Thanks for the tip Don. I'll be picking up a diamond nail file ASAP

.

Motors, I need motors!

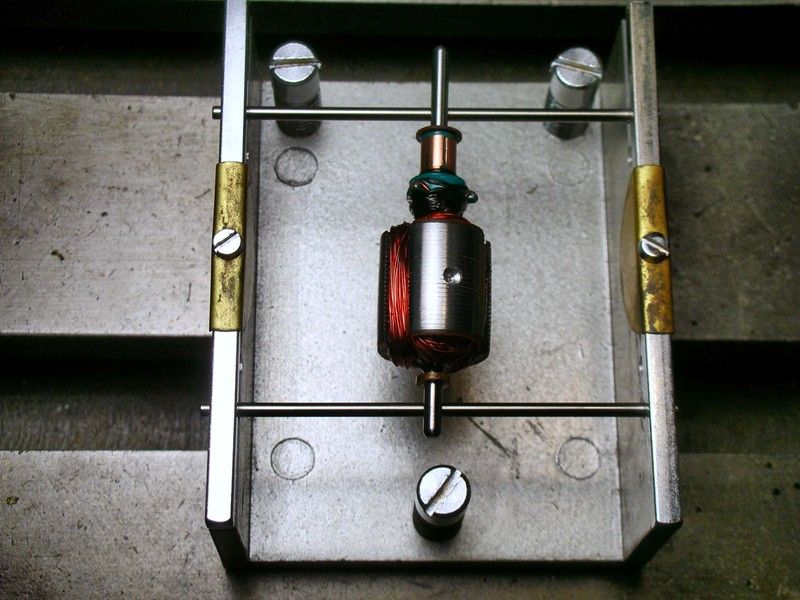

What I'm starting out with is a motor that I like very much for the 1966 Pro type cars. It's the 1968 Mabuchi but it will be fitted to a Russkit 23 style can and epoxied and balanced to look like a period rewind. I buzzed up several of them and these two sounded very similar. One is well used and the other is like new:

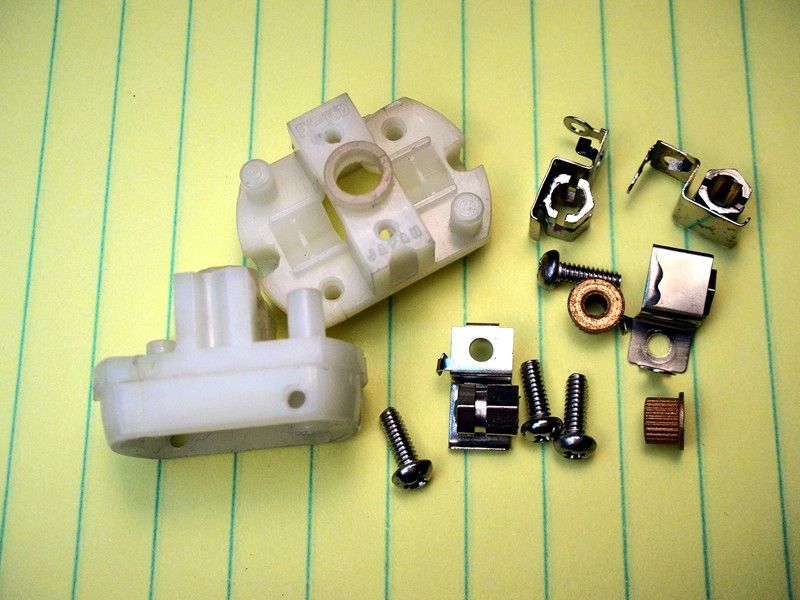

Here's what the used one looks like torn down:

I asked our pal Fate what he thought the wind was and he said one wind used was 65 turns of 30 ga wire. That's a milder wind for the R&C races and that's what I want. Here's a shot of the arm with a piece of 30 ga Simco wire laid along side and above the factory wire:

Closer.........

I could only measure the wire on the factory arm with dial calipers instead of a micrometer. When I measured some Simco and La Ganke 30 ga wire I found over .001" variation between all three. Maybe there is a difference in wire coating thickness? Anyway, it LOOKS like 30 ga

.

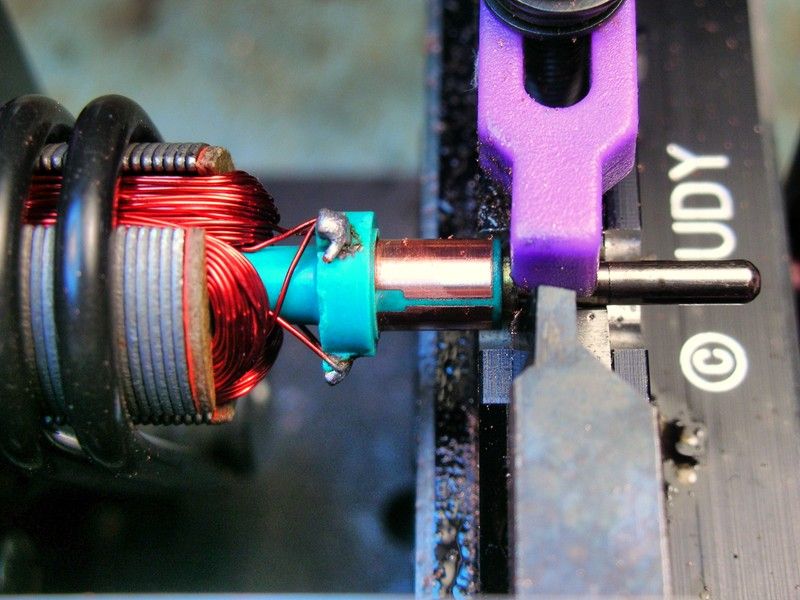

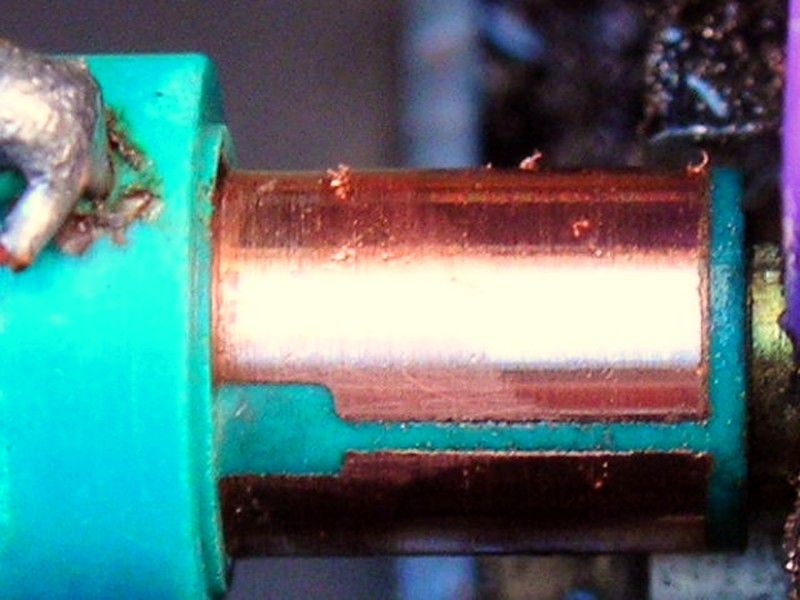

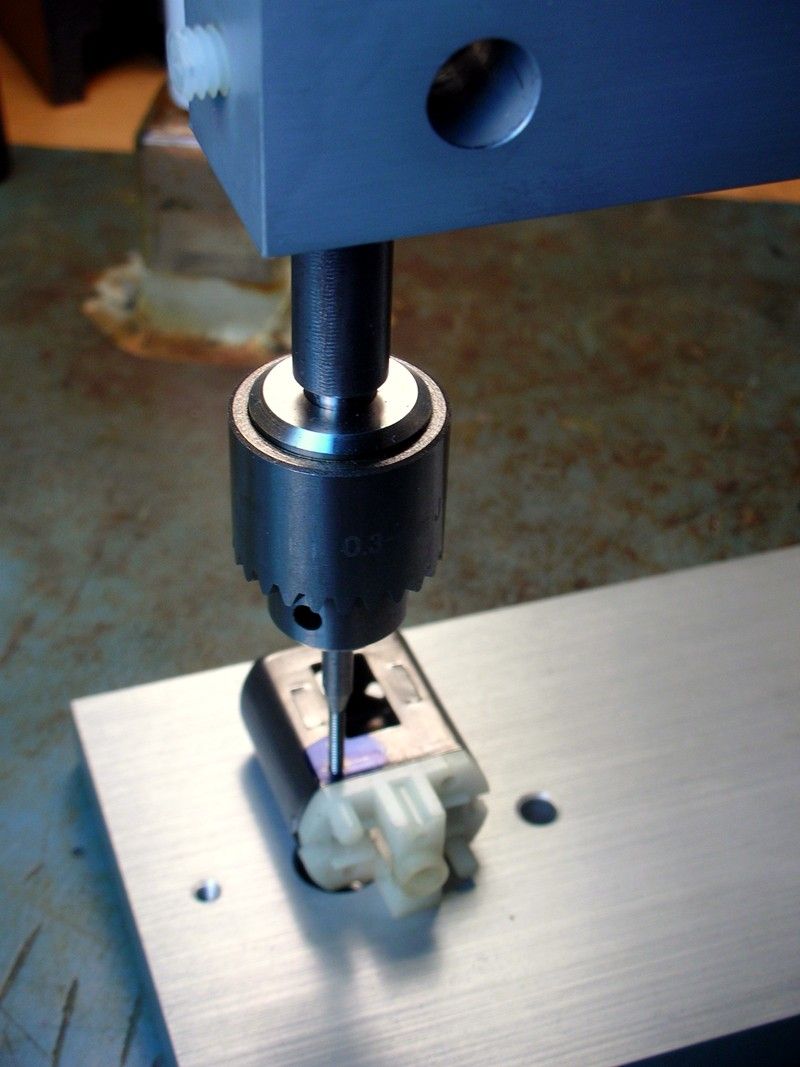

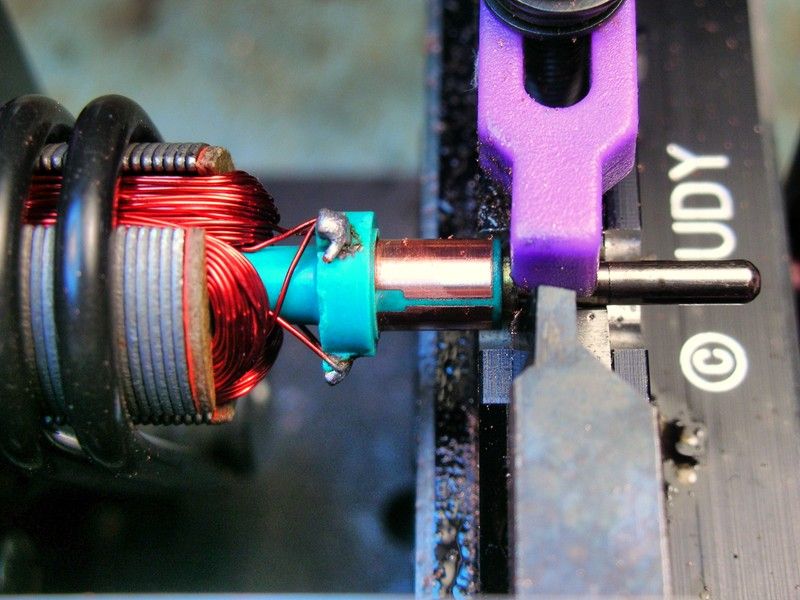

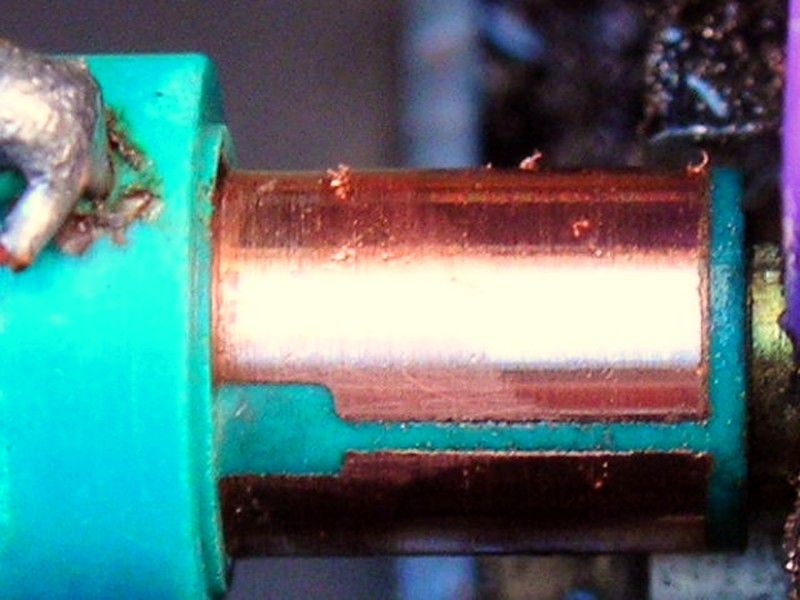

After cleaning I very lightly cleaned up the comms on the Hudy:

You can see how out of round it was. The dull area on the left hasn't come in contact with the cutter yet and the shiny area on the right has:

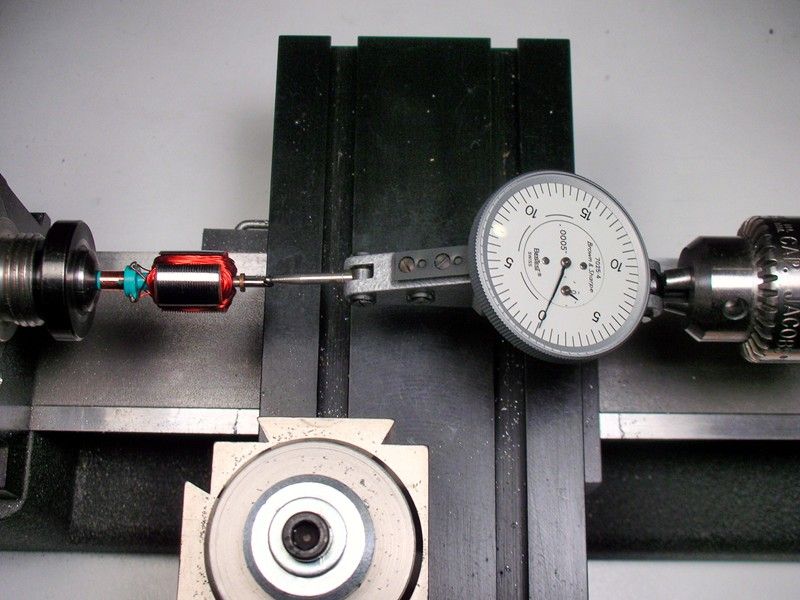

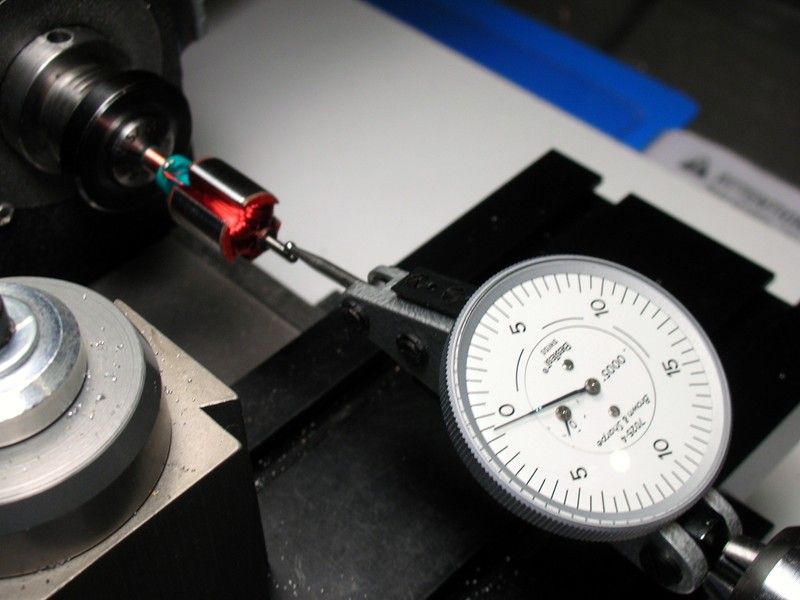

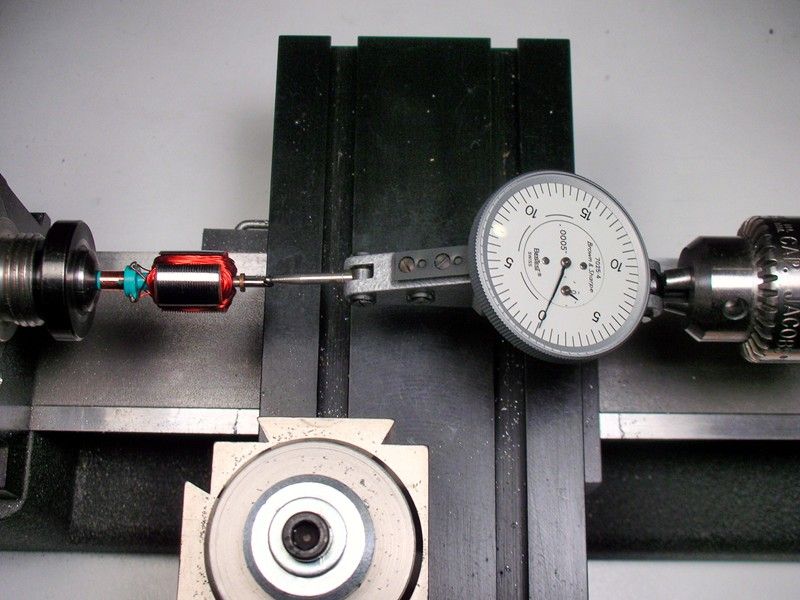

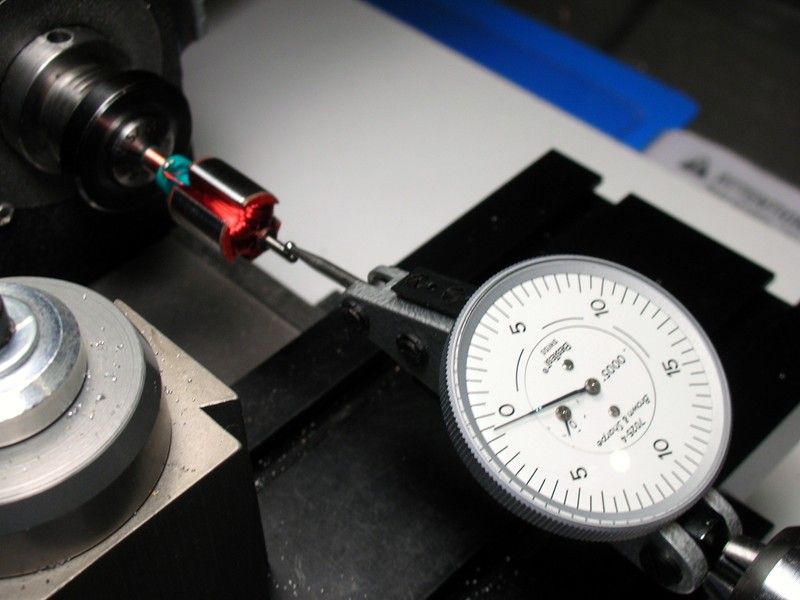

I also thought I'd check out how straight the armature shafts were. Into the lathe collet and Mr. Dial Indicator will tell the tale:

YIKES

.009" out:

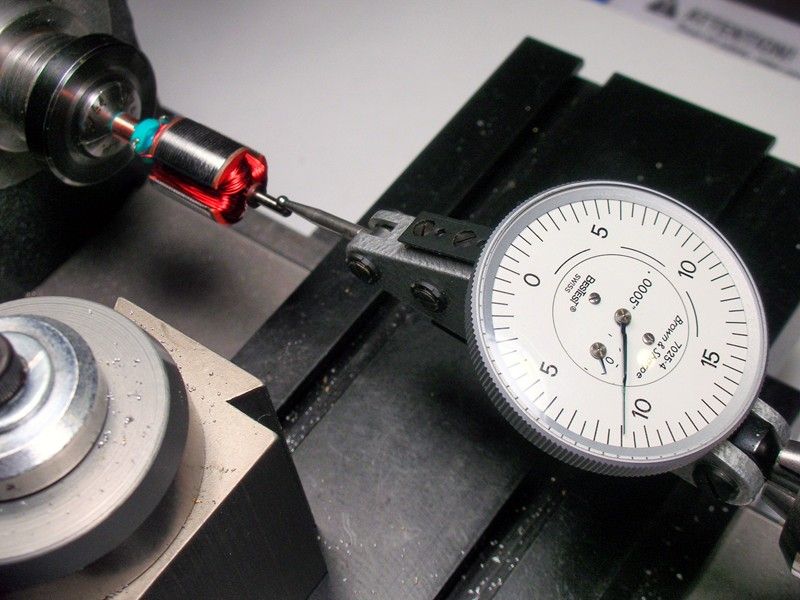

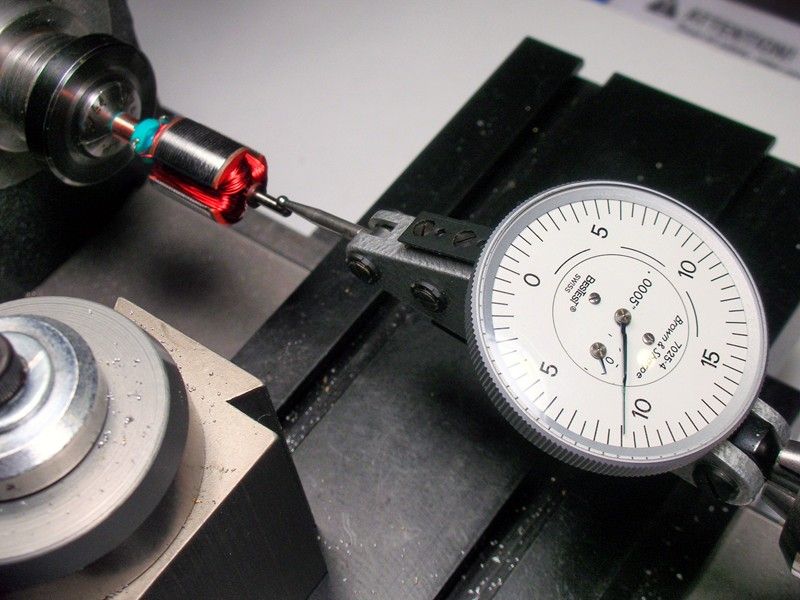

After some careful persuasion, less than .001" out:

I got some Kevlar thread..........

........and wrapped the wires leading to the comm tabs and the comm itself. I also got a fiber "oil slinger" washer ready to epoxy onto the end of the comm:

I use Devcon 2-Ton epoxy on these early arms. In the day the magazines all told us to use "Klinks" epoxy so I'm thinking Devcon is the modern hardware store "Klinks"

. Anywho, I goop on a pile of epoxy.....

.....then hit it with a heat gun while I rotate it and let the epoxy sink into the windings....

........wipe any extra off with your finger and bake in your toaster oven:

One thing though...the heat makes the epoxy flow like water but it also accelerates the curing process. You have to work fast once you put the heat to it. Also, don't overheat the epoxy. If it starts smoking you're gone too far and your screwed........I did that ONCE...it's a funny story.

Onward