1249.2-Cc3 Build Sequence, Prologue

The last build sequence thread I posted was for the 1237-Cb3+ way back in March 2017. While it is still generally valid as a base sequence for many of the single center main rail (sCMR) chassis designs in the 1237 Series, there have been enough changes in both design and build to warrant a new chassis build sequence post to bring “where I’m at” in my all-wire chassis frames up-to-date. In particular there are the “diverging main rail with iso-guide mount” (DMR/iG) chassis, the 1243, 1247, 1258, 1249, and 1256 designs (listed longest to shortest main rail length). Trying to overcome my well-honed propensity for procrastination, I figured if I was ever going to do another build sequence again I had better get it done with the 1249.2-Cc3 build…

If any poor souls are still trying to figure these weird wire chassis out, or worse take complete leave of their senses wanting to try to build one of these, this is where I would recommend you focus your efforts within the 1237-Series at this time, with the DMR/iG chassis. In that regard this thread should be of some benefit. Otherwise, for any actual value, at best, there is always just grabbing a favorite beverage and perusing the pics to kill some time for mild amusement.

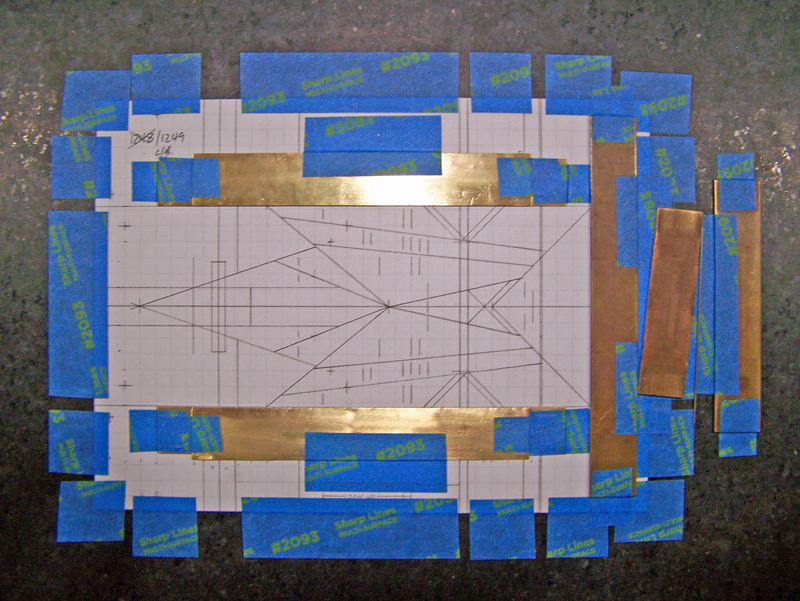

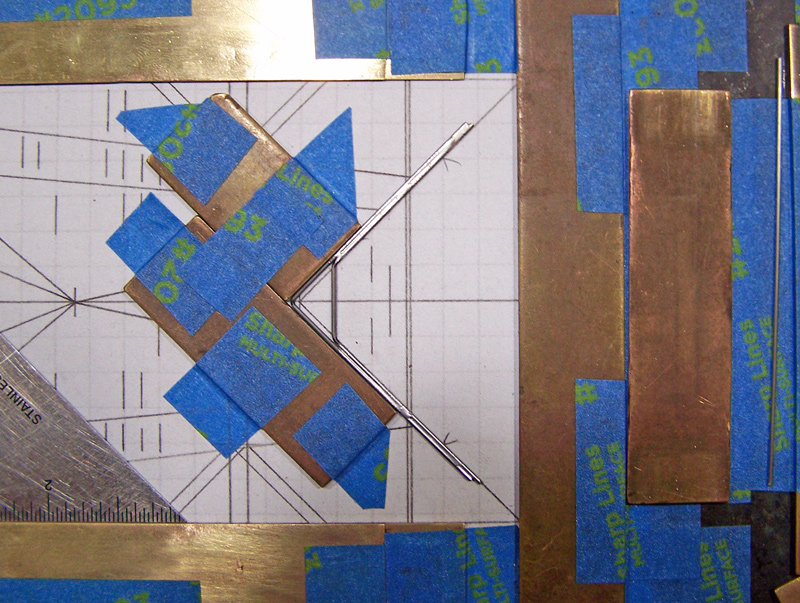

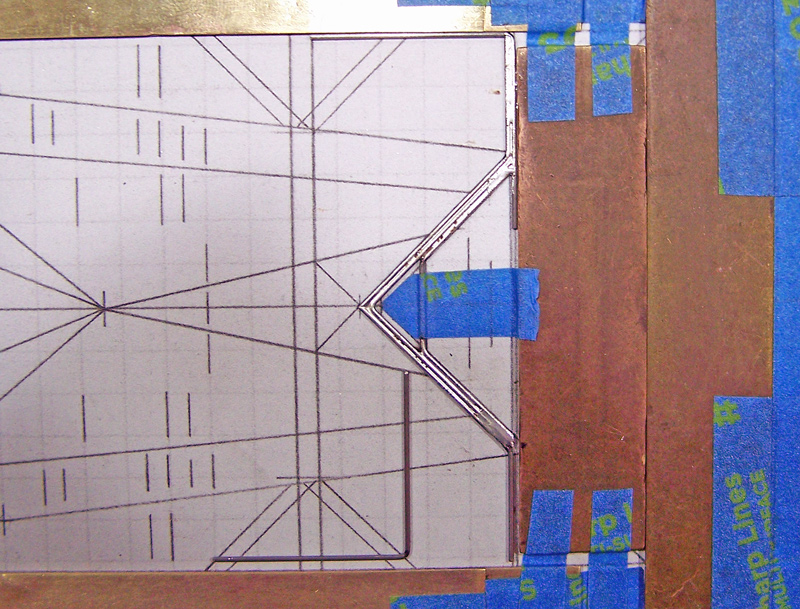

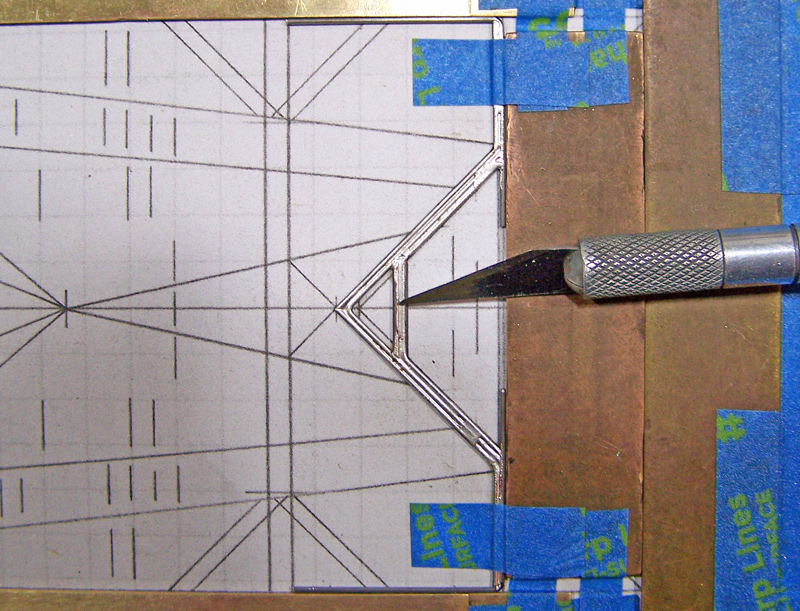

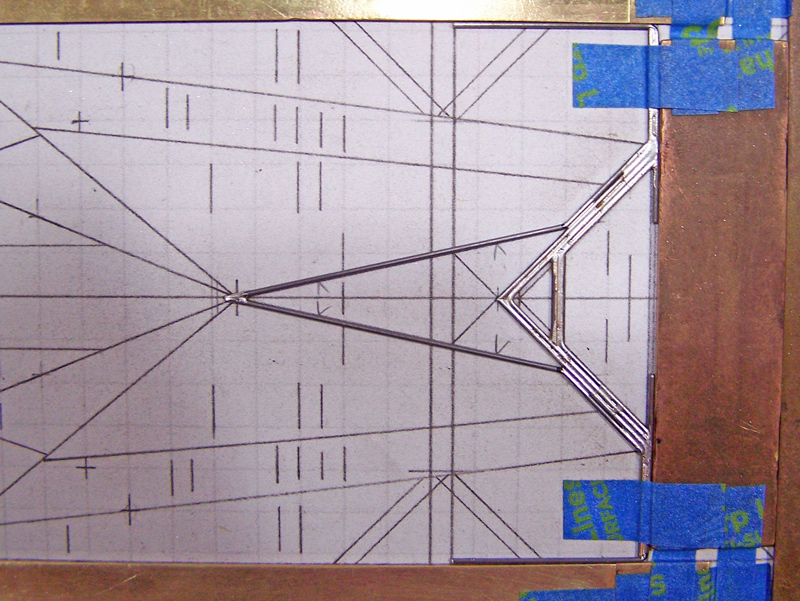

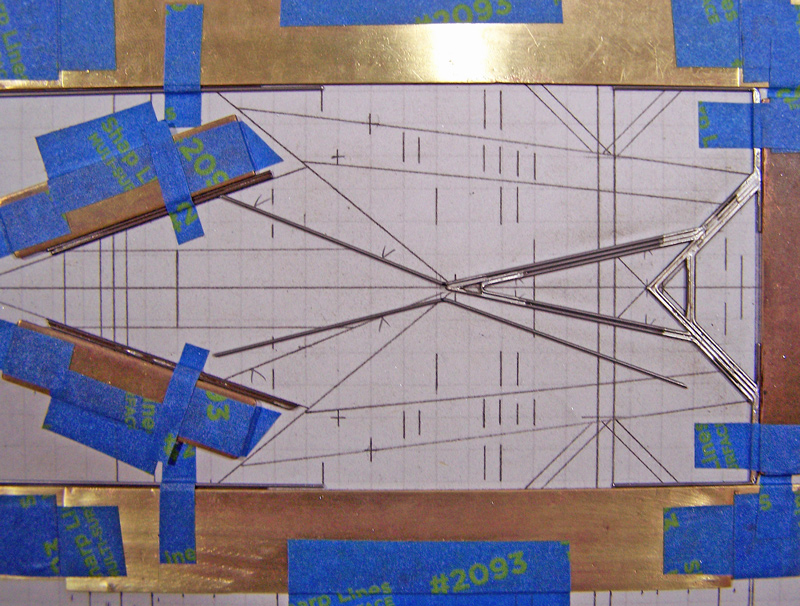

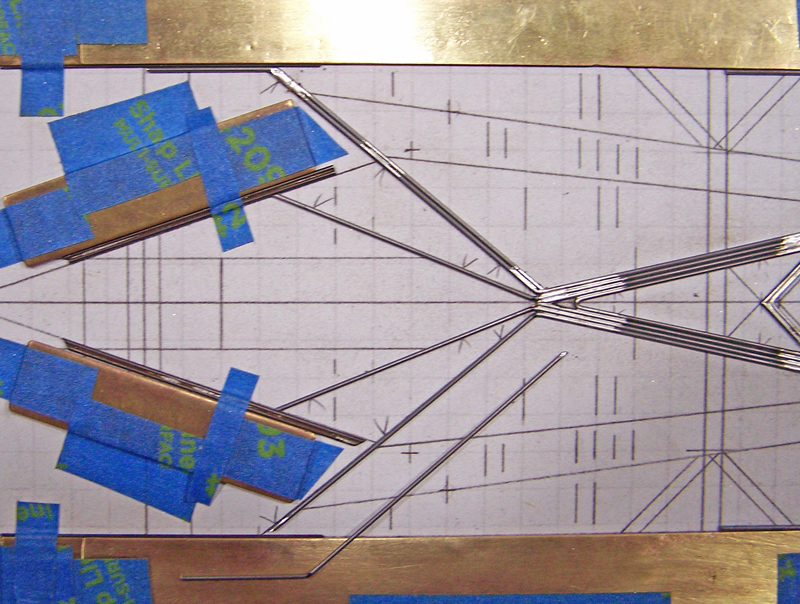

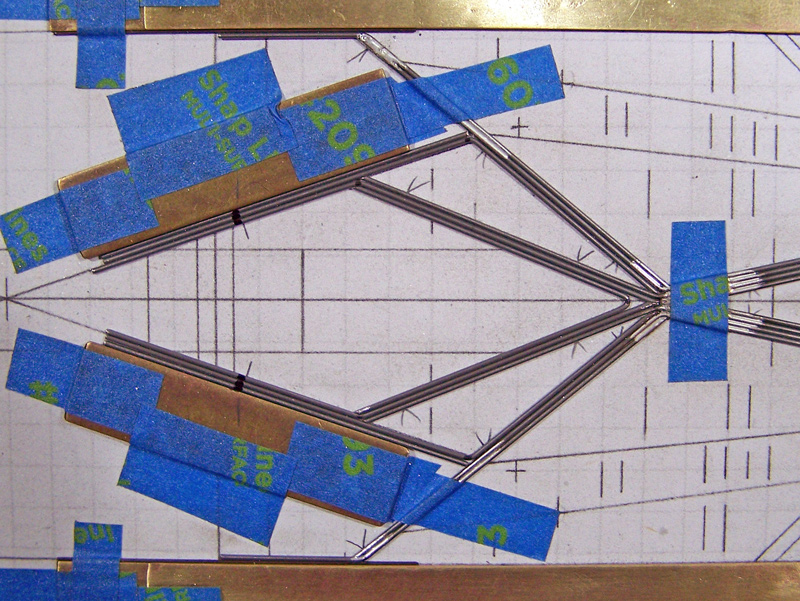

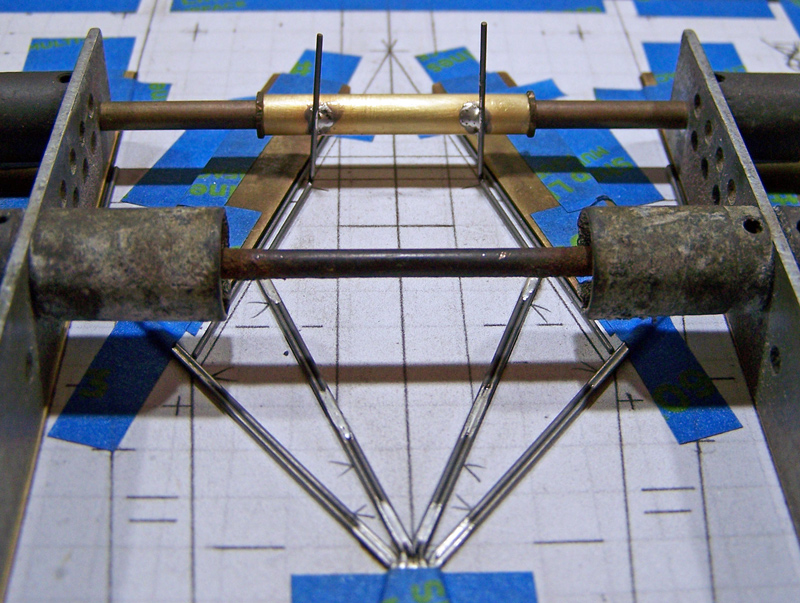

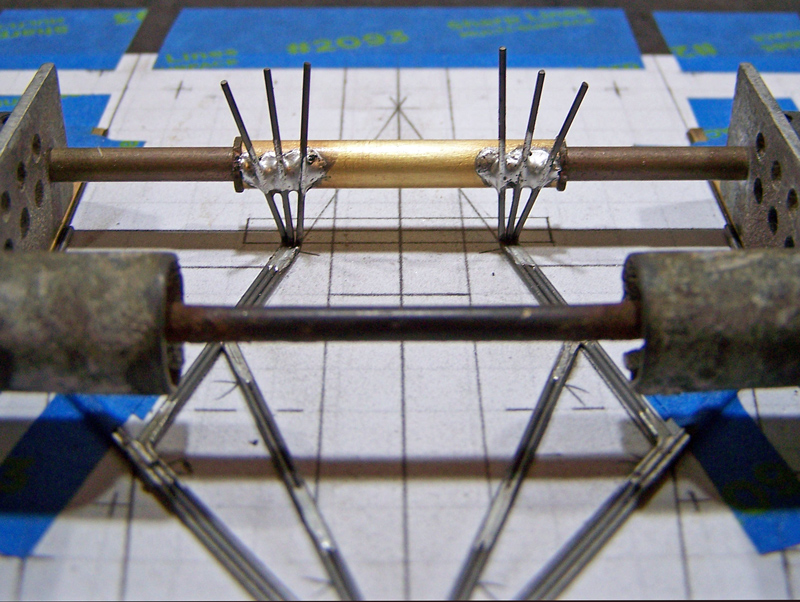

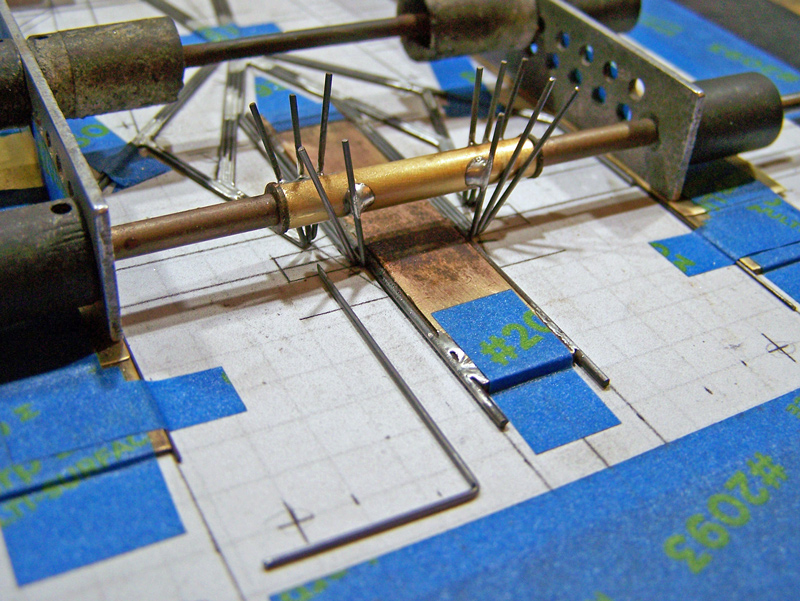

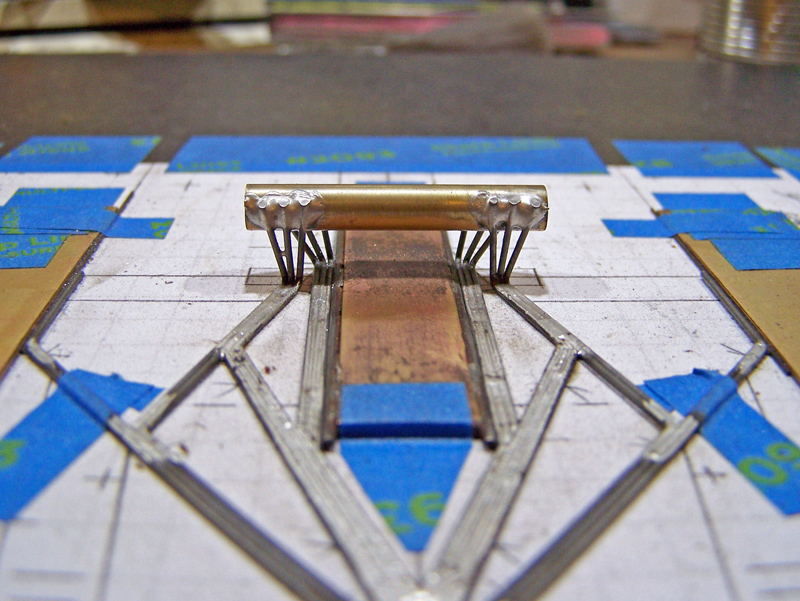

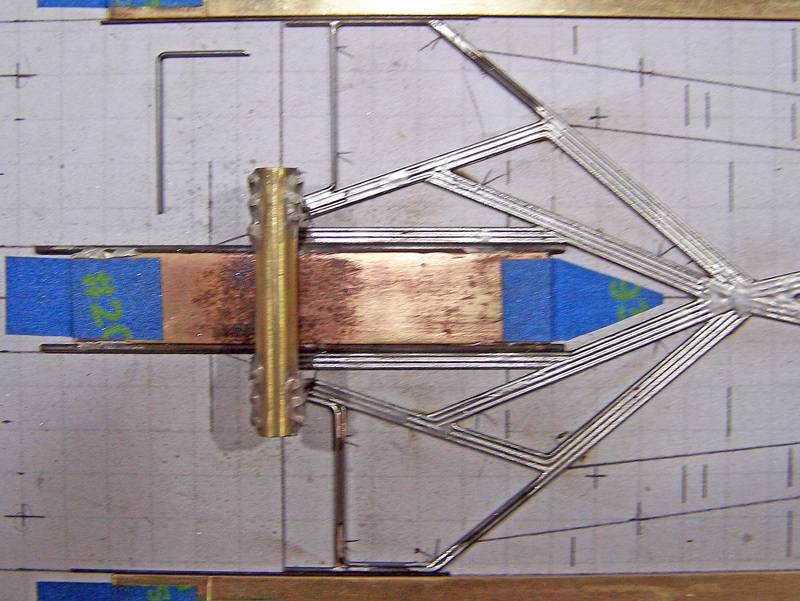

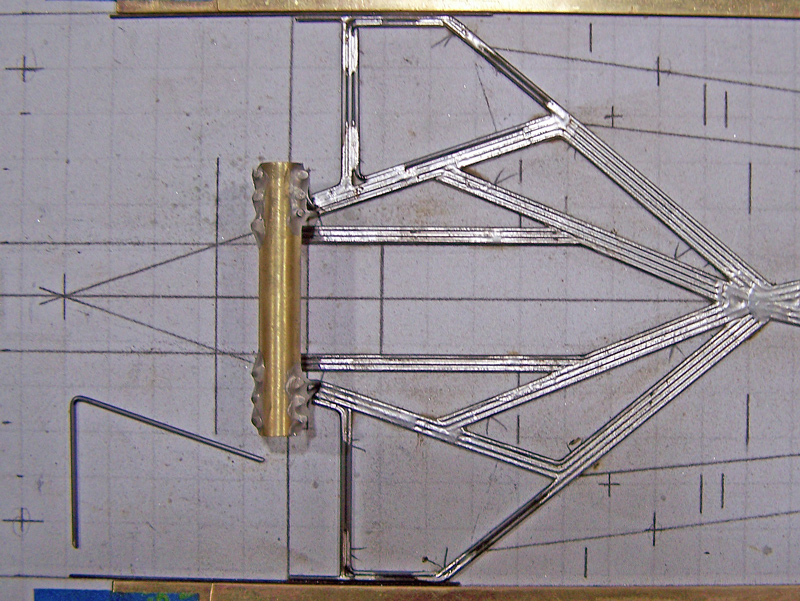

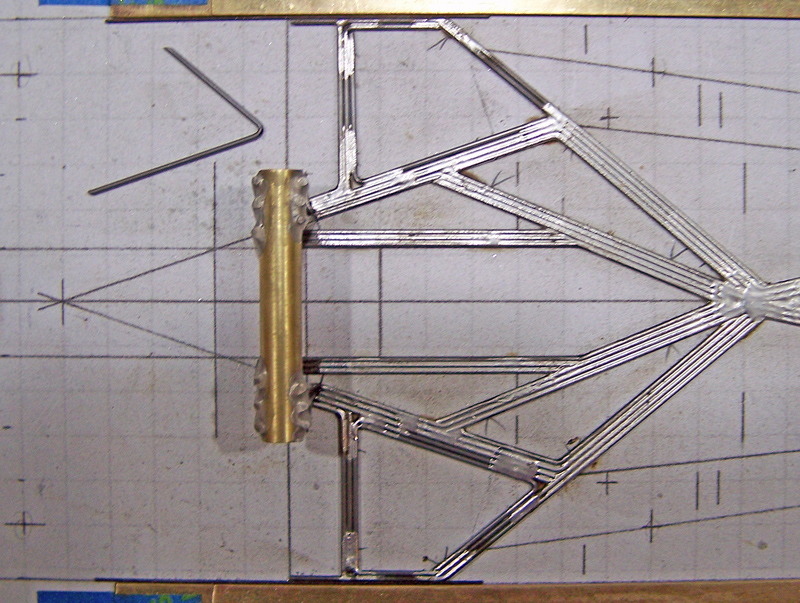

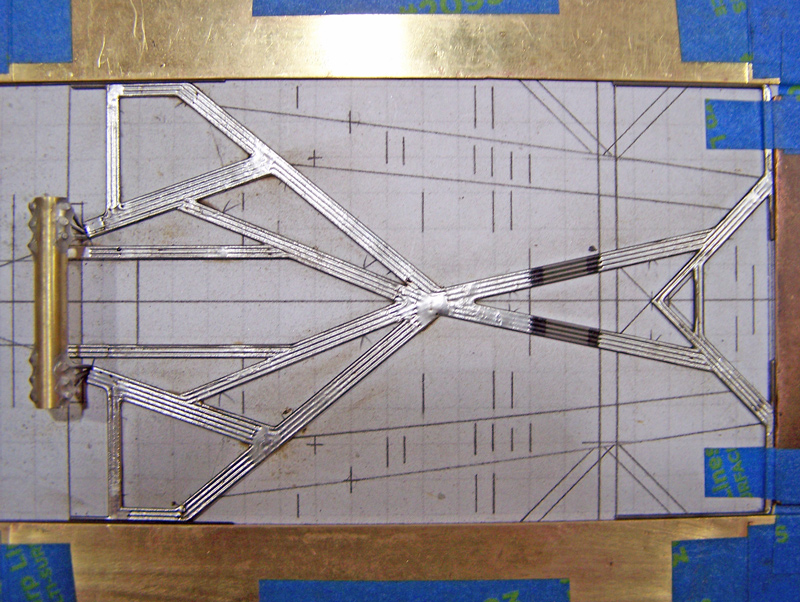

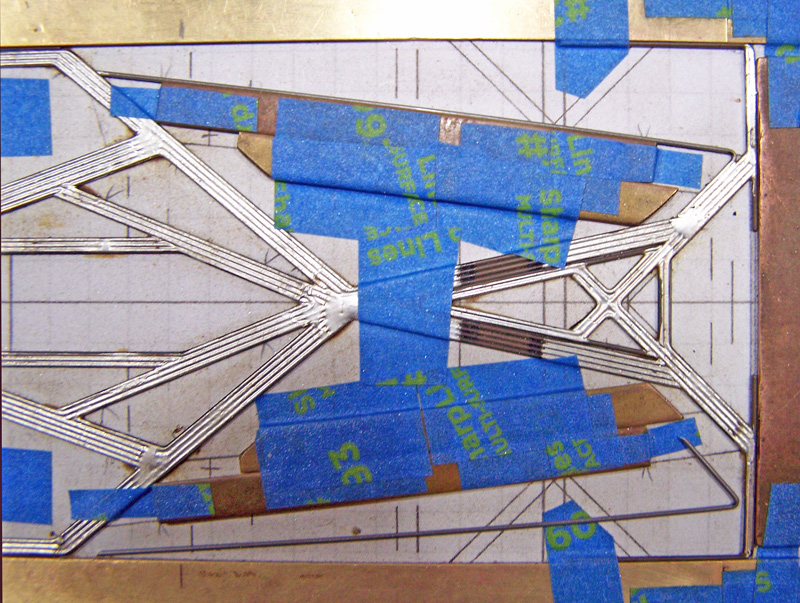

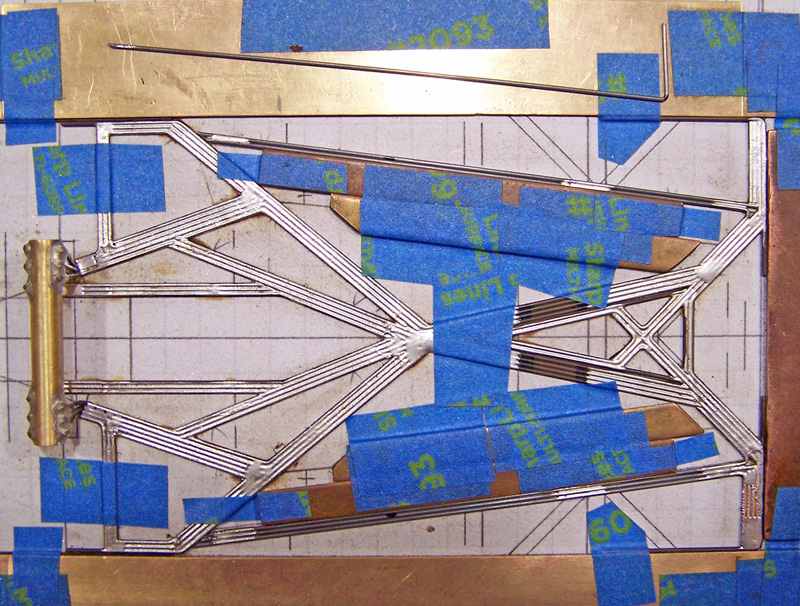

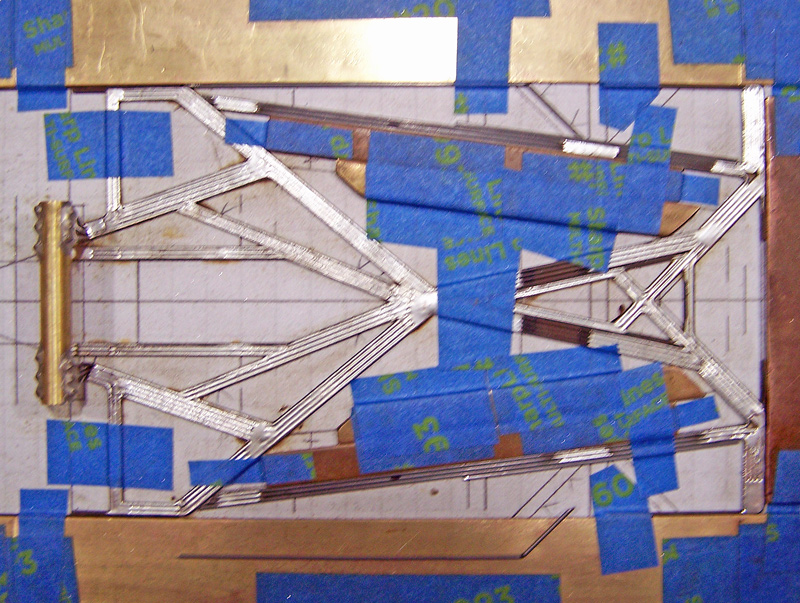

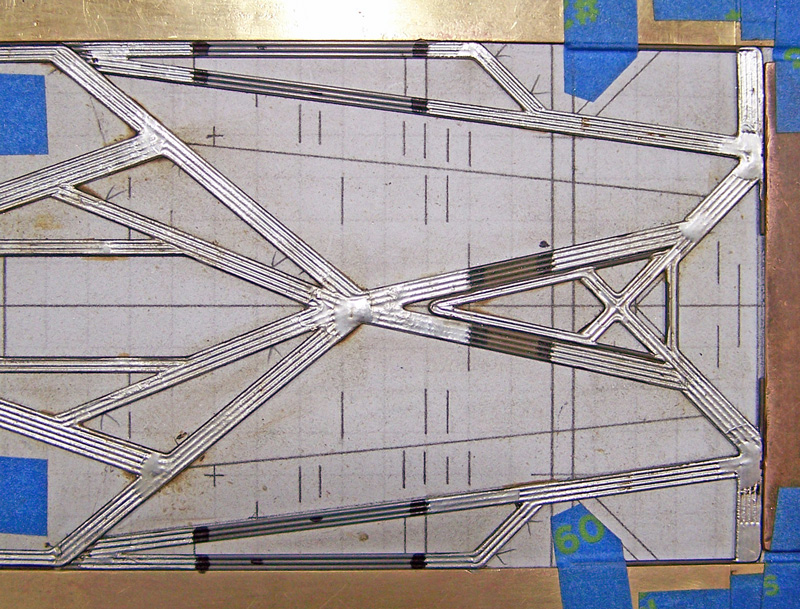

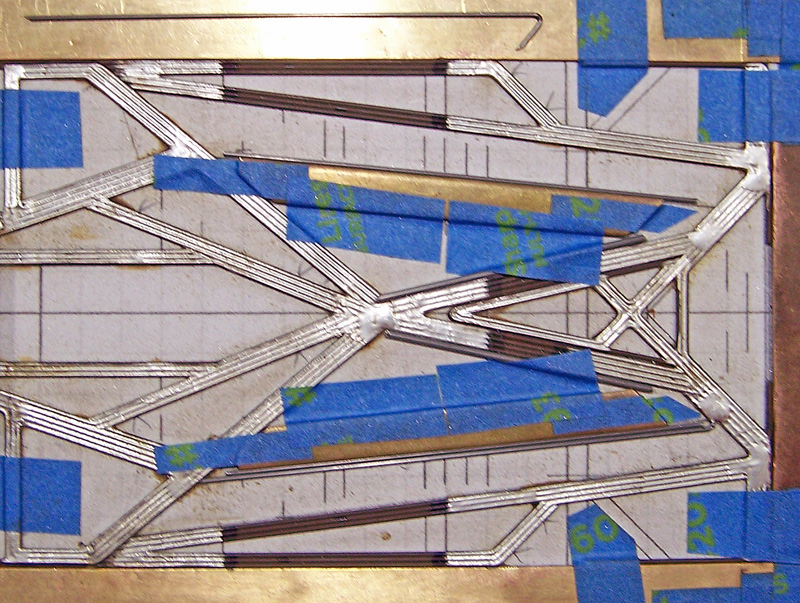

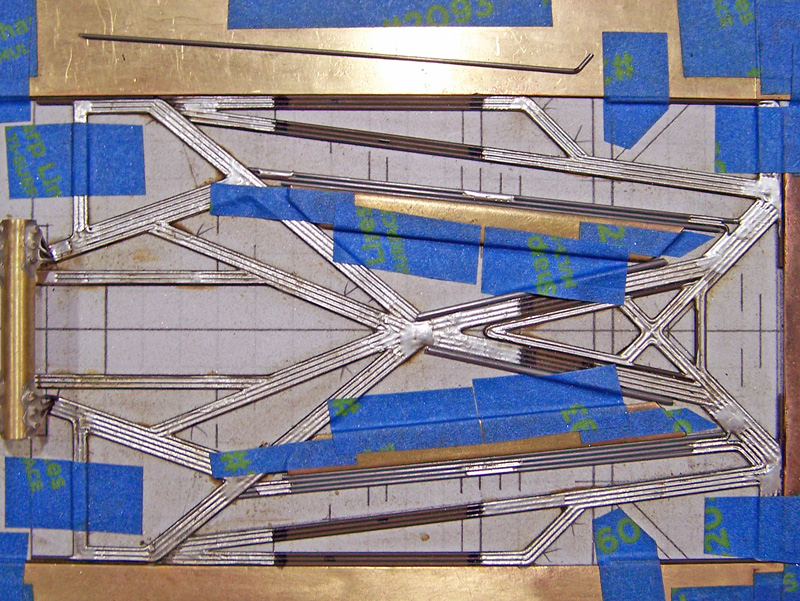

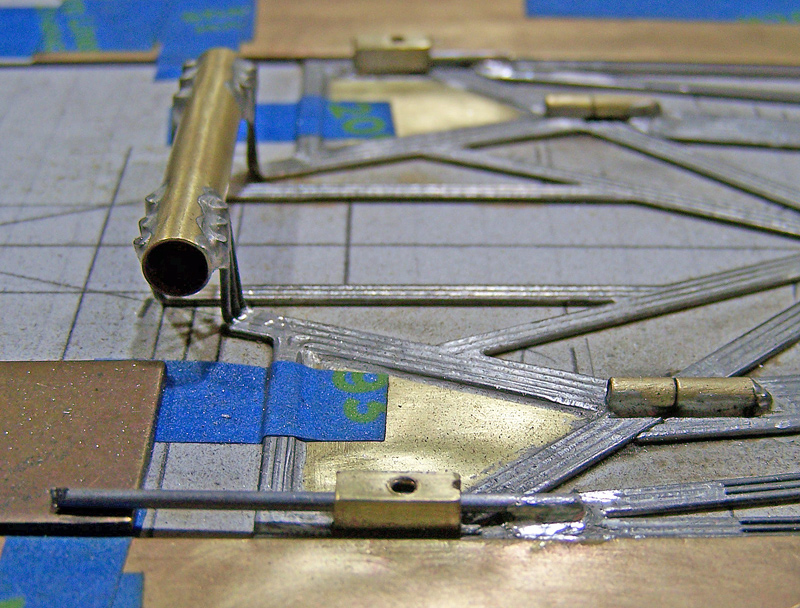

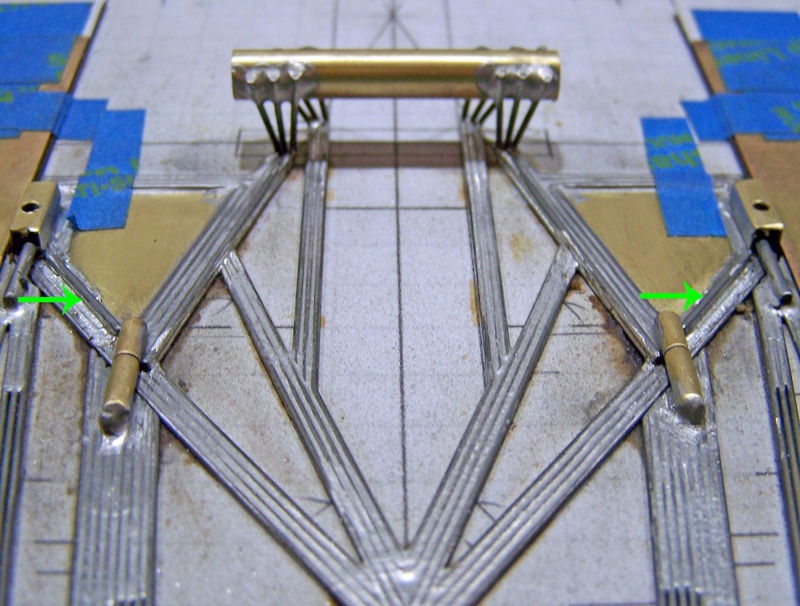

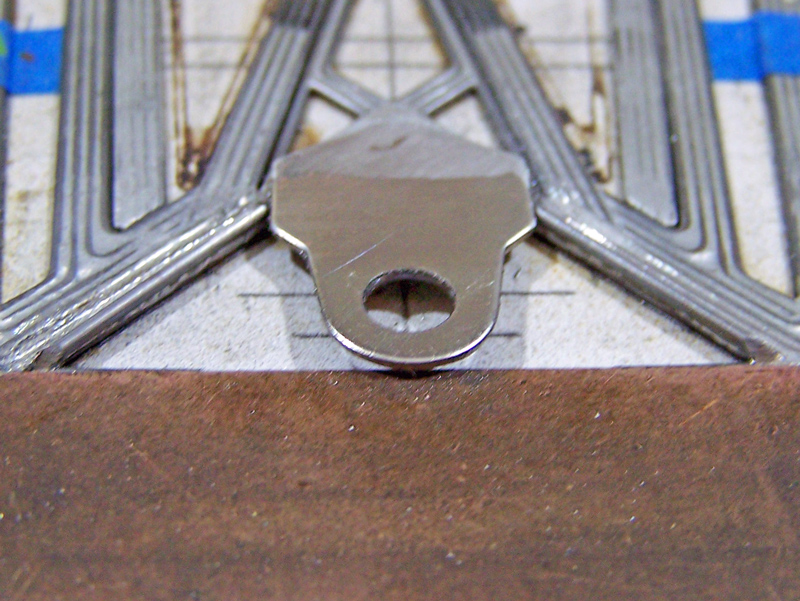

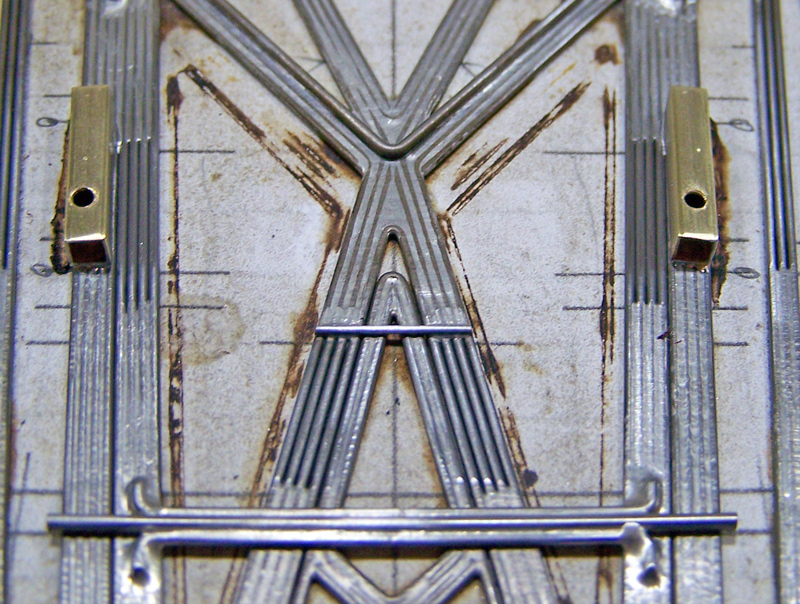

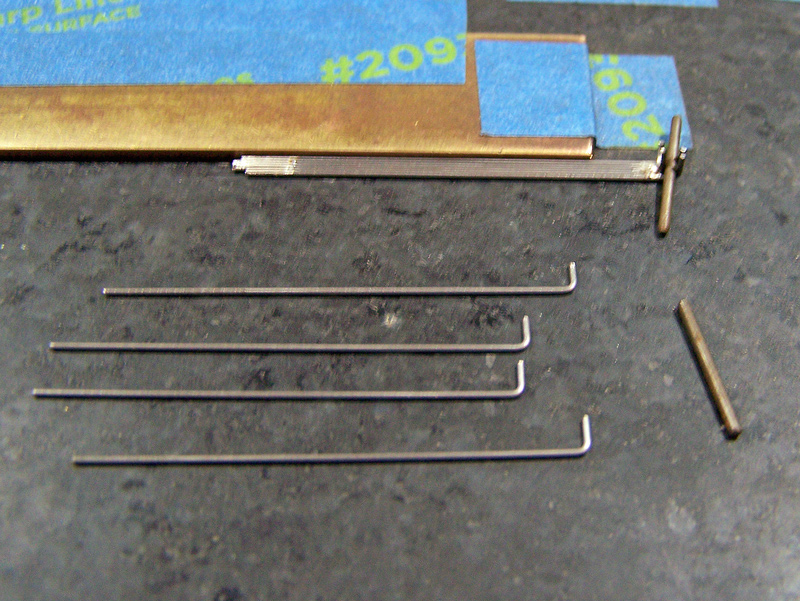

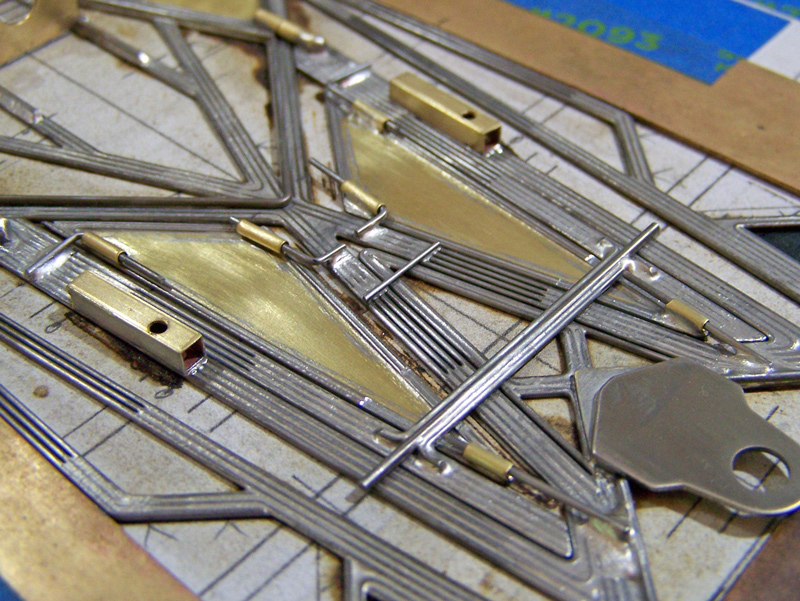

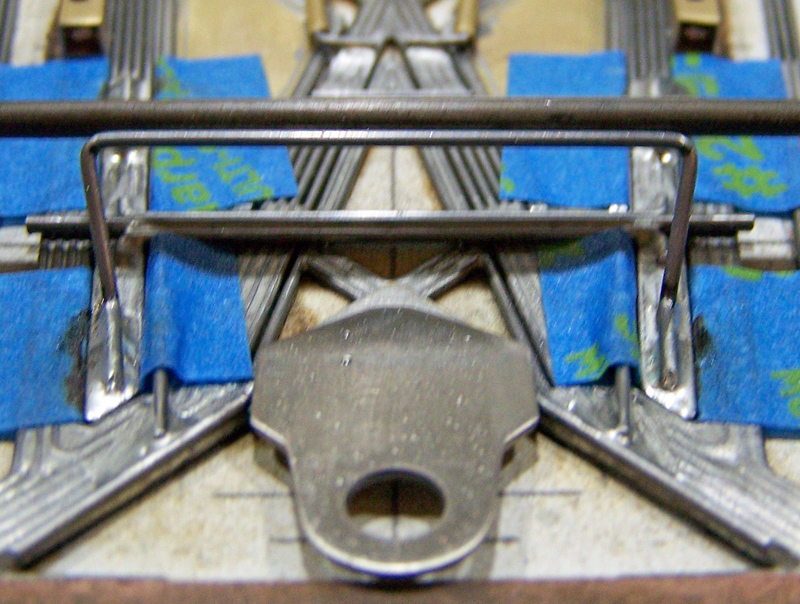

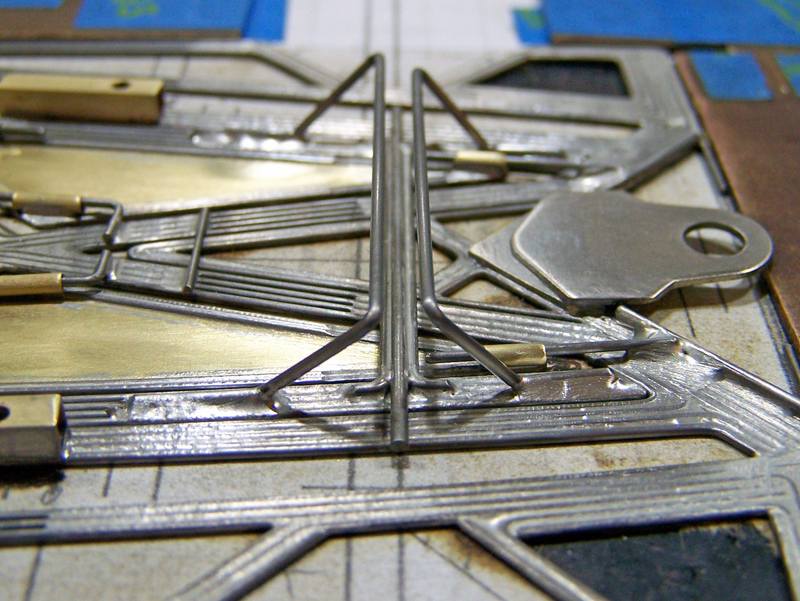

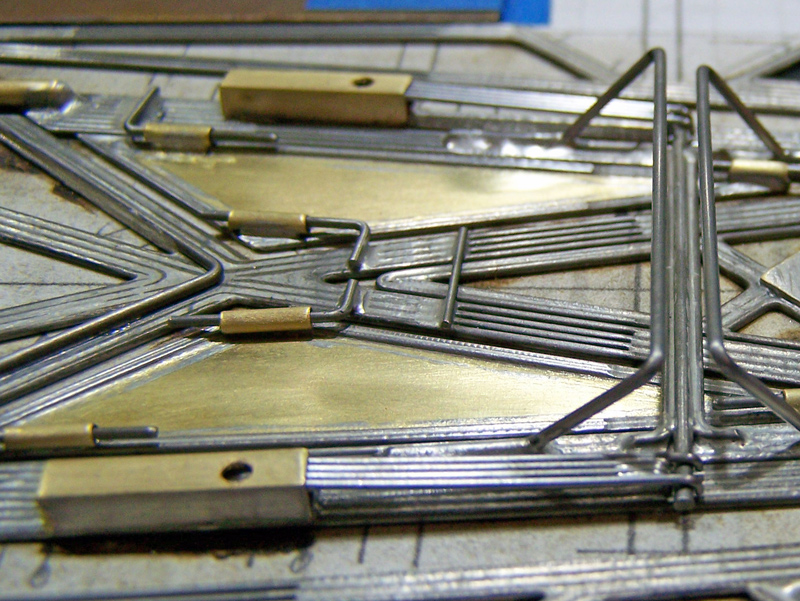

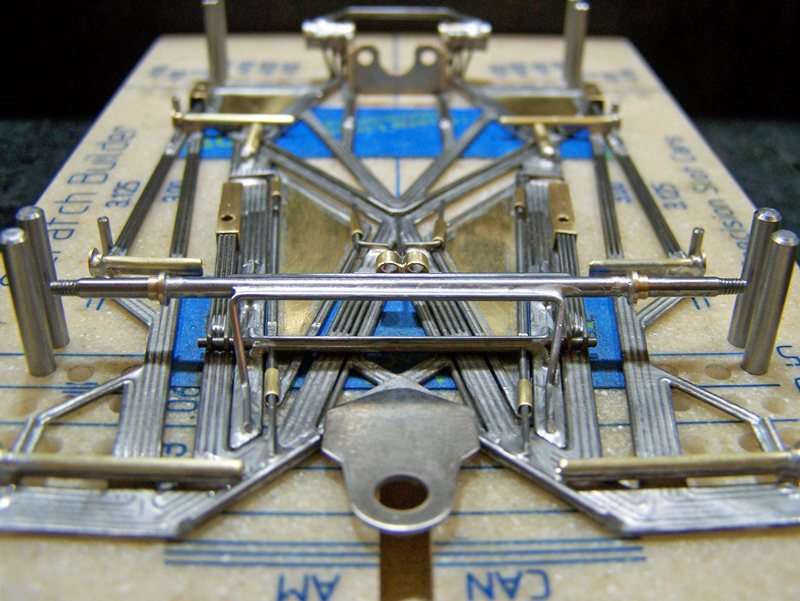

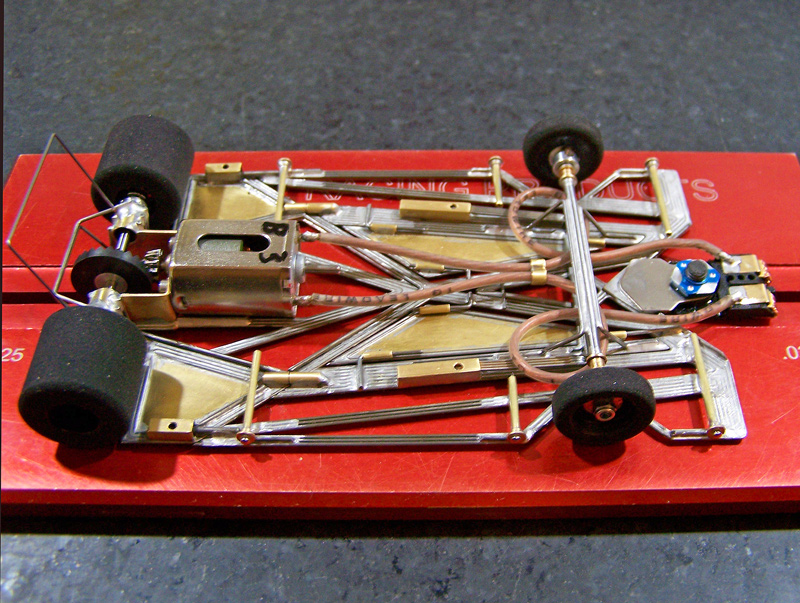

On the less technical side, and being a creature of questionable habits, my use of a graph paper design layout with well-worn pieces of brass, lots of blue tape, and the mandatory cameo appearance from my prehistoric Champion Align-O-Jig will once again be on full display. Off-camera, all the wires are still hand bent with the same pair of needle-nosed pliers I’ve had for twenty-five years.

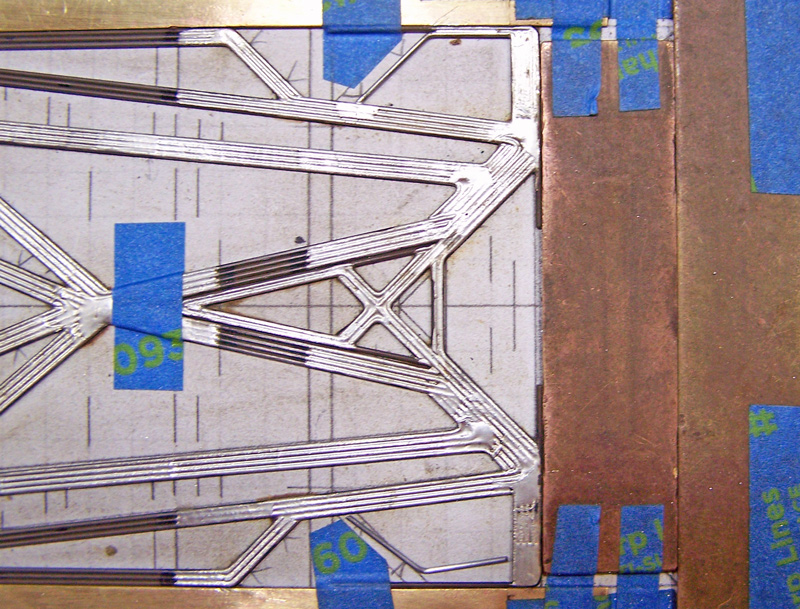

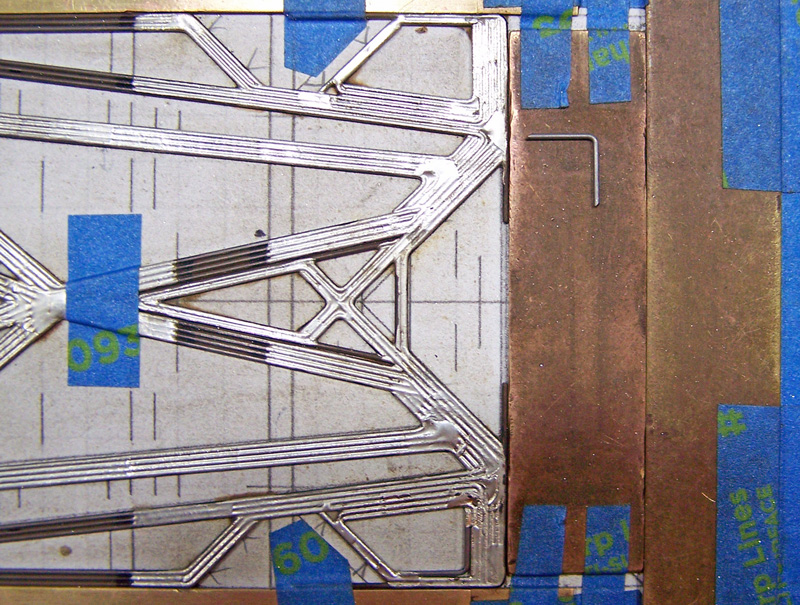

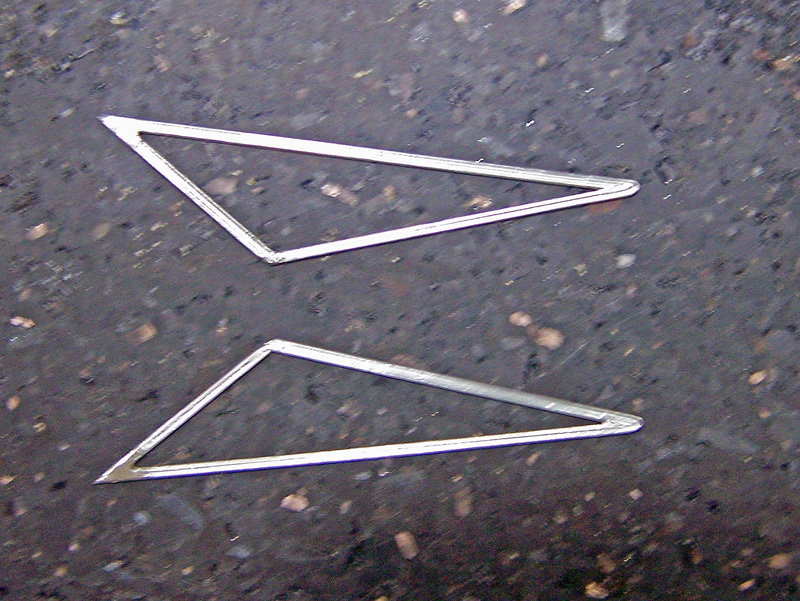

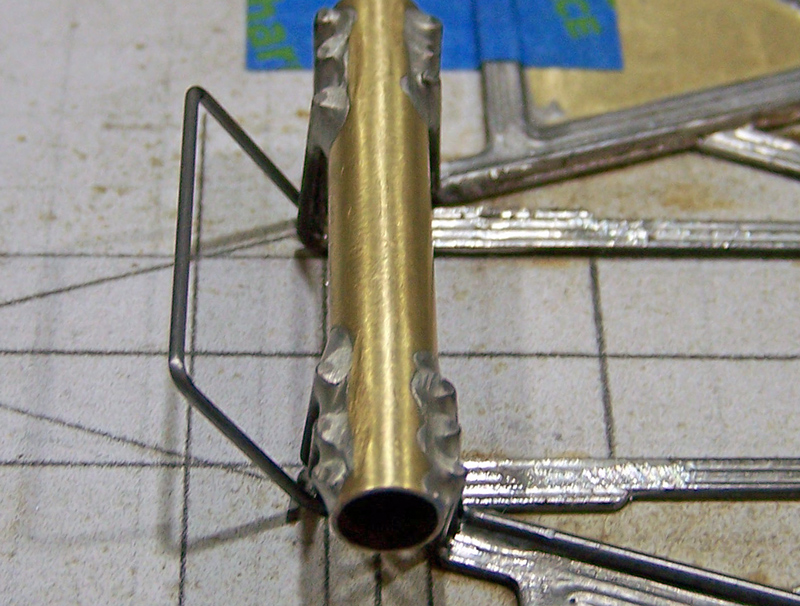

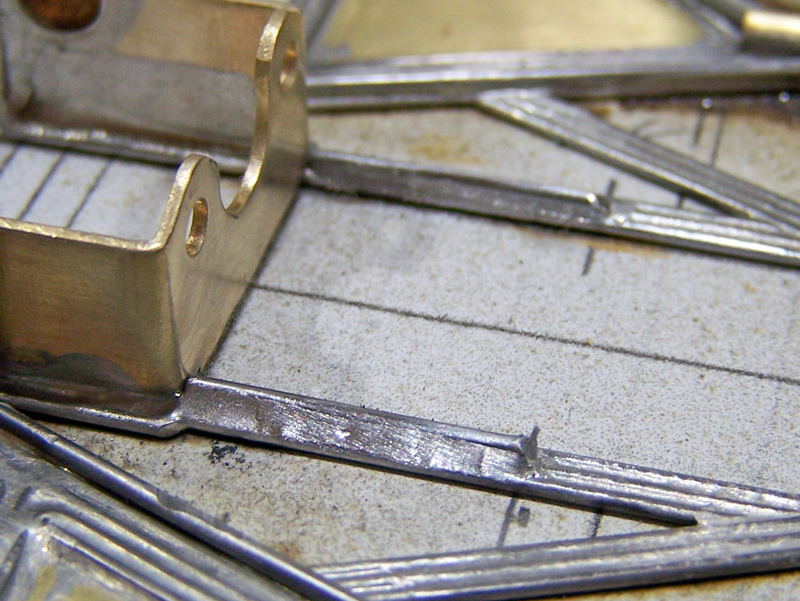

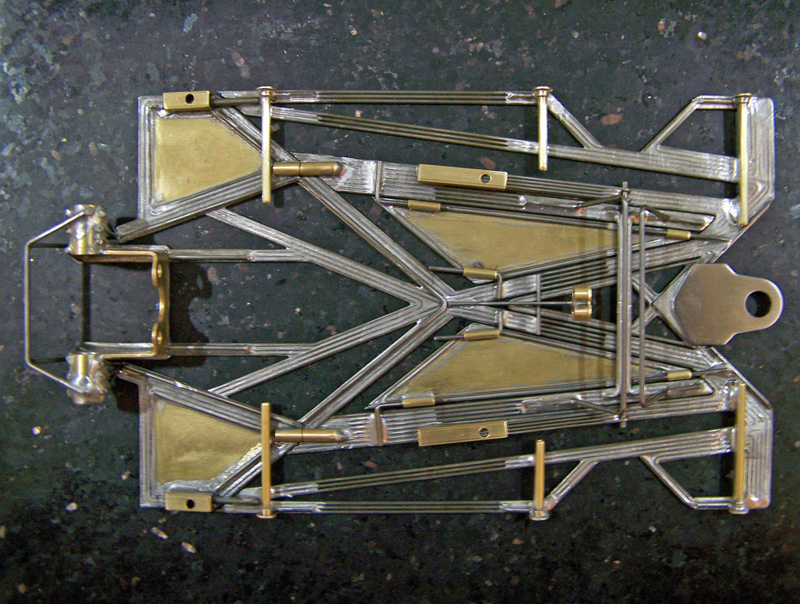

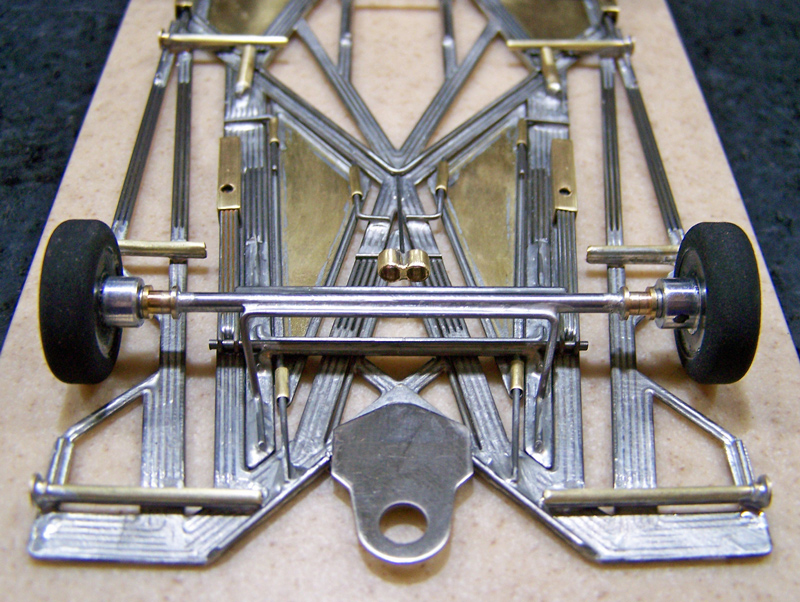

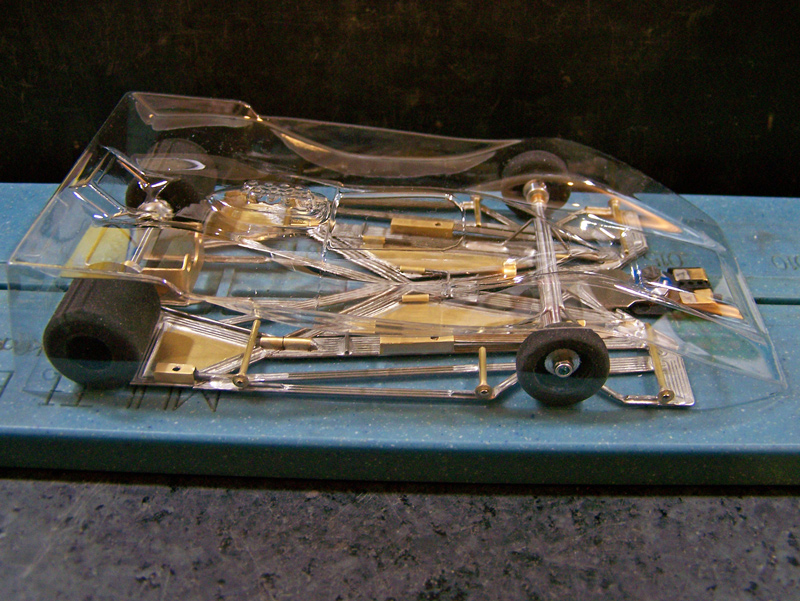

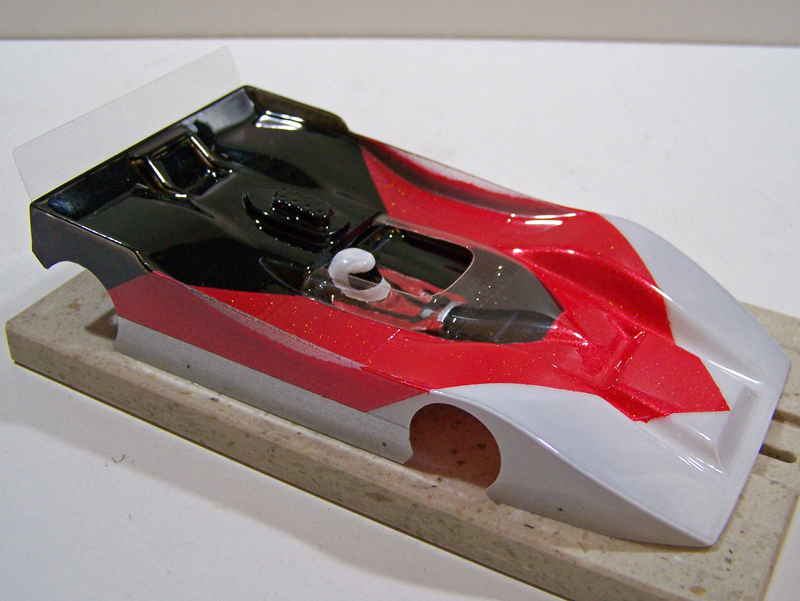

On the more technical side, the 1249.2-Cc3 build sequence will fill in some “holes” not covered in the 1237-Cb3+ post, that is in addition to the 1249 having the diverging main rails and the iso-guide mount. This 1249 is more appropriately a “c” dimensioned (4.875” RAx-GPC / 3.875” WB / 1.00” GL) chassis, and a CanAm class chassis, so it will include the dynamic pans. It will show the main frame’s wire layout sequencing which has changed slightly since the early 1237-Series builds. It also incorporates the “xxxx.2” front axle rail (FAR) layout with the accompanying torsion bar and variable spring wire (VSW) set-up. And the 1249 also has the extended version of the rear motor / drive assembly with the latest version of spine wires being used, and minor revision of the gear guard.

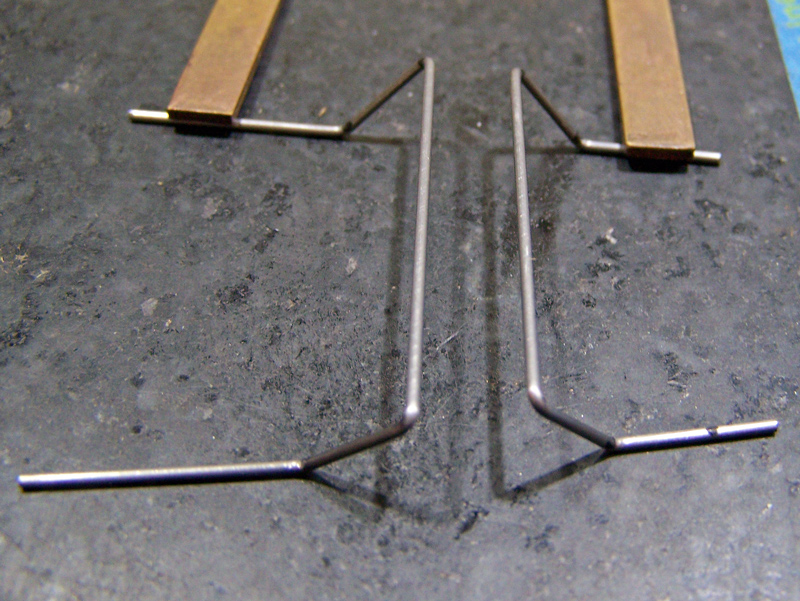

On the dysfunctional side, throughout I’ll try to go into more detail for better “visualization”, using more pictures per step for better clarity when deemed warranted (and when I remember to take the extra pics; at this point I pretty much build these things on auto-pilot, and any synaptic function is purely coincidental). Where there are two “mirror” wires being installed I’m still taking the picture with one wire in place and the other lying about somewhere in the picture, so, happy hunting.

And for even more fun I’m also throwing in pics taking the 1249.2-Cc3 chassis through roller, including the sissy bar installation, and into its final ready-to-run status.

In other words, this should be a ridiculously long thread. Please try to contain your excitement. Adult beverages and/or medications may be required.

As usual, my apologies for any blur in the photos, as I still use the quickie Bend-Solder-Click process.

Descriptions are above each picture.

All wire is 0.032”, unless stated.

Side effects may include depression, anger, ambivalence, anti-social behavior, and in extreme cases violent activities and/or homicidal actions.

Rick / CMF3