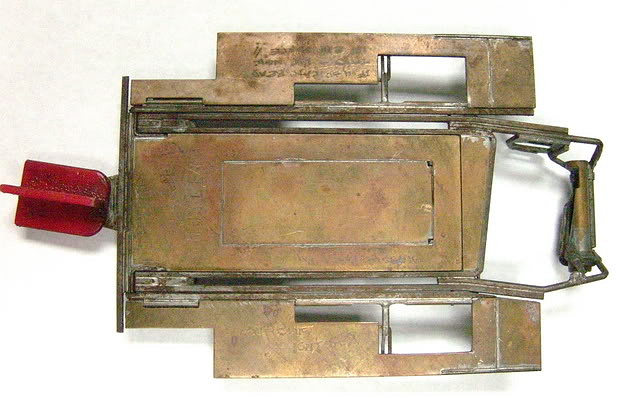

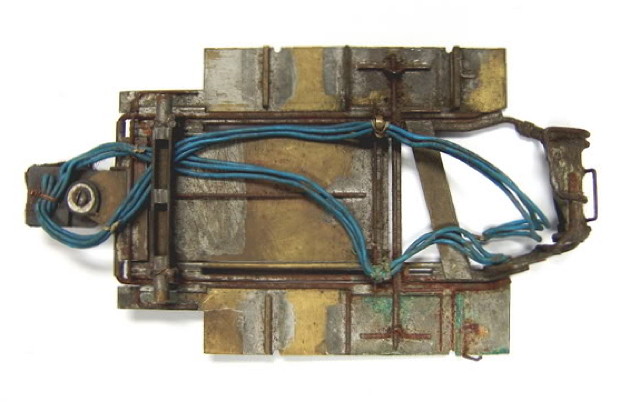

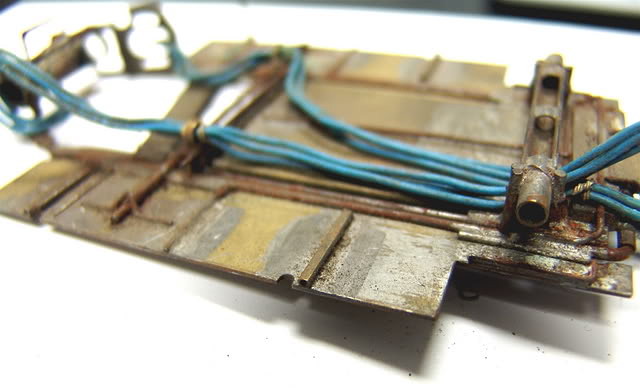

Here is a two-rail he did. 4" wheelbase, 3/4" guide lead. Two rails .063", one brass rod and one piano wire. .063" plumber rail, .032" pans.

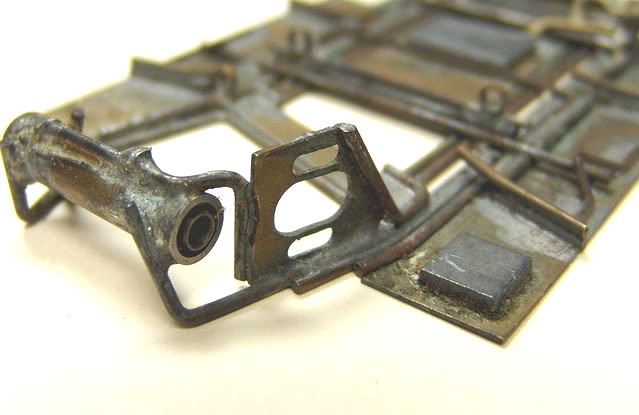

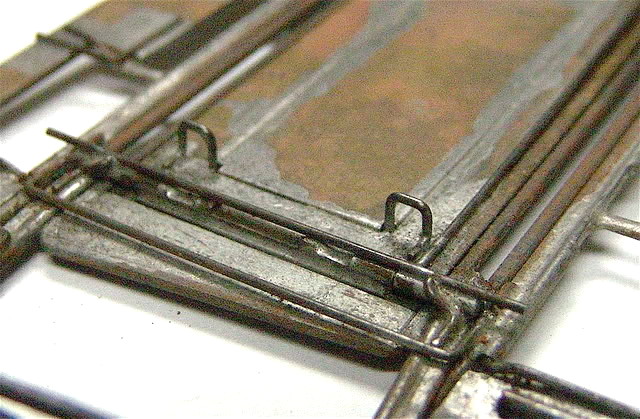

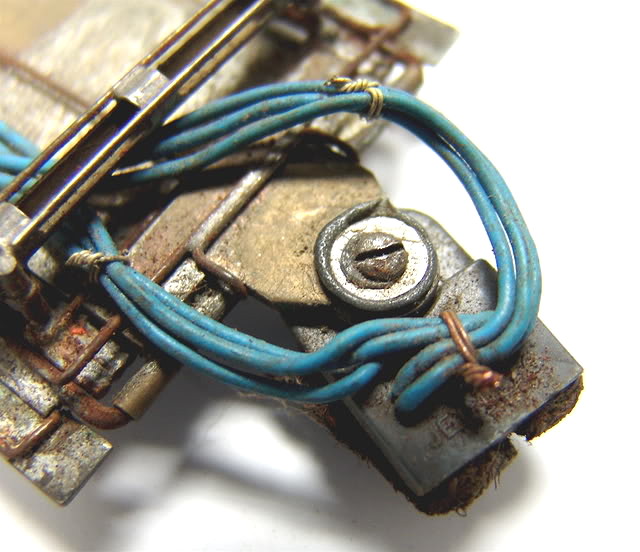

Bob used brass tubing for lead wire holders. Right behind the pan down stop you can see an .015" piano wire spring.

The drop arm is a Cobra 1.25" x .063" piece which Bob modified by cutting the guide holder off and frabricating his own. The 1/8" front axle tube is cut away then braced with piano wire and of course tied to the front uprights. The .032" crosspiece for the plumber doubles as the down stop for the drop arm.

Typical guide set-up. Cox guide, with the screw and washer melted into the guide. Marklin train wire for leads. Wires are all tied to keep them neat.

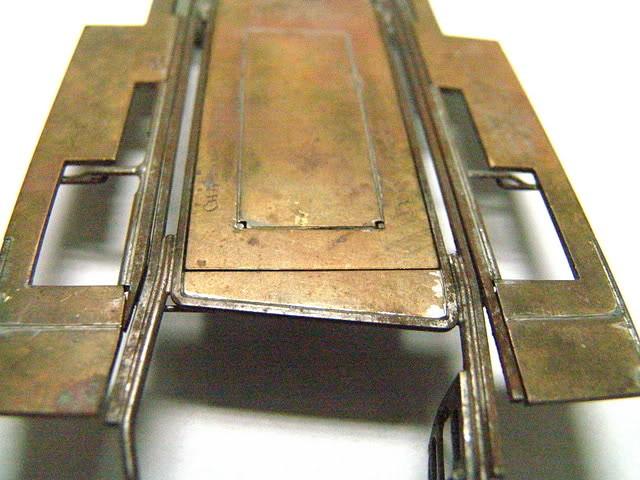

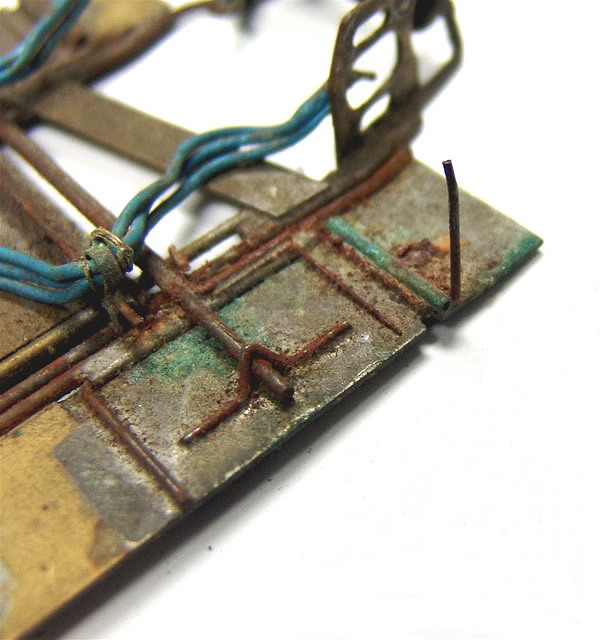

If you look right behind the front pin tubes (which are all filed flat to save weight), you will see notches in the pans. The rules had just changed from 3" to 3.125" chassis width and Bob did not have time to re-drill his jig when he built this car.

Here you can see the remaining body brace to keep the body from moving too much side to side and hitting tires.

The drop arm is engraved. Looks like Bob built this one for himself.