If it was mine, I'd:

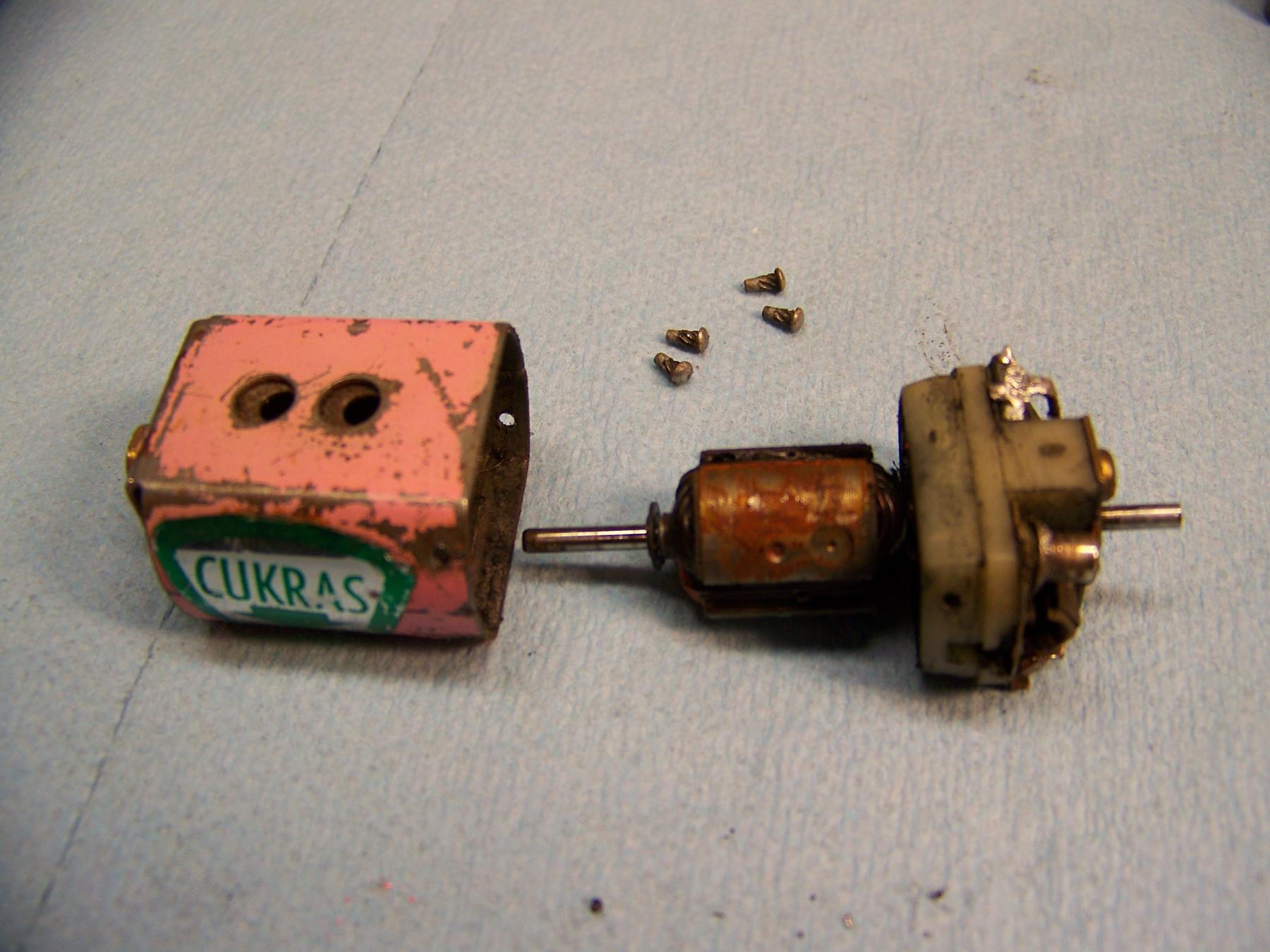

-take the time to find an original Mura white endbell with Mura hardware

-check the arm shaft for straightness, then send it to a refurbisher for cleaning, a comm cut and dynamic re-balance

-also send in the can to have the magnets re-zapped (in the can)

-leave the can paint and stickers alone

-do NOT re-install the EB gizmo

-use brass post protectors, not chrome

-new-pre-radiused brushes, new springs

-I hate to say it, but I'd use the dammits to secure the new EB.

Make yourself a gizmo so the can won't get nicked when you hammer them in gently with a small brass hammer.

Maybe a piece of .032 brass sheet with a hole drilled slightly larger than the dammit.

Now that you have the arm out, what is the OD, and what is the ID of the magnet hole?

I'd recommend an airgap on that motor of between 10 and 15 thou per side.

In other words, let's say the arm is .513, the hole should be between .533 and .543

If you absolutely cannot find the proper Mura EB, a Tradeship would be perfectly acceptable as a substitute.

Approved by the Vintage Police, Electric Dreams still sells them at $25