And years later, in Manuel Maldonado's own words...

Hi There, I just got the bug to search and see if anything was on the web regarding Slot Cars that ran in the 60's at the Rod & Custom races. My name is Manuel Maldonado and I built cars for many racers at that time. Chuck Blayney had me build him an altered, won first time out, Then Gary Gabelich wanted a top fuel car, won first time out, now these guy's where racing have years head start on me being around slot car's. Bob Braverman and Gene Hustings where the king's. Chuck and I even went to the race's up in the Bay Area on a Greyhound bus, neither had a driver's license. Set low E T and runner up, always ran good up there, San Jose and San Mateo, Oakland. One race had low E T and got to the final and dropped a chunk of weight in the final and wheel stood and I lost, the guy's running the show asked if I thought I could go faster and I told them yes, so they announced that I would make a single for a track record. The crowed gathered, it was a car show, so there was a big crowd, well this thing gets about 50 feet and blow's both rear tires throwing the car in the air screaming! You could hear a collective OOOOOH from the crow. Sold a car to one guy up there that told me if I could build him a car he could go under 1:20 with a Pittman Motor (he had lots of them) everyone was using the Ram 7 poll now, he would be able to win races. First run right out of the box it went 1:18. The other car I sold up there the guy never paid and when I asked for it back it was in peices and you could see the lead from the pencil tracing the parts! I quit building cars for people right then. I did go into Gene Hustings and Bob Braverman's home track and beat them both, then I got drafted and served in Viet Nam as a gunner on a Huey. When I came back the sport was gone. This article came out well I was in Aberdeen proving grounds in the service. I still have this car! They had a slot car exhibit at the Peterson Museum a few months back, all road race stuff, no dragsters when I showed them my car I got run around to all the guys putting on the exhibit and a few collectors wanting to buy the car! They stopped at $50,000.00 I loved those days Rod and Custom had a race at a different track each month and it was a dog fight, had top time more than once, bragging right's was always worth a lot in drag racing. Manuel

Alan,

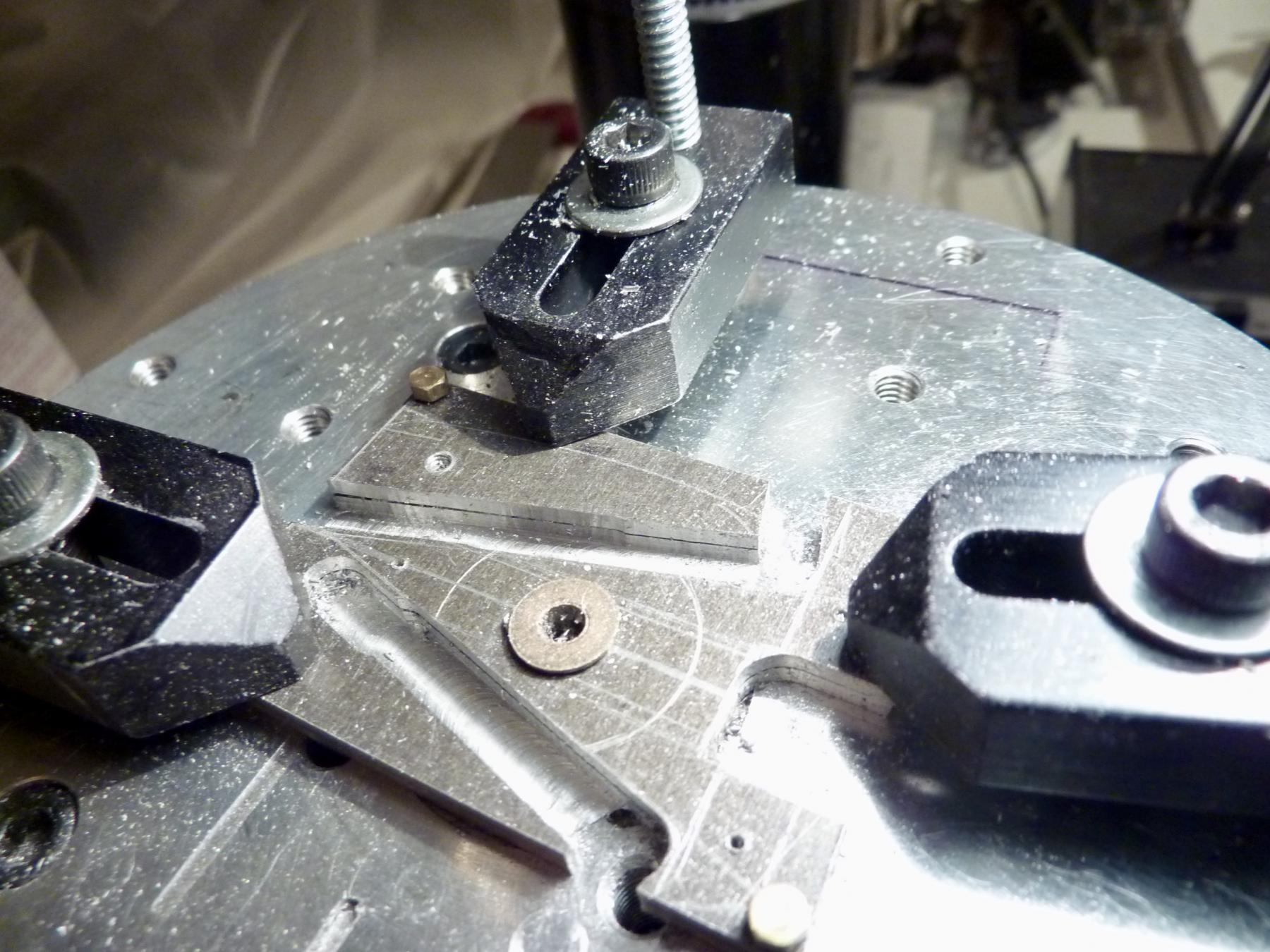

You're doing a terrific job on this car, just as I expected.

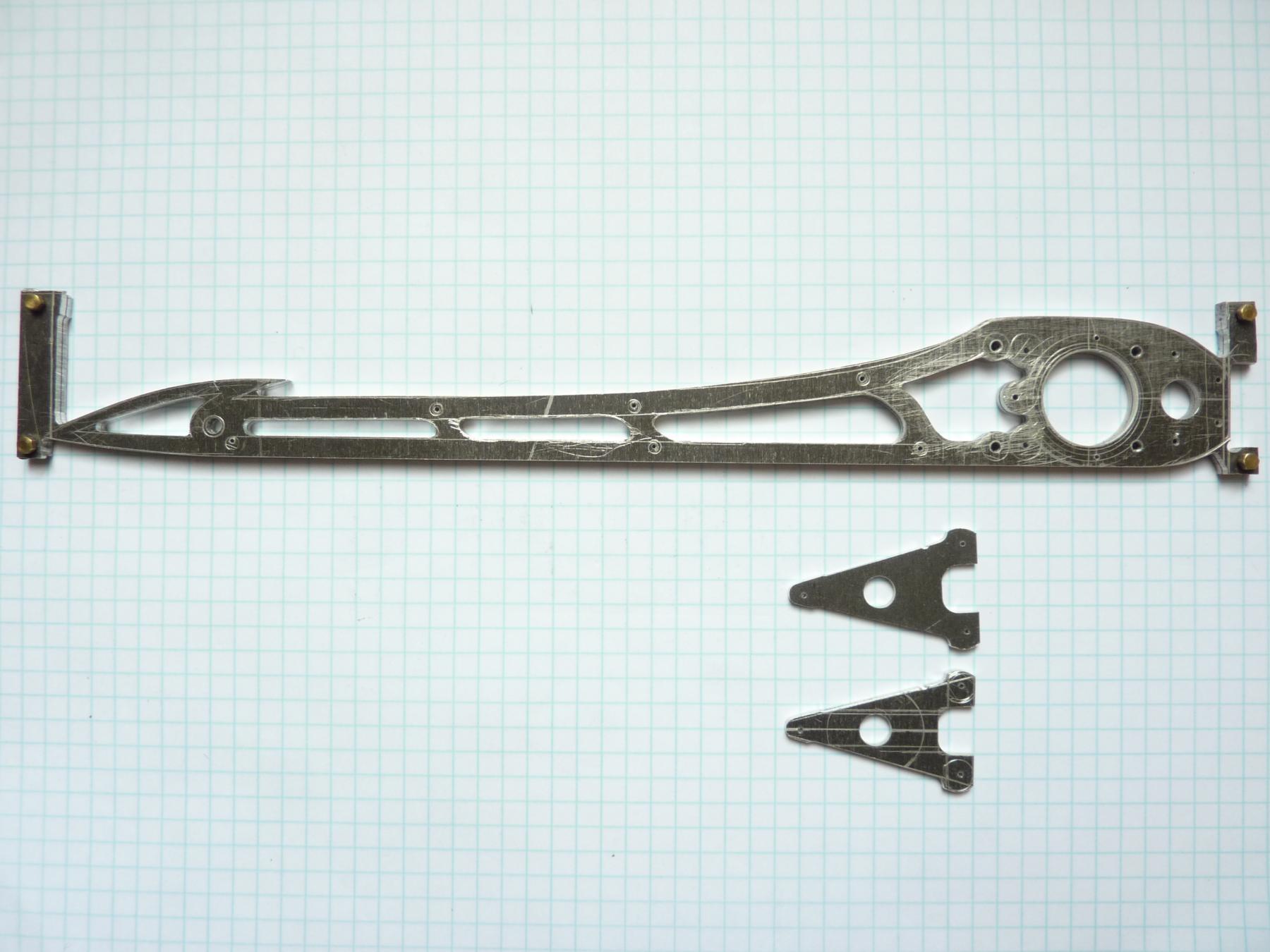

Manuel had a great sense of style.

His rail is stunning.

By his above letter/post, he wasn't without confidence.

A bit of swagger is good, in winning races.

That said, something about the end of that letter is a bit odd.

A fair amount of detail, but something is missing.

No payoff on the $50K comment.

Did he sell it?

Or had he already declared, it was not for sale, and the unnamed 2 collectors were just posturing, with no chance of having to put up.

It's hard for me to believe there are 2 slot car collectors, willing to put up that kind of money.

Maybe, there is one.

And if he(Scott Bader) had it, I think we would know about it.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

![]()