One_Track_Mind, on Dec 16 2008, 03:08 PM, said:

..............finally a how-to-do-it for drop front axles...

Thank You,

Hi Brian,

I've only done a couple of drop axle cars so I kind of made things up as I went along. Everything worked out great and it was really easy to do......here goes:

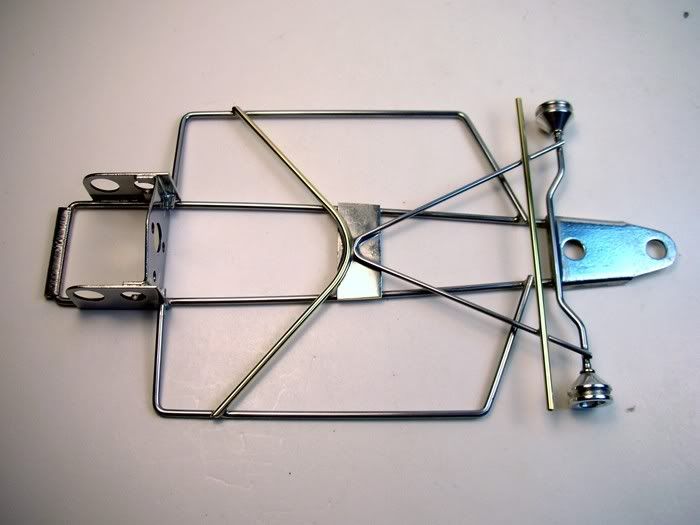

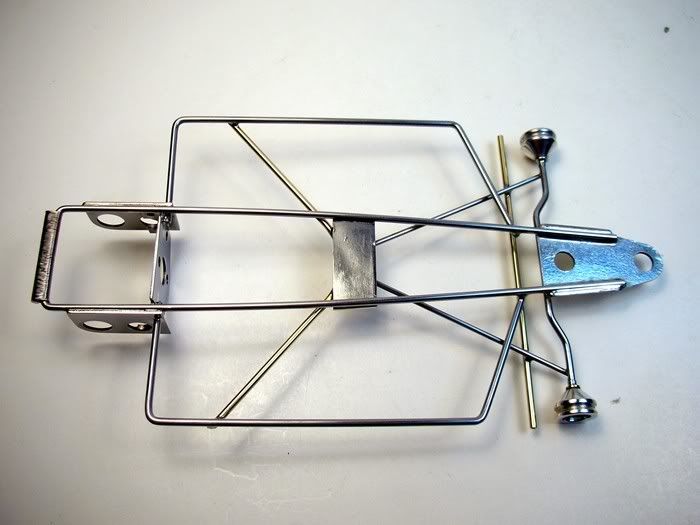

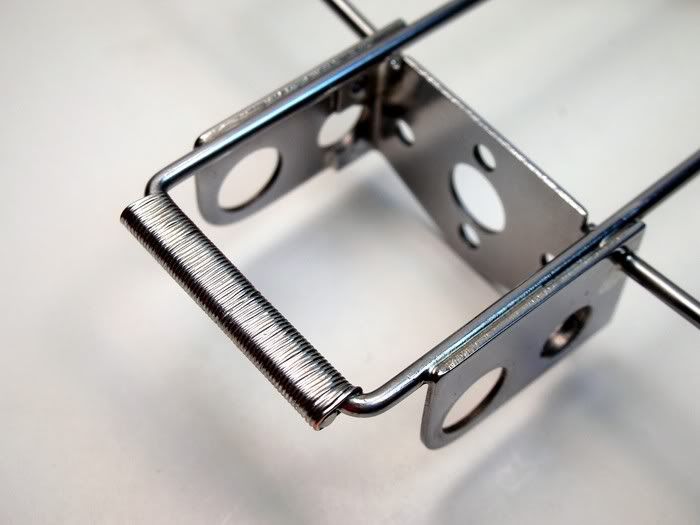

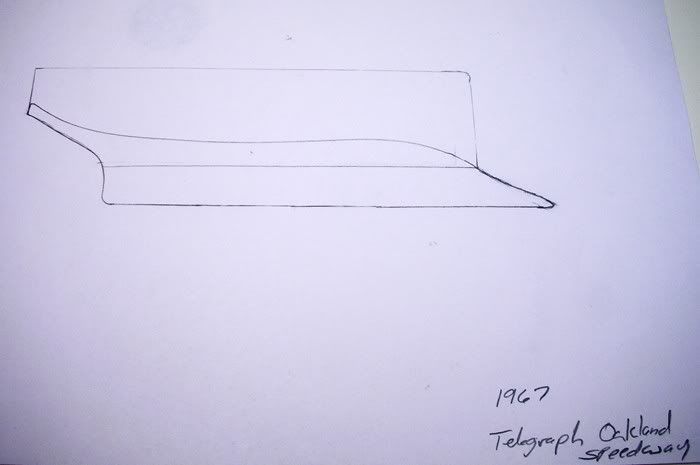

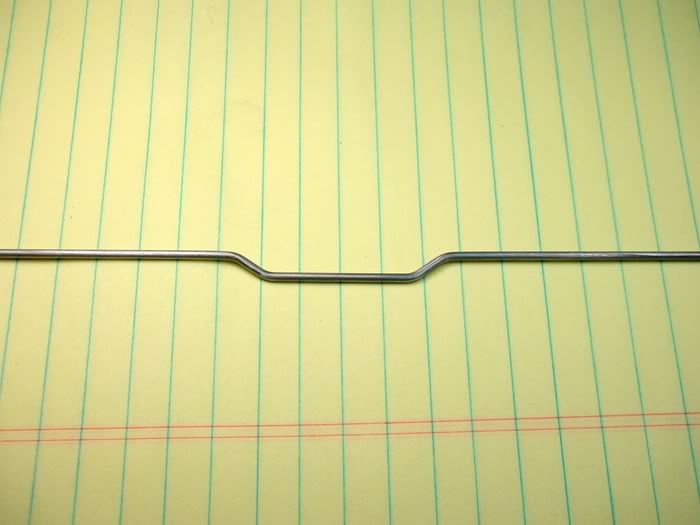

Spend some time bending the drop axle. Use a protractor and make sure the angles are both the same. Use a flat surface like a tech block to get the axle flat and both ends parallel with the bottom, etc:

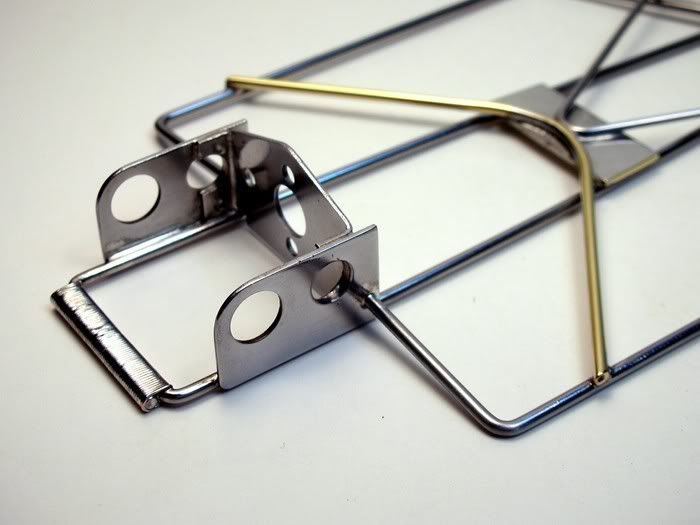

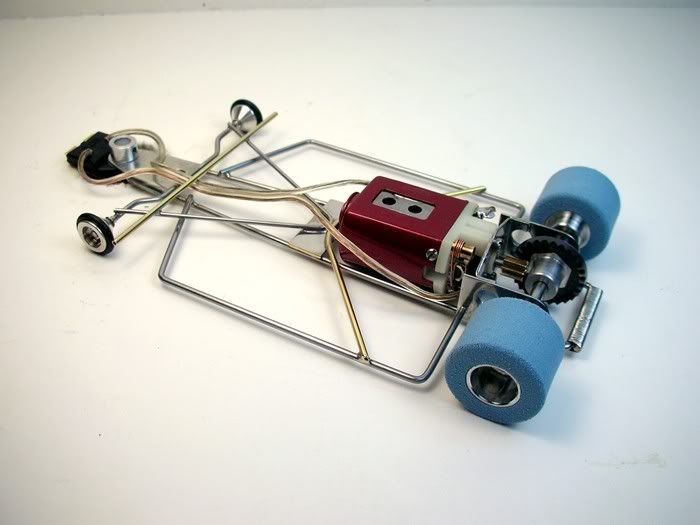

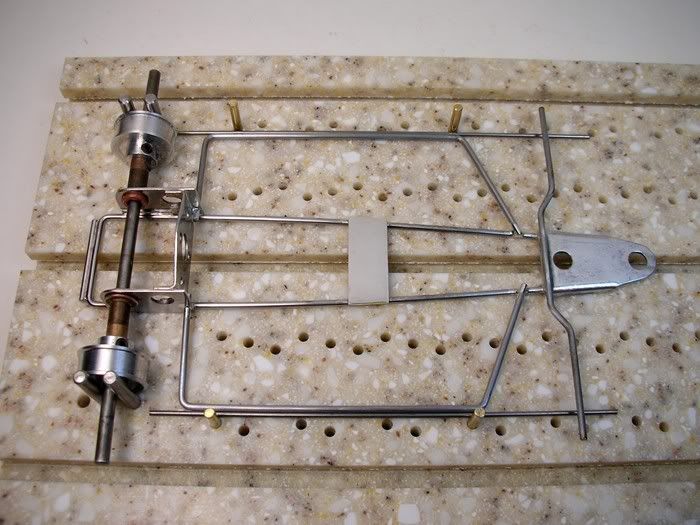

I left the axle extra long so I could locate it with the precision pins in the jig. To set up the track clearance I just removed the tires and let the wheels rest on the jig:

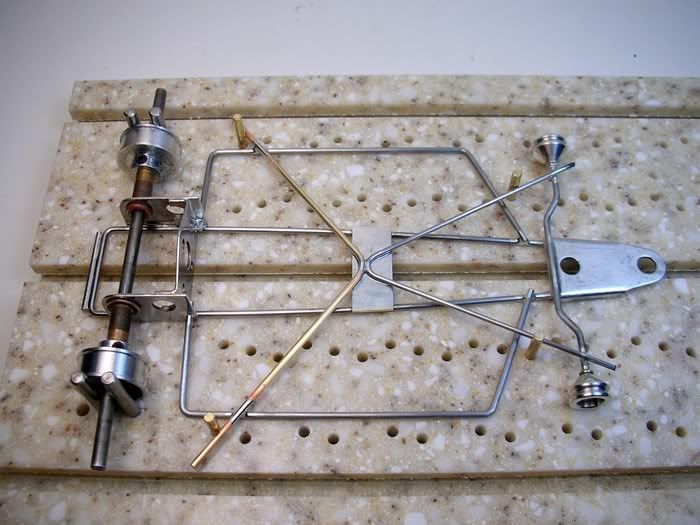

Next with the axle in place the jig helped me line up the outriggers:

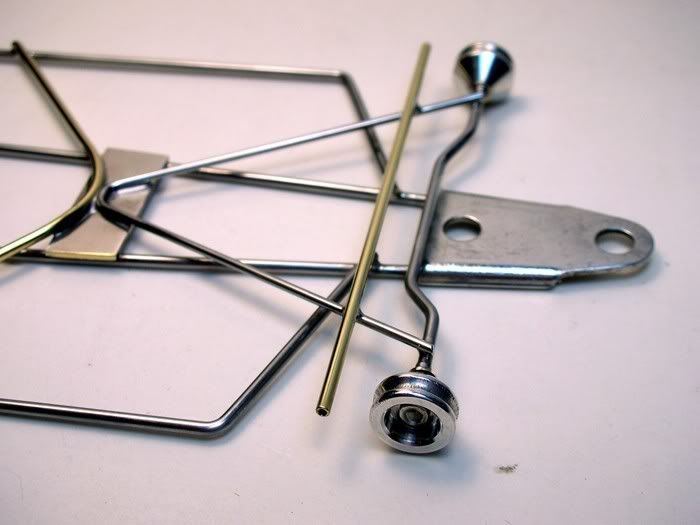

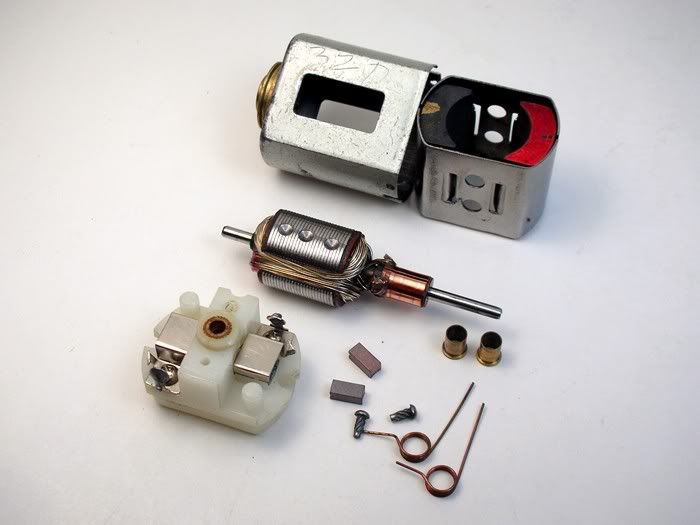

Before installing the front wheels I had to modify them. I ruined the 1/16" hole in the wheel with my lemon juice fiasco so I reamed them out to 3/32 and I used some Slick 7 axle retaining hardware. I modified the 3/32 stub axle on the left by drilling the 1/16 axle hole all the way through and shortening it so just a bit sticks out the back of the wheel when it's installed:

Again, you can't have too many holes in a chassis jig

This worked really slick. Slide on the inside wheel retainer then the wheel protected with tape. Solder the stub axle flush with the axle. This will look like an old school washer soldered to the axle when the wheel is flush against it:

Then slide the inside retainer up tight against the stub axle and solder:

Since we left the stub axle a little long the slop needed for the wheel to rotate freely is set automatically.........weeeeeeeeeeeeeeeeeee........done

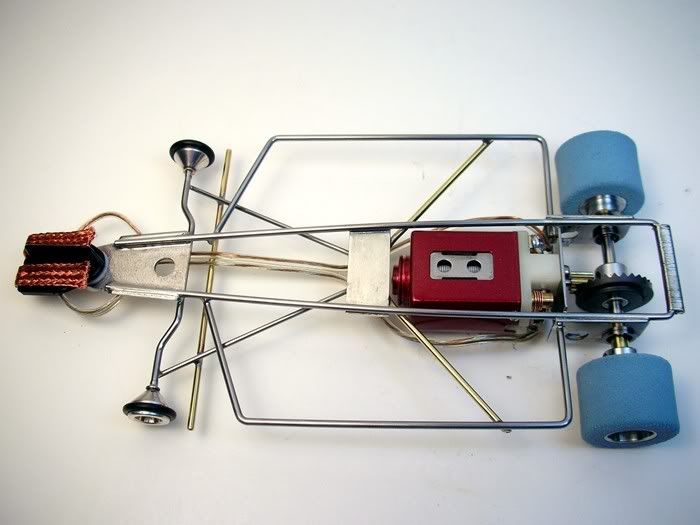

To finish the chassis off more pin locations helped line up the rear body mount and front axle brace by leaving them long:

Finally the front body mount was lined up with jig pins and mounted to the front axle brace:

Time to trim off all the long pieces and spiff this thingie up a bit.....................