Martin,

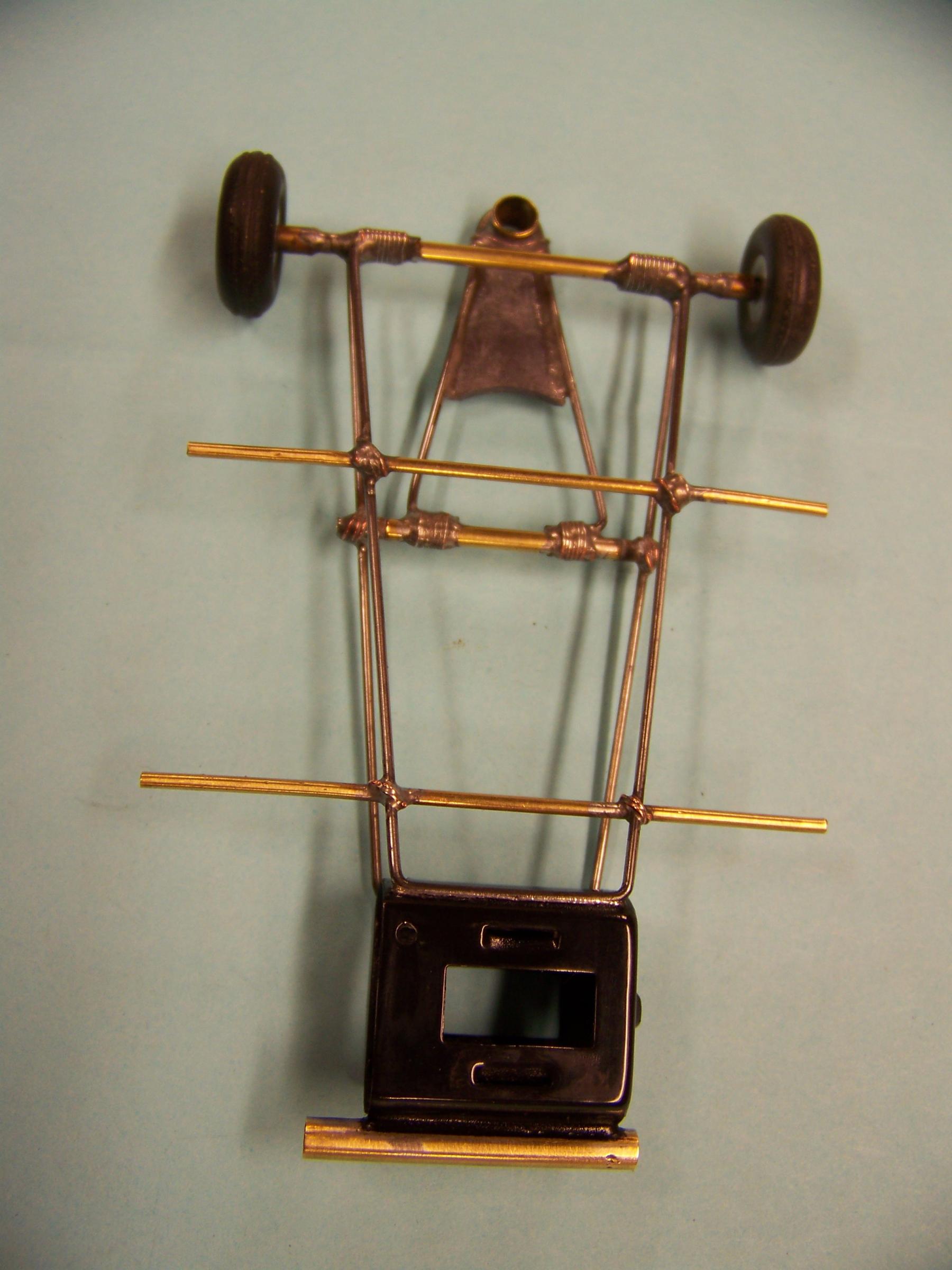

Gotta agree with Don about those front wheels; they are far smaller (proportionally) than the rears, so using a body that is a replica of an actual race car (Lola T70, Cooper Ford, etc.) is not going to end up looking so good.

Just my opinion – yours may vary. ![]() Better it should be a Thingie or a show car or an imaginary car (like the Avenger) – or a drag car.

Better it should be a Thingie or a show car or an imaginary car (like the Avenger) – or a drag car.

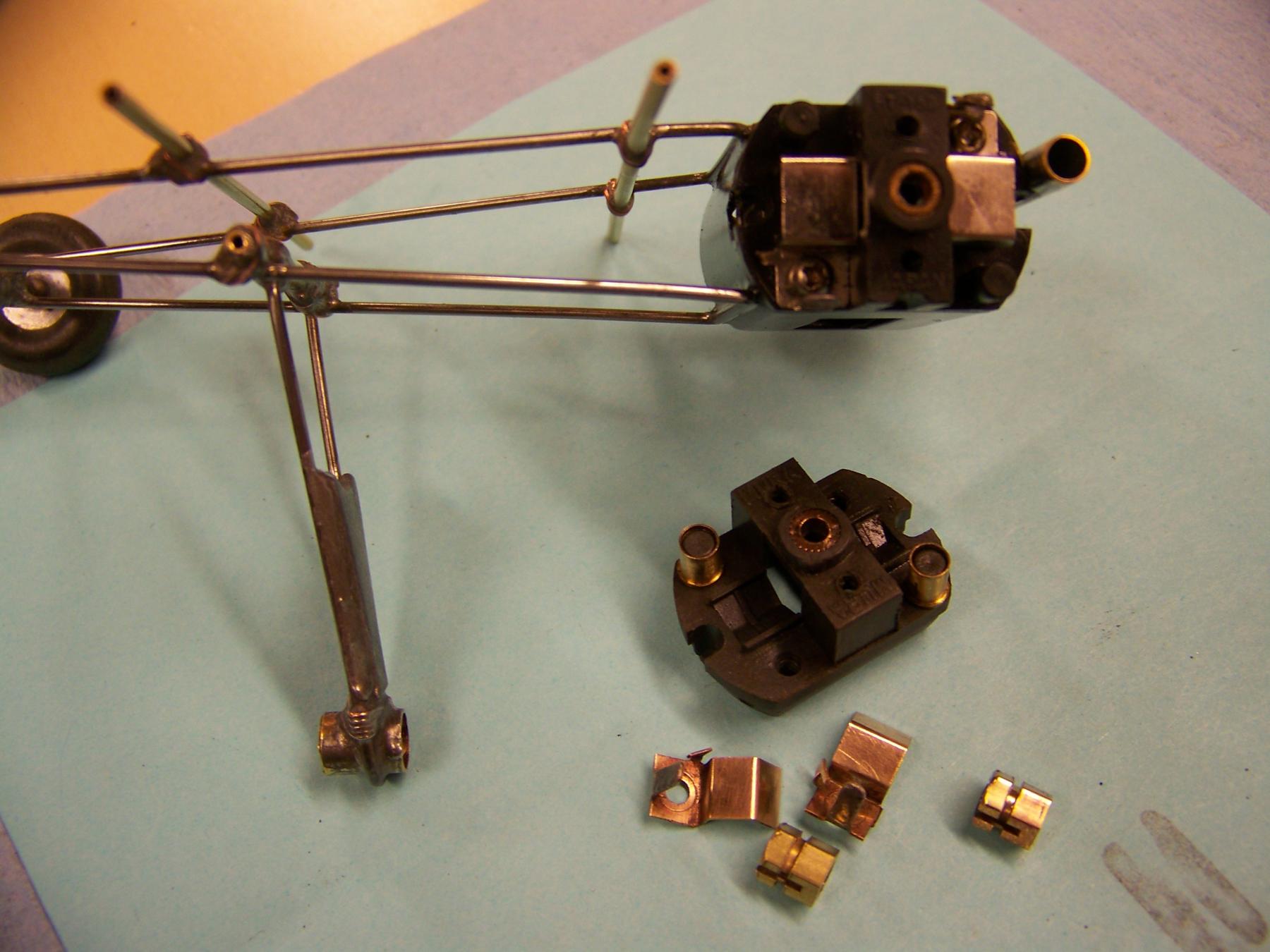

About the gearing, those larger rear tires will make a significant difference in gearing requirements. Instead of simple gear ratios, you might consider selecting gears (and your motor) based on the Final Drive Ratio, which takes the tire size into account

To calculate Final Drive Ratio, the formula is gear ratio divided by tire size.

So for example a vintage anglewinder with a higher RPM 26 gauge motor, 7/8” tires and 8x34 (4.25) gears would be 4.25 divided by .875, or 4.86 Final Drive Ratio.

A more modern Flexi-car with a higher torque, lower RPM 16D motor, .750” tires and 14x39 (2.79) gears would be 2.79 divided by .750, or 3.71 Final Drive Ratio.

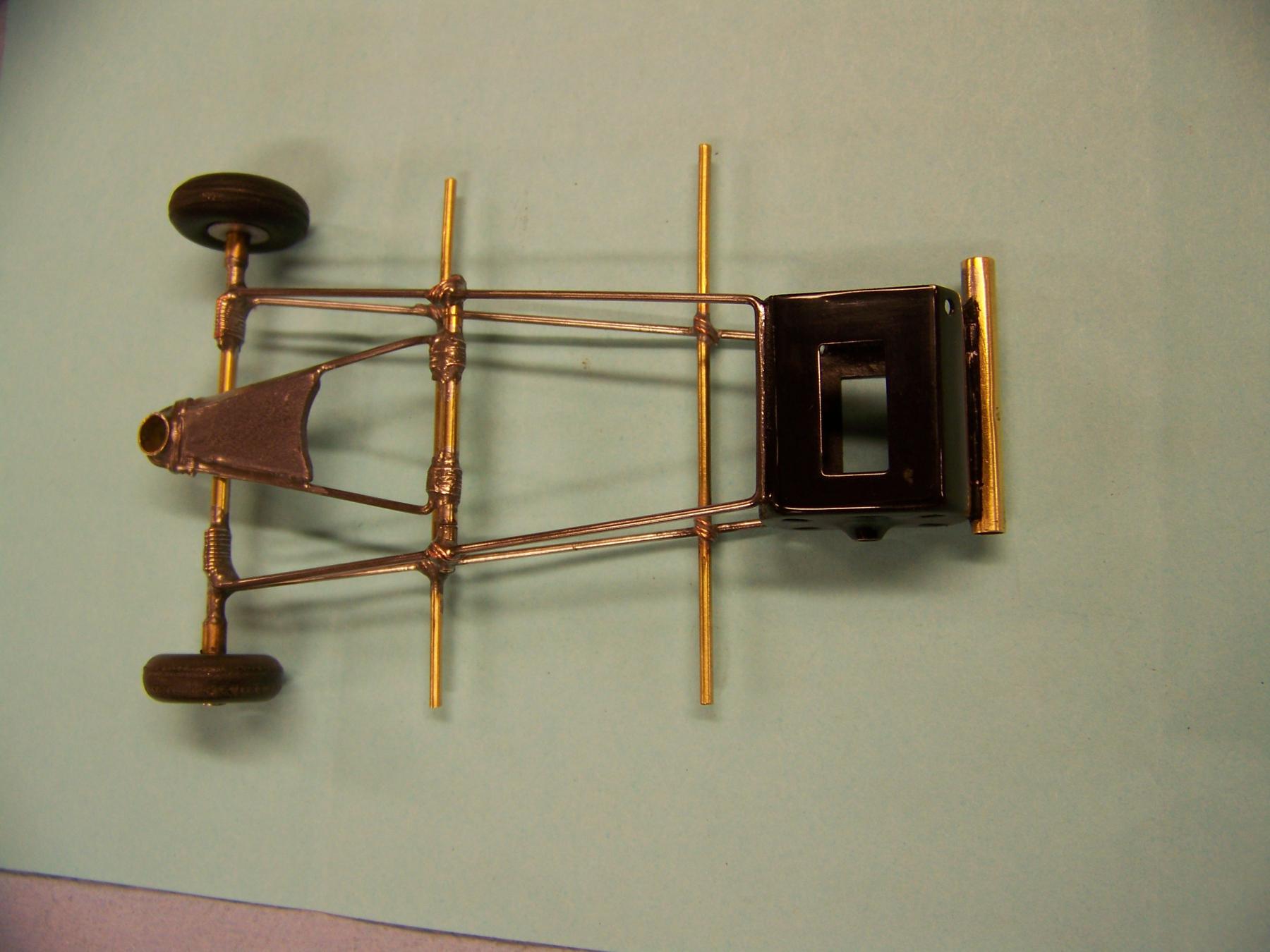

In your car, the 12x39 gears are 3.25 ratio and the tires are 1.063. So the Final Drive Ratio would be 3.25 divided by 1.063, or 3.06 (that's pretty low).

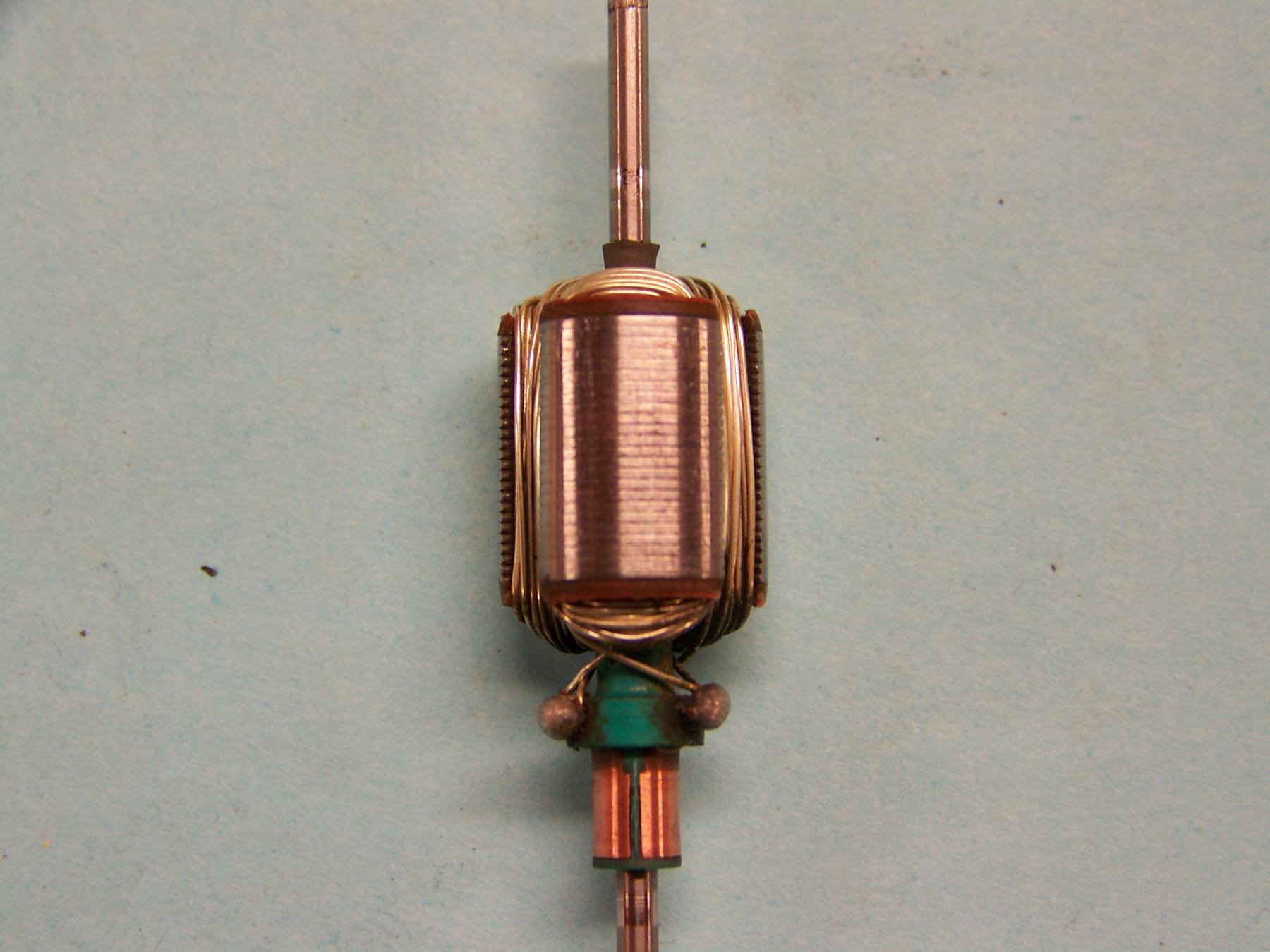

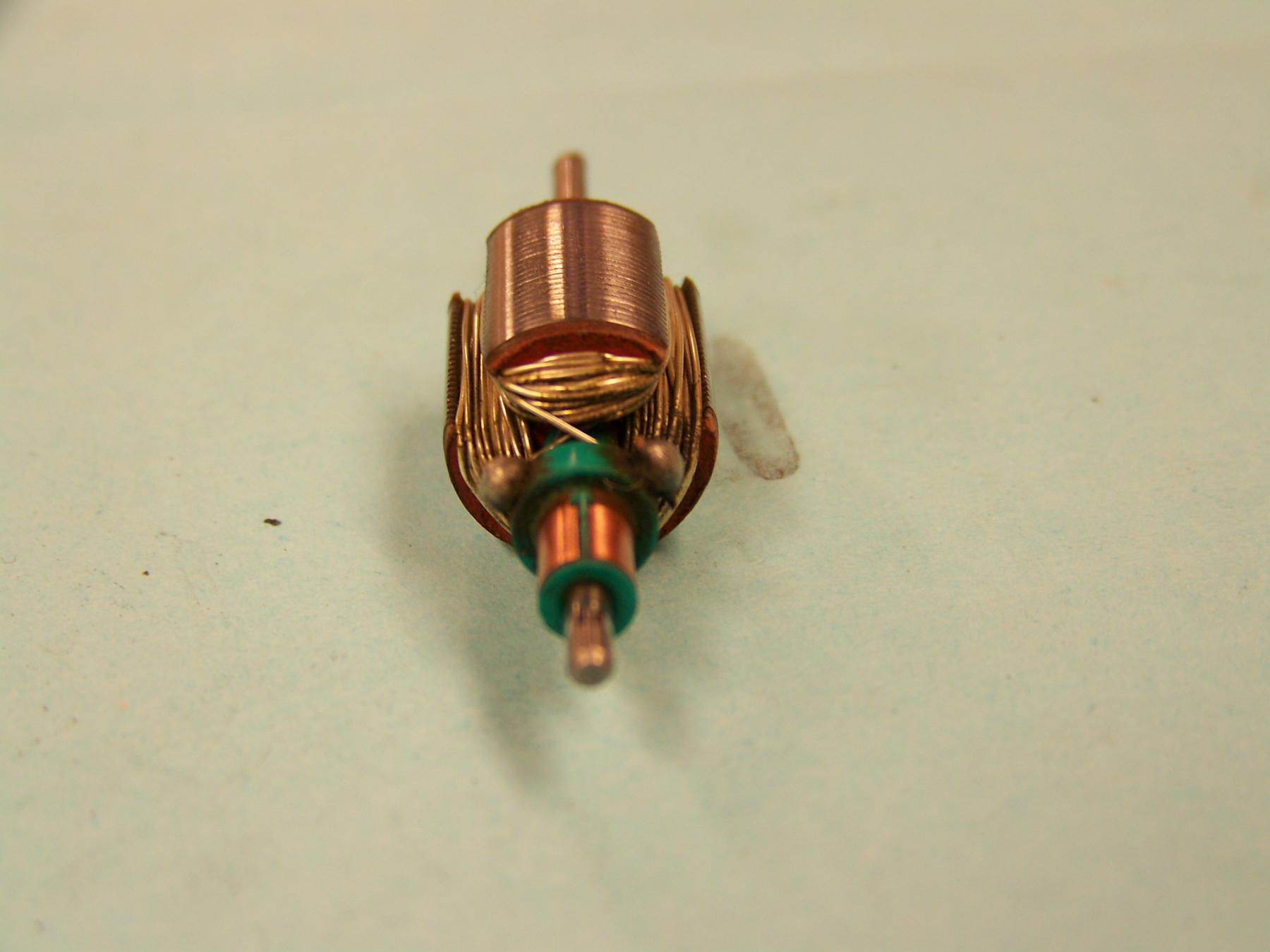

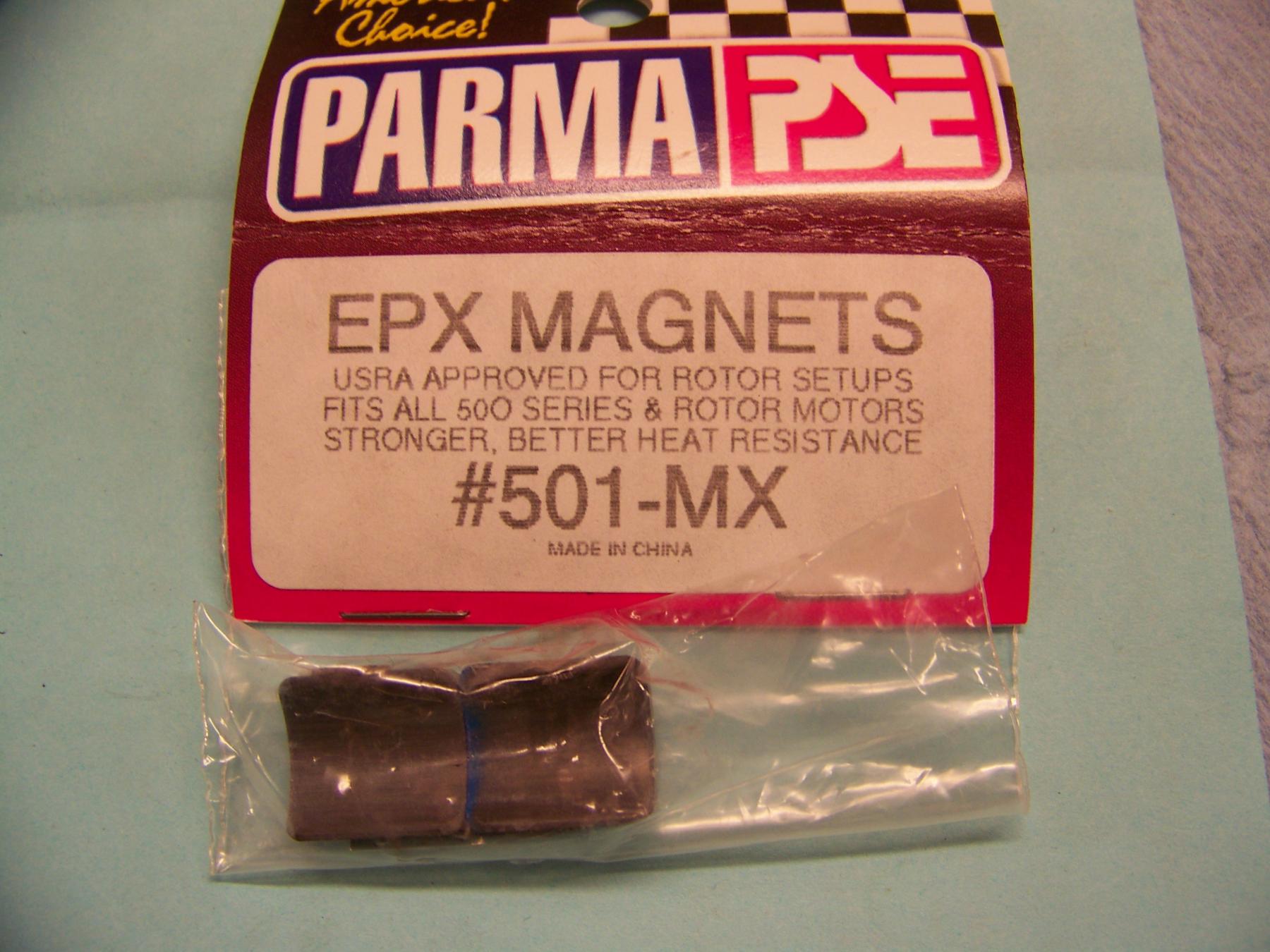

You’re going to need a relatively higher torque, lower RPM motor (something like a modern .560" diameter 16D arm and strong magnets) or a taller gear ratio (11x40 which gives you a 3.42 Final Drive Ratio) or both to power the car effectively (in other words make it go fast).

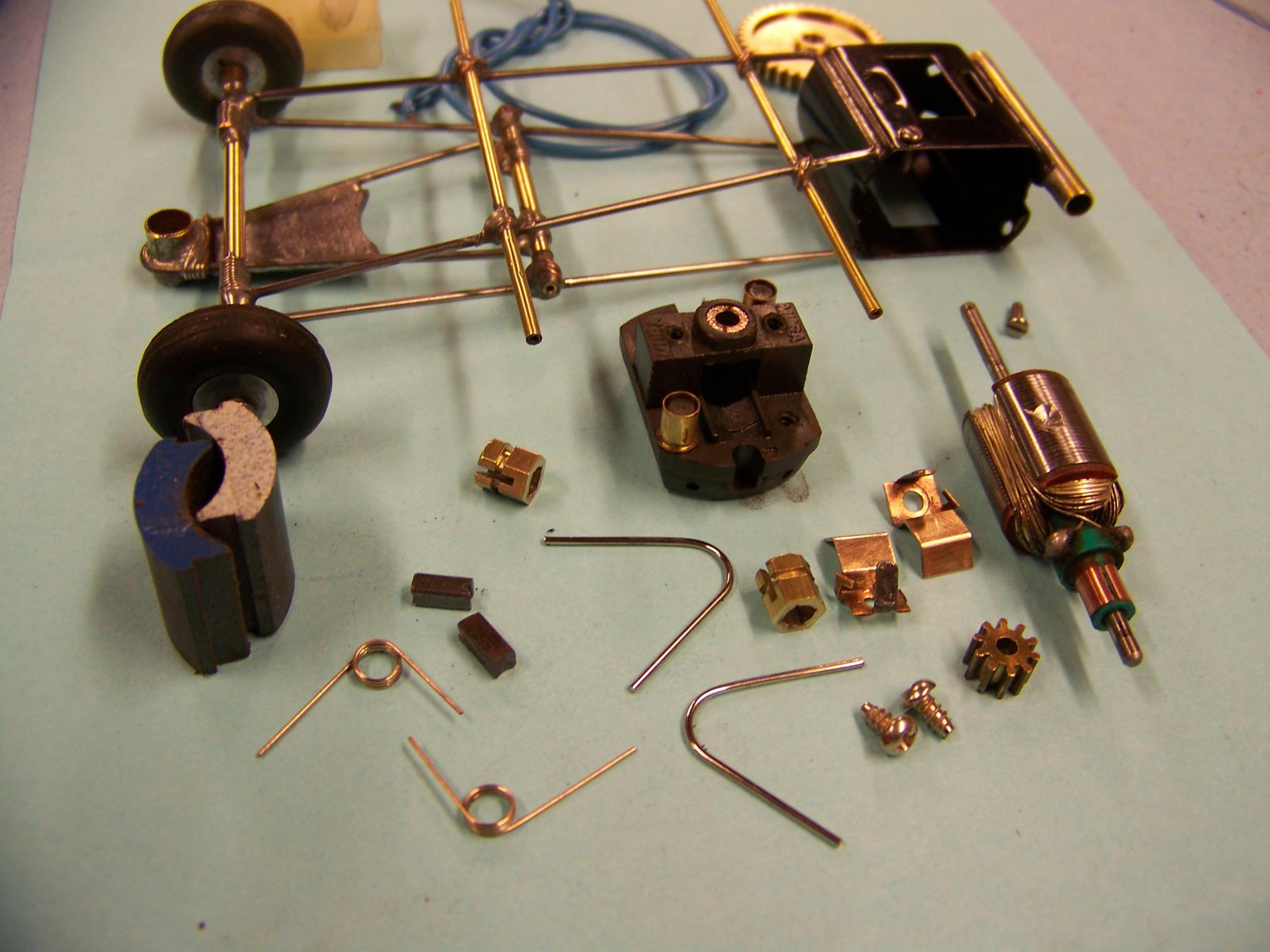

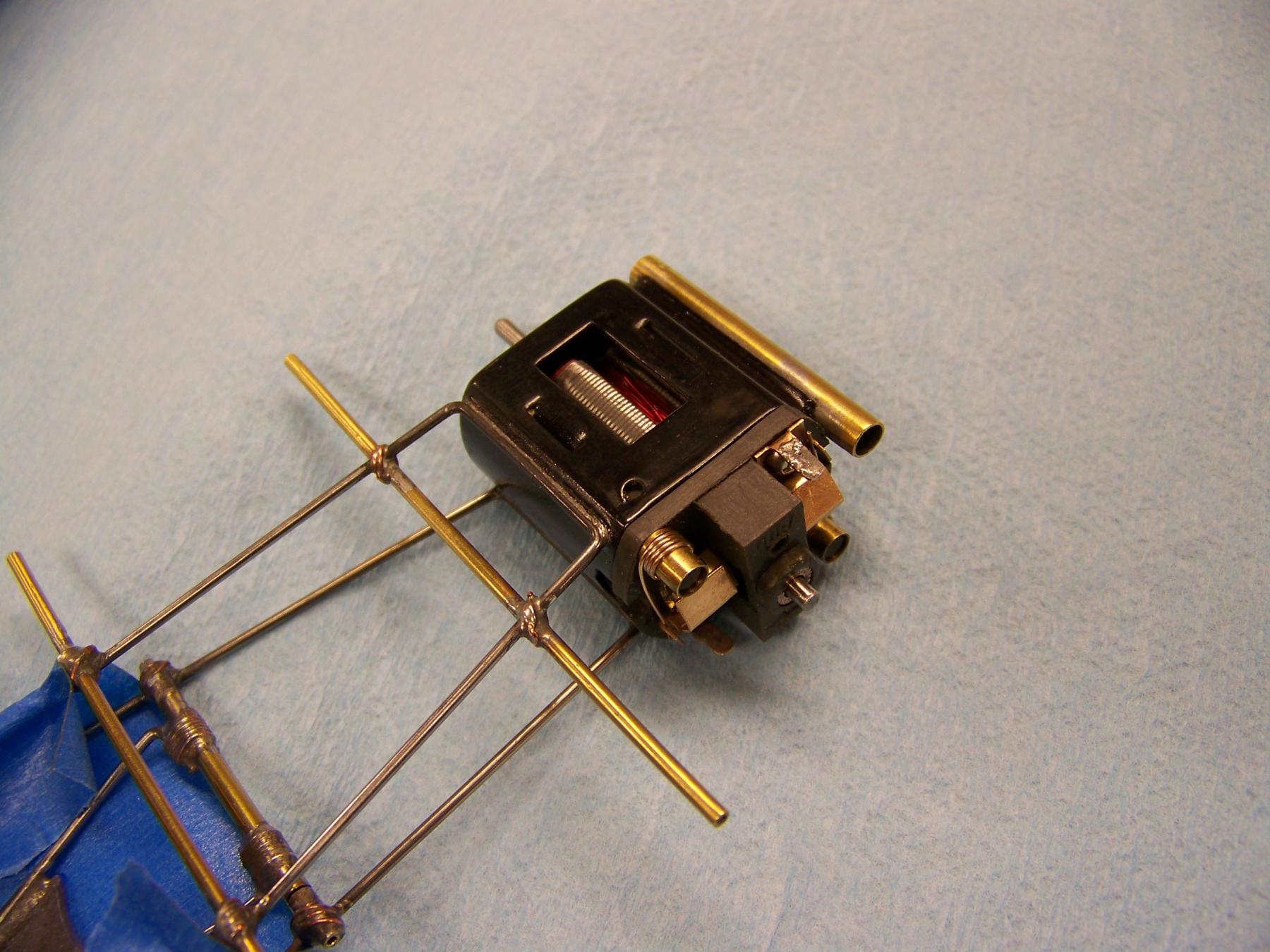

Side note: This is a case where I would not use 64 pitch (example: Weldun) gears. They require a fairly close and precise mesh, and there is too much slop in the 5/32" axle tube, which means they could chew themselves up pretty quick... ![]()

BTW the ProSlot website (www.proslot.com) has a nifty Final Drive Ratio gear chart if you want to let it do the math for you.

Carry on! ![]()