How to Make a "Thingie\RTR" Universal Tire Machine

Cost around $70.00 and some labor.

I will be using a bead drilling machine

example; https://www.ebay.com...US!-1:rk:2:pf:0

Watch how this works;

https://video.search...251&action=view

Most "Thingie\RTR" cars require modified tire sets using rims with fresh glued tire donuts.

So lets get started, study the photos

I wanted a universal tire sander\grinder for Thingie\RTR kit cars.

A tire sander\grinder with 120 volt horse power with direct drive, also variable speed control.

A tire sander\grinder that can fit up 1\8" axles, 1\8" threaded axles and maybe a 3\32" axle, change out easily.

A tire sander\grinder that can service 2 tires at once.

Study the photos.

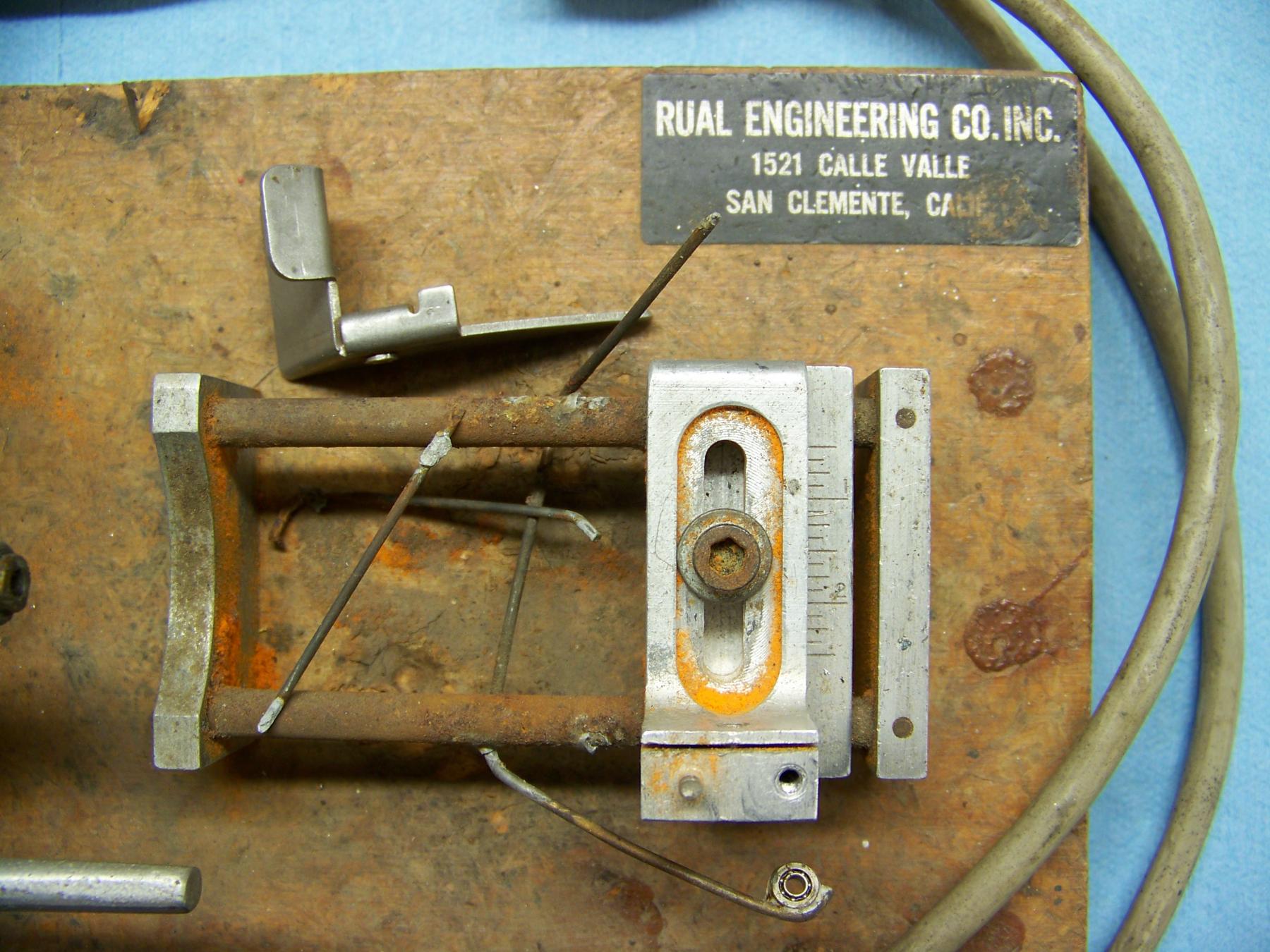

The bead drill

Remove these parts from the gold 2 vertical jaws, not needed

Parts removed

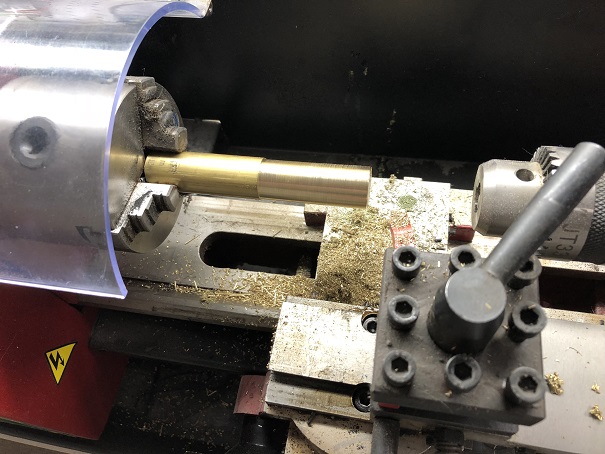

Get a piece of 3\4" brass rod and turn down so it will fit into the hole as shown in parts removed photo.

Make 2 brass disks as shown

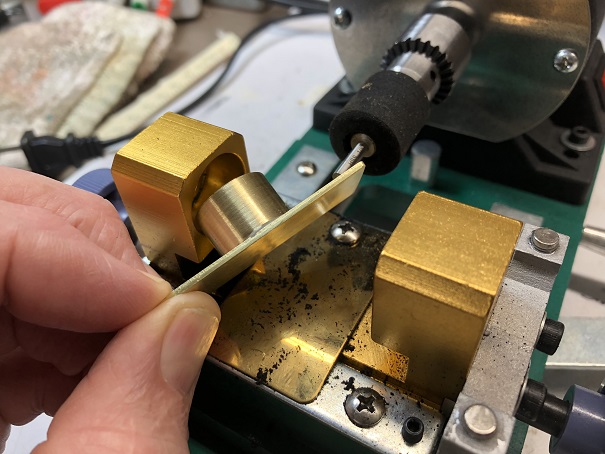

Test fit the disks into the gold 2 vertical jaws and make sure they extend just past the vertical jaw as shown

Make 2 flat pieces of brass flat stock, 3\4" x 2" (sanding pad plates), use JB Weld and glue the brass disc to the brass plate. Let cure for a couple of days.

Test fit the brass assembly in the hole as shown.

With the brass assembly in place for a fit up look over.

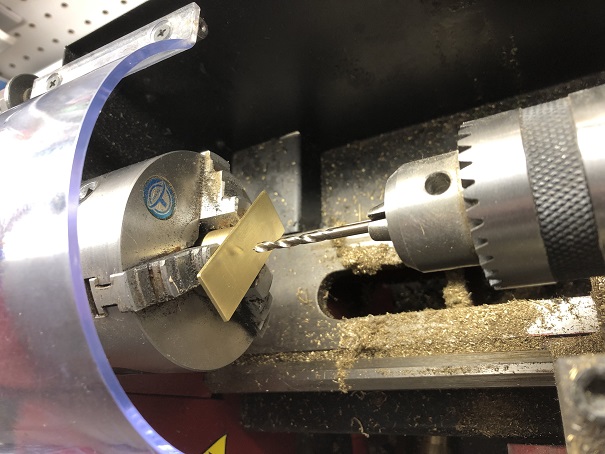

Now setting up to do a center bore shot in each brass assembly.

Power on boring a hole, hole diameter must accept the #6 flat head bolt.

After the center bore is complete flute out to accept the #6 flat head screw, must be flush with the brass sanding plate.

Cut sand paper, your choice of grit, apply some spray glue. I will be using peel and stick paper later, just wanted to test this contraption out. PLACE THE FLAT HEAD SCREWS IN THE BRASS PLATES PRIOR TO PLACING SAND PAPER ON THE BRASS PLATES!

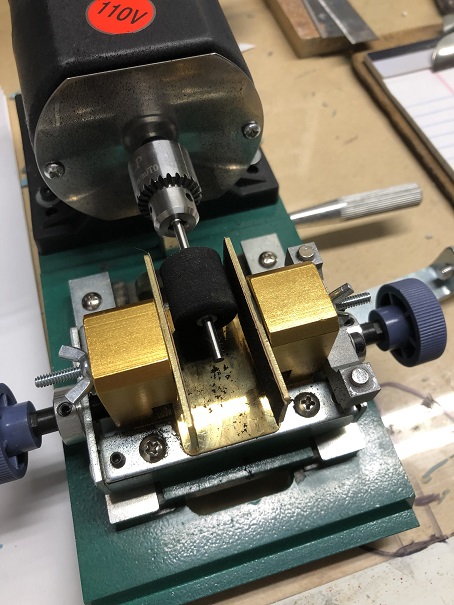

Attach the sanding disc plates into the holes and secure using the flat head screw,washer and wing nut as shown.

Test run; Power up set desired RPM turn the blue plastic knobs and the sanding jaw plates will close on the tire..

Grind to desired diameter Use the silver lever on the right and the sanding plate move forward and backwards to smooth the tire.

Bingo, it sand great.

Going to make a fixed diameter control stops.

You guys can take it from here, modify as you see fit, it does work well, the motor is strong

regards gene