Blow-molding slot car bodies

#1

Posted 19 November 2008 - 06:02 PM

Do you have any info on blow-molding slot car bodies? Or could you do a thread on them?

Very interesting method of making a body.

Thanks.

Gene Adams AKA Gene/ZR1

ZR1 Corvette owner

Hand-carved balsa bodies, resin body plugs, silicone molds, vacuum bodies

Genes_World@ymail.com

#2

Posted 19 November 2008 - 09:38 PM

TSR

Do you have any info. on Blow Mold Slot Car Bodies?

Bodies? Plural? The only one I know of is the MPC Manta-Ray. I'm interested to know what others there were.

Regards,

Steve C

Stephen Corneille

#3

Posted 20 November 2008 - 03:50 AM

Plus I am unsure whether one could use Poly-carbonate materials in a Blow Mold process.

Were Many Bodies actually Made this way ??

Stewart Amos

Old Racer from Sydney, Australia

FASTUFF Race Proven Products

https://ascra.au - Australian Slot Car Racers Association

#4

Posted 20 November 2008 - 04:15 AM

Link to: The Independent Scratchbuilder - 1966 1/2 Auto World Catalogue - page 111

8/19/54-8/?/21

Requiescat in Pace

#5

Posted 20 November 2008 - 04:24 AM

Yep, wouldn't be cheap, but blow moulding can mould Polycarbonate (Lexan), Polypropylene, Polyurethane, Polystyrene, Polyethylene, PETG, plus others.

As an example, the comon moulded babybottles are usually made with Polycarb.

Steve, I'm surprised that the Manta Ray was blow moulded. I've got one here that is thinner around the edges, plus at each end, than it is on top. Blow Moulding usually makes the edges at each end of the moulding thicker than the middle. This is due to where the mould reduces in size and shuts off to pinch the tube of plastic prior to air being blown in. Of course, my example may not be a genuine either, so I'm interested to know.

Doc

Steve King

#6

Posted 20 November 2008 - 04:35 AM

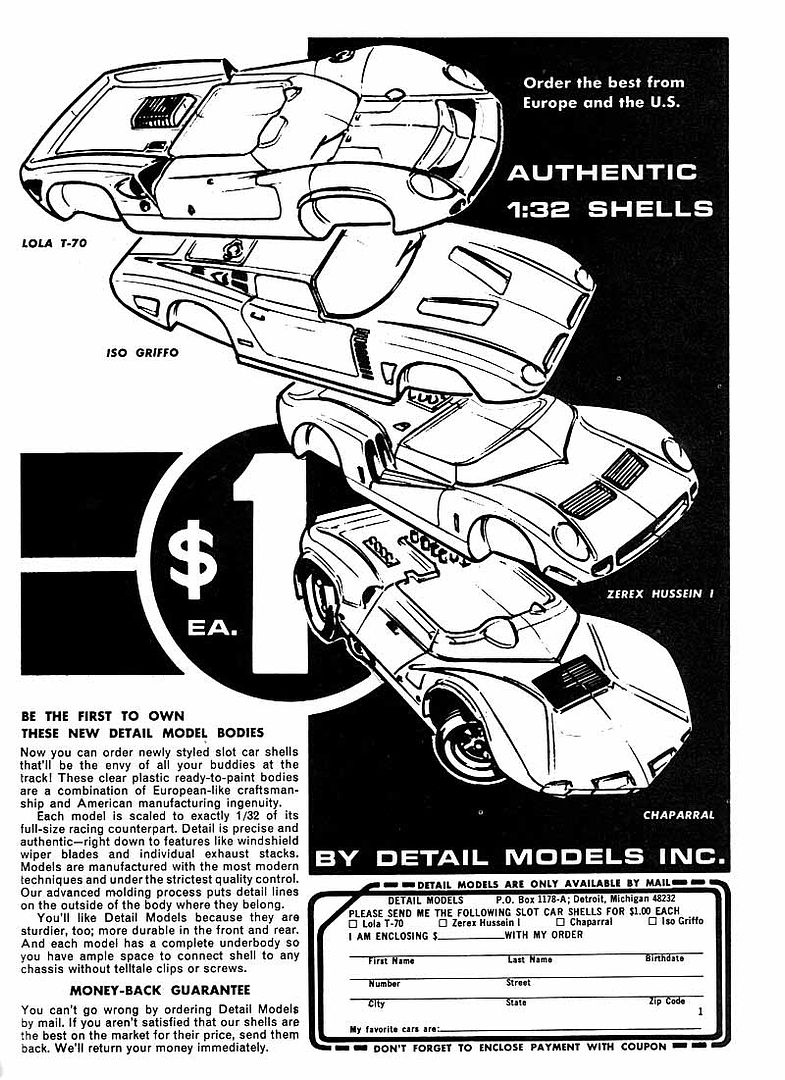

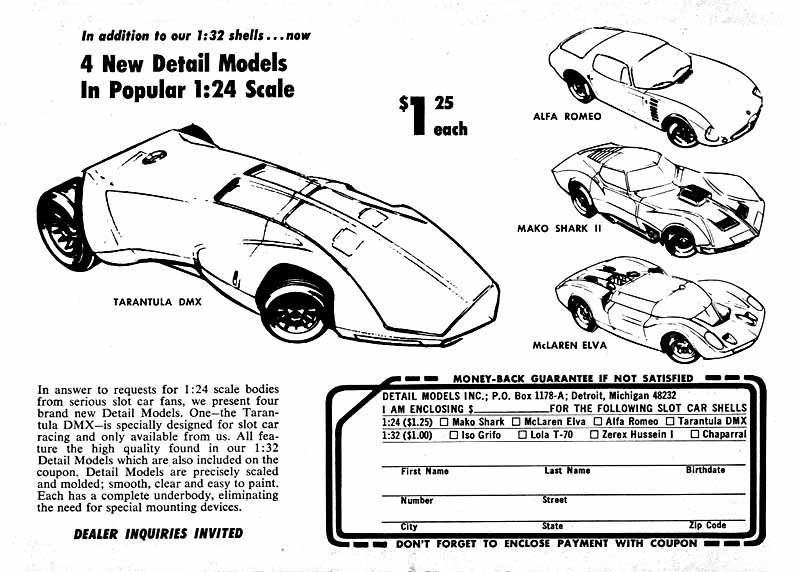

Bob,I've seen the Tarantula DMX and Mako Shark that were blow molded by a company called Detail Models. A little look see at the 1966 1/2 Auto World catalogue shows them on the top right hand corner of this page at Steve Okeefe's website.

Link to: The Independent Scratchbuilder - 1966 1/2 Auto World Catalogue - page 111

That article appears to be "Injection" moulded bodies.

This is quite different to Blow Moulding (Molding).

Blow Moulding is the process that makes the plastic soda bottle. You can have reasonable detail on the outside, but only wall thickness flow shape on the inside.

Injection mouldings are the same as the model kits where good detail can be made on both inside/outside of the part.

The parts that you have seen may have been clear (polycarb, acrylic, or ?) material injection moulded. The same as the clear parts in model kits.

Steve King

#7

Posted 20 November 2008 - 05:55 AM

Bob,

That article appears to be "Injection" moulded bodies.

This is quite different to Blow Moulding (Molding).

Blow Moulding is the process that makes the plastic soda bottle. You can have reasonable detail on the outside, but only wall thickness flow shape on the inside.

Injection mouldings are the same as the model kits where good detail can be made on both inside/outside of the part.

The parts that you have seen may have been clear (polycarb, acrylic, or ?) material injection moulded. The same as the clear parts in model kits.

Gents -

I think the process used for these bodies was quite different than how plastic soda bottles are made.

I worked in a plant where bottles were blow molded. It involves a 2 part female mold. The halves open, a tube of hot plastic is extruded and hangs down between the molds. The 2 halves close, and air pressure is applied at the top of the plastic, and that blows the plastic into the shape of the bottle.

The blow molded slot bodies were made with air pressure instead of vacuum, forcing the plastic down into a female mold

rather than over the more traditional male mold.

vsrn

#9

Posted 20 November 2008 - 08:54 AM

It was, and Greg is 100% correct in his description of the process.Steve, I'm surprised that the Manta Ray was blow molded.

Detail Models also made a 1/32 scale Lola T70 and a 1/24 scale McLaren-Elva.

Philippe de Lespinay

#10

Posted 20 November 2008 - 10:41 AM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#11

Posted 20 November 2008 - 10:52 AM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#12

Posted 20 November 2008 - 03:27 PM

Fair enough, as mentioned, my Manta Ray may not be original.It was, and Greg is 100% correct in his description of the process.

Any idea what material the Manta Ray was blow moulded in??

And yep, Greg is 100% correct with his description of the process.

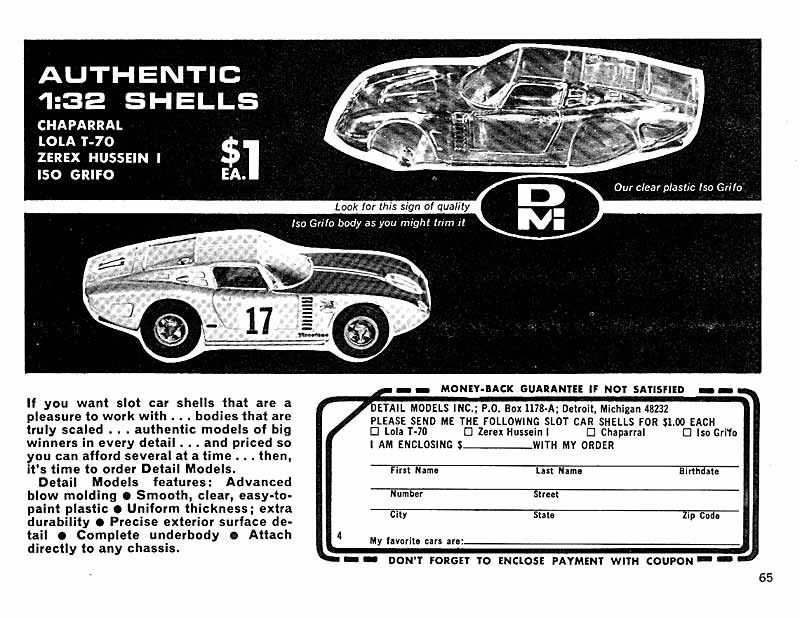

That Iso-Griffo is a great body.

Steve King

#13

Posted 20 November 2008 - 05:40 PM

Detail Models made the Tarantula, a Mako Shark and a McLaren-Elva in the 1/24 scale, a Lola T70 and the ISO Grifo in the 1/32 scale. The Mako Shark body was used by Unique on their very rare slot car model, of which only one boxed example appears to have survived so far.

No other Detail Models bodies were used on known cars or kits. I believe that no other slot car bodies were blow molded.

Philippe de Lespinay

#14

Posted 20 November 2008 - 06:12 PM

Both will put the detail on the outside of the plastic, but using a female mold still uses vacuum rather than pressure, right?

#15

Posted 20 November 2008 - 06:20 PM

Philippe de Lespinay

#16

Posted 20 November 2008 - 06:52 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#17

Posted 21 November 2008 - 03:28 AM

There have to be strategically placed vent holes in the vac mould in order to draw the sheet down into low areas where trapped air would otherwise form bubbles. On a male mould, these can be placed discreetly on panel lines and in vents and intakes. On a female mould, they have to be on the high, exposed parts of the finished shell- roofs, wheel fenders etc.

This is what intrigues me about this interesting thread- how does the entrapped air escape in this blow-moulding process? I can't see any evidence of vent holes in the Iso Grifo shell. Is the whole process carried out in a vacuum? If so, this has to be an industrial scale installation!

In practice, at least in my amateur workshop, I find the detail finish of a conventional male mould is as good as you get with the more problematic female mould, which is still a little blurry, but just 'inside out'. The only use I have for it now is moulding screens and minor parts for use in resin shells and repros, where they have to fit flush with the exterior surface of the shell. Using a male mould you get a slightly oversized screen.

John Dilworth

#18

Posted 21 November 2008 - 10:13 AM

From what I have seen in bottle making, it is just a puff of compressed air, then as the material cools on the mold, the air is let out the same way it came in. There are tiny air holes in the bodies.

Philippe de Lespinay

#19

Posted 28 December 2008 - 09:56 PM

Eau contrair my good doktooor. ALL the Russkit Styrene early kit bodies in both 1/32 and 1/24 scale were indeed reverse vac formed into female molds.Indeed, but I do not know of a single slot car company that used female molds for forming bodies

The Porsche RSK, Lotus 25, Lister Jag etc were all done this way.

OK, what did I win??????

Next question, just ask me anything Eh!

Also, I believe the blow molded 1/24 McLaren was the first MKI organ pipe thingy, and, not an Elva(unless of course they were the same????). I have one, still uncut.

#20

Posted 28 December 2008 - 11:13 PM

You win nothing but I slap myself silly to get me yet another concussion...

The Detail Models McLaren-Elva is not the "organ-pipe thingie", that one was the ex-Zerex/Penske Cooper-Olds that Bruce purchased from John Mecom and raced until the new McLaren MK1, AKA McLaren-Elva because they were produced by the Elva/Trojan company, came out. The "organ-pipe" car was dark green with a white, then silver stripe, while the MK1 driven by Bruce was black with a silver stripe and an entirely different animal altogether.

Lancer made a body of the original 1962 Zerex-Cooper (to be painted in red as a center-cockpit car), then they made the widened cockpit 1963 version with the Climax engine (metallic blue and white), then the 1964 Cooper-Olds (green). All and the same car, basically a re-bodied 1961 Cooper T53 F1 car.

Lancer and Russkit made the McLaren MK1 but it is seemingly always called "McLaren-Elva" on the body tags.

Philippe de Lespinay

#21

Posted 29 December 2008 - 04:00 AM

Bodies? Plural? The only one I know of is the MPC Manta-Ray. I'm interested to know what others there were.

Detail Models made the Tarantula, a Mako Shark and a McLaren-Elva in the 1/24 scale, a Lola T70 and the ISO Grifo in the 1/32 scale. The Mako Shark body was used by Unique on their very rare slot car model, of which only one boxed example appears to have survived so far.

No other Detail Models bodies were used on known cars or kits. I believe that no other slot car bodies were blow molded.

Ads from late 1965. A complete (?) line of Detail Models bodies:

Four in 1/32 (Chaparral, Hussein, Iso Grifo, Lola) and four in 1/24 (Alfa, Mako, Elva, Tarantula).

MC&T october 1965:

MC&T november 1965:

MC&T december 1965:

Overseas Observer

#22

Posted 29 December 2008 - 11:23 AM

Philippe de Lespinay

#23

Posted 29 December 2008 - 10:47 PM

EM

#24

Posted 30 December 2008 - 11:49 AM

Philippe, I did have one of the Husseins in the day. I still have a T70 somewhere unpainted.

I ran the crap out of the Hussein, but it was too heavy to compete with my normal vac club cars. It was just for amusement.

Fate

3/6/48-1/1/12

Requiescat in Pace

#25

Posted 30 December 2008 - 12:13 PM

I have seen all the others and actually there is at least one of each at the LASCM.

The most commonly found are the 1/32 scale T70 and the 1/24 scale McLaren-Elva.

Philippe de Lespinay