I don't know what materials Sherline uses, but Injecta Machine in Switzerland has been making high precision woodworking machines of aluminum using the Inca brand name starting in the 1920's. They are not machines that need constant fiddling with to keep accurate. I don't own one, but I've had my hands on their bench saws, jointers/planers, & band saws. The Inca line is still available, now owned by Multico in France.

My cute Unimat

#26

Posted 31 July 2021 - 10:23 PM

I intend to live forever! So far, so good.

#28

Posted 08 August 2021 - 04:24 PM

Cast iron is superior to aluminum and steel. It is far stiffer and dense (absorbs induced vibrations). Steel's advantage over cast iron (the ability too bend without fracturing) is it's disadvantage in machine tools.

Even in the big industrial mills and lathes having box/dovetail ways is better than machines having linear guideways for heavy machining. Now, you might wonder why this might matter with machining small things like slot car/model car parts: the forces being delevoped by cutting isn't really that much less than, say, a 12" lathe. In fact, small parts often require stiffer heavier machines than you'd think. Look at Swiss-style lathes and see how their constructed. They need stiffness and the ability to cancel out any harmonics for the parts they make.

You don't see Levin lathes made from aluminum, do you? I'd take a cast iron machine over aluminum *anytime*.

- S.O. Watt and Phil Smith like this

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

#29

Posted 03 September 2021 - 07:07 PM

#30

Posted 03 September 2021 - 07:44 PM

Side note, Isaac if you ever need EJ's #15 rubber front tires, I have lots of them

- Isaac S. likes this

Paul Wolcott

#31

Posted 03 September 2021 - 08:53 PM

- Pablo likes this

#32

Posted 03 September 2021 - 08:57 PM

Nice job Isaac. ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#33

Posted 04 September 2021 - 10:49 PM

Nice job! I wish I could do that.

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#34

Posted 05 September 2021 - 06:29 AM

Looks good Isaac! Did you have gray dust everywhere to clean up, or did you grind the tires outside or some other inconspicuous space? What diameter & width did they end up as? If you ever find a diamond comm cutting bit reasonably priced, pick one up. They're a good all-around bit to use with a Unimat.

I intend to live forever! So far, so good.

#35

Posted 14 September 2021 - 07:38 AM

#36

Posted 03 January 2022 - 08:30 PM

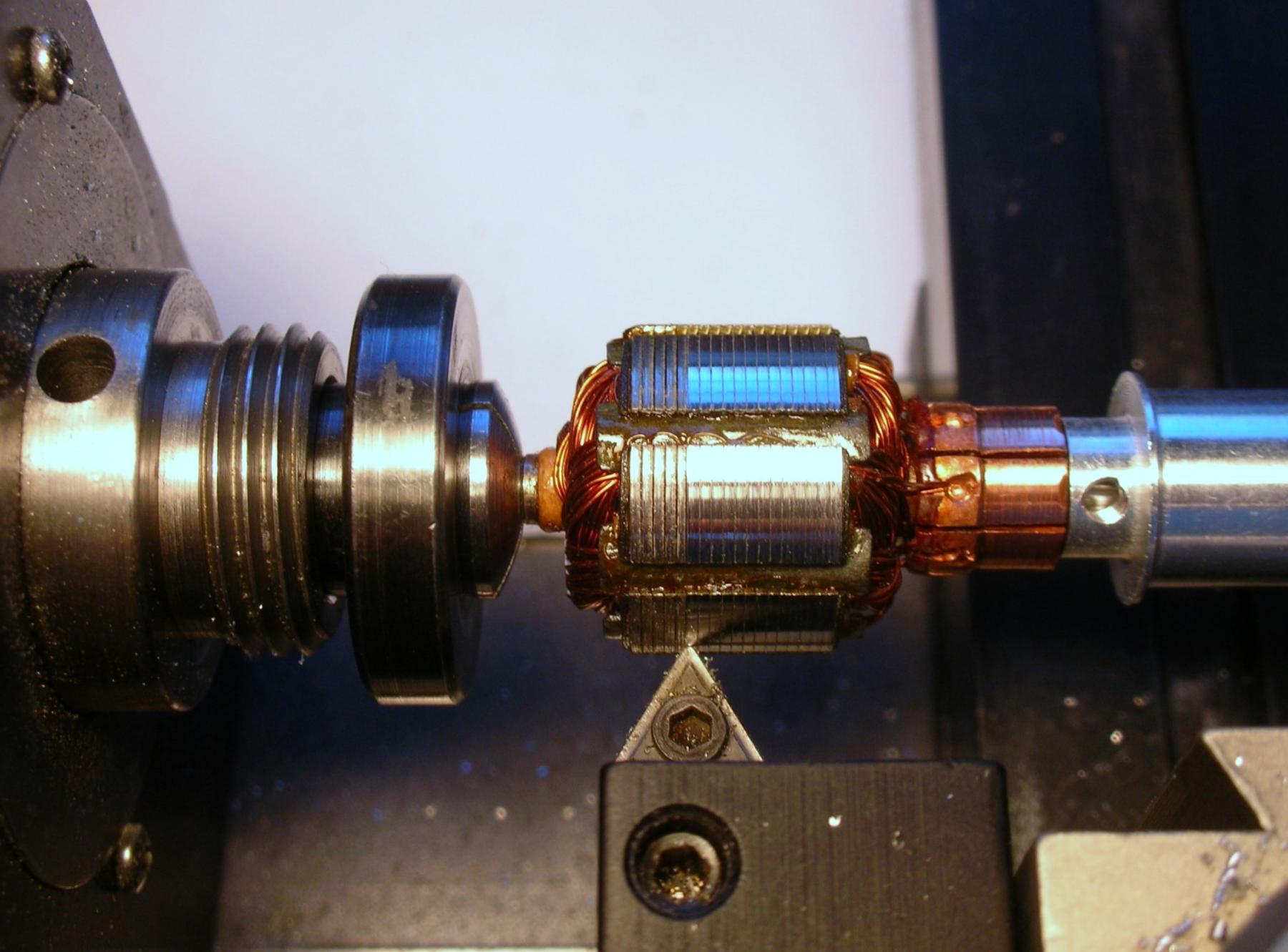

Wanted to turn down the stack on a 26D arm but I knew my cheap C2 carbide bits were not going to work. Looking at all the options McMaster Carr had, I decided to go with the micrograin carbide so that I could cut not only steel but tougher materials like stainless steel, cast iron and gummy aluminum alloys.

After advancig the timing a little I epoxyed the windings, ground down the stack and did a static balance. Turned out well.

Afterwards I decided to mess around a little and see what the new bit could do. Here's the aftermath-

Overall, pretty great. An added bonus is that it is super fun. ![]()

#37

Posted 03 January 2022 - 08:45 PM

Tap Magic has a cutting fluid for aluminum too. It works well when turning.

- Isaac S. likes this

I intend to live forever! So far, so good.

#38

Posted 13 January 2022 - 04:47 PM

I have the Green Unimat and would consider a trade for the Book : The 60's of Slot racing by Oliver K Bryant 798 pages . Pm me and I can send pics.

Best Regards,

Don

#39

Posted 14 January 2022 - 12:56 PM

Issac, how are you supporting the armature, at both ends ?

#40

Posted 14 January 2022 - 01:36 PM

For a 1/8" shaft armature like this RAM a true running wheel in a live center that's free to spin supported the arm great for light turning:

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#41

Posted 14 January 2022 - 01:51 PM

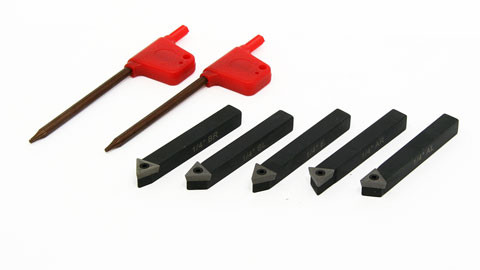

The tool being used in the photo above looks to have three usable points on a plate mounted on a bar. It seems to be rather popular.

What is it called and what is it good for and anything else you would care to share about it.

#42

Posted 14 January 2022 - 03:21 PM

Hi Eddie,

The lathe tool is one of a set like this one from Little Machine Shop:

Here's a link with the info:

Turning Tools, 1/4" Indexable, Triangle Inserts

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#43

Posted 14 January 2022 - 10:11 PM

Martin, I just have the end spinning in a just slightly loose drill chuck in the tailstock. I also add plenty of oil. Actually supports it really well. For axles I put a ball bearing in the chuck and this works well. This didn't work well with the armatures for some reason.

Eddie, the indexable tools are very useful. Just make sure to get a varying grade of inserts tat can cut from aluminum to steel.

#44

Posted 15 January 2022 - 12:11 PM

Here's an idea. if you put a small piece of bronze or Delrin held in the tail stock chuck. You could then put your straightest drill bit in the main chuck.

Run the tail stock with the material in it into the drill bit to make a cone shape to support the motor or axle shaft you plan to cut on.

Its a quick fix, but really you need a custom live center with a bearing. You could make one on the lathe with a axle bearing plus holder.

It would be held in the tail stock chuck.

#45

Posted 15 January 2022 - 01:11 PM

You could also hold a proper size bushing or bearing in the Jacob chuck for shaft support.

I intend to live forever! So far, so good.