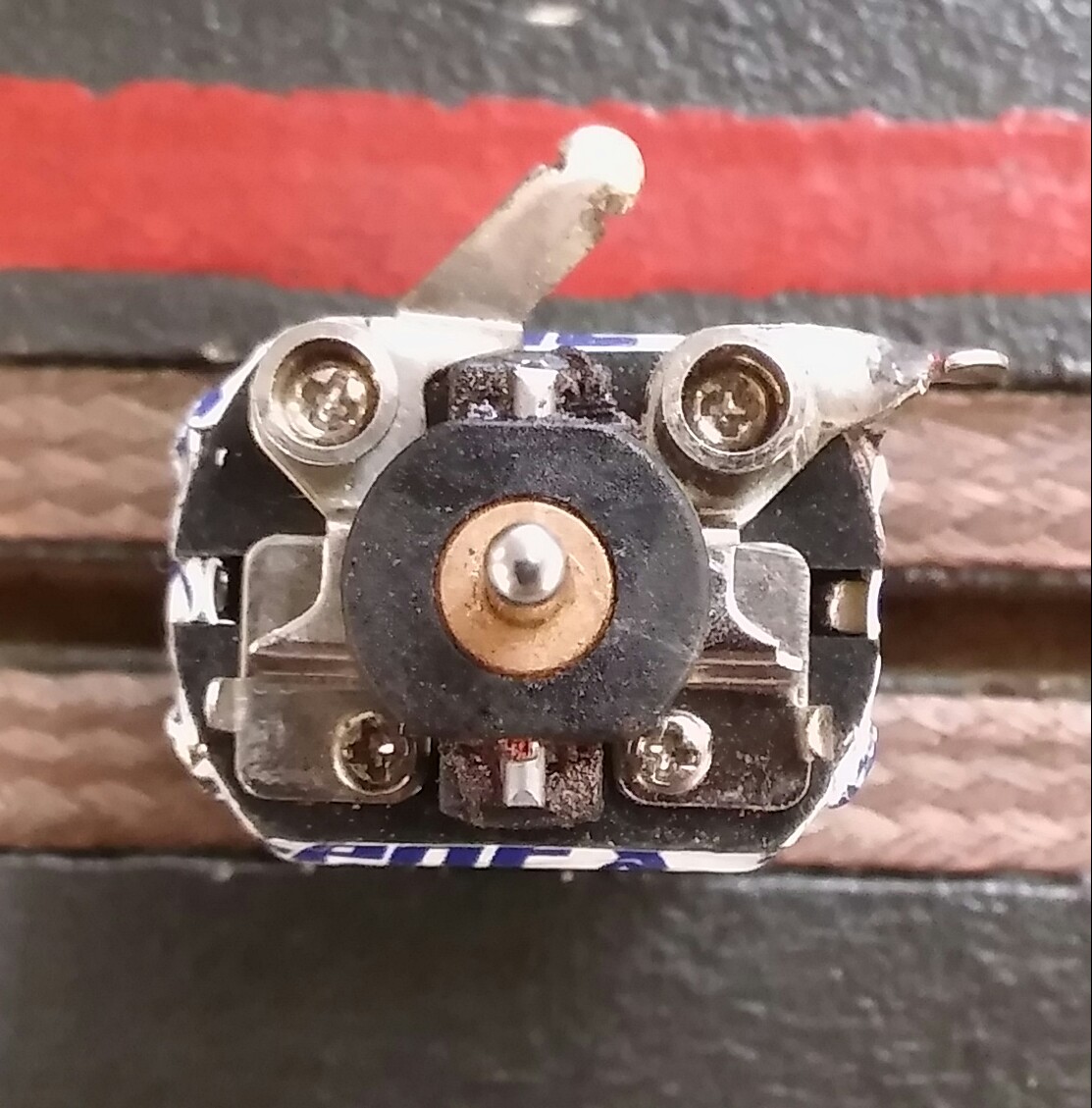

It has a piece of .045" wire keyed into a hole that is not quite drilled through the body of the oilite

Posted 04 April 2018 - 05:43 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 04 April 2018 - 05:54 PM

Nice. I'm going to need that trick sooner or later ![]()

The PS EB I adapted onto a 13uo motor yesterday had a loose bushing.

Question, is that red stuff Loctite, and does it adhere well to the EB material?

Paul Wolcott

Posted 04 April 2018 - 05:58 PM

Posted 04 April 2018 - 06:05 PM

Steve Meadows

Posted 04 April 2018 - 06:10 PM

the endbell gets hot and then soft ... losing grip on the bushing

Posted 04 April 2018 - 06:46 PM

Why do you need something so strong to stop an oilite spinning?

It’s not like the arm shaft can really grab it...

In my mind, I can only really see vibration making the thing turn, but surely it will stop at the point of least resistance, which is ideal.

If it’s turning it can only be because it’s binding due to poor alignment, so why pin it bound up?

Sent from my iPhone using Tapatalk Pro

This is a problem for both the ProSlot and the JK Hawk motors, although maybe a "little" less so for the Hawk. Having said that, here's the reason(s) it should be fixed.

*the oilite is loose and can spin in place...no...it doesn;t just stop at some point, it will spin more and more with time.

*as the oilite is spinning in the now-warm and softer end bell plastic, the pocket it sits in gets slightly larger, meaning more spinning and a continually looser pocket.

*as the oilite spins and the pocket gets a little sloppier, the commutator end of the armature that rides in that oilite is now riding less true and can also move around, even vibrate a bit.

*all the above keeps happening and current draw can go up, along with heat and the motor is running less efficiently.

This doesn't necessarily happen with every motor, and variances from motor-to-motor in terms of end play might make any motor more or less prone to the problem. Any motor with a loose end bell bushing/bearing should be fixed.

Posted 04 April 2018 - 07:09 PM

I don't see the problem as being the bushing "spinning", but I agree a spinning bushing isn't good.

The way I see it, the problem is the bushing backing out and riding against the comm.

All racing motors should have a certain amount of "play", or "slop" while being centered in the magnetic field.

When that "play" or "slop" is not present, or lost, it creates friction, which turns to heat, lost power, etc.

If and when that bushing slides free of it's factory press fit and migrates to the comm, removing the arm "play",

performance goes right down the drain. Arm gets hot, motor slows down, ending in an eventual "cookoff" ![]()

Mike's idea would preclude that. As John H. points out, any bushing movement isn't good.

swodem, I think if Swiss told you the sky is blue on cloudless days, you'd argue with it.

The problem is, this is a public forum. ![]() "Don't be a wanker". Your words, not mine.

"Don't be a wanker". Your words, not mine.

You have enough experience with racing motors to understand all this.

But you just love to argue.

See your post #90 here:

http://slotblog.net/...e-4#entry684321

Paul Wolcott

Posted 04 April 2018 - 09:22 PM

If you think this can't happen check the motor I ran in our Outlaw Can-am race 2 week ago worst case scenario is what you will see about 30 sec into the 6 heat of the race last lap turned was a 3.03 then boom on the back straight

jason

at least use some super glue before you oil and break it in but not much

Posted 04 April 2018 - 10:21 PM

Probably any rule set that requires a sticker, wouldn't allow it.Mikes solution looks great for a sealed fk.

If your not running sealed motors it's best to shoot the endbell and oilite with brake clean or your choice of acetone and use JB weld or other super strong, slow curing epoxy to set the bushing.

JB has never failed me

Yes, Loctite 271.Nice. I'm going to need that trick sooner or later

The PS EB I adapted onto a 13uo motor yesterday had a loose bushing.

Question, is that red stuff Loctite, and does it adhere well to the EB material?

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 05 April 2018 - 03:07 AM

Livin the dream!

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven

Posted 05 April 2018 - 05:52 AM

The way I see it, the problem is the bushing backing out and riding against the comm.

Yeah...except I've actually seen them spin Pablo. ![]() What I *think* may happen is that, the bushing does back out (*why I mentioned end play being a possible factor), and the fit between the bushing and it's bushing pocket becomes even looser at that point. I don't know if friction between the back end of the bushing and the top end of the com (*or actually the com spacers) is the main problem, but it's probably a significant one. I think of it this way; if the com bushing was loose enough to back out, it's probably also able to ride back-in. No matter what though, a loose end bell bushing is not a good thing, as Jason pointed out above.

What I *think* may happen is that, the bushing does back out (*why I mentioned end play being a possible factor), and the fit between the bushing and it's bushing pocket becomes even looser at that point. I don't know if friction between the back end of the bushing and the top end of the com (*or actually the com spacers) is the main problem, but it's probably a significant one. I think of it this way; if the com bushing was loose enough to back out, it's probably also able to ride back-in. No matter what though, a loose end bell bushing is not a good thing, as Jason pointed out above.

Posted 05 April 2018 - 07:18 AM

I am not questioning the need for or the effectiveness of the pinning.

In a class requiring sealed cheep motors would a fix requiring this much skill and effort be within the spirit of the rules? A little CA or epoxy seams more fitting even if not as effective.

Posted 05 April 2018 - 08:22 AM

In a class requiring sealed cheep motors would a fix requiring this much skill and effort be within the spirit of the rules?

Of course not. Probably why the OP put the thread in "Motors & Motor Building" vice "Retro Racing".

Lots of guys are using those type motors for "other than sealed motor racing", like my Go-kart.

H arm in a Puppy Dog PS 4002B

Paul Wolcott

Posted 05 April 2018 - 10:15 AM

The Proslot endbell bushings have been a problem for a very long time. When I blueprint a motor I always epoxy the bushing in place. The problem on the PS 4002FK is the bushings are glassy smooth and so is the endbell bore. If the bushing was rough it would hold it's place better. Since this is a sealed motor I've gone to just super gluing the bushing. You need to use a brand new tube of the glue so it seeps between the bushing and the endbell bore. If the glue is thick it just won't do the job. I just push the bushing down until it contacts the comm. then rough up what I can on the endbell bore. Very carefully apply the glue around the very edge of the bore and quickly push the bushing back in place. I have also tried just applying the glue to the bushing and endbell without moving it but it didn't work as well.

Posted 05 April 2018 - 10:49 AM

Swiss! A little food for thought! Using Loctite on your guides is not the same as using it on your bushings. The "MAJOR" difference is the amount of heat that develops in the two cases. You should never obtain the amount of heat at the guide that is developed at the bushings, and we know what heat does to Loctite! Please excuse my drift, but I feel that caution should be taken when using this method to pin an endbell!

Posted 05 April 2018 - 11:09 AM

I used Blue Loctite, successfully, to keep screws from backing out, in aluminum endbells, for 20 years, in G7 open motors.

The type of heat required, to loosen that Loctite, would of already melted the endbell.

IOW, I wouldn't be touching the pin directly with the tip of a soldering iron, from a 800-1000 degree iron.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 05 April 2018 - 11:17 AM

I am not questioning the need for or the effectiveness of the pinning.

In a class requiring sealed cheep motors would a fix requiring this much skill and effort be within the spirit of the rules? A little CA or epoxy seams more fitting even if not as effective.

I'm not telling anyone to do this.

I'm just making the technique aware to guys like John H. who make motors that are not governed by exact rules.

On FB, when the new 4007 was announced, a lot of racers complained about endbell bushings coming loose, as an issue, with this style motor.

Top racers chimed in that they still had them come loose, despite gluing them.

A minor aside, most orgs who use this motor, in the sealed form, allow soldering the can bushing in.

Has anyone ever spun a can bushing in one of these motors?

I've never seen it and we use this motor extensively.

It seems like soldering in the bushing would be like walking in MacDonalds, and purchasing insurance from getting hit with a meteor.

I went ahead and put a top pin in.

I'll take the motor apart tomorrow or Saturday and see what kind of effort it takes to move that bushing.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 05 April 2018 - 01:05 PM

Yeah, this issue isn't exactly some sort of "top secret", and the reason for fixing it (when the rules...or lack of rules allows) should be pretty obvious. Personally, I think a bushing with a splined outside and a slightly tighter fit *might* have solved the problem, but that would not be an easy/cheap thing considering how many of these things get produced, and how many are sitting there waiting to be purchased from the last production run.

I'm just making the technique aware to guys like John H. who make motors that are not governed by exact rules

It's a good idea, and one I haven't tried, but I have been doing something about it for a while. Slightly (not much) more involved, but not at all applicable for motors that need to have their seals unbroken. I *think* being able to take care of it with a pin should be OK with the rules (?), but that's not my thing.

Posted 05 April 2018 - 01:57 PM

Tiresome.

Used to be there were serrated bushings in plastic endbells.

Then there weren't.

Needless complicated Rube Goldberg hassle to fix something that was unfixed long ago for whatever reason.

....never mind.

Jim Honeycutt

"I don't think I'm ever more 'aware' than I am right after I hit my thumb with a hammer." - Jack Handey [Deep Thoughts]

Posted 05 April 2018 - 03:04 PM

Posted 05 April 2018 - 03:50 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 06 April 2018 - 03:39 AM

"Has anyone ever spun a can bushing in one of these motors?"

I have spun can bearings in two of them. ![]()

![]()

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven

Posted 06 April 2018 - 06:13 AM

The 'flusher fix' pin probably is not needed. Drill the hole and fill with red loctitie should be sufficient. Do 180 dregree opposed if need be.

Bob K.

Posted 06 April 2018 - 06:30 AM

I'll take the motor apart tomorrow or Saturday and see what kind of effort it takes to move that bushing

I'd be surprised if you *could* move it short of doing damage to the end bell itself. It should be about as strong as you could make it. I've tested my way and it seems very strong. Yours seems way stronger.

Using nylon rod would work just as well. Steel pin seems like overkill

Nylon rod that small (whatever hole you drill needs to be small enough not to weaken the entire end bell) would be more fiddly than using piano wire...may as well use use monofilament fishing line. Steel wire may be stronger than is necessary, but it's ridgidity makes it a really good choice.

Used to be there were serrated bushings in plastic endbells.

Then there weren't.

Exactly right. Some sort of a "knurled" or grooved OD on a bearing meant to be installed in plastic seems like it *should* be the norm...and it was!

The 'flusher fix' pin probably is not needed. Drill the hole and fill with red loctitie should be sufficient. Do 180 dregree opposed if need be.

Bob

Huh? End-bonding plastic that probably doesn't do well with any adhesive...even with drilling...in an application where the plastic is a long-arm "actuator" (lots of leverage) is bound to fail, probably after a few flushes at best. I'm not sure that even the heavy steel pin would last for long, but it doesn't have to since a flush arm costs around $2-3 and the replacement takes minutes. Still, the pin gets you a working toilet until the replacement can be done.

"Has anyone ever spun a can bushing in one of these motors?"

I have spun can bearings in two of them.

Yikes...that's one I HAVEN'T seen! Bummer! I've wondered why people solder them in myself...until now!

Posted 06 April 2018 - 06:35 AM

John,

My suggestion was for the endbell not the toilet flusher. Basically same drilling technique but do away with the 'pin' and let the loctitie alone do the work. Drill and loctitie in 2 places for added security.

Bob K.