Here is a tip. You may already know this, or you may benefit from it.

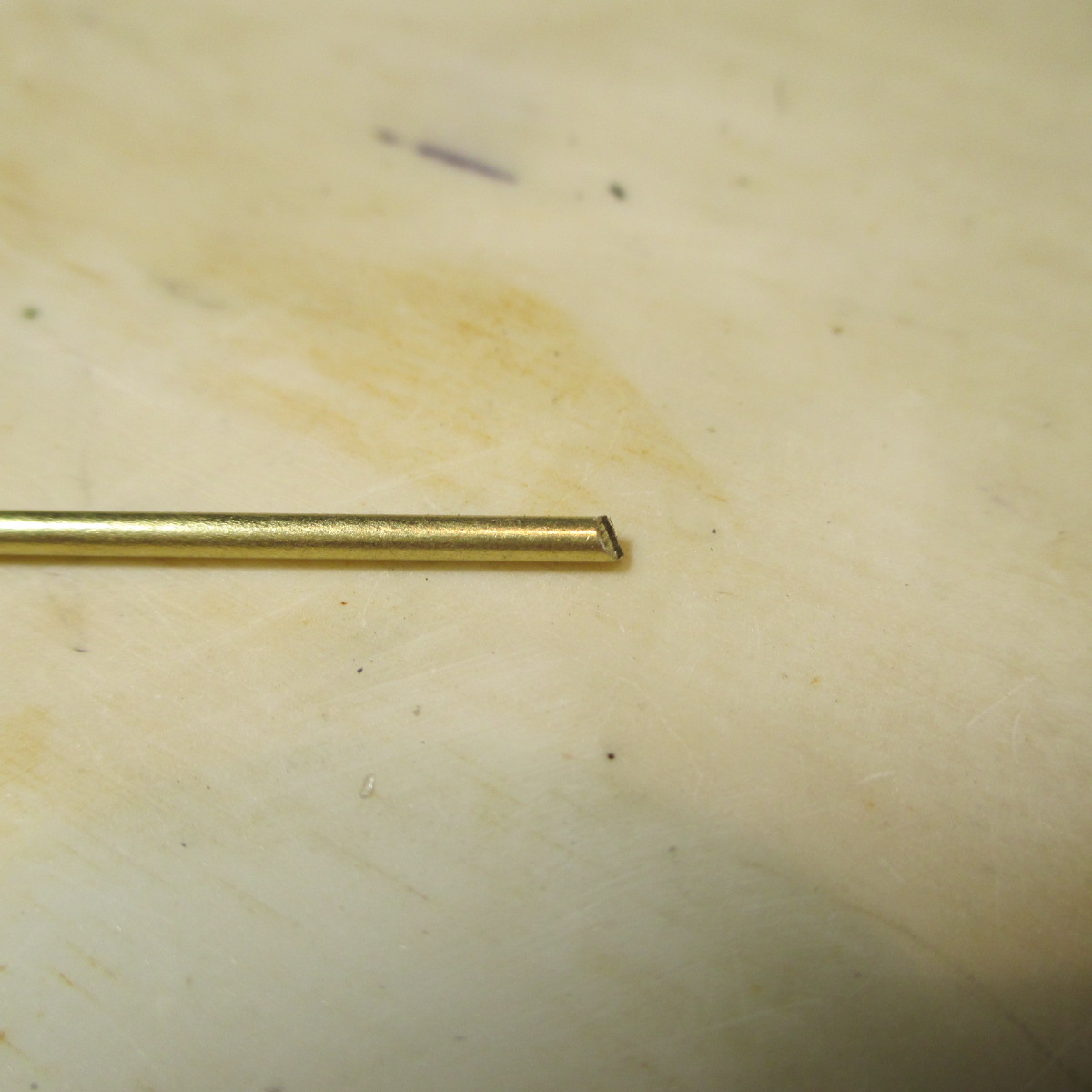

When you cut lengths of rod or wire with a pair of dikes or Linesmans pliers, it leaves high and low spots, like this

If you don't make that cut concentric by rolling it on a Dremel disc or whatever, when you lay in on your jig and solder it in, that piece is going to cause high and low spots on your chassis. So you can make your wires and rods flat to begin with, or you can fight a continual "lack of flatness" issue for the duration of your build.

I guess it depends on how flat you want your chassis and how much you want to avoid issues by making your parts as perfect as possible ![]()

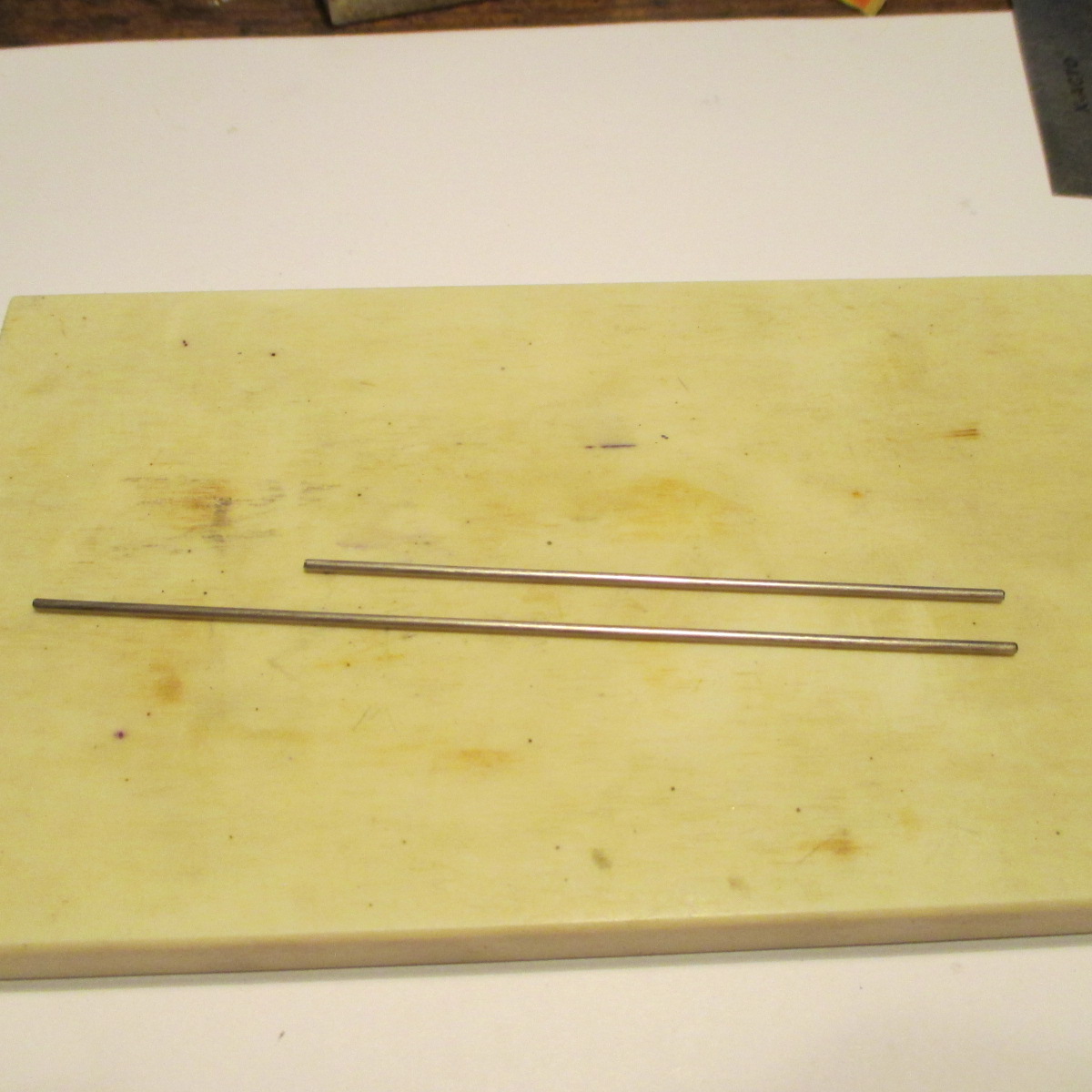

Here are a couple of lengths of Swiss plated .063 wire for main rails on my Lola hardbody

All four ends are champhered and I haven't even made any bends or soldered them yet. They lay flat and they get soldered flat