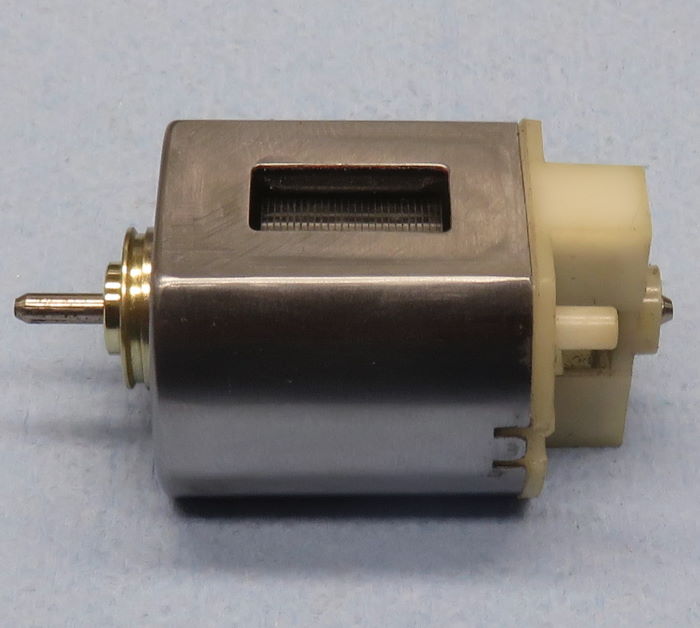

I'm in the process of working on a Blogger's 36D motors, so while in "Big Block" mode, I got busy with another FT36D. The Blogger has one FT36D with a can bushing that came out of it's pocket as they often do, so I took apart an RS360 Mabuchi for it's two oilites. These are the only source for modern oilites that properly fit the odd 36D shaft size, so one went into his motor and the other went into the one I'm doing. Installing a fixed bushing in any of the Mabuchi cans is a major upgrade in smoothness and ultimately motor life, and this becomes even more important for rewound motors where the higher revs can shorten that can bushing's life even further. After removing the old bushing and the brass finger ring that retains it, the new bushing needs to be turned down to fit the brass can bushing retainer. Putting a small bevel on the seating edge of the new bushing does a good job of centering the new oilite, and it can be either soldered or epoxied in to the can afterwards. Either way, it's a good idea to make sure the new oilite's outer surfaces are cleaned well with solvent, and when soldering, it's best to not heat everything too much so the impregnated oil doesn't boil out. From the outside, nothing visible has changed, from the inside it all looks like this:

The RS360 motor also has a set of dandy ceramics that measure just over 1200 on my meter, which is very strong indeed. For a comparison, the FT36D Arco mags measure around 1000 or a little less. Here, I shimmed the RS360 magnets around 15 thousandths per side to close up the gigantic 36D air-gap. The RS360 can when cut up provides approximately 20 or so thousandths shim material with the perfect curve radius, but that's a bit too tight without taking down the arm's OD, and I prefer not to do that in most cases. Anyway, the magnets are in, the bearing has been replaced and the beginnings of a very solid FT36D are there. I even have an end bell here with no cracks...imagine that! ![]() Of course, with the RS360 being a full-round motor, the top and bottom edges of the magnets need to be taken down with a diamond wheel to fit the FT36D's flatted round profile, and that's a dusty mess, but if it came in a box, everyone would do it!

Of course, with the RS360 being a full-round motor, the top and bottom edges of the magnets need to be taken down with a diamond wheel to fit the FT36D's flatted round profile, and that's a dusty mess, but if it came in a box, everyone would do it!

From the small to the large

#1

Posted 18 November 2019 - 07:15 AM

- slotbaker, Pablo, hiline2 and 11 others like this

#2

Posted 18 November 2019 - 11:08 AM

Gonna be sweet John... ![]()

- havlicek likes this

Yes, to be sure, this is it...

#3

Posted 18 November 2019 - 03:03 PM

Of course, with the RS360 being a full-round motor, the top and bottom edges of the magnets need to be taken down with a diamond wheel to fit the FT36D's flatted round profile, and that's a dusty mess, but if it came in a box, everyone would do it!

John, years ago I cut some mags shorter for a I-15 setup. I won't ever do that again, so you're right! Not for the faint of heart.

- havlicek likes this

???-2/31/23

Requiescat in Pace

#4

Posted 19 November 2019 - 05:38 AM

John, years ago I cut some mags shorter for a I-15 setup. I won't ever do that again, so you're right! Not for the faint of heart.

Hi Phil,

It's not just dusty and messy as heck , it's tedious also. It's one of those things I tend to put off...until I can't and need to get a project done. Like all jobs, there does seem to be some "easing of the pain" that happens just by figuring out better ways to have at it and things not to do, but it's still pretty awful.

#5

Posted 19 November 2019 - 06:16 PM

Can's all gussied-up, and I chose to stay with the original Classic color, and even add a repop sticker, since the original was in poor shape. For the arm, I went with a "lotta wire" # 28 (47/28R), with a good bit of advance dialed-in. The force is strong with this one. ![]()

- slotbaker, Jencar17, miko and 6 others like this