I think it's important to remember that the chassis' Rick is mostly recreating here were literally being invented FOR THE VERY FIRST TIME the night before the race! This was THE moment in time... pro-racing anglewinders were born! Mike, Terry and others were figuring it out, pulling ideas out of thin air. Some ideas would work and survive to the next chassis, some ideas didn't, giving way to yet other new ideas to replace those that proved unsuccessful. It became a seemingly never-ending evolution from one week to the next, one race to the next... who had the better mousetrap(?).

The first Pro anglewinder race

#26

Posted 08 December 2023 - 06:37 AM

- NSwanberg, Samiam and Eddie Fleming like this

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#27

Posted 08 December 2023 - 12:19 PM

That's right Tex. ![]()

Once Hustings proved the anglewinders performance potential they virtually reinvented the Pro 1/24 slot car overnight.

In building my version I'm trying not to use "improvements" that evolved in later designs. I want to have a car that's as close to a first generation anglewinder as I can.

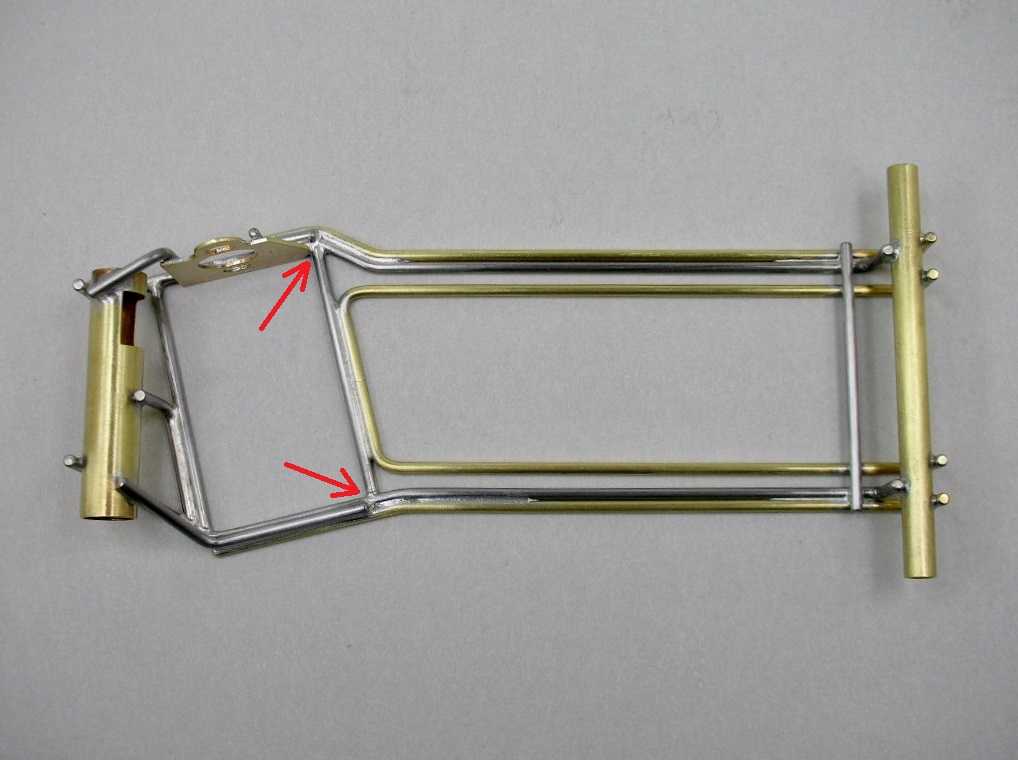

Below is a real "weak link" in this chassis design, unreinforced butt joints:

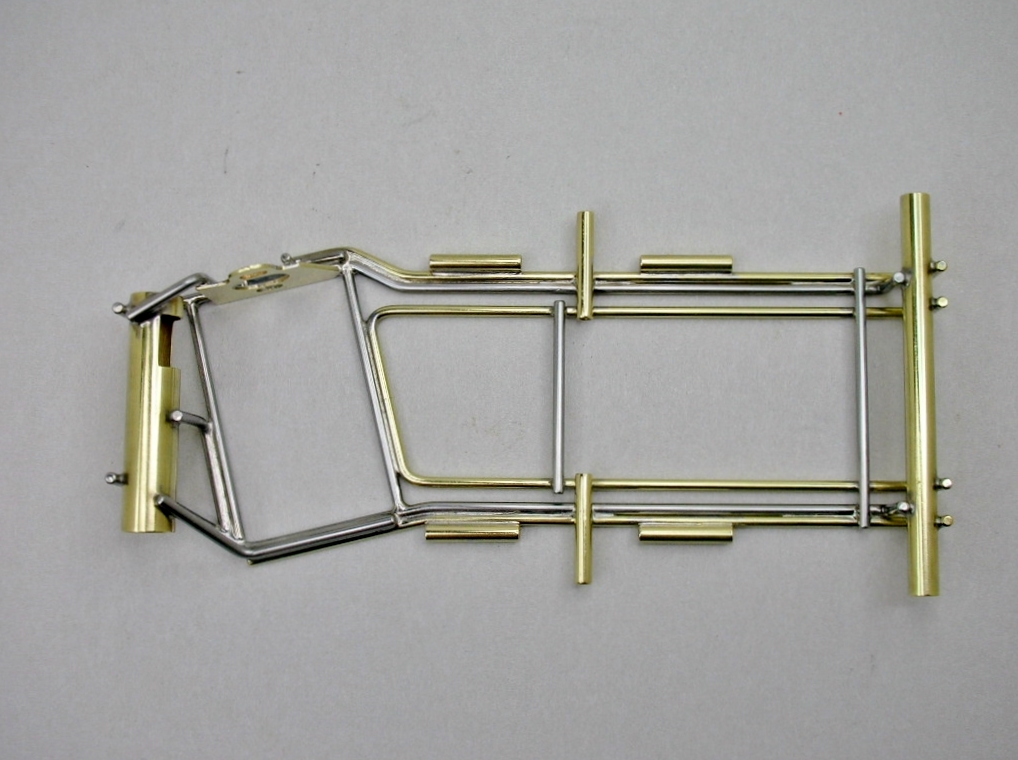

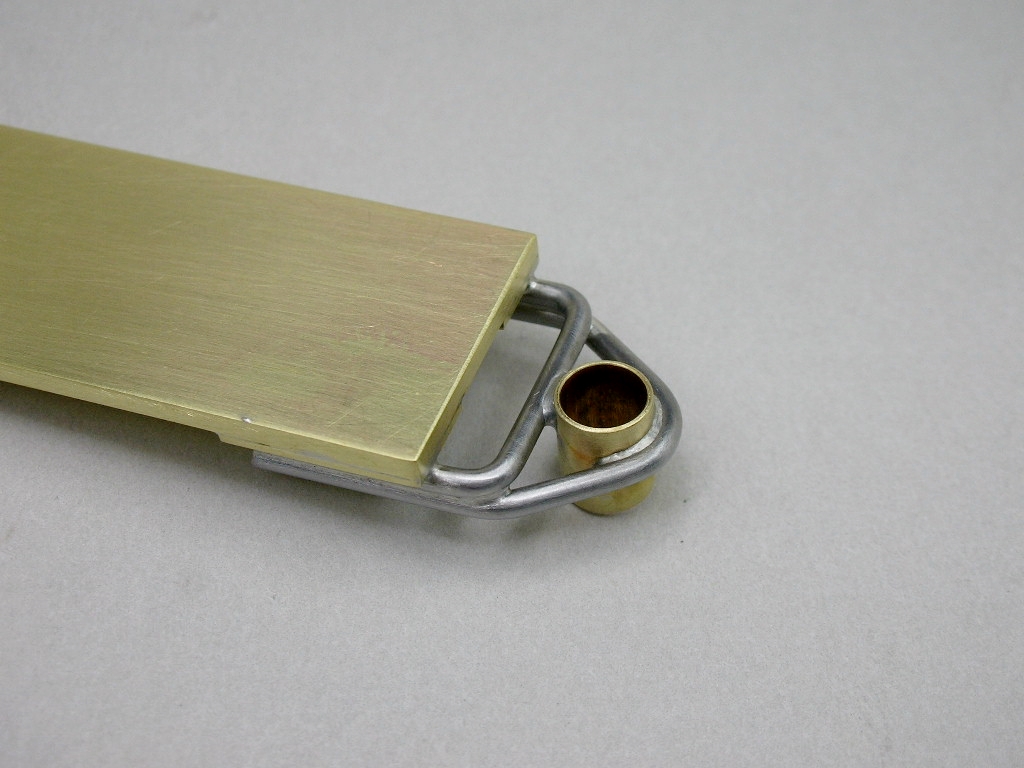

This area just begs for the ubiquitous 1/4" wide brass strip to be laid across the frame. of most later designs like this Phase III chassis:

I've already "popped" these 2 joints loose in handling the chassis. I think I'm going to have to try a bit bigger solder blob joint.

Anyway as my friend and mentor Dave used to say, "That's vintage!" ![]()

- Pablo, Tex and NSwanberg like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#28

Posted 08 December 2023 - 12:38 PM

Rick, can you reinforce those joints with short lengths of ;032 or .020 piano wire on top of the joints? You could use silver solder on those joints too. I realize that neither one is vintage for that chassis, but additional strength comes with a price.

I intend to live forever! So far, so good.

#29

Posted 08 December 2023 - 12:46 PM

You have the same situation in the opposite two corners. Do you think a small triangular gusset might work and still clear the motor can? Having met Gene at a drag meet when I was a teen, this build is another to add to my list of "senior projects". One I absolutely have to do.

Nice work. I assure you, Gene's solder joints were not that nice. Witness the chassis in the photo in post #1

- NSwanberg likes this

#30

Posted 08 December 2023 - 12:51 PM

Hi Bill. I always use nothing but Stay Brite Silver Bearing Solder except for soldering in motors and on lead wires.....just my personal preference.

I know the joints could be reinforced but I mention them to show an area gets improved in later designs and how I am resisting the temptation to apply it here.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#31

Posted 08 December 2023 - 04:40 PM

Could you just bird mouth the ends of the cross rails before soldering?

My chassis in the '70s were 100% silver solder. It does stiffen up a chassis until you get 2 or 3 races on it.

I intend to live forever! So far, so good.

#32

Posted 10 December 2023 - 06:16 PM

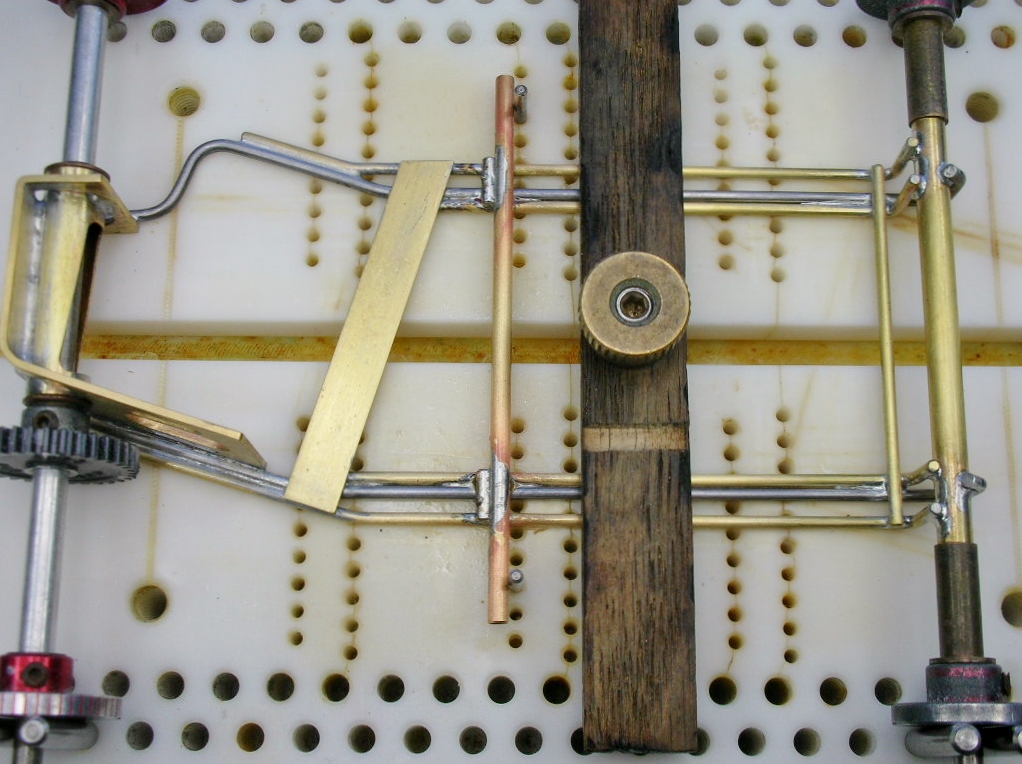

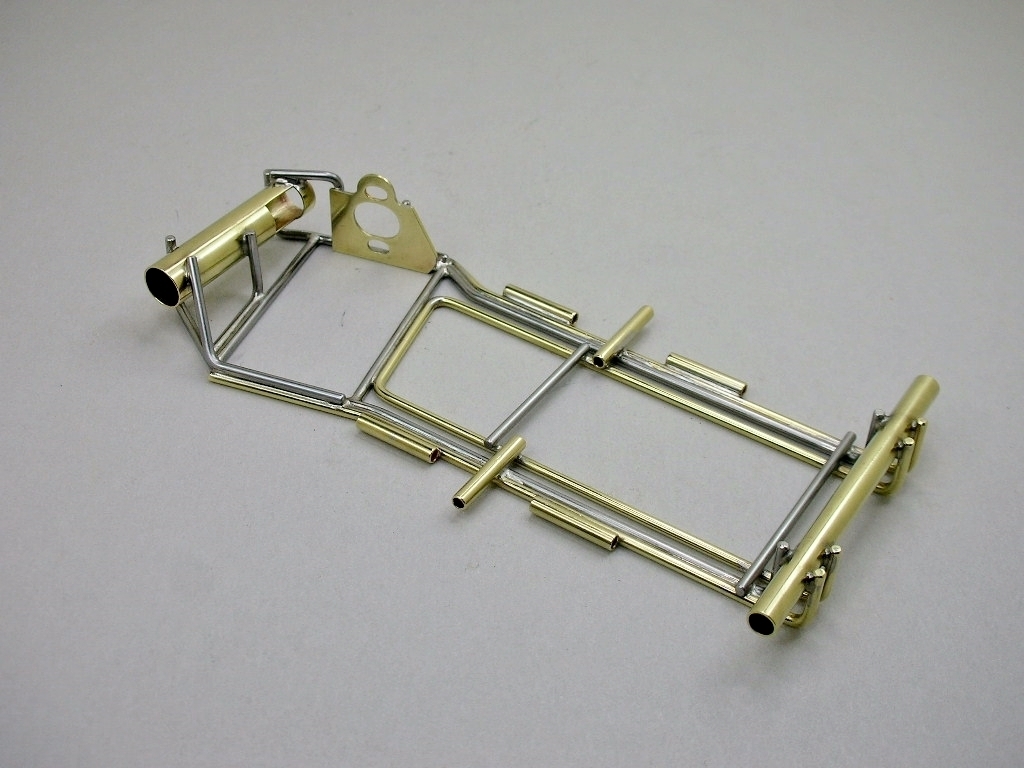

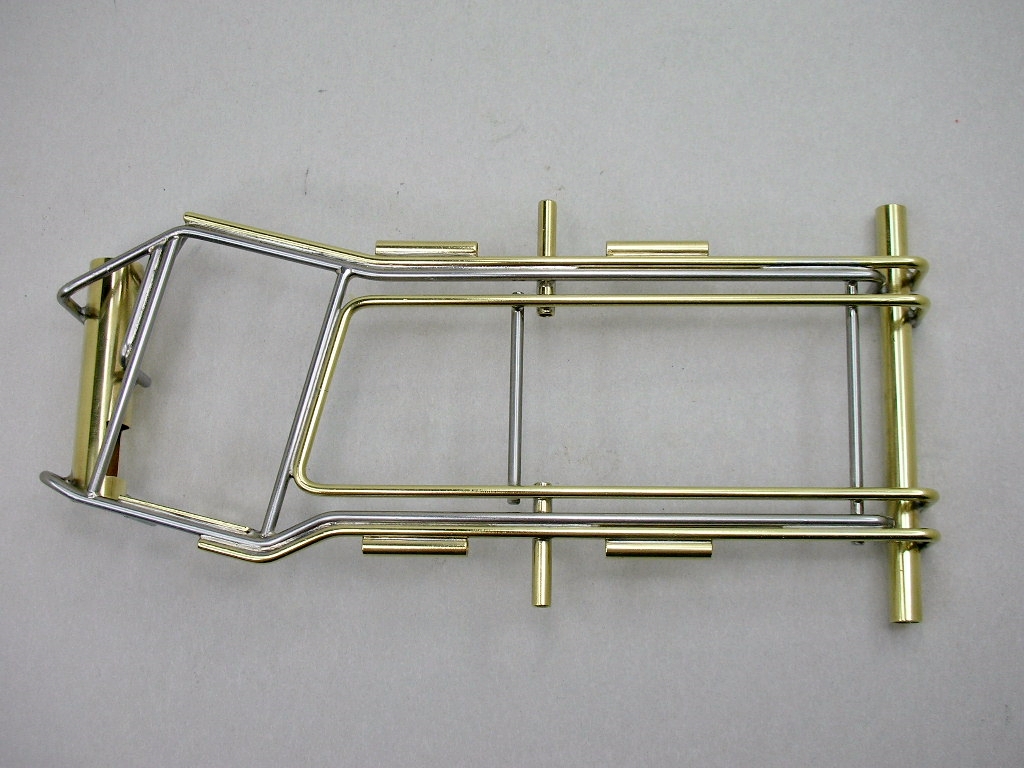

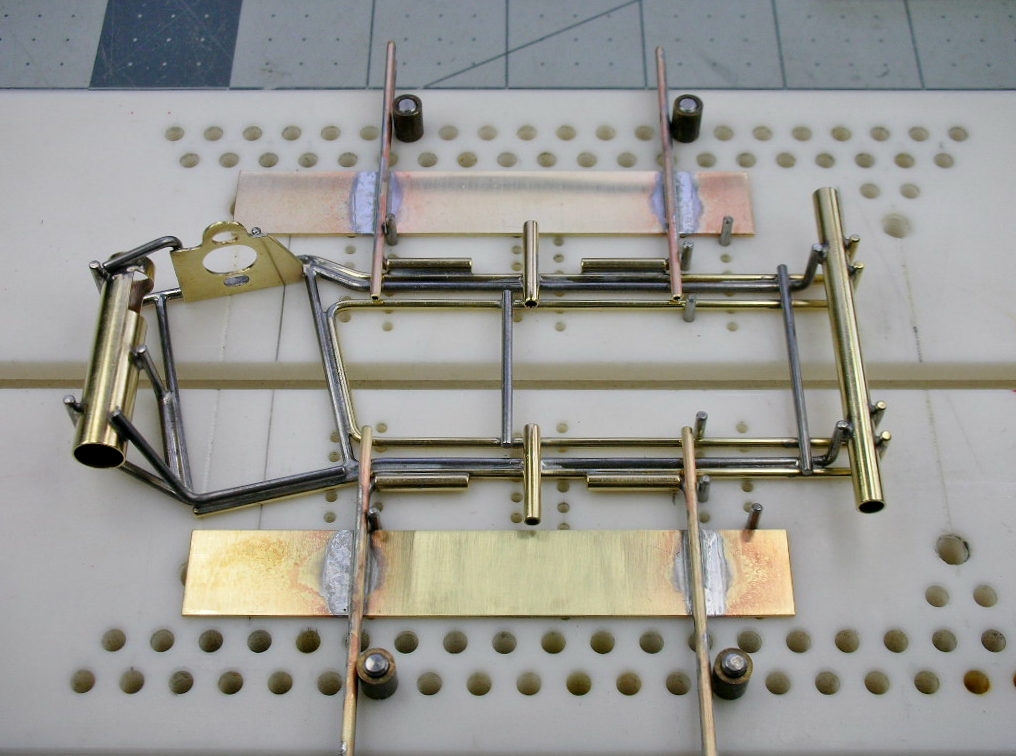

I have the hinge tubes for the pans, the hinge tubes for the drop arm and the "anti-spreader bar" (not sure what to call it) behind them installed:

I think I'll work on a drop arm next....

- Slot Car Rod, Samiam, Larry Horner and 1 other like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#33

Posted 11 December 2023 - 07:17 AM

Nice work. I assure you, Gene's solder joints were not that nice. Witness the chassis in the photo in post #1

Someone on the Blog once described Husting's solder joints as looking like something a poor welder might have done who had no idea of what soldering required.

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven

#34

Posted 11 December 2023 - 07:54 AM

Someone on the Blog once described Husting's solder joints as looking like something a poor welder might have done who had no idea of what soldering required.

I believe I read somewhere Gene's soldering method involved heating the solder over the joint then letting the drop fall onto the parts to be joined.

- NSwanberg likes this

#35

Posted 11 December 2023 - 09:10 AM

Gene's chassis may have been built using a soldering gun rather than an iron. I saw Gene & his son about 30 years ago at the ROAR Nats in Attleboro. MA. He knew how to build cars.

I intend to live forever! So far, so good.

#36

Posted 11 December 2023 - 10:12 AM

I'm quite sure that as time went on his skills improved greatly. He certainly knew how to design a chassis.

My first brass scratchbuilts were soldered with a propane torch. I would cut and fit all the parts, then align them using a home made jig made from a piece of 2x4. I then soldered everything at once. After, I would use a Craftsman Lil' Crafty rotary tool with a rotary wire brush to polish off all the scorching from the wood. I used pennies stacked under the axles to get the axle heights. I can't remember if I ever had a solder joint break, but certainly had a lot of bent up chassis. Later used a huge Unger soldering iron. Not pretty but held up. Some of my cobbled up creations from back then;

Compare with this recent restoration I did of a dragster frame someone gave me.

One good thing about getting older; Like fine wine, we get better.

- Tex and Bill from NH like this

#37

Posted 11 December 2023 - 03:23 PM

Neat chassis Dave! I have a couple new Royal Bobcats & a Pittman 196 I could bild into cars, but no local tracks to run them on if I did. The Drag chassis looks nicely built.

I intend to live forever! So far, so good.

#38

Posted 12 December 2023 - 09:52 AM

There's no reason a local track can't have a truly vintage race night, for scratch built cars from the early '60's, and clones built with vintage motors in modern day copies of the oldies, just as Rick is doing here. There are enough of us old codgers still around who have kept their cars from days of yore. And the "I'm afraid I might damage it" cop-out doesn't hold. Being mostly soldered creations, damage can almost always be repaired. After all, if guys can race million dollar, historically significant race cars, beyond their safe limits, then we can still enjoy the little thrill we get from bringing out our old toys. I once watched Augie Pabst (RIP) take hot laps of Road America, drifting through turn 5, and return to the pits with the biggest smile I think I had ever seen on his face.

I really hate seeing these spectacular builds, done by guys like Rick, become shelf queens. After all, isn't the only way to fully enjoy them, running them?

P.S. If you want to see the complete restoration of that dragster frame, it is in the Slot Drag Racing forum, under the title " Like I need another project".

- Bill Breck likes this

#39

Posted 12 December 2023 - 11:40 AM

I appreciate your passion for vintage slots Dave. I have long since given up on trying to promote running vintage slots locally and my last proxy event was a disaster, my car's hand carved balsawood body broken in half. ![]()

I really don't want to get into that quagmire here in my simple build thread.

Please feel welcome to start your own new thread on that topic and I wish you much success that I never had. ![]()

- Pablo likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#40

Posted 12 December 2023 - 12:10 PM

Some thoughts:

Gene's build was a horror but it proved the concept.

The history and recreations presented here are great and answered questions I have had for years..

This post/thread is my candidate for post of the year! ![]()

Cheers

- Steve Okeefe, brnursebmt and Pablo like this

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

#41

Posted 13 December 2023 - 12:23 PM

Thanks Bill. I thought putting all the great information I looked into for this topic in one place would be helpful. I'm glad you are enjoying it.

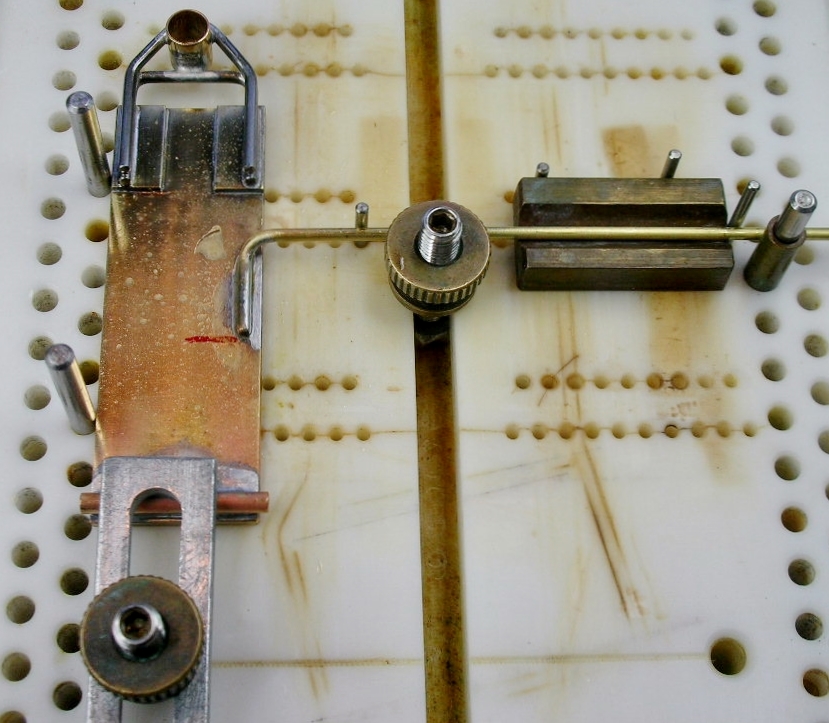

Drop arm time. This is Col's recreation of Steube's drop arm. I'm not a fan of the way the braces are just tilted up and soldered:

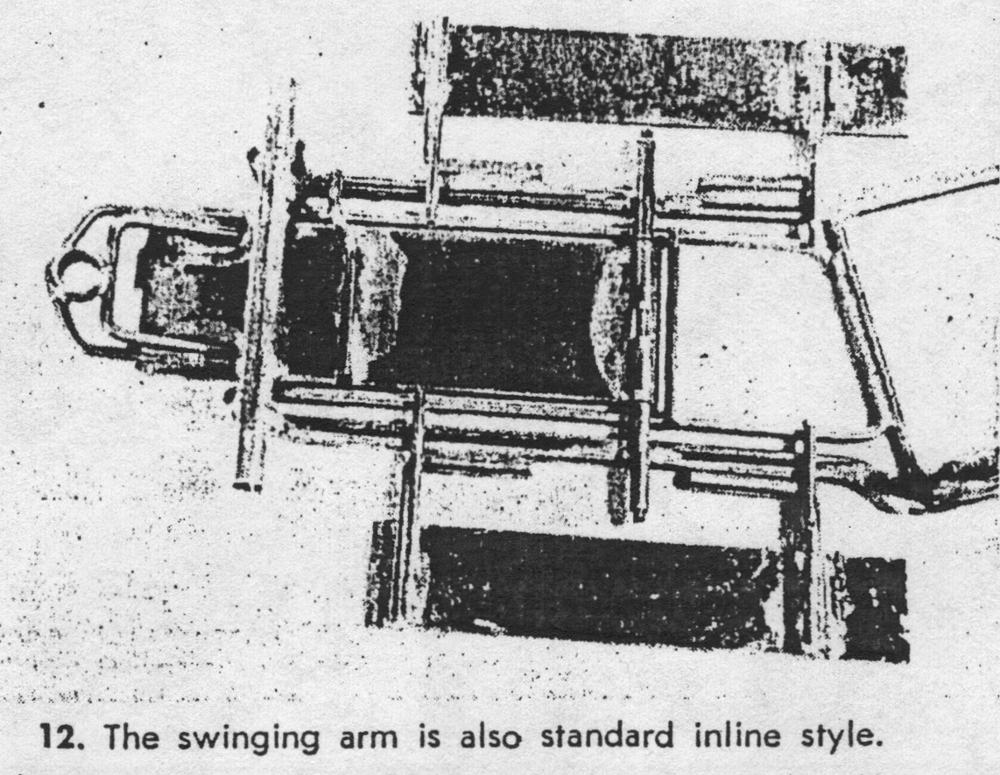

This is Terry Schmid's drop arm for his construction article and it might be the same. He calls it an "inline style":

Mike Morrissey called this inline style drop arm the "Model Car Journal style drop arm". He detailed it in a construction article in the MCJ issue before the first anglewinder race. I'm going to use it:

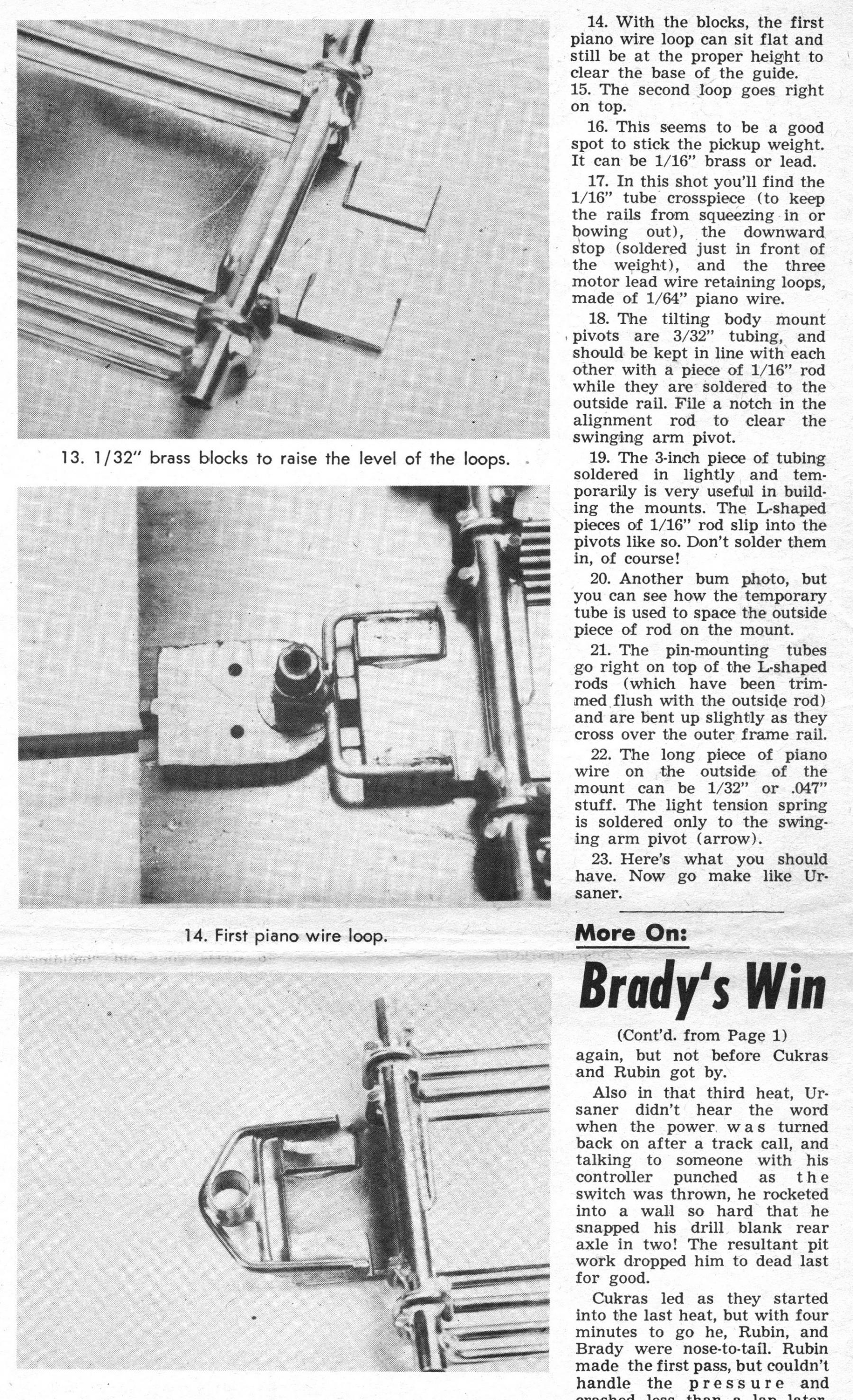

First thing is to solder on those 1/4" spacer strips. I decided to make things extra long to give me a place to drag the excess solder to and then cut it off:

The next one I make will have half as much excess to cut off:

Time to start bending piano wire.......

- Pablo, Tex, Eddie Fleming and 1 other like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#42

Posted 13 December 2023 - 12:34 PM

I know nothing but I would bet on that late night build the drop arm came out of some inline chassis that was laying around.

#43

Posted 13 December 2023 - 12:47 PM

very nice build! Congrats on that

"Stop whining, Slot Car racing is only big boys racing toys"

#44

Posted 13 December 2023 - 01:25 PM

Thanks Chris.

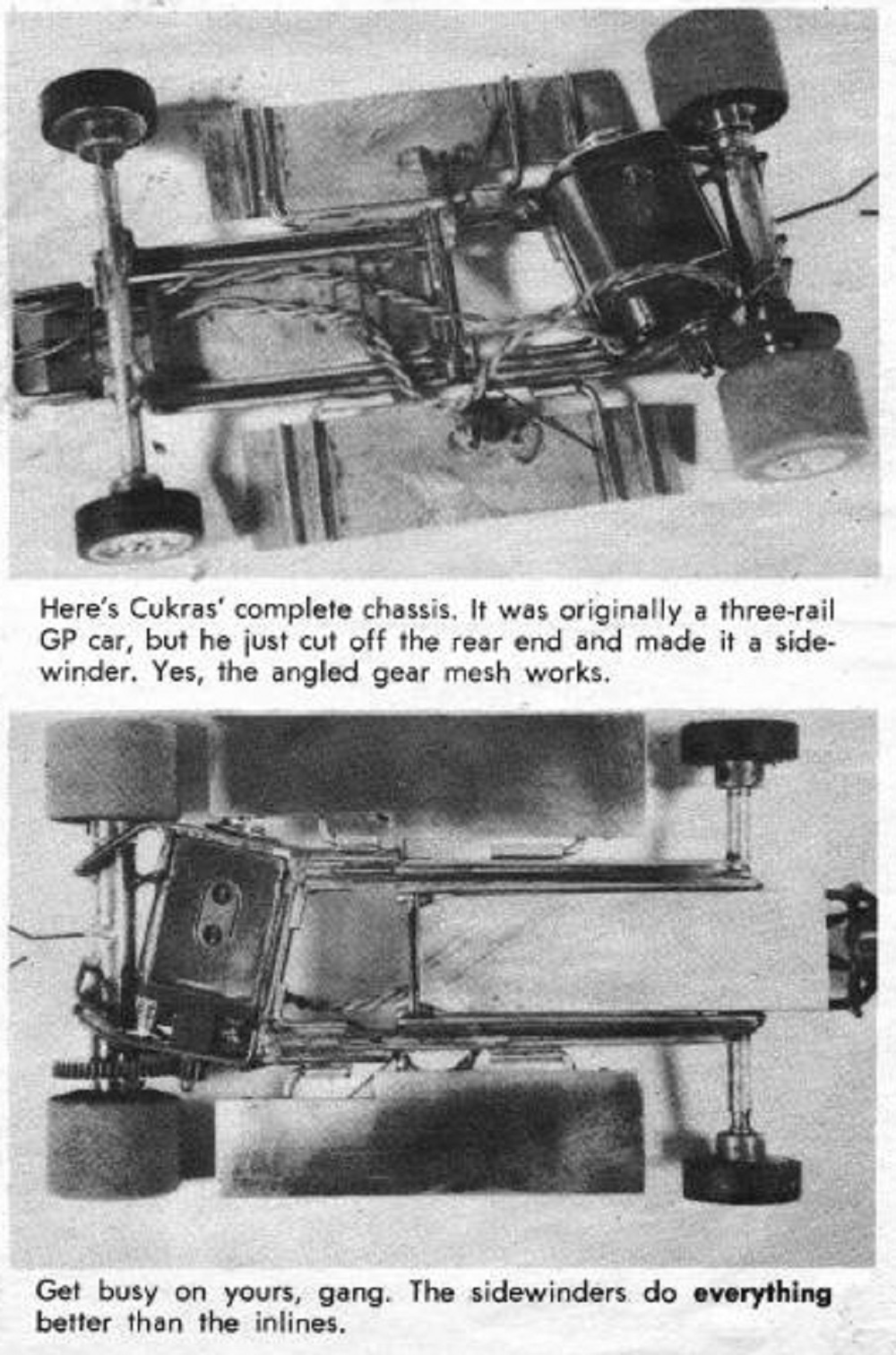

You are probably right Eddie. John Cukras third place car was an inline GP chassis he cut the back end off of and rebuilt as an anglewinder:

- Pablo, Tex and Samiam like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#45

Posted 13 December 2023 - 07:20 PM

Pure magic ![]()

Paul Wolcott

#46

Posted 13 December 2023 - 08:40 PM

Hi Pablo ![]()

The front end of the drop arm all soldered up in the jig:

View from the bottom:

All buffed up:

- Pablo, Tex and Larry Horner like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#47

Posted 13 December 2023 - 08:47 PM

Hard to imagine the impact that would make this design fail ![]() Nicely done Rick.

Nicely done Rick.

- Pablo likes this

#48

Posted 14 December 2023 - 08:40 PM

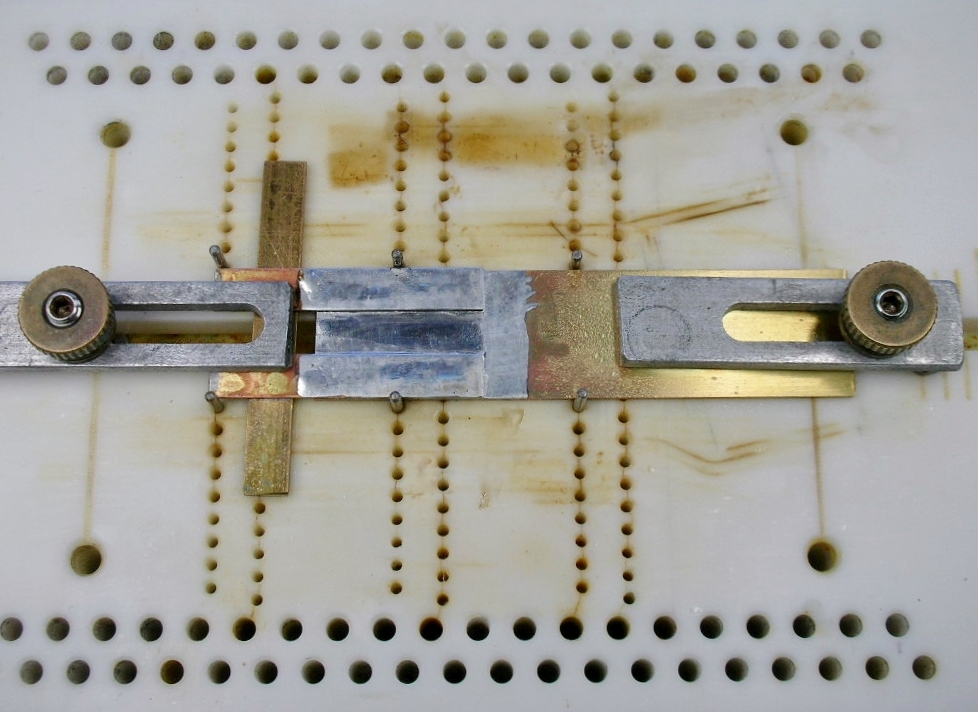

Thanks Martin. Here's the arm back in the jig to get the hinge tube installed:

This is my personal favorite style of drop arm down stop. The setup in the "Rick's" jig aligns and hold the stop in place for easy installation.

The typical down stop that goes across the entire width of the drop arm require lots of heat to solder. This style require only a small part of the arm to get hot for soldering:

The finished drop arm:

The pans are next and the chassis will be done.

- Tex and Larry Horner like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#49

Posted 16 December 2023 - 09:04 PM

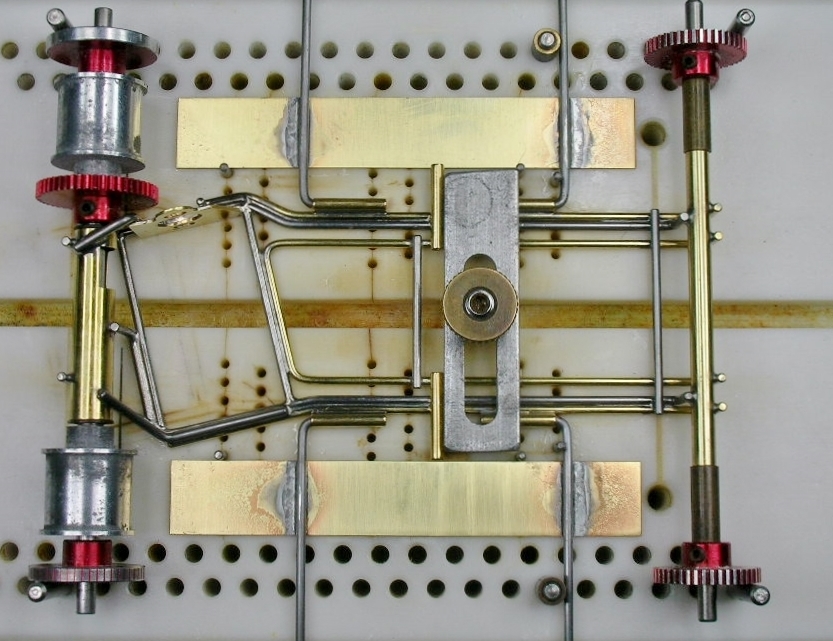

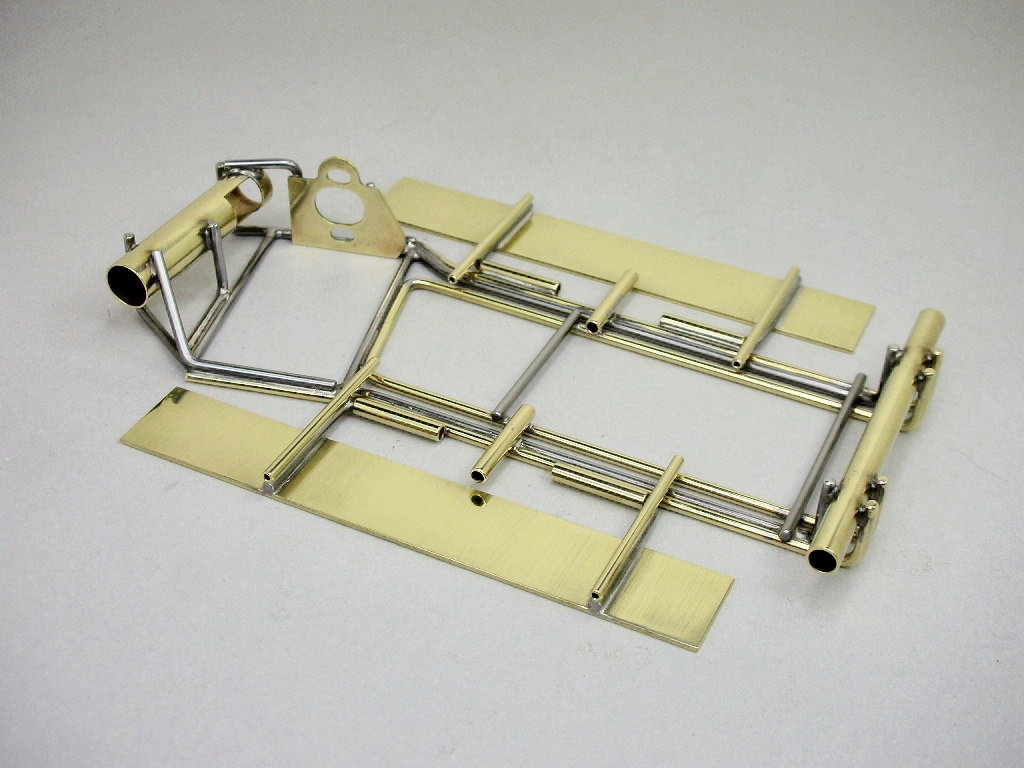

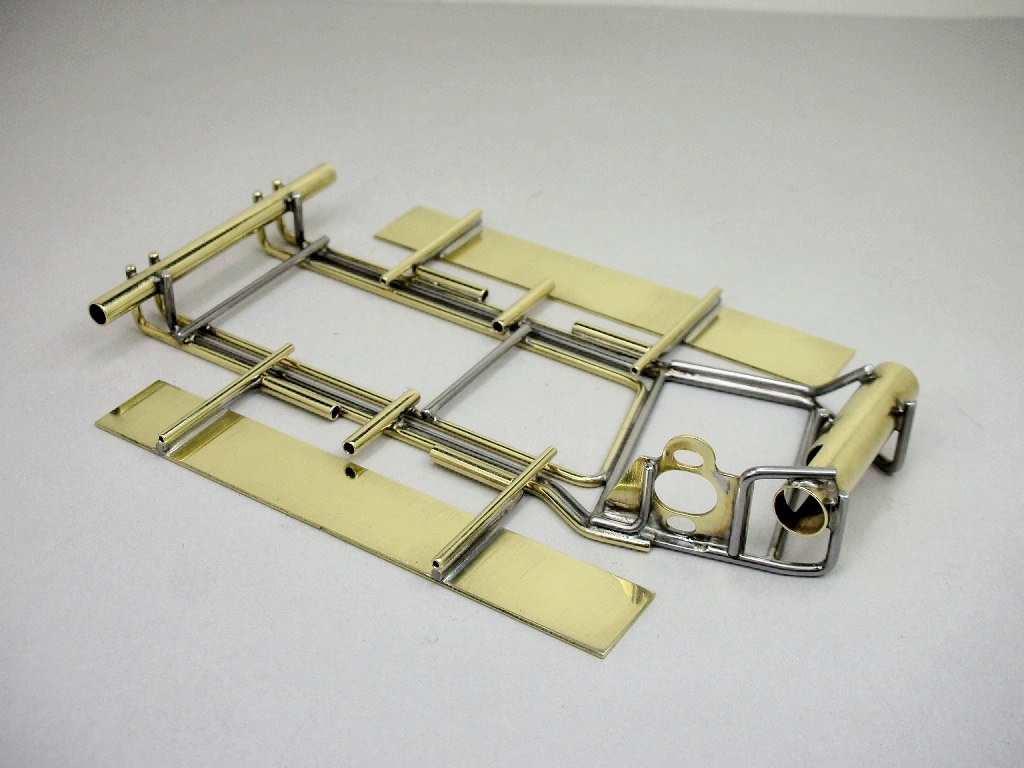

Pan and pan hinges installed:

Body mount pin tubes go on top of the hinges:

The chassis is most finished:

All that's left is putting a slight bend in the pin tubes to act as a pan upward stop and adding a pan down stop gizmo like Steube's:

- Tex, Chris Stemman, NSwanberg and 5 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#50

Posted 17 December 2023 - 06:18 AM

Hi Rick,

always a pleasure reading your articles and thanks a lot for the great pics!

JSR gallery