Hudy comm lathe cutter?

#26

Posted 04 November 2010 - 08:24 PM

I intend to live forever! So far, so good.

#27

Posted 04 November 2010 - 08:30 PM

PCD = Polycrystalline Diamond (as stated above) It is basically a hard metal (cobalt) with small grains of diamond in it.

CBN = Cubic Boron Nitride, the second hardest known material.

I guess for what we do either one will work just fine.

#28

Posted 05 November 2010 - 05:00 AM

Michael Rigsby

"... a good and wholesome thing is a little harmless fun in this world; it tones a body up and keeps him human and prevents him from souring." - Mark Twain

#29

Posted 05 November 2010 - 05:11 AM

Like, what is a capped com? Is this like a retread on a car tire when you where out a comm they replace over the old worn with a new?

Thank You, everbody for the contribution.

Slots-4-Ever

Brian McPherson

REM Raceway

"We didn't realize we were making memories, we just knew we were having FUN!"

#30

Posted 05 November 2010 - 05:40 AM

Coms are usually weakest at the top since the com connections and tie/epoxy at the bottom serve to help strengthen that area. Since coms are under extreme duress under use from both heat and centrifugal force, "caps" are sometimes used on the end of the com to help keep it from flying apart and having the plates/segments doing an imitation of "scrambled eggs" inside the endbell. The cap is just a one piece...er...cap that is inserted over the end of the com and bonded in place. When cutting the com, a regular cutter won't be able to cut right up to the cap because of the angle of the cutter tip. A straight cutter (angled from both sides to a point) can cut equally well in both directions and right up to the cap.

-john

#31

Posted 05 November 2010 - 06:46 AM

Now, I understand

Is it possible though to change a com. on a known good arm that has been turned or cut too much?

Slots-4-Ever

Brian McPherson

REM Raceway

"We didn't realize we were making memories, we just knew we were having FUN!"

#32

Posted 05 November 2010 - 08:30 AM

I have heard it said right here (I think it was Tony P) that this can be done. It sounds like a difficult job to do, and if the com connections have been welded/brazed...even worse. I wouldn't want to try it with an arm that wasn't...er...expendable!

-john

PS...why would you be "blushing" for asking a question???

#33

Posted 05 November 2010 - 08:59 AM

I wanted to ask you, I have an older Mura 20 arm that's in good shape but threw a wind. Do you think it would be worth stripping down for a rewind? Or is it more trouble than it's worth. The com looks pretty good on it. Maybe 1 or 2 cuts.

Vic

#34

Posted 05 November 2010 - 09:43 AM

I can tell you that stripping these sorts of arms is a real bear. Then, even if you do get it all cleaned-up...a G20 arm has already been balanced. If not much needed to be taken off when it first balanced, it's probably re-balanceable (is that a word????), but you probably would want to plan things out by starting on the lightest pole, because sometimes the last pole will be the heaviest. I can totally understand re-cycling arms because of "economic considerations", but this will likely turn into an excercise in frustration. If you can ever manage it Vic, Bill Bugenis has new arms and coms that are as good (or maybe better???) as anything out there. His prices are VERY reasonable too. Anyway, if the arm is toast anyway, you may as well give it a try. I can usually save the com without too much trouble from these arms...the stack itself is another matter.

-john

#35

Posted 05 November 2010 - 11:51 PM

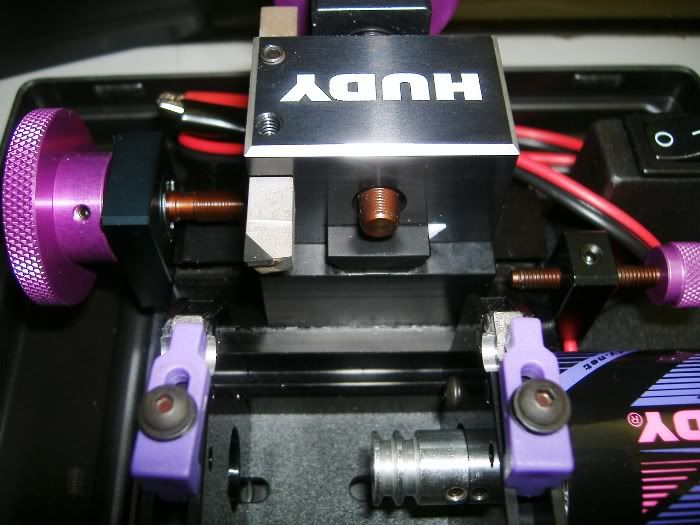

Until Gary Chimes in..........You can not go wrong with E4...........60 degree straight cut . 1/4" is what fits a Hudy

Exactly my thought Ray.

#36

Posted 10 November 2010 - 04:14 PM

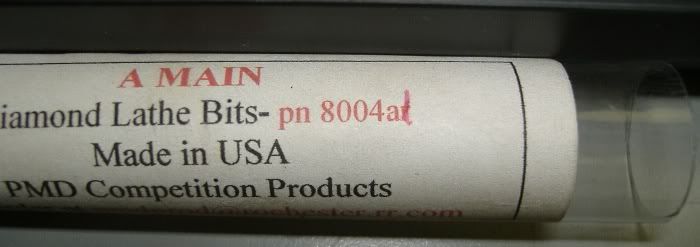

This is wrong ! correct?

Notice the write-over on the tube AFTER we contacted the seller and asked to change it, he said not a problem.

Going back on E-bay, unless someone here could use it?

Slots-4-Ever

Brian McPherson

REM Raceway

"We didn't realize we were making memories, we just knew we were having FUN!"

#37

Posted 10 November 2010 - 06:35 PM

2/23/51-5/20/14

Requiescat in Pace

#38

Posted 10 November 2010 - 07:22 PM

This is the Bit from Proformance.........David Liebenthal.............expensive but worth it

This is a trick I got from Benny Justice at the 2006 Wing Nats...........He liked to true comms from the other direction.............this is a bit like yours... but he reversed the mounting block....let me know how much you need for it......

11/4/49-1/23/15

Requiescat in Pace

#39

Posted 10 November 2010 - 08:21 PM

Ray, that bit sure looks like the one they show on the DiamondTools site for under $50. For now, I'm just using my Hudy bit that came with my lathes. When one of them gets to the point I need it lapped, I might just go ahead and order the 60 degree 1/4" bit from Diamond Tools.

#40

Posted 10 November 2010 - 09:10 PM

#41

Posted 10 November 2010 - 10:48 PM

I intend to live forever! So far, so good.

#42

Posted 28 September 2024 - 09:22 PM

In Australia a carbide tip AL-4 cutting tool is $28.29 AUD .

Don't know about diamond tip i will have to find that out .