'The Goat' - Pablo custom stock car

#1

Posted 24 March 2023 - 02:37 PM

- Jencar17, Tim Neja, Slot Car Rod and 4 others like this

Paul Wolcott

#2

Posted 24 March 2023 - 05:05 PM

Builds like this are why I'm glad to see you posting again on this site. Nothing better than a step by step to show how it's done! I'll be following this one closely, I owend a 68' GTO way back when.

- Geary Carrier likes this

#4

Posted 24 March 2023 - 07:52 PM

Thanks for the photo, Mike ![]()

- Geary Carrier likes this

Paul Wolcott

#5

Posted 24 March 2023 - 07:56 PM

Hi Pablo,

Looks like a great project. I'm looking forward to following along....thanks!

- Geary Carrier likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#6

Posted 25 March 2023 - 09:02 PM

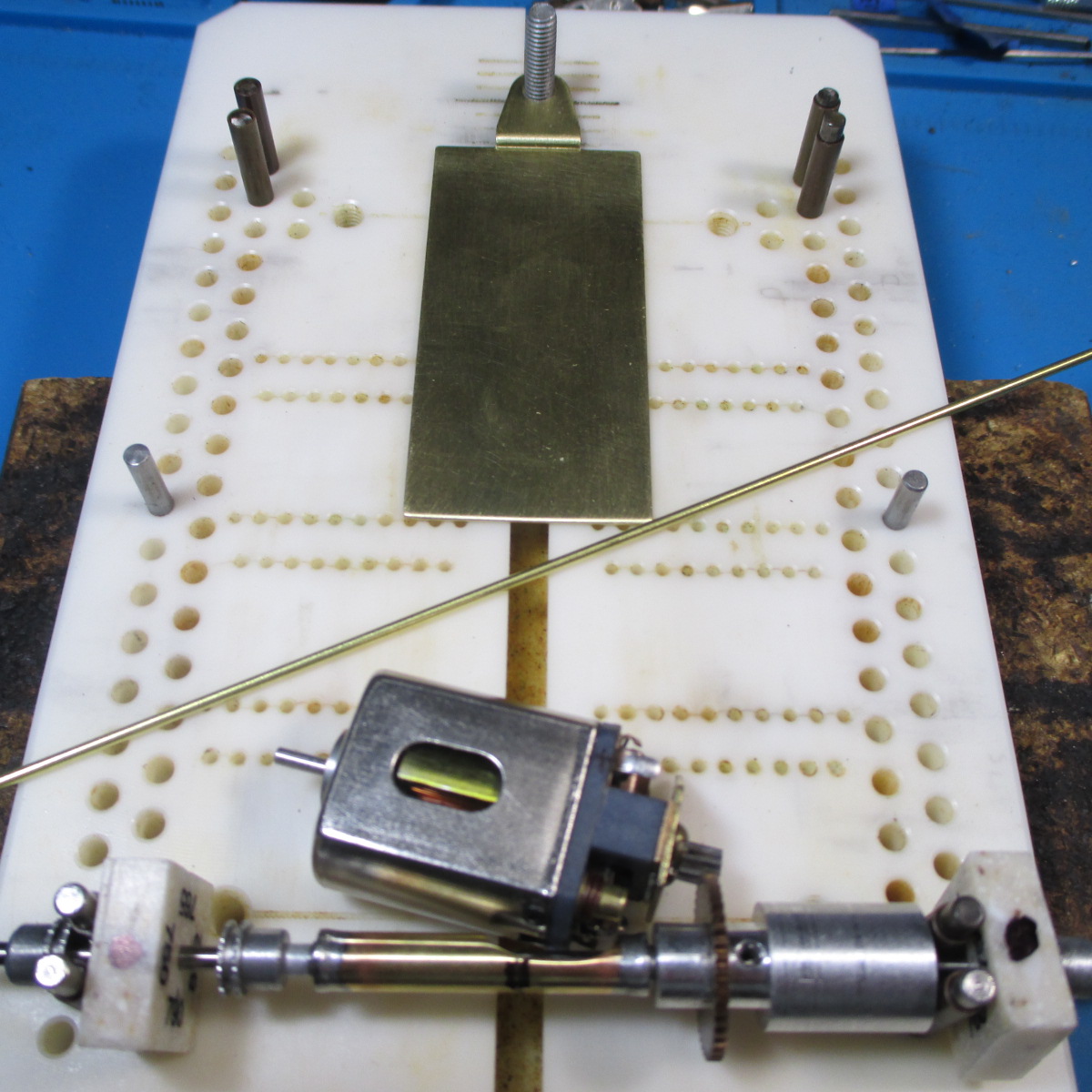

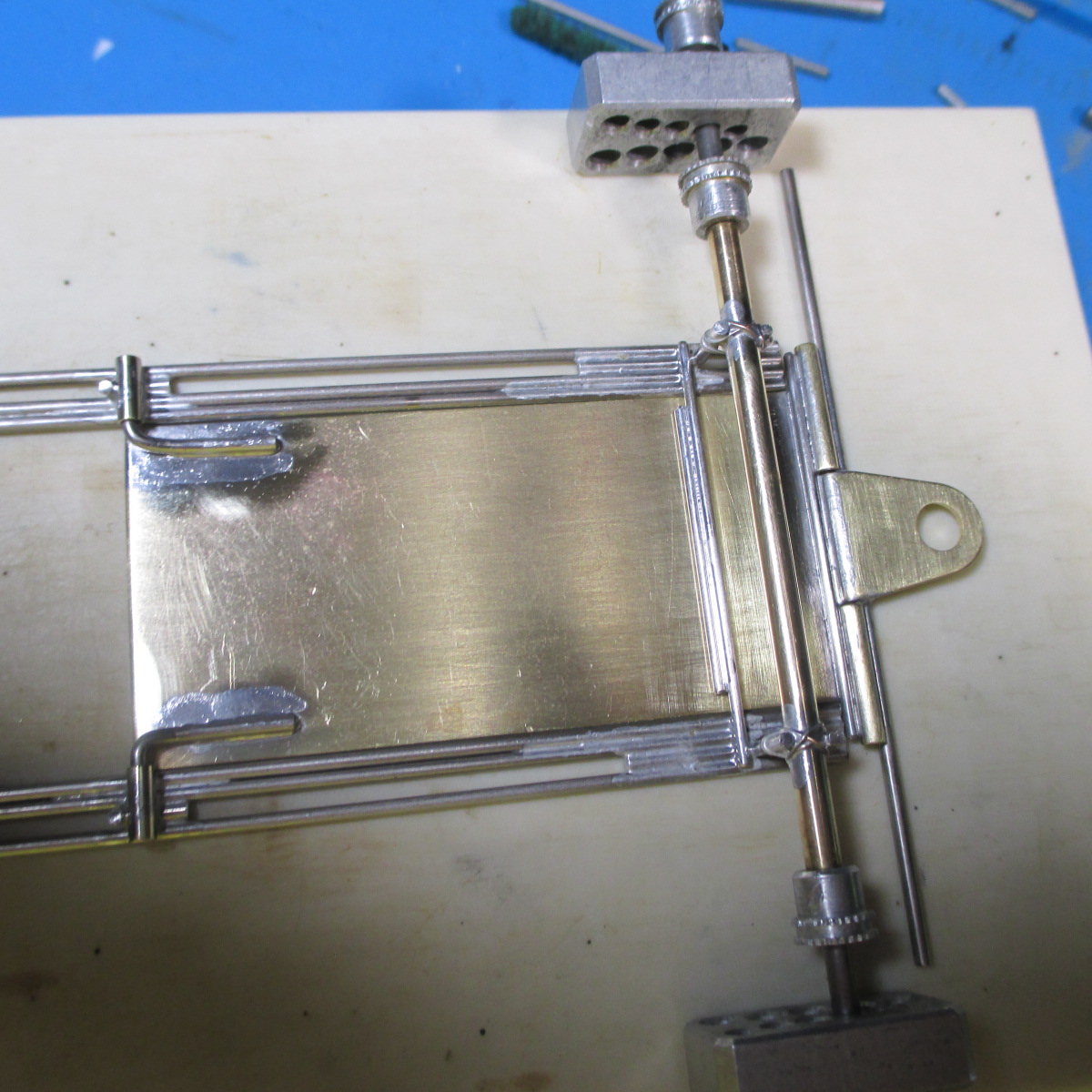

Pro-era 1 1/4" wide .032 drop arm, never used. It cleaned up nicely and I tweaked the tilt up very slightly.

Rear axle tube finished and BB's installed with silver solder. Not for strength, but to prevent melting when I start flinging 60/40 and piano wires in close proximity ![]()

Motor bracket attached temporarily. My plan is to make a practice motor box from 1/16 rod - much easier to work with as a "template" for the real one - .055 Swiss wire

- Slot Car Rod, Peter Horvath and olescratch like this

Paul Wolcott

#7

Posted 26 March 2023 - 01:06 PM

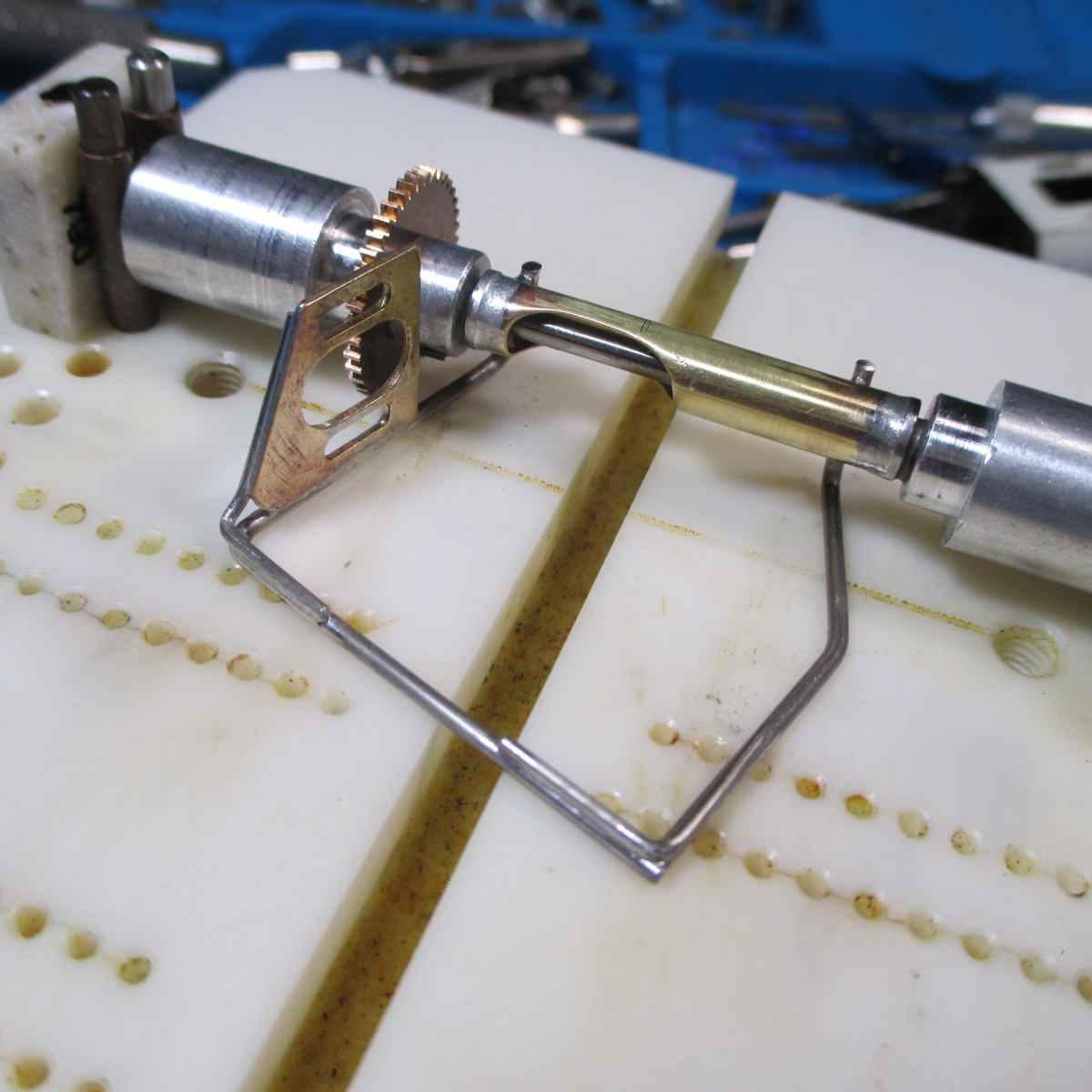

Making the "practice" motor box, it became clear the motor needs to be set as far right as possible.

It's a tricky tap dance between wheel clearances, weight bias, motor angle and gear mesh.

So I trimmed the pinion and shaft (very carefully). Scary, but it worked

- NSwanberg likes this

Paul Wolcott

#8

Posted 26 March 2023 - 07:53 PM

Nice pinion shortening job. ![]()

I find getting a motor box Korrectly setup is a real pain Pablo. Whenever I build one I

am reminded how much easier it is to build a good old Lee Gilbert style half rail chassis.

Unfortunately my favorite period of angle winder cars are mostly motor box style chassis. ![]()

- Pablo likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#9

Posted 26 March 2023 - 09:52 PM

Steve Okeefe still has a "how-to" article on here making the Emott style motor box.

I intend to live forever! So far, so good.

#11

Posted 27 March 2023 - 11:25 AM

Nice start to the motor box. I like the idea of using two pieces plus an 'L'" brace.

#13

Posted 05 April 2023 - 11:49 AM

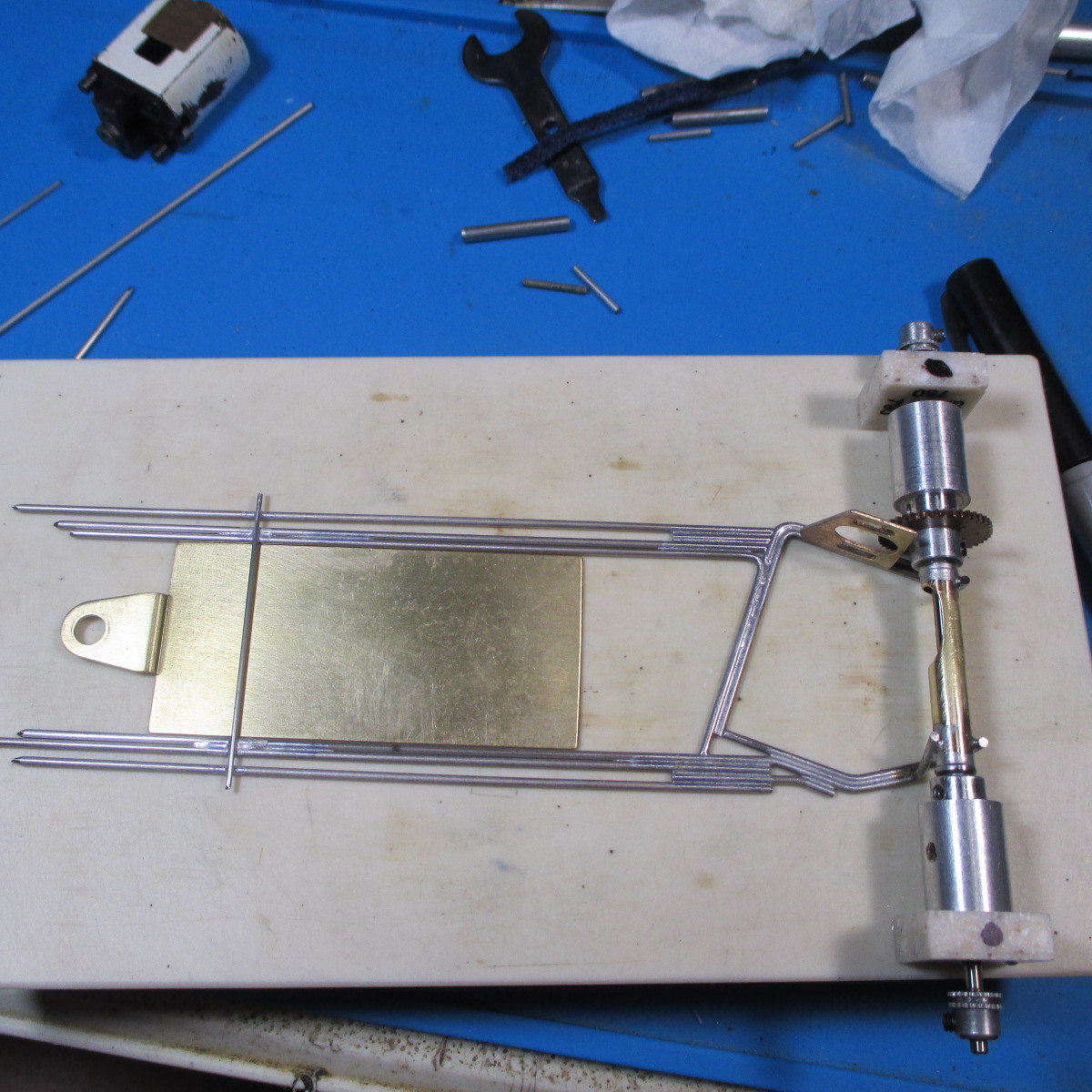

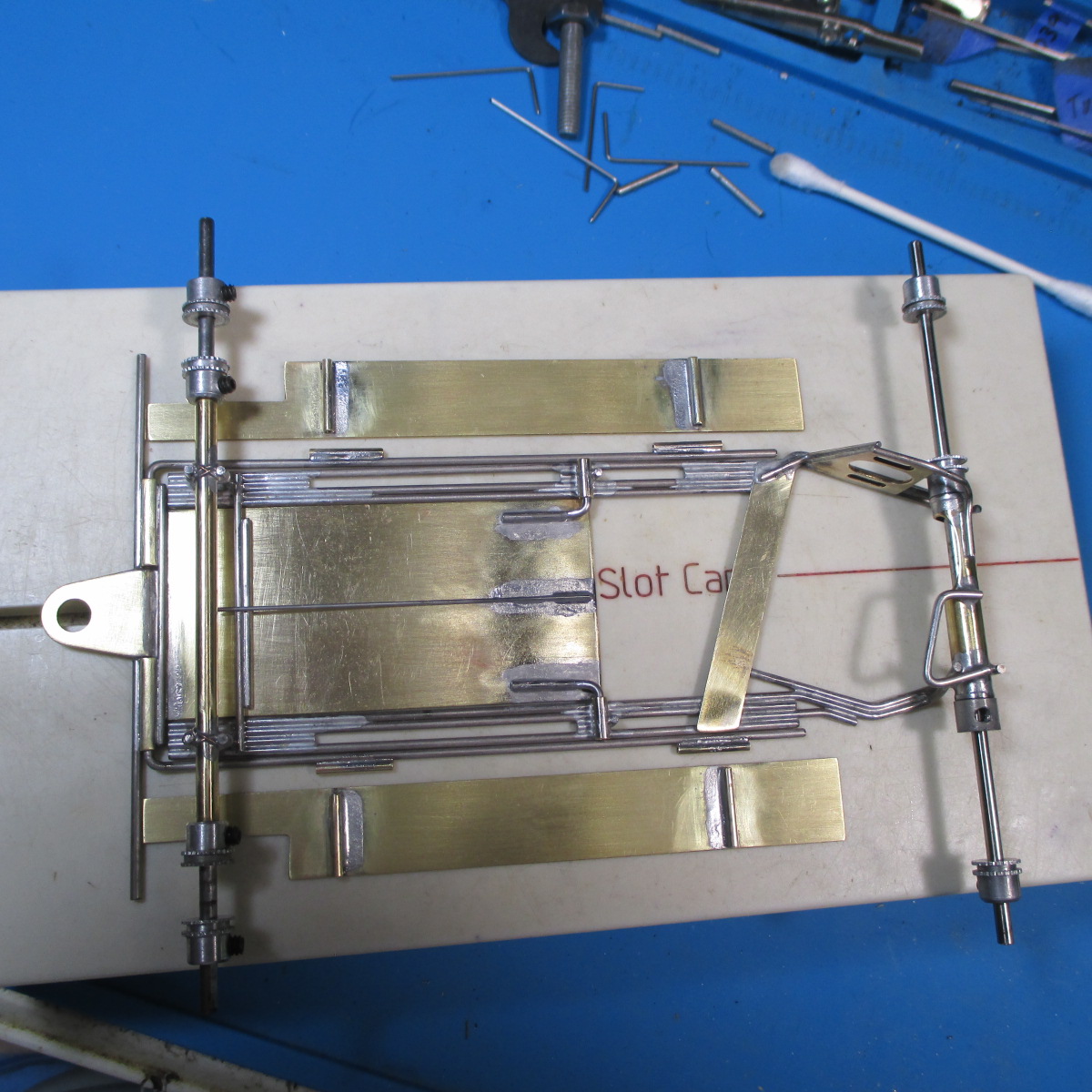

Motor box transition to rails is unconventional - this car isn't a clone, just me having fun using my gut feelings. A 1/4 wide .025 brass strip will cover and strengthen.

Since the actual BB's are already installed, a bubble bath with Dawn and baking soda is mandatory between each step ![]()

Some Lee Gilbert (R.I.P.) influence. Maybe somewhat overbuilt, but it is a big stock car after all ........

- Richie likes this

Paul Wolcott

#14

Posted 06 April 2023 - 10:32 PM

Motor box to rails cross connect brass sheet is 15 thou, not 25 - no sense adding heft to something that's already stout enough.

Front axle tube secured, dummy front rail cross connector discarded. All wires are Swiss plated - strong stuff and saves lots of time

- Richie and John Luongo like this

Paul Wolcott

#15

Posted 07 April 2023 - 12:22 PM

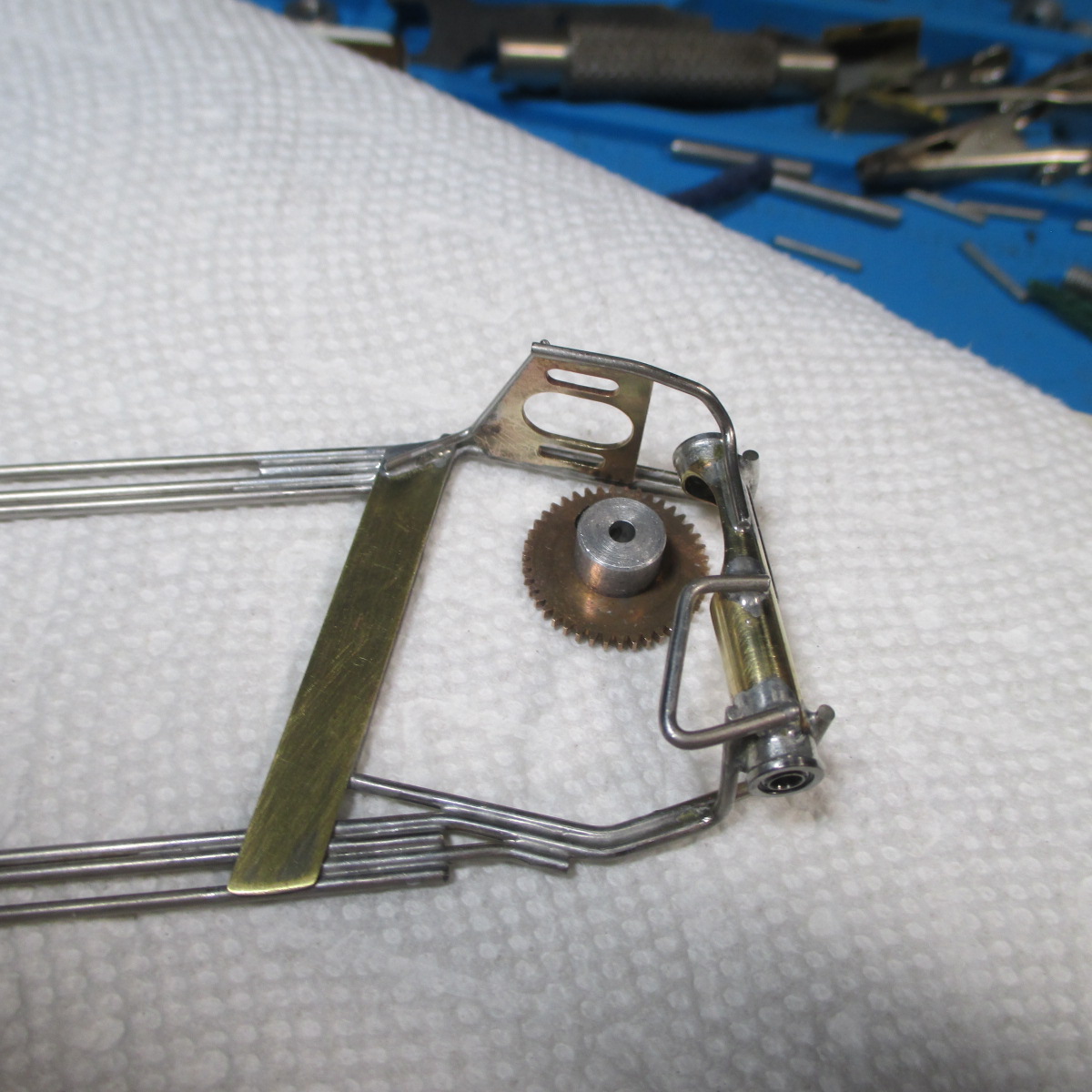

Drop arm setup for tilting plumber rails. This time I did it just like dc-65x - .063 under, then 3/32 pieces buttressed with .047 piece up top ![]()

Motor and axle supports done. Feels good to get that precious Faas spur out of there and scrubbed

Overbuilt? yes. The S16C arm is .540 OD, it's going to push a big stock car dangerously fast. You'd have to break several joints back there for a failure

- Richie, NY Nick and Slot Car Rod like this

Paul Wolcott

#16

Posted 11 April 2023 - 10:12 PM

Front axle tube uprights wire wrapped and drop arm installed. Lots of inspiration here, from Lee Gilbert, dc-65, Jairus, Okeefe, and all my Slotblog vintage heroes.

Hinge wires .055 for a hair of extra droop and wiggle. Upstop crosspiece has an extra piece placed about .023 lower to compensate for the .032/.055 disparity.

- Tex, Richie, Slot Car Rod and 1 other like this

Paul Wolcott

#17

Posted 12 April 2023 - 10:27 AM

I am enjoying your build, looking "super sano" ![]()

- olescratch likes this

#18

Posted 12 April 2023 - 10:57 AM

Very nice work P! ![]()

![]()

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#19

Posted 12 April 2023 - 11:14 PM

Thank you, gentlemen ![]()

Design influence now turns to Mike Katz, in a world where simple rectangular pans always work well on stock cars. 1/2 x .032 trussed up for pin tube surgery on the RGeo jig

Solder is Koford silver. It won't melt when I attach hinge wires in close proximity with 60/40. Dries super fast and it's easy to see when it's done

- Richie likes this

Paul Wolcott

#20

Posted 13 April 2023 - 01:06 PM

This is going to be one hot GTO!

- olescratch likes this

#21

Posted 13 April 2023 - 01:40 PM

Can we see the body Paul? Pleeezzze?

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#23

Posted 13 April 2023 - 06:20 PM

looked bloated. My brother had a red '72 GTO which I drove several times.

- Pablo likes this

I intend to live forever! So far, so good.

#24

Posted 13 April 2023 - 07:24 PM

So... what you gonna paint on it?

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#25

Posted 13 April 2023 - 08:40 PM

The car has not been earmarked for a potential buyer yet so the paint can be anything I want.

The moment I saw Mike Low's post #3, my mind was made up - black

Jairus, do you want to do it for me? That would be great ![]()

Chassis is coming along nicely. Drop arm wire is .025 - I started the solder joint a little at a time going forward until I got the amount of pressure I wanted.

When I lift the front axle, the tongue droops a little, not much. A little "decoupling" is all it needs

- Richie likes this

Paul Wolcott

This topic is locked

This topic is locked