I am building a replica of Manuel Maldonado's 1966 Rod & Custom "Car of The Meet" Top Fuel Eliminator dragster.

I begin with the Rod & Custom race report by Gene Husting of the drag meet that took place at Motorama Raceways in Van Nuys, CA.

Posted 11 August 2020 - 05:35 PM

I am building a replica of Manuel Maldonado's 1966 Rod & Custom "Car of The Meet" Top Fuel Eliminator dragster.

I begin with the Rod & Custom race report by Gene Husting of the drag meet that took place at Motorama Raceways in Van Nuys, CA.

Posted 11 August 2020 - 05:46 PM

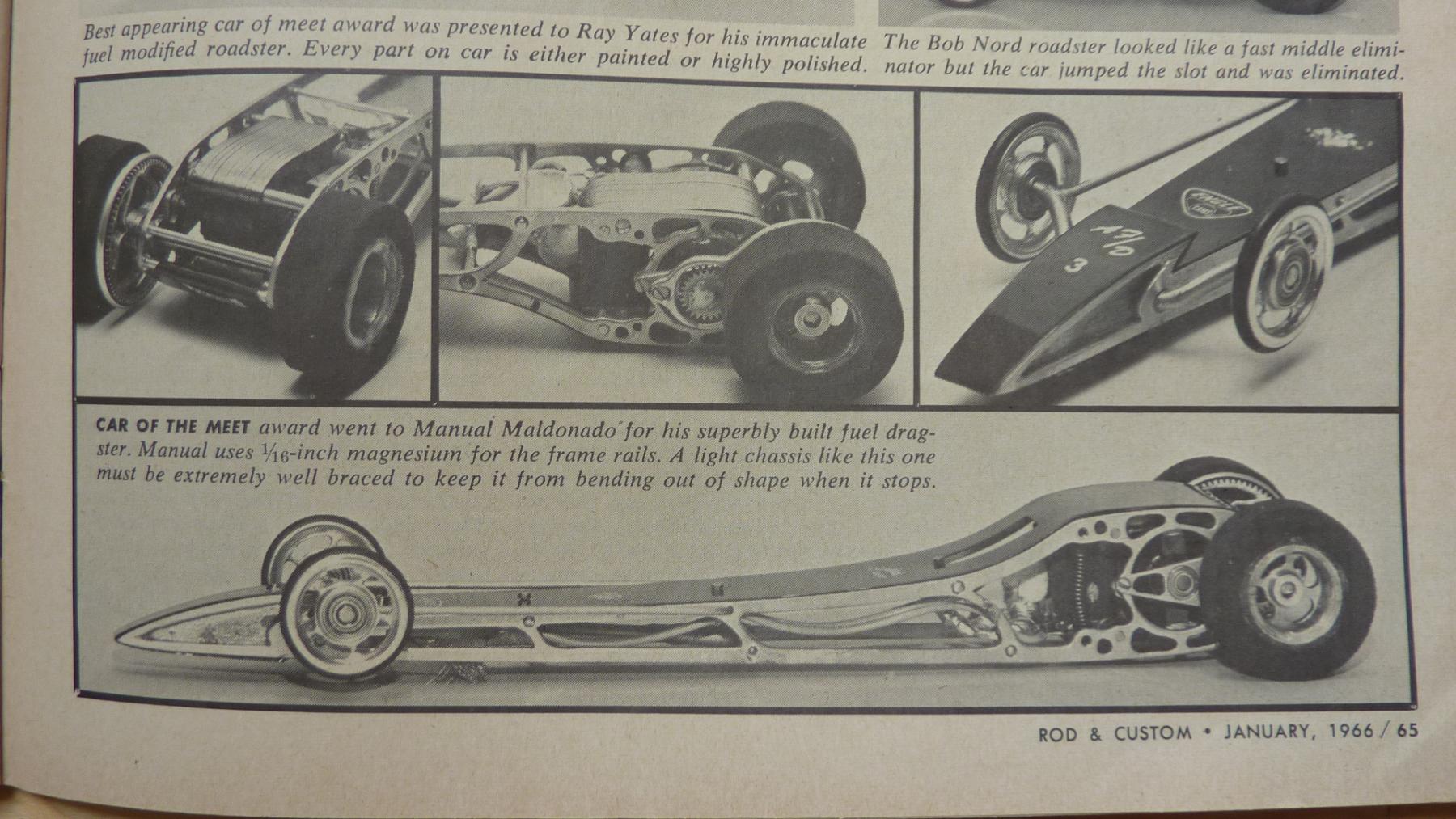

Manuel Maldonado's dragster is featured in the four photos displayed at the bottom of the page, and described by Gene Husting in some detail in the text of the race report above the photos.

These four photos are the only ones in existence.

These photos and some detailed descriptions of the car in the race report and in a few photo captions comprise the sum total of information available for a builder to replicate this classic magwinder from the golden age of slot car drag racing.

Posted 11 August 2020 - 05:55 PM

And years later, in Manuel Maldonado's own words...

Hi There, I just got the bug to search and see if anything was on the web regarding Slot Cars that ran in the 60's at the Rod & Custom races. My name is Manuel Maldonado and I built cars for many racers at that time. Chuck Blayney had me build him an altered, won first time out, Then Gary Gabelich wanted a top fuel car, won first time out, now these guy's where racing have years head start on me being around slot car's. Bob Braverman and Gene Hustings where the king's. Chuck and I even went to the race's up in the Bay Area on a Greyhound bus, neither had a driver's license. Set low E T and runner up, always ran good up there, San Jose and San Mateo, Oakland. One race had low E T and got to the final and dropped a chunk of weight in the final and wheel stood and I lost, the guy's running the show asked if I thought I could go faster and I told them yes, so they announced that I would make a single for a track record. The crowed gathered, it was a car show, so there was a big crowd, well this thing gets about 50 feet and blow's both rear tires throwing the car in the air screaming! You could hear a collective OOOOOH from the crow. Sold a car to one guy up there that told me if I could build him a car he could go under 1:20 with a Pittman Motor (he had lots of them) everyone was using the Ram 7 poll now, he would be able to win races. First run right out of the box it went 1:18. The other car I sold up there the guy never paid and when I asked for it back it was in peices and you could see the lead from the pencil tracing the parts! I quit building cars for people right then. I did go into Gene Hustings and Bob Braverman's home track and beat them both, then I got drafted and served in Viet Nam as a gunner on a Huey. When I came back the sport was gone. This article came out well I was in Aberdeen proving grounds in the service. I still have this car! They had a slot car exhibit at the Peterson Museum a few months back, all road race stuff, no dragsters when I showed them my car I got run around to all the guys putting on the exhibit and a few collectors wanting to buy the car! They stopped at $50,000.00 I loved those days Rod and Custom had a race at a different track each month and it was a dog fight, had top time more than once, bragging right's was always worth a lot in drag racing. Manuel

Posted 11 August 2020 - 07:12 PM

Back to the four photos...

I took bright screen shots of Slotblog's enlarged versions of these photos (when you "click" on the picture below) and printed out multiple copies.

I've spent a lot of time studying these photos of the car, even while I was in the process of building a replica of Gene Husting's dragster.

Slowly over time, many of the details of the car's construction became clearer to me.

Posted 11 August 2020 - 09:22 PM

I taped two photos together to create a composite of the entire car as a reference tool.

I used a known and measurable feature, like the actual dimension between the forward two Ram motor screw holes, to create a scale of 1.2895" of the photo equals 1.00" of the actual car.

I used this 1.2895" = 1.00" scale, digital calipers, a calculator, and drawing aids such as french curves and a drafting compass to draw the car's frame and key hole locations to final exact scale.

Posted 11 August 2020 - 09:48 PM

After a drawing is done, it's time to begin work on the magwinder frame rails.

The first couple of steps outlined in Husting's R&C build article are applied to the Maldonado build process.

A couple of pieces of 1/16" thick magnesium sheet, approximately 10" long x 2" high are bolted together at the four corners with 2-56 screws.

The distance between the 64 pitch Weldun pinion's and rear axle spur gear's centers is determined by formula. A tiny bit of "slop" is added for optimal gear mesh.

The Ram motor's brush-side endplate is used to locate and align the key 2-56 screw holes and pinion center on the magnesium frame plates.

Posted 12 August 2020 - 05:32 AM

very nice.

Steve Lang

Posted 12 August 2020 - 12:45 PM

Thanks, Steve! ![]()

At this point in the build process as Gene Husting describes it in his Rod & Custom magazine articles, he drills a 3/4" hole for the armature through the main magnesium frame rails.

Separately, he machines the two stock motor endplates to lighten them.

The Maldonado dragster, however, doesn't use the motor endplates at all.

Instead, the armature is carried by 1/4" ball bearings set into two small 1/16" thick triangular-shaped magnesium plates which are bolted to the main rails, left and right, one attachment at the front or apex of the triangle, and two attachment points at the rear end of the car, above and below the rear axle.

Posted 12 August 2020 - 01:13 PM

For the Maldonado build, instead of drilling a 3/4" diameter hole through the main rails for the armature, that step is deferred until later so that the existing 1/4" hole with a 1/8" ID hole ball bearing for the pinion shaft can be preserved as a reference point necessary to align the triangular-shaped armature carriers with the main rails.

Two pieces of 1/16"thick magnesium sheet, 2" long x 1.25" high are bolted together with 2-56 screws, one at each corner.

Then, the edges of the long sides of that assembly are milled straight and parallel to each other and match the main rail assembly height of 1.1250".

The main rail assembly and the armature carriers can be aligned with each other, stacked in the mill vise, and machined together to assure perfect alignment of all parts fixed and moving.

The stock motor commutator-side endplate is used again as a template to locate the four motor through-screw holes on the endplate assembly.

Posted 12 August 2020 - 01:24 PM

Note that with this type of magwinder, the posts for the motor's brushes are located on the inside of the left-side main rail.

In order to perfectly locate the centers of these two brush assembly posts on the inside on the rail, I drilled through the stock endplate's post centers and continued the holes straight through both sides of the main rail assembly.

If you look closely at photos of Manuel Maldonado's dragster, holes for the brush assembly posts are visible on both sides of the frame.

Posted 12 August 2020 - 01:34 PM

So, the main rail assembly and the endplate assembly are bolted together, aligned by means of the four motor screw through-holes, two in front of the pinion shaft hole and two behind it.

That sandwich of aligned assemblies all bolted together is clamped into the mill vise and a 1/4" diameter hole is reamed through the endplate assembly, continuing through the existing 1/4" holes in the main rails, all holes aligned up and down the stack.

Posted 12 August 2020 - 01:53 PM

This is what we have so far:

Most of the critical holes located at the rear end of the chassis have been drilled through the main rail assembly.

A 1:1 scale drawing of the Maldonado dragster's main rails has been drawn.

Tracing paper is overlaid on the drawing and the main rail design is ready to be traced over in pencil.

Posted 12 August 2020 - 02:24 PM

was going to all the trouble of integrating the motor and frame in the interest of saving weight in the back?

Steve Lang

Posted 12 August 2020 - 03:39 PM

I'm sure weight savings was a consideration.

The Husting replica I finished building last month weighs in at 7.7 oz. with a 1 oz. nose weight. That chassis incorporates both stock motor end plates to carry the armature and brush assembly, although they are heavily machined to reduce weight.

Manuel Maldonado's 1966 R&C "Car of The Meet" magwinder weighed in at 6.5 oz. including a nose weight (which isn't quantified in Husting's race report).

Besides weight savings, though, the Maldonado dragster and others like it that used only the magnesium frame rails to provide structural support for the motor's magnet and field laminations, the armature, the brush assembly and geartrain were generally more complicated and tricky to build, so they were regarded as special and more sophisticated by design.

Dragsters of this type were considered to be the "Holy Grail" of magwinders in the mid-1960's.

Posted 12 August 2020 - 03:52 PM

Similar to the process used for the main rails, the rear end of the car was drawn onto tracing paper.

The exact shape of the "triangle" and its three attachment points in relation to the main frame rails was all determined on layered tracing paper first.

Then the triangular armature carrier's exact shape and three attachment locations as drawn on the tracing paper was overlaid on the magnesium endplate assembly and scribed onto the surface of the left endplate.

Posted 12 August 2020 - 04:07 PM

The partially-machined gear guard (which I milled together with the one that is installed on my replica of the Husting magwinder) is aligned with the main rail assembly and the endplate assembly.

There are three attachment points for the gear guard. The forward attachment point is at the apex of the triangular endplate as the photos show.

The gear guard's other two attachment points cannot be seen in the photos.

There is a limited area of overlap on the main rails above and below the armature opening where these two rear attachment points can be located.

Again, all of this is determined in advance using tracing paper drawings of the rear end of the chassis aligned and overlaid on one another to find areas of overlap and/ or interference.

Posted 16 August 2020 - 03:00 PM

you certainly have a good machine shop! nice work.

Steve Lang