Having observed my step-son create so many versatile and appealing creations with his three 'D' printers, I find this project to be an innovation to the slot car industry. The design is very functional and adjustable, and most of all, very cost effective. Having said that, I have to admit that I've been out of the slot car world for the past 20 years, so I'm not very qualified to evaluate the feasibility of this endeavor. I do find this outside of the box approach interesting, and I look forward to monitoring the evolution of this project, and wish all involved much success.

Most innovative slot car in 50 years...

#26

Posted 02 January 2024 - 04:14 PM

- Cheater likes this

#27

Posted 03 January 2024 - 10:06 AM

One observation I forgot to mention was the tires. As I stated, I've been away from slot car racing for some time; has tire evolution gone from foam construction assisted with tire bite to a smooth, what appears to be a silicone coated slick? Or is this tire specific to the next gen concept?

#28

Posted 03 January 2024 - 03:17 PM

Just curious... by what yardstick are you claiming “most innovative”? Performance, scales appearance... what??

And BTW I’ve been continuously involved as shop owner in slots and R/C since the early sixties. I’ve seen almost everything produced for sale. Early slots had suspension and some had steering. Failures across the board. And I only remember one R/C car from the '70s that had a stamped steel chassis. And it was a toy.

- team burrito and Tim Neja like this

#29

Posted 03 January 2024 - 03:27 PM

As I said in post #4 in this thread, the subject line is "simply puffery." I am sure it was designed to drive viewership.

IMO it does not refer to the actual product.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#30

Posted 03 January 2024 - 08:10 PM

Mike,

I'm not claiming it to be the 'most innovative,' I just find it to be a fresh approach to what I was racing in slots, again some 20 years ago! The appeal for me is the utilization of 3D printing, as noted not requiring the investment of tooling, etc.,, and yes, I remember steering and independent suspension in slot cars from the '60s. Sometimes forgotten (or underdeveloped technology) makes a comeback, as noted in a prior thread analogy.

We don't know if it's going to work out better than what you have today, or what I raced 20 years ago, but when creativity and innovation are permitted to exercise in an open environment, good results can happen. As a youngster, my dad took me to Indy Car, NASCAR, Trans-Am, and Can-Am races during the '60s and early '70s, and one of the most appealing aspects of those incredible experiences was the revolutionary technical evolution that exploded in front of us. Roadsters to rear engine cars, turbocharging, wings, turbine power, ground effects, and so on!

So, yes, a few years later down the road, I still get a little excited when something new pops up.

Regards,

Steve

#31

Posted 03 January 2024 - 10:26 PM

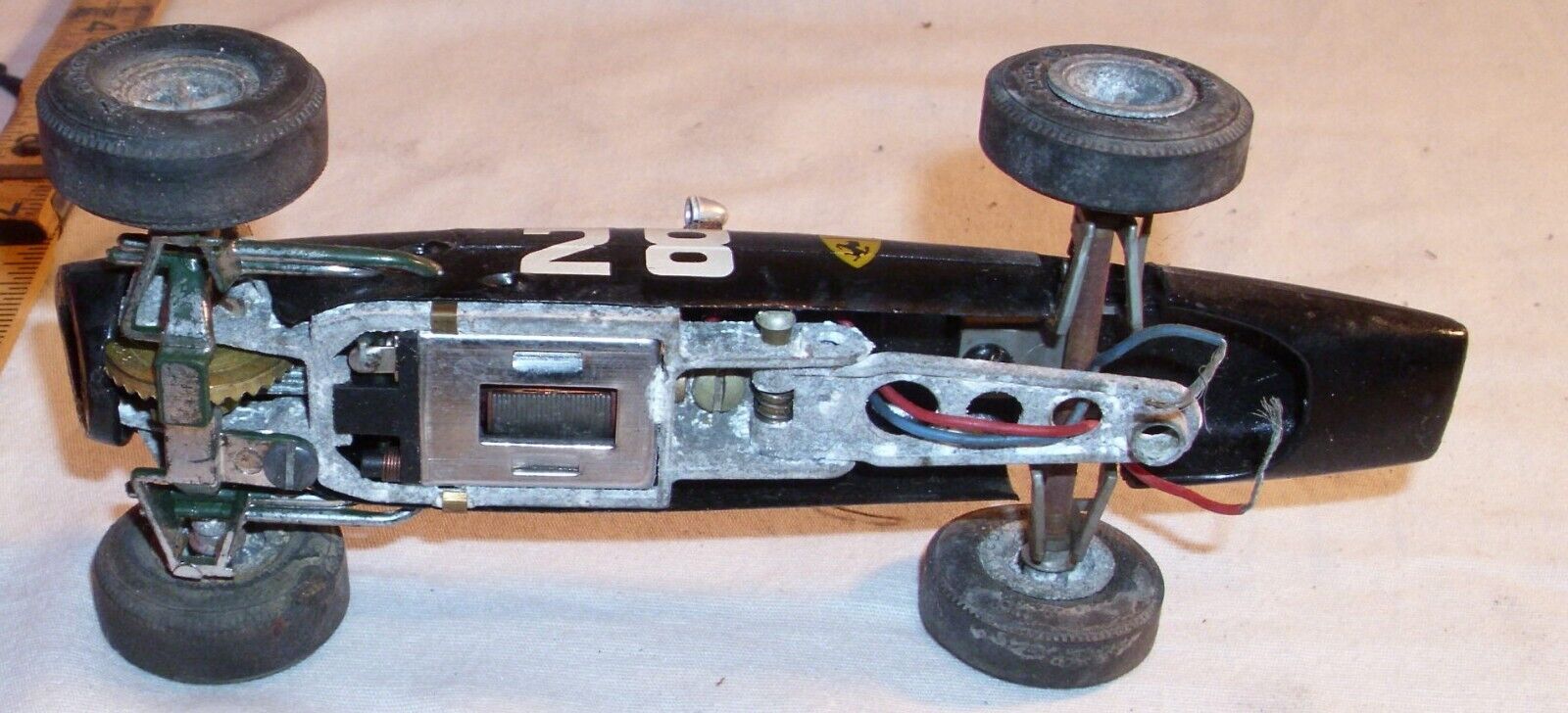

Every time I see your car it reminds me of the Cox magnesium chassis of the mid 1960s. Some had an Ackerman type front steering set-up and others had a front suspension set-up.

Yes, of course, the Cox car is a sidewinder and this new car is inline but it has a lot of similarities.

And then there is the Cox inline magnesium cars with a front suspension.

I have to agree with Aaron's post wondering who this car is targeted for? Maybe an entirely new class of it's own?

That might make sense rather than a car that would be competitive with a recent inline IRRA car like one of these.

Nonetheless, I'm all for innovation and am looking forward to see how your project progresses.

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Co-Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#32

Posted 03 January 2024 - 10:33 PM

I most certainly agree with innovation. The reason that I love the 1:1 racing in the sixties the most of any era is just that. Innovation. Even though I still never miss an Indycar race, I yearn for the old days when drivers/mechanics pulled all nighters pounding sheet metal in their garages and dragged the finished product to the Speedway.

But be careful over-hyping your newest endeavor. Slot racers can be a fickle bunch and you will turn them off before you’ve had a chance to plead your case. IMHO your car has zero chance competing against even the simplest commercial car today. They look deceptively simple but have a ton of technology behind them.

All that being said I will keep an eye out for your future developments. I can see a class for just your new cars working. Just make them durable and realistic. Bonus points if it includes the ability to tune the suspension, etc., similar to 1:1 racing. That that would be cool.

- team burrito likes this

#33

Posted 04 January 2024 - 10:06 AM

Yes, everything about this new car (except the 3D printing) has been done before. I would have been more impressed if it featured a rear differential that was adjustable like those on R/C cars. The diffs tried in the past were "open" types, which allowed the unloaded tire on curves to loose grip. A ball type diff keeps power on the loaded tire (outside) yet allows the rear wheels to spin at the different speeds required by the different radii each tire follows. That means that each tire remains at it's own limit of adhesion, and is not scrubbed along, breaking traction.

We are comparing apples to oranges here. This new car represents a different approach to slot racing. Building cars that emulate real cars with the use of tunable fully independent suspension. This approach may gain some traction once the cars are on the market. A new market segment might develop around these cars, but slot racers tend to be set in their ways. It will be a hard sell. I suspect the new segment will be made up of people who have never slot raced before, and are more interested in the "realism" and less interested in just going fast.

And then, what happens if this concept takes off. Now you need thousands, (or tens of thousands as we have seen in the 1/32 home set market), of copies to supply to the market. 3D printing, as it is now, is no longer viable. The fastest SLS printer would take up to 15 minutes to make a single suspension control arm for one of these cars. A plastic injection machine, with a twenty cavity mold and a one-second cycle time, could make twenty parts per second, or 1,200 parts per hour. And at that rate, the cost of the tooling fades away. It would be fully amortized in a single run. For the next run, if the market supports it, the tooling cost would be zero (not considering mold maintenance costs, which on plastic injection molds is pretty low).

#34

Posted 04 January 2024 - 10:17 AM

Actually, Dave, I was at a Pepsi 500 race way back when and Trinity, by way of Tony P, showed up with an experimental ball diff in a Grp 7 car. It was very cool engineering wise but feel flat on its face in the donut. He fiddled with for awhile then took it out and raced with a straight axle. I asked him months later about it and he said something like “junk” or something.

- MSwiss likes this

#35

Posted 04 January 2024 - 10:28 AM

As far as the 3D printing issue not working for high production, if this concept takes off I think Doug would be very happy to have that problem in the future.

- Dave Crevie likes this

Jim Difalco

Difalco Design

3075 NE Loquat Lane

Jensen Beach, FL 34957

(772) 334-1987

askjim@difalcoonline.com

#36

Posted 04 January 2024 - 01:21 PM

Well, in 1987 I built a 1/24th scale R/C car, since a few racers had discussed building smaller tracks that would fit small facilities. It had a ball diff that worked as well as the 1/12th scale units. At the time I couldn't find a spur gear with holes for balls, that was small enough in O.D. for the much smaller tires slot cars were using. R/C car tires, being closer to scale size, were less of a problem. Also, as the balls got smaller, fine adjustment became more difficult. All problems I knew were solvable, but I was not slot racing at the time and wasn't able to devote time on both hobbies.

The 1/24th scale R/C cars (full proportional steering and speed control ) appear to be all off-road machines with big tires. One company, Carisma, had rallye cars that have smaller tires. I don't know what type of arrangement they use for drivelines. And at this point, I'm not going to get involved in producing a new product. I agree with Tony P., a wing car probably would not see much of an advantage. But cars that rely mostly on mechanical grip, like Retro and Flexi-cars, might.