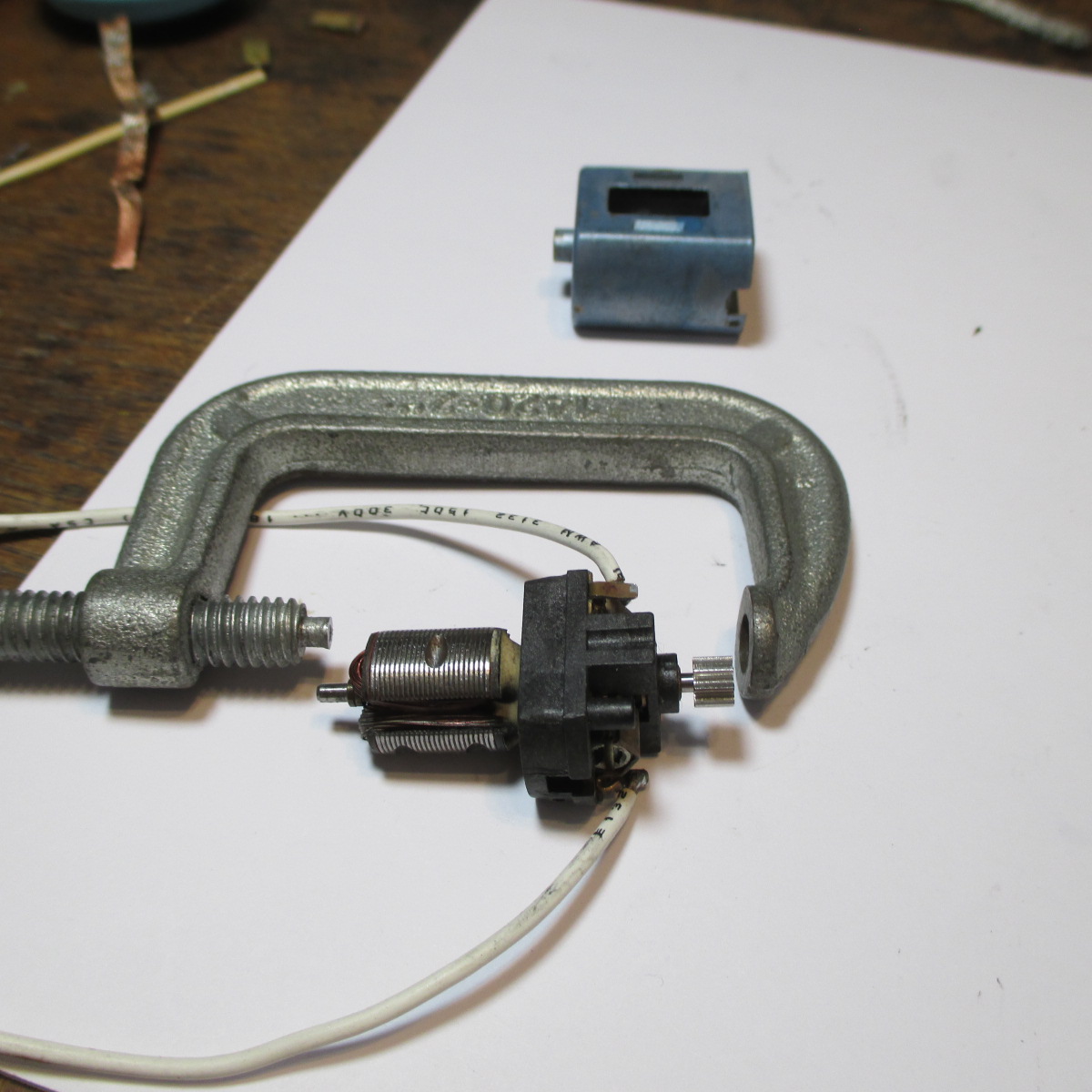

Can't remove the press on brass pinion because the gear puller won't fit. No biggie, I just use the Swiss destruction method - crush the sacrificial part in a vice. Or in my case, linesmans pliers worked fine. As long as I'm fiddling with the motor, may as well upgrade to a press-on straight 48P 8T steel pinion

The culprit was a worn press-in EB bushing. Easy fix, a new one installed. While I had the motor opened, I did an inspection and cleaned the brushes and comm. No problems found. Since the can bushing is a blind (closed end) old style, the gear needed to be pressed on before attaching the can

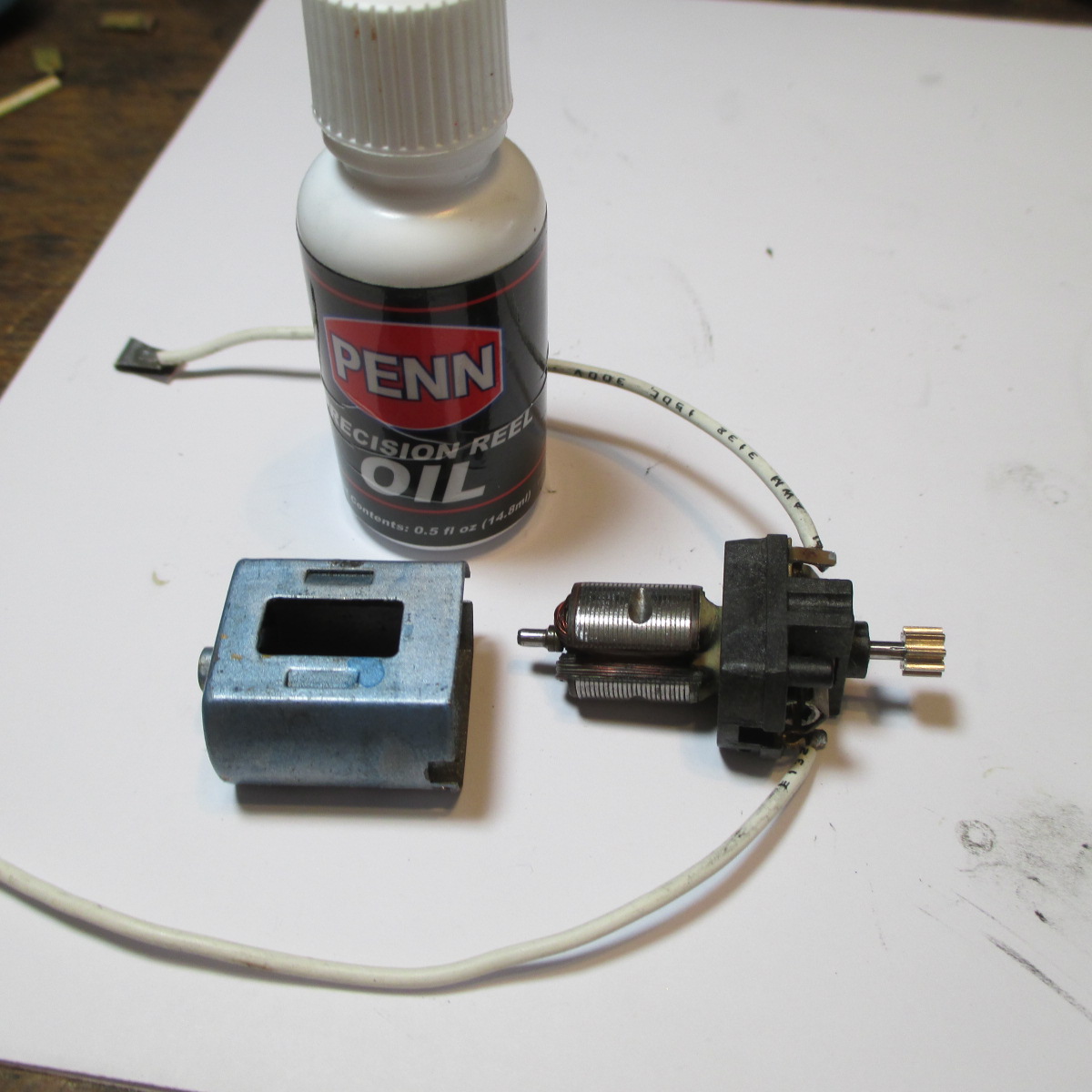

Since the can bushing cannot be lubed (with the can attached) I lubed it with a drop of fishing reel oil. Higher viscosity than slot car oil so it will last longer. Not to mention, a sloppy bushing needs as thick a lube as possible

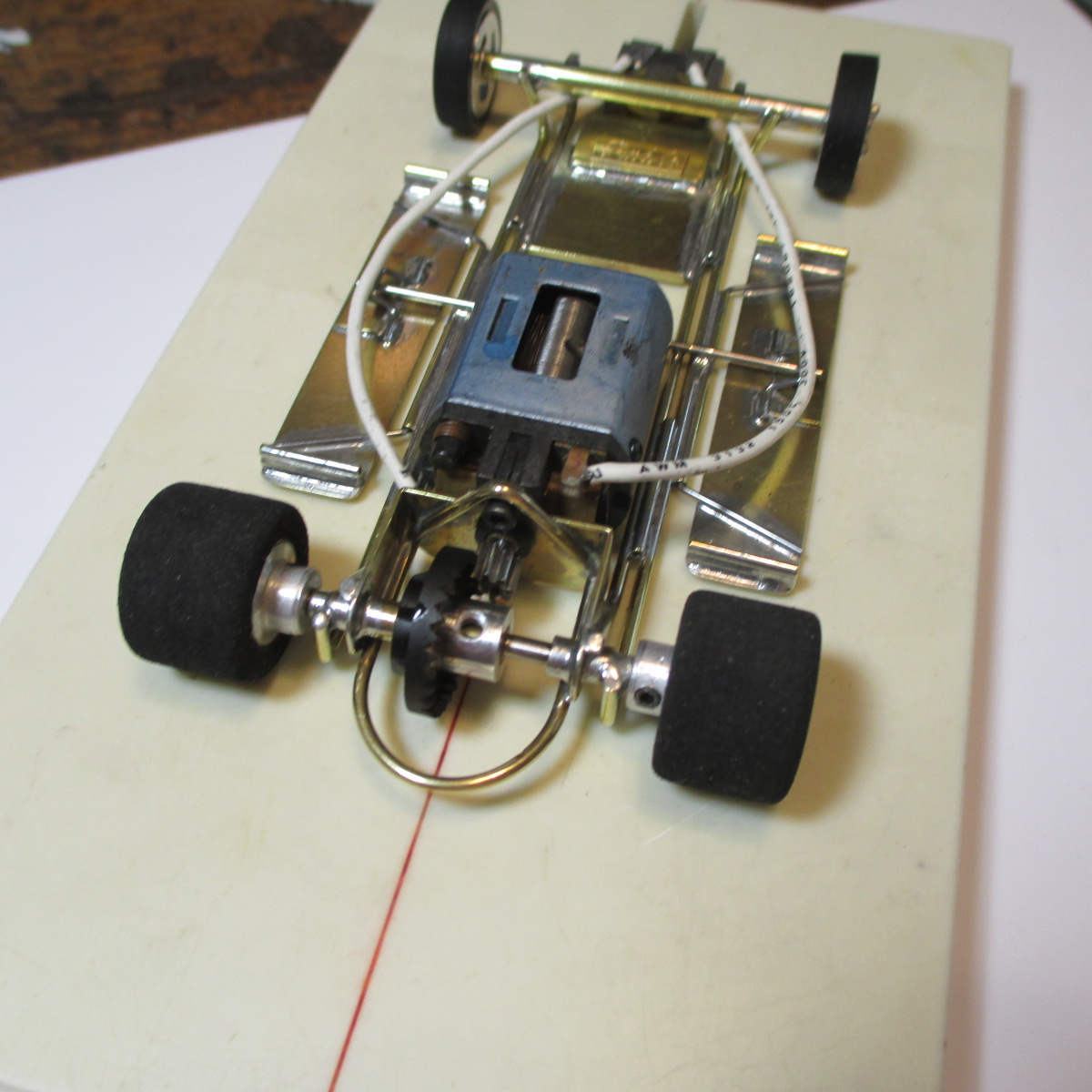

Back in business. Now she passes the drivetrain test to my complete satisfaction. The EB does have a hairline crack. In the future if it causes problems I will simply replace it, no charge

All buttoned up and ready to go with new braids. All rotating parts oiled, even the pan hinges ![]()