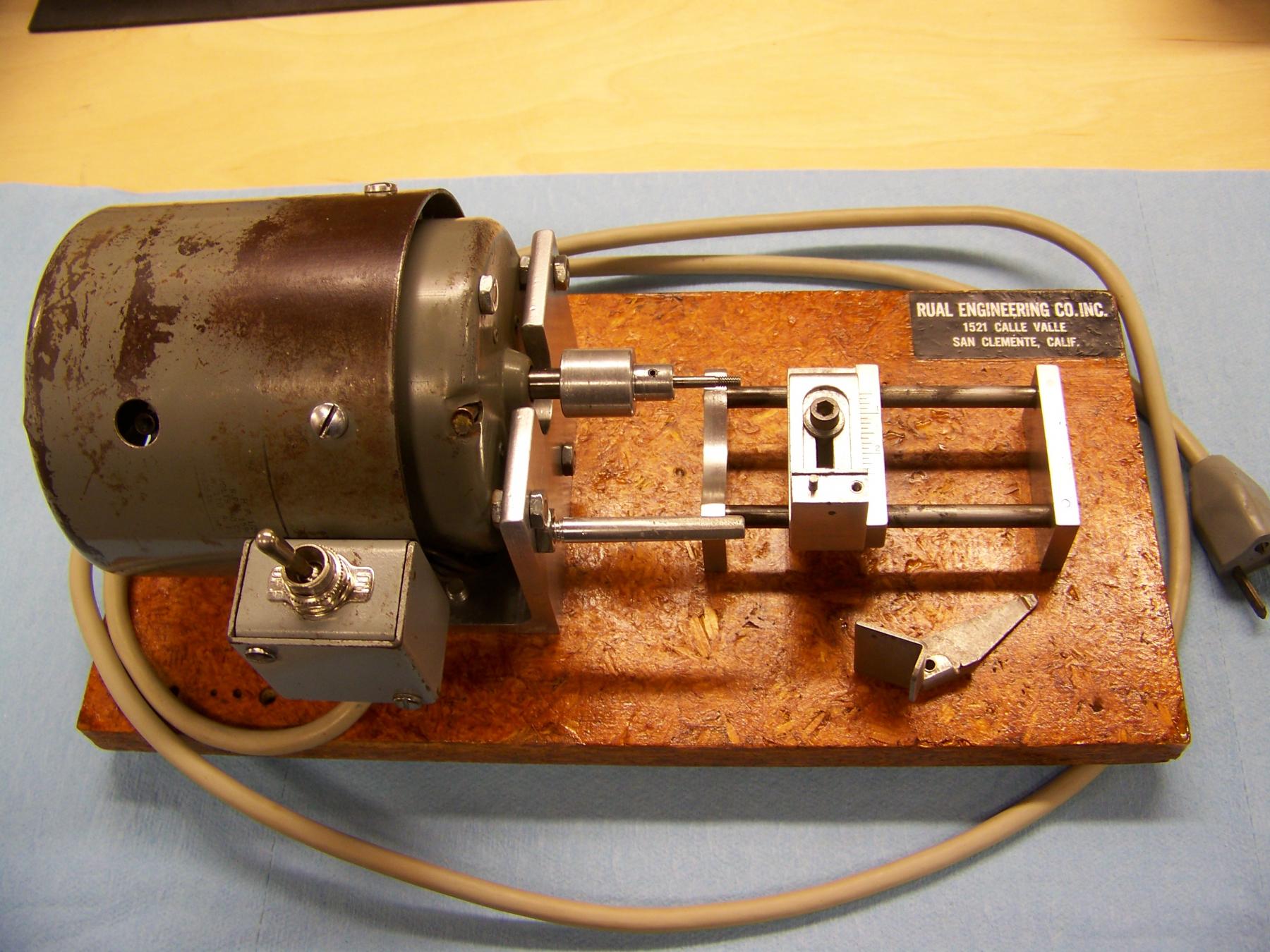

Its as clean I need to get it at this point. Would still like to see a pic of the "blade" cutting a tire. Not even sure how the blade attaches here. But I will give it go.

Making a Thingie/RTR universal tire machine

#28

Posted 16 February 2019 - 07:20 PM

Billy, nice use of an old machine! ! always found grinding tires to be one of the dirtest jobs in slot racing. There were times I was cleaning up orange dust for weeks when I lived in an apartment

- airhead likes this

I intend to live forever! So far, so good.

#29

Posted 17 February 2019 - 09:15 AM

Its as clean I need to get it at this point. Would still like to see a pic of the "blade" cutting a tire. Not even sure how the blade attaches here. But I will give it go.

Martin

I saw an advertisement to a similar tire machine, I will look around and see if I can find it.

Your vintage tire machine is really interesting. I see between your vintage tire machine and my contraption tire machine basically do the objective.

I see that your vintage motor has oil felt wicks for the bearings and most likely good old 3 in 1 oil was used. That motor most likely will run forever.

Regards gene

Gene Adams AKA Gene/ZR1

ZR1 Corvette owner

Hand-carved balsa bodies, resin body plugs, silicone molds, vacuum bodies

Genes_World@ymail.com

#30

Posted 17 February 2019 - 11:42 AM

That would be great if you can find the advertisement.

The motor sounds smooth and tight. I was thinking I would add a spinning sanding drum and that would replace the blade. Not sure yet. I should at least try a blade at some point.

Billy, thanks for the pic of your machine. I feel so dirty now ![]()

#31

Posted 17 February 2019 - 04:14 PM

Martin:

I know that using a slightly modified x-acto blade can work well to quickly take a lot of excess material off the OD. I always use an x-acto knife to remove the excess from both sides and it leaves a perfect "finish" there. From the looks of your machine it looks like it's designed to take a blade to cut the OD and I would at least try it to see if it works well, and hey, don't forget the safety glasses! If it works its a lot faster and cleaner than grinding away all of the excess rubber plus it doesn't heat the rubber up as much as grinding. You will still have to grind them to the final OD but I always leave my tires .030"-.060" large and only do the final grind to size right before use.

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#32

Posted 17 February 2019 - 05:50 PM

I agree with your suggestions. It may turn out that I use this tool to get fresh sponge close to size,using a blade. Then finish off with my small lathe and the clamped in sanding drum.

I will let you know when I get to do some tires for vintage projects. It also has become handy for polishing rims and axles etc.

#33

Posted 25 July 2019 - 10:27 PM

now Im recalling over 50 yrs but the blade on the unimat one worked very slick. cutting sponge and rubber

#34

Posted 12 August 2019 - 08:17 PM

Martin

I saw an advertisement to a similar tire machine, I will look around and see if I can find it.

Your vintage tire machine is really interesting. I see between your vintage tire machine and my contraption tire machine basically do the objective.

I see that your vintage motor has oil felt wicks for the bearings and most likely good old 3 in 1 oil was used. That motor most likely will run forever.

Regards gene

go back and look at post # 4 , is that the advertisement you mean ?