Tube, rod, and flat stock bender

#26

Posted 03 March 2025 - 08:19 AM

- olescratch likes this

Paul Nadeau

#27

Posted 03 March 2025 - 10:18 AM

Thanks Guys for the encouragement and suggestions ![]()

I will make a few today after I polish the die in the spot I missed.

It does feel good to make a needed product and I can give back to slotblog, the place we love to hang. ![]()

- olescratch likes this

#28

Posted 03 March 2025 - 10:33 AM

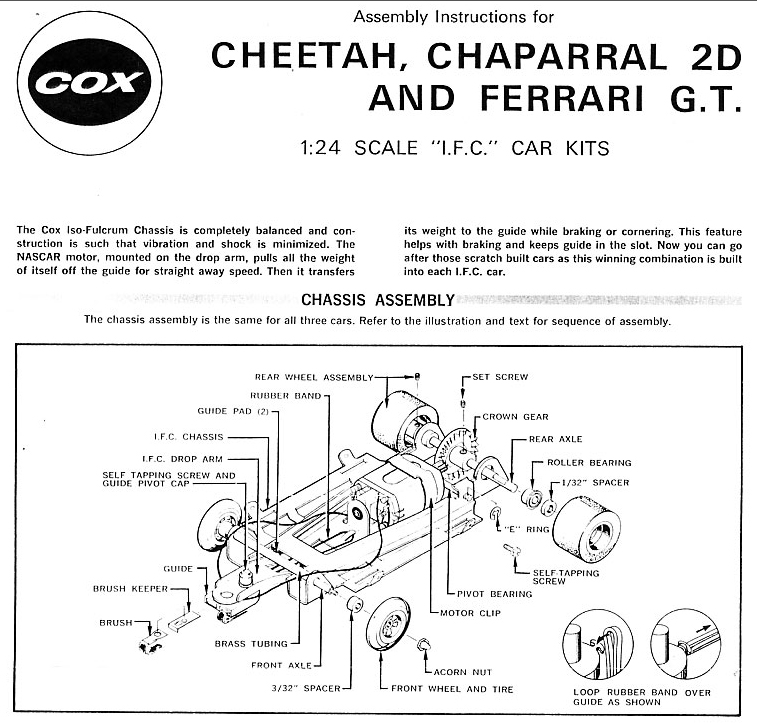

Hey Bill, I thought that the subject of a IFC chassis with a 26D would come up. If there was enough demand I would make that die too.

It needs a bearing adaptor as the 26D motor is 1/4" shorter.

But if Brian has them I will move on to the next project.

I do love making tools

Now if someone can figure out how to stamp those super skinny numbers 4809R. R being for reproduction. Any ideas ?

From Grainger;

To get the "R", you have to buy a set of letters.

They also sell a holder to stamp all the numbers at once. I would just engrave the "R" by hand with a Dremel and a pointed carbide burr.

#29

Posted 03 March 2025 - 10:50 AM

Thanks Dave for your effort. I do have those stamps but there are nowhere close to the delicate numbers on the Cox part. The clip has a 1/2'' flat to fit 4 or 5 numbers in.

If I did it I would want the same font so a custom stamp would be needed IMO. So for now they are sans numbers.

#30

Posted 03 March 2025 - 12:32 PM

Did you check the size? 1/16 is the smallest size available. And some other fonts are available, at extra cost, of course. I doubt Cox had custom stamps made for these. If I had a picture, it would help. In any event, is no number better than what these give you?

If I was still working, I would simply engrave them in a CNC router or mill. Check with trophy shops, they might be able to engrave them pretty cheap. It really only comes down to how many you are going to make.

#31

Posted 03 March 2025 - 12:57 PM

Is that clip in the photo from post #21 with the numbers stamped an original? Nothing special about those numbers. 1/8th inch high, normal font, done with a light hit with a small hammer.

You won't get an "R" on that line, but you could engrave one on the other side, not visible when the clip is installed. But still IDs it as a repop.

Good forming tool!

- olescratch likes this

#32

Posted 03 March 2025 - 01:07 PM

That is a Cox clip that I used to make my repo. The numbers are .150'' tall and .450'' wide all together.

I like the trophy shop engraver, I wonder what Pablo paid for his little name plates? Paging Pablo, Paging Pablo. ![]()

#34

Posted 03 March 2025 - 02:32 PM

Wow! That's fast. Superb.

#35

Posted 03 March 2025 - 04:12 PM

For shipping, you could use small-padded envelopes marked "Hand Cancel." For multiple orders, tape them together first. As I recall. that's how I sent my 26D clip to Brian in Ohio & received it back with a couple extras, all in good shape. That's also how I sent my arms out for rebalancing to Thorp, Camen, & Alpha. I never had a problem with them either.

I intend to live forever! So far, so good.

#36

Posted 05 March 2025 - 01:22 PM

Now 16D IFC motor clip are for sale here on slotblog http://slotblog.net/...ss-motor-clips/

Thank you Greg and all that inspirer these projects.

#37

Posted 06 March 2025 - 12:02 AM

#38

Posted 25 June 2025 - 03:37 PM

#39

Posted 25 June 2025 - 10:02 PM

Lets see a pic of what you got, I need (want) more tools ![]() always.

always.

#41

Posted 02 July 2025 - 11:29 PM

They look like good quality tools Mark, good hinge joint.

Probably designed for jewelry type work. But I used my simullar tools on every project. I am sure you will find lots of uses for them.

#42

Posted 03 July 2025 - 12:23 PM

My mentor the late great Tony P recommended these pliers when I started building and they work perfectly. They're called parallel jaw pliers

https://www.amazon.c...=A1LIB4DETCSOWT

- NSwanberg, glueside and Eddie Fleming like this

Jersey John Molnar

"Certified Tony P Chassis God 2007.2023

RETRO EAST 2025 Constructor Champion

#43

Posted 03 July 2025 - 01:34 PM

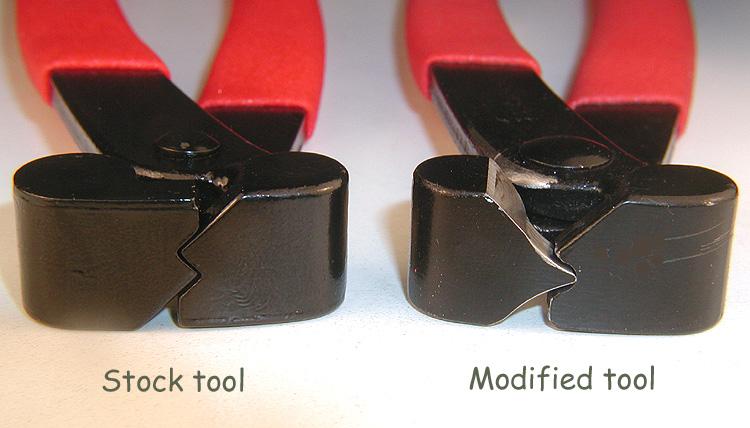

I don't remember which one but one of the great builders on the forum a few years ago showed a bending tool he had created by grinding out one side of a Z bender to create a 90% bending tool. I built one. Not as well done as his but very functional. I have used it a lot and the only problem with it is .062 wire will some times fracture during the bend. anything smaller works great as does .062 if you don't over do it Anyone want to claim credit for the tool?

Thank you whoever that is.

- JerseyJohn likes this

#44

Posted 03 July 2025 - 02:46 PM

Eddie, that was Steve Okeefe who modified the Z-bender jaw. He showed it in his how-to article for building Emott motor boxes.

- JerseyJohn and Eddie Fleming like this

I intend to live forever! So far, so good.

#46

Posted 03 July 2025 - 05:28 PM

I modified one and then bought another to use as a Z bender. Both are very handy.

- grooverunner likes this

#47

Posted 04 July 2025 - 12:42 PM

The "Z" pliers could probably be made from a pair of tile nippers or a nail puller. Hmmmm? Harbor Freight 4th sale here I come

- JerseyJohn likes this