I am thinking about a small sheet metal brake for bending brass. probably .032 say 5 inches long would be the largest I would want to bend. My biggest concern is getting an accurate position and angle in the bend.

Anyone have any suggestions?

Posted 11 March 2019 - 09:20 AM

I am thinking about a small sheet metal brake for bending brass. probably .032 say 5 inches long would be the largest I would want to bend. My biggest concern is getting an accurate position and angle in the bend.

Anyone have any suggestions?

Posted 11 March 2019 - 11:30 AM

Layout what you want to do...scribed lines, whatever. You will need to do that, or, if you're thinking of producing more than a few pieces, you will need to make a formed back gage to pocket the part/stock.

I'm sure there are members here that know more about brakes than I....

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

Posted 11 March 2019 - 11:31 AM

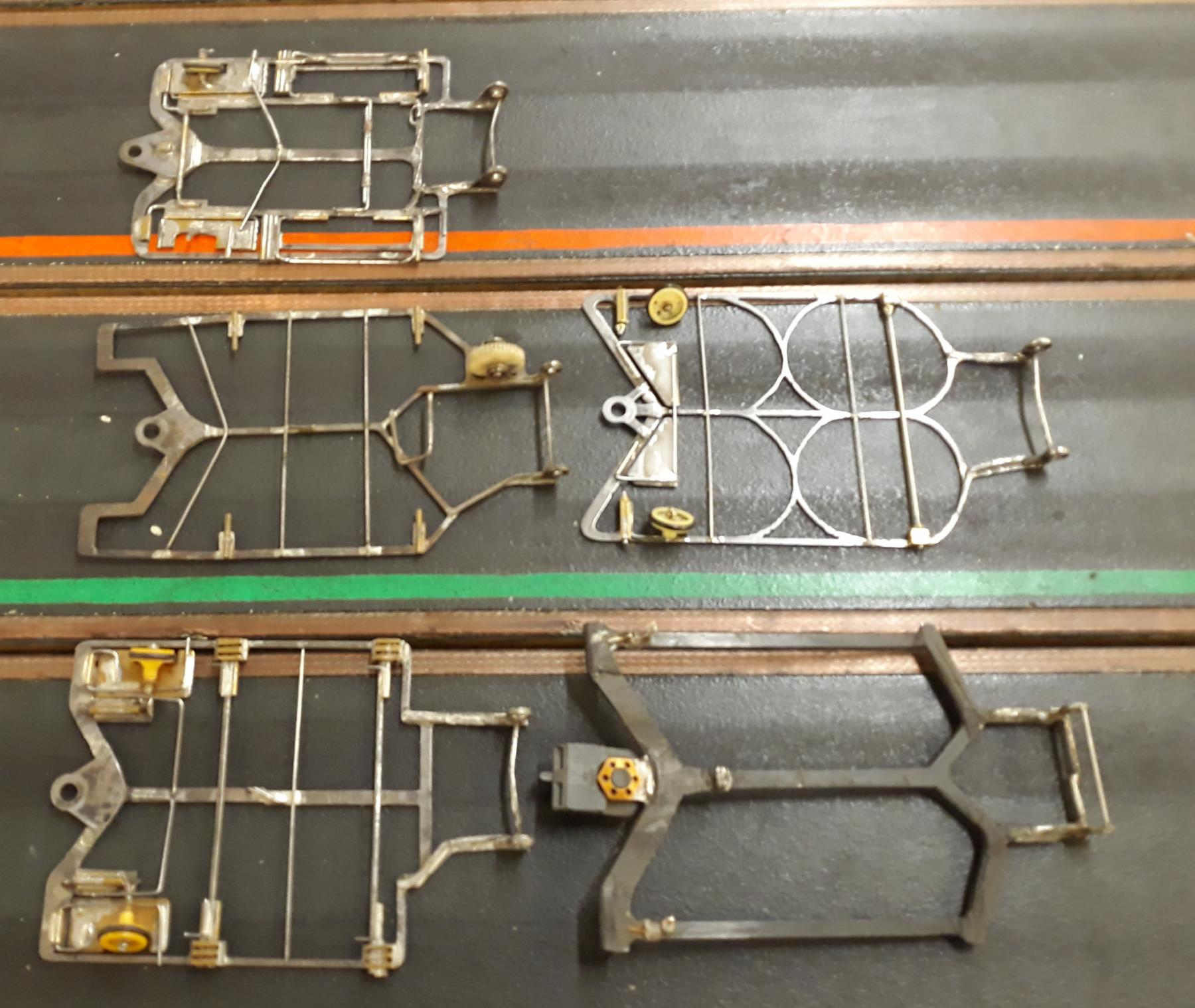

I built a small press brake to fit in my milling machine. I originally made it for building brass model railroad locomotives, and

was designed by Frank Pawlikowski. It is real simple, but you need a good milling machine to make one, since the guide

posts and bushing hole locations need to be jig-bored. It does sharp, 1/8th, 1/4, and 3/8ths inch radius bends. It is not set

up right now, but if I can make it down into the basement I will set it up and photo it. I need to make some vintage style

motor brackets anyway. The last time I used it was to make chassis pans for my resin bodied sprint cars.

Posted 11 March 2019 - 11:57 AM

Posted 11 March 2019 - 12:09 PM

Harbor freight !

Posted 11 March 2019 - 01:10 PM

The DYI solution is something I am thinking about and I could make it very compact.

Thanks Billy I just got back from Harbor Freight, They have a 18 " brake that looks like it would be fine except it has no clamping mechanism. If I can come up with a clamping setup I like that may well be the way to go.

Posted 11 March 2019 - 01:25 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 11 March 2019 - 01:34 PM

I use two small "C" clamps with my 18" Micro-Mark brake. Wood would be a good material if bending plastics, but I'd want a metal brake for anything other than thin, soft metals. For most slot car work, 12" is plenty long enough.

Posted 11 March 2019 - 03:09 PM

The Harbor Freight version needs c-clamps and a length of steel bar to hold the stock. There also is no way to guarantee

that the bends will be exactly 90 degrees, which is a problem with most pan-type brakes. Plus it is very hard to get the

bends exactly parallel with the opposite edge. A press brake, with overbend designed in, is the only way to go there.

Posted 11 March 2019 - 10:26 PM

Eddie, YouTube has several videos on setting up & using the Harbor Freight 18" brake.

Posted 12 March 2019 - 09:32 AM

Most of what I have been doing is bending 1" .032 to make uprights for front axles. keeping the bend square across the stock is the trick and I am not seeing much in the cheap brakes that will improve that. I have been cutting groves in the stock much like the motor brackets from Mike Swiss but I am cutting with a dremel and the cuts are not always consistent so some of the bends go a little wonky.

Well I will keep on moving and see what comes up next.

Posted 12 March 2019 - 10:05 AM

To keep your bending grooves straight, invest in a Dremel drill press stand, and pull your brass along the bed, like I use to do , to cut steel center sections.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 12 March 2019 - 11:30 AM

Better than the Dremel approach - I have used one of these for ~ 20 years. The dial calibrations are only to 0.005" but reproducibility is probably +/- 0.002" and work is easily squared with a small machinist's square.

http://vanda-layindustries.com/

EM

Posted 12 March 2019 - 01:39 PM

I don't see anything there for bending. If all you are doing is narrow pieces less than one inch wide, buy a cheap machinists V-block

to use as the bottom die, and a piece of 1/2 inch or so square steel stock as the upper die, and use a c-clamp to supply the pressure.

Make a scribe line exactly on center of the bend, and another parallel line at the width of the square stock to line up on. You can make

a v-groove in the foot of the c-clamp to keep it from walking off the square stock.

Posted 12 March 2019 - 01:54 PM

Not for bending per se - a way to cut shallow grooves to define bend points. (see post #12)

EM

Posted 12 March 2019 - 02:04 PM

Thanks Dave

what I have been doing is one inch and less but would like to bend as much as 4 or 5 inches all with improved accuracy from what I have been getting.

That is an interesting machine Alan. It would sure improve my cutting.

Posted 12 March 2019 - 04:54 PM

Thanks Dave

what I have been doing is one inch and less but would like to bend as much as 4 or 5 inches all with improved accuracy from what I have been getting.

That is an interesting machine Alan. It would sure improve my cutting.

I find it very useful. It will cut 1/32 brass with several passes with an abrasive or diamond coated cutter. - steel as well although that requires patience. My Dremel tool resides in it full time since I bought a Foredom flex shaft unit with foot pedal control for all of the "usual" stuff.

EM

Posted 12 March 2019 - 05:54 PM

To keep your bending grooves straight, invest in a Dremel drill press stand, and pull your brass along the bed, like I use to do , to cut steel center sections.

Man, I wish would have known/thought of that years ago! It would have saved me a lot of work.

Posted 12 March 2019 - 06:02 PM

I always used a piece of steel with a straight edge to use as a guide for my Dremmel abrasive wheel. The edge would only be straight for X amount of cuts. I went through a lot of cheap combination square slides.

Posted 12 March 2019 - 09:11 PM

The untoothed edge of a bi-metallic hacksaw blade makes a good cutting straightedge too.

Posted 12 March 2019 - 09:22 PM

Along with easy, straight cuts, the beauty of it was, you just flipped it around 180 degrees, and right side rails would be the same width as left side, and the middle rail, would be dead center.

Man, I wish would have known/thought of that years ago! It would have saved me a lot of work.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 13 March 2019 - 06:55 AM

Mike I may have missed it but what were you using for a cutting blade or tool?

Posted 13 March 2019 - 07:12 AM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 13 March 2019 - 07:45 AM

I have been using 420's for that. thanks.

Posted 13 March 2019 - 09:24 AM

Hey Eddie

Have you tried using a hand held metal brake like heating and a/c guys use to make bends for duct work?

I have been experimenting with that on light brass and seems to work well.