I want to give you a little history on these cars. This class was started by a guy named Dan Dyke here in Cincinnati. He was the first to cast the bodies in resin and make up the rules for this class. Starting out the chassis had to be made of wood. Most of the guys used popsicle sticks for the main rail of the chassis.

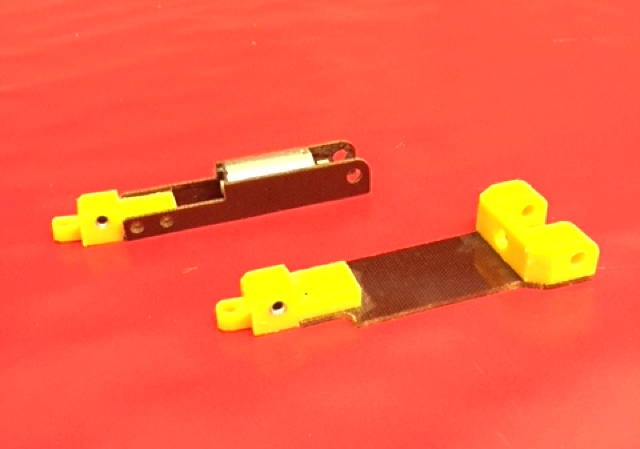

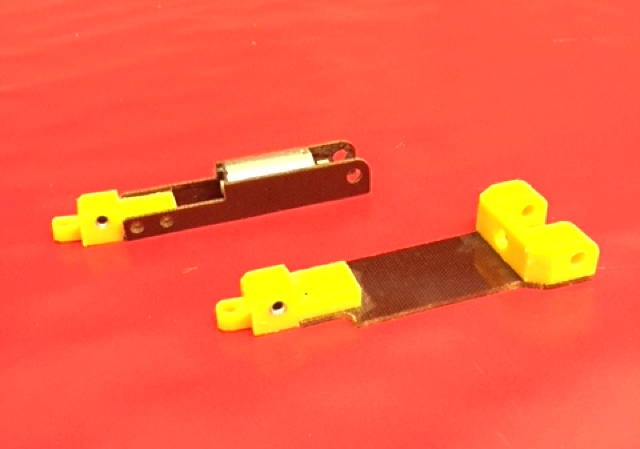

One of the guys in the series made a mold and casted chassis out of plastic. The guys liked it so plastic and wood chassis were legal. Since plastic was now legal I had some 1/2” thick plastic in yellow and black that I cut into nose pieces and motor brackets. I then bought a piece of 1/16” phenolic (which is plastic) and cut out the pieces to hold the motor bracket and the nose piece. I use little 1.6 x 4mm flat head screws to hold them together.

Dan is no longer making bodies and we basically out of them so another guy in our group made a 3D printed body and chassis combo. You just snap the motor and guide flag in, install your axles and gears and you’re up and running. Since his body is a lot lighter than the casted resin bodies I decided to make them out of PETG.

So that’s where we’re at right now. It’s a fun little car to race, the motors cost about $1.50 if you order a hundred of them so that’s what Dan and I did, we split a hundred of them. I’ve never had to replace a motor yet and we run them on 13.6 volts. I’ll be selling these bodies for $3 each and I sell the motors for $3 each. I’ll be rich before you know it. LOL

The first two pictures are my vacuum-forming machine. The 2x4 post's are my guides to keep the frame centered over the platen. In the background of the second picture is my toaster oven I use to heat the PETG.

Third picture is my vacuum pump (it's old but it works) and the fourth picture is the frame that holds the PETG.

The fifth and sixth pictures are the mold that supports the body so I can back-pour it to make more molds. The seventh picture is the body I used to make the mold and I'm going to use to back-pour.

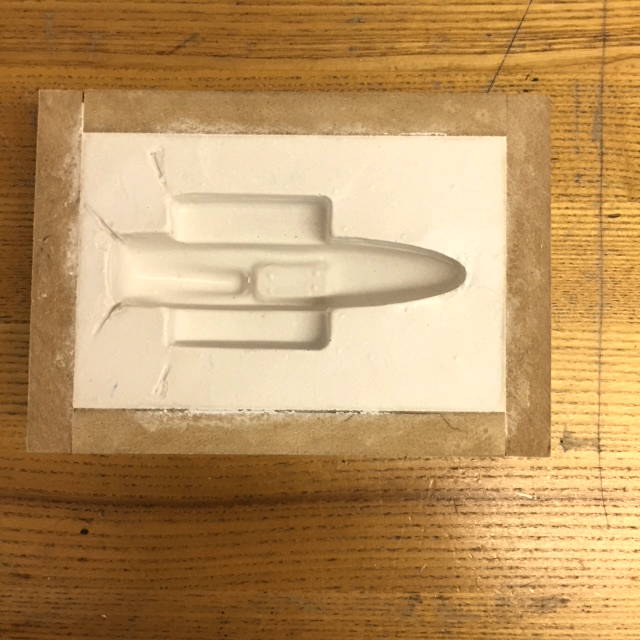

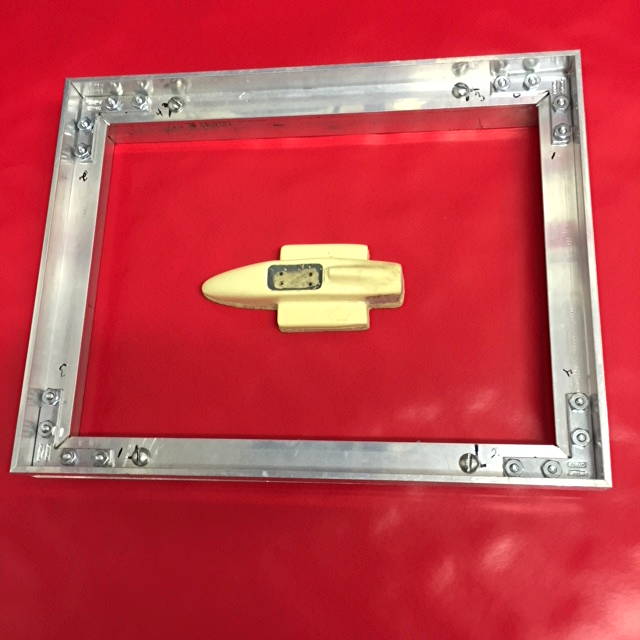

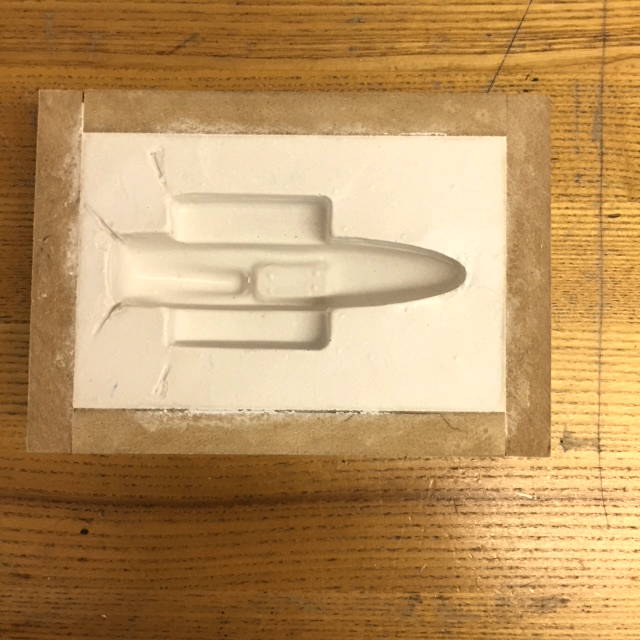

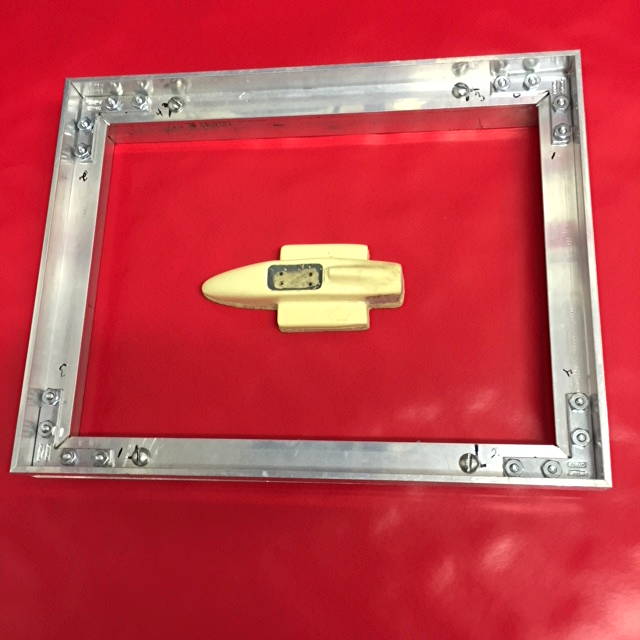

Eighth, ninth and tenth pictures is my mold. It's one of resin-casted bodies that we race that I modified to work as a mold. As you can see I put some wood filler on it but it still needs some sanding and cleaning up.

The rest of these pictures are just to show you how we make these cars. All the bodies are plastic resin and the chassis can be made of wood or plastic, no brass or piano wire.

Jim "Butch" Dunaway

I don't always go the extra mile, but when I do it's because I missed my exit.

All my life I've strived to keep from becoming a millionaire, so far I've succeeded.

There are three kinds of people in the world, those that are good at math and those that aren't.

No matter how big of a hammer you use, you can't pound common sense into stupid people, believe me, I've tried.