Things cleaned up nicely...and yes, those are the original type magnets...

The Semi-Can cleaned up good too...I've had some that were rusted in so bad that it seemed like they were almost bonded in...and when I got them out they were so deeply pitted / corroded they distorted badly upon removal...almost crumbled.

FWIW there are 2 different thicknesses of the can-in-a-can shim, .007" and .015"

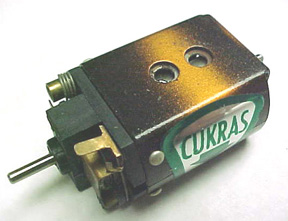

Looks like you found a good endbell replacement too...gonna make a real nice motor...the Cukras sticker looks to be in decent condition.